Elevating and installing method and device for T beam wet joint formwork

A technology of installation device and installation method, which is applied in hoisting device, transportation and packaging, clockwork mechanism, etc., can solve the problem of using hoisting equipment and a large amount of labor, low construction efficiency of installation technology, and prone to seams and wrong platforms and other problems, to achieve the effect of convenient, fast and flexible walking, avoiding seams and staggered platforms, reducing labor and hoisting machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

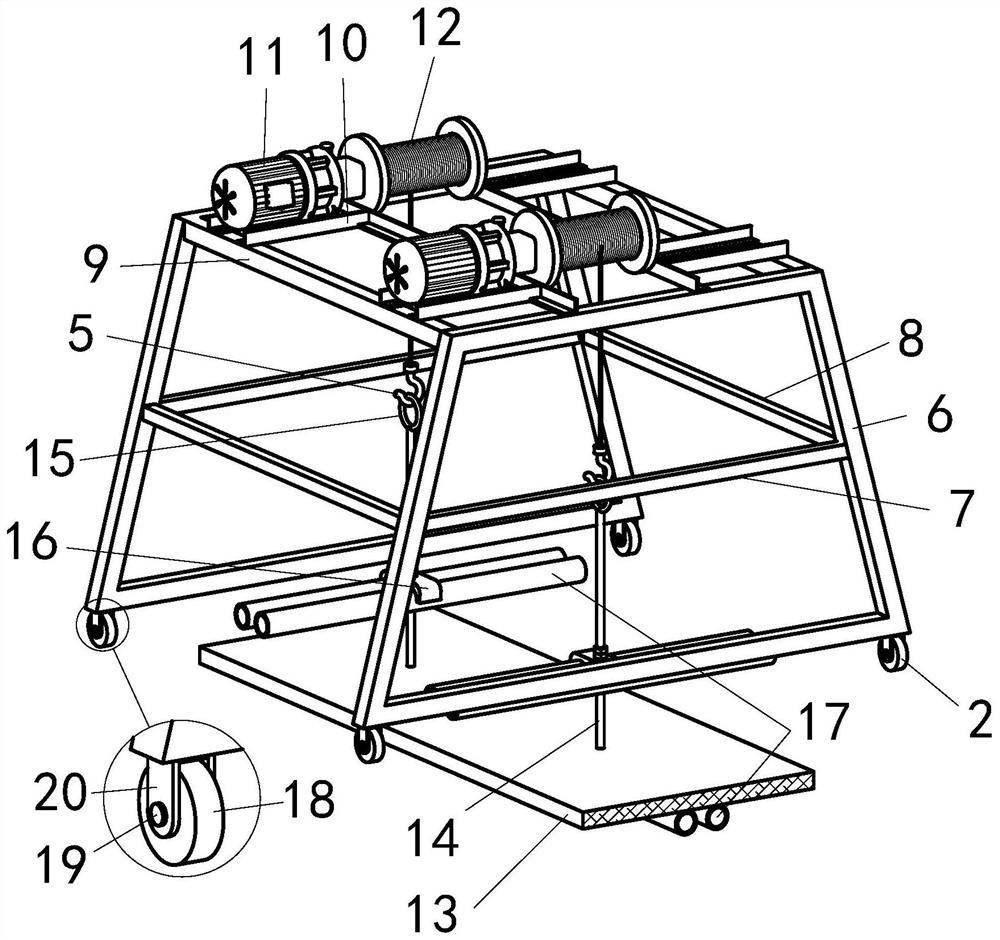

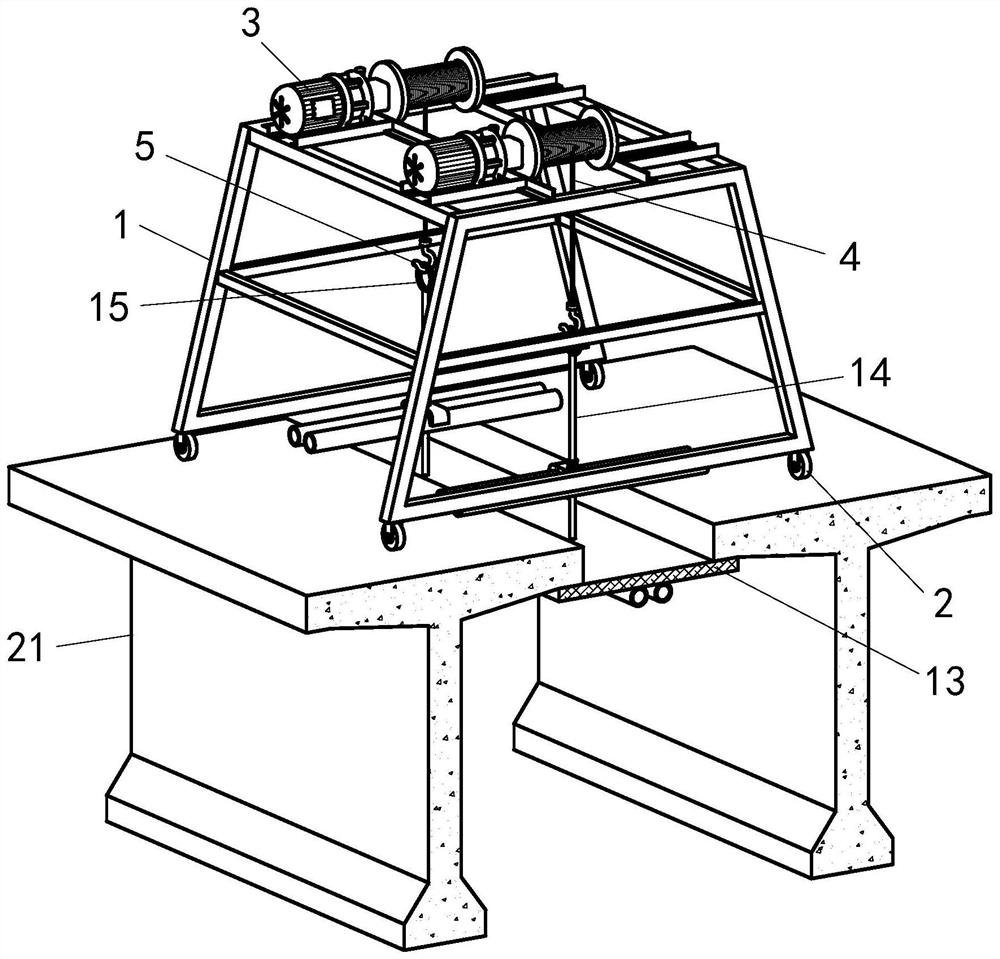

[0030] This example figure 1 and 2 As shown, it includes hoist 3, hoist installation frame 10, steel cable 4, frame 1, suspension hook 5, pull screw 14, roller 2, suspension ring 15, butterfly card 16 and steel pipe 17, wet joint template 13.

[0031] During specific construction, such as figure 1 and figure 2 As shown, the hoist 3 is installed on the hoist mounting frame 10, the steel cable 4 is wound on the reel 12 of the hoist 3, the frame 1 is welded with high-quality square steel, the hook 5 is connected with the steel cable 4, and the pull screw 14 is connected with the The butterfly card 16 and the double steel pipe 17 are connected and passed through the hole of the tie rod of the wet joint template 13. The roller assembly 2 is two pairs of rollers with bearings, which are welded at both ends of the bottom of the frame 1. The lifting ring 15 and the tension screw 14 Welded together to form a T-beam wet joint formwork installation lifting operation overall device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com