Full-hydraulic self-propelled culvert abutment body trolley and construction technology process

A technology of automatic walking and culvert platform, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of high cost of operation team, increased risk of hidden safety hazards, large number of poles and formwork, etc., to improve work efficiency. Efficiency and operating costs, shortening the construction period, reducing the number of formwork and the number of steel pipe supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] (1) The production method of the fully hydraulic automatic walking culvert platform trolley:

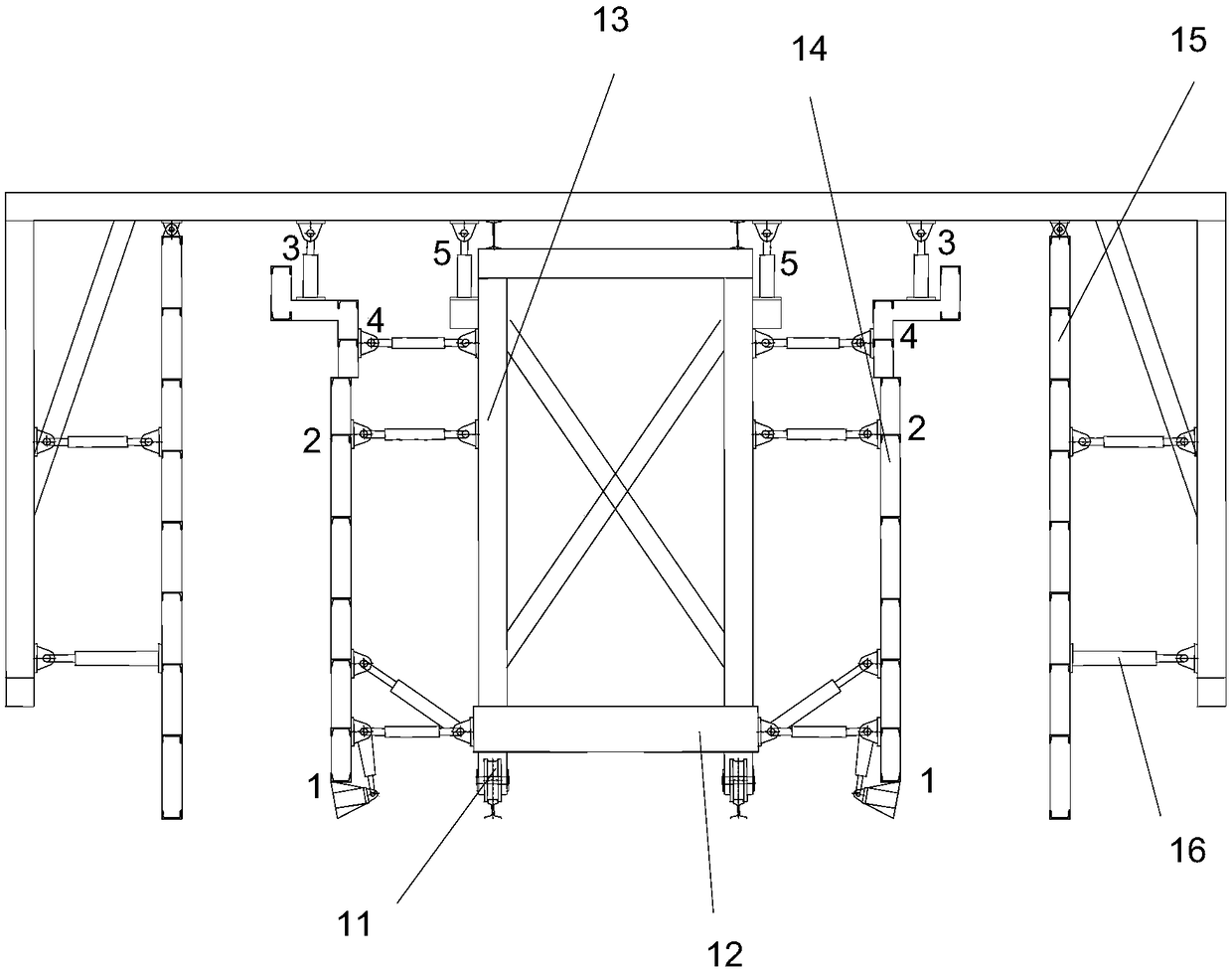

[0031] The box culvert steel formwork trolley is composed of a walking bottom frame 12, a main formwork frame 13, an inner mold 14, an outer mold 15, a hydraulic system, a vibration system and a power distribution system.

[0032] 1. The bottom frame 12 of the trolley is welded by rectangular steel pipes with a thickness of 300×200×10. The strength of the weld seam during the welding process must meet the specification requirements. Walking wheel 11 will be installed parallel, and wheel shaft center is 15cm away from track surface, and walking motor and speed reducer are installed according to actual size. The traveling speed of the trolley is 5m / min.

[0033] 2. The main template frame 13 is the core component of the trolley. It is welded by 320×200×10 H-shaped steel. The main frame not only supports the shrinkage of the inner mold, but also the main frame for the shrinka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com