Construction method of secondary-lining trolley separated window pouring and pouring structure thereof

A construction method and a technology of dividing windows, which are applied in wellbore lining, tunnel lining, earth-moving drilling, etc., can solve the problems of heavy repairing work, affecting structural strength, and difficulty in dismantling and transporting pipe joints, so as to reduce labor consumption and labor. cost, improve construction safety, and reduce the effect of pipeline blockage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

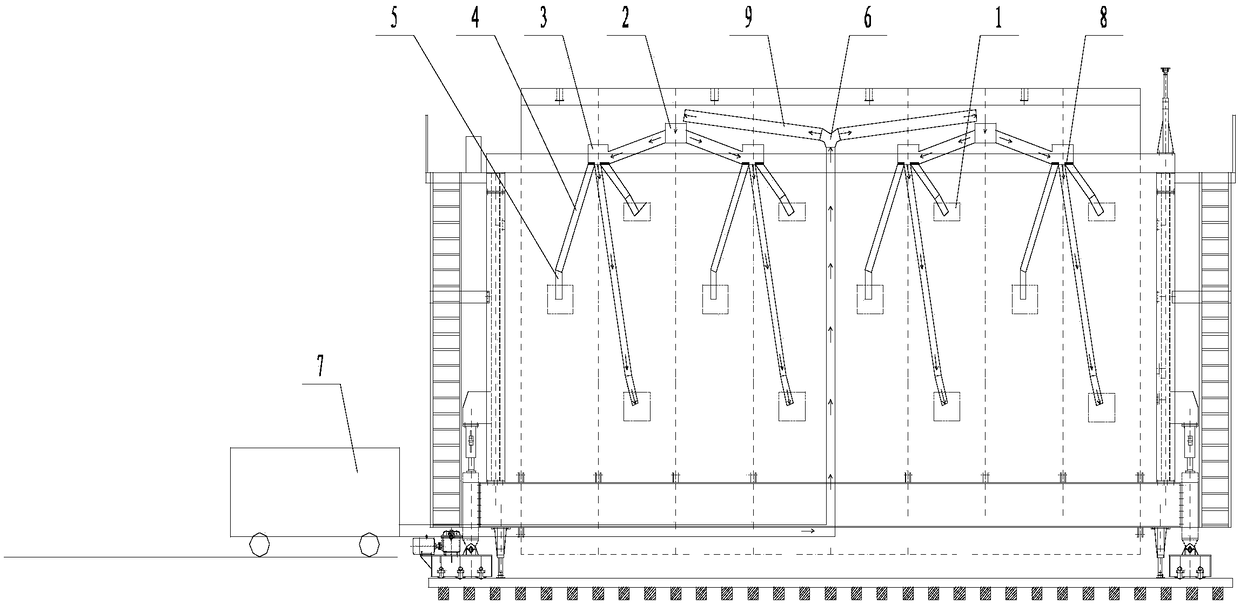

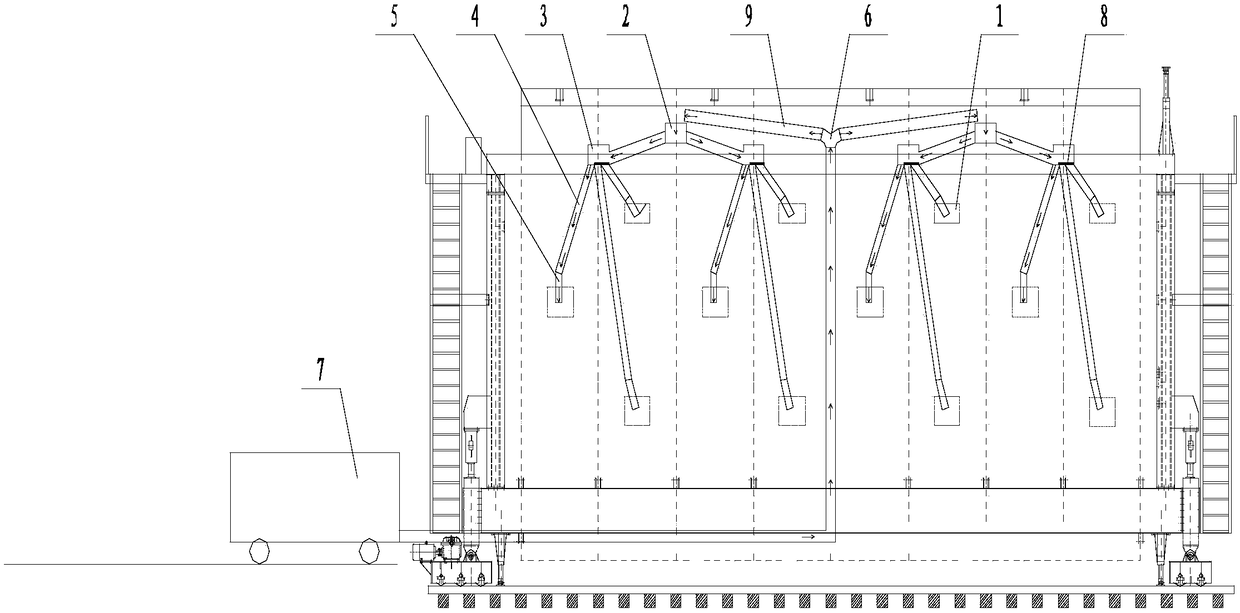

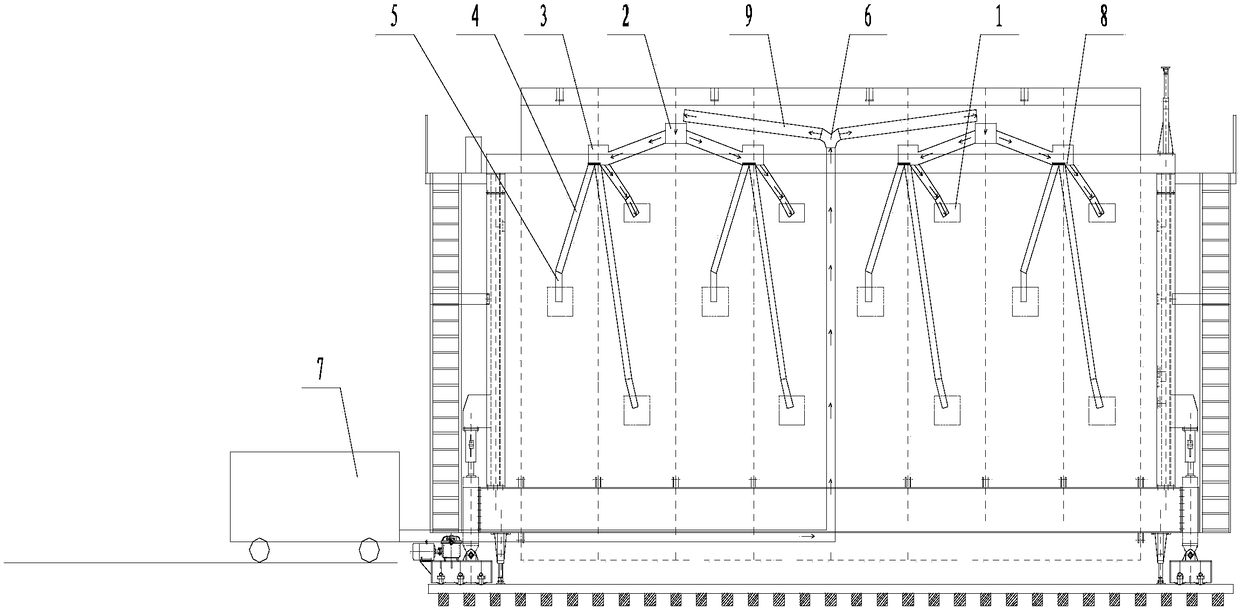

[0034] Such as Figure 1 to Figure 4 A construction method for split-window pouring of two lining trolleys shown includes the following steps: (a) Divide the pouring window 1 into three rows according to the diagram of the split-window material distribution system, and set several main material troughs 2 and several distribution material troughs. Groove 3, each distribution trough 3 controls several pouring windows 1, and a fixed chute 4 is set between the distribution chute 3 and the pouring window 1; each distribution chute 3 is connected with the main feed trough 2; (b) carry out Pouring of the first row of pouring windows 1: Make the distribution chute 3 communicate with the fixed chute 4 corresponding to the first row of pouring windows 1, close the connection between the distribution chute 3 and other fixed chutes 4, and pour in the first row The end of the fixed chute 4 corresponding to the window 1 is connected to the movable chute 5, so that the movable chute 5 is con...

Embodiment 2

[0036] Such as Figure 1 to Figure 4 The shown pouring structure of a two-lined trolley divided into windows includes several rows of pouring windows 1, and also includes several main material troughs 2 and several material distribution troughs 3. The chute 2 is connected, and the outlet ends of the distribution chute 3 are respectively fixedly connected with several fixed chutes 4, and the end of the fixed chute 4 away from the distribution chute 3 is detachably connected to the movable chute 5, and each movable chute The trough 5 is connected to a pouring window 1; the opening and closing device 8 is provided at the connection between the distribution trough 3 and each fixed chute 4; it also includes a pipe joint 6, and the pipe joint 6 is connected to the pump truck 7 and All main feed tanks 2 are connected. The opening and closing device 8 is a detachably connected galvanized iron sheet. Among all the pouring windows 1 connected to the distribution trough 3, any two pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com