Overall-type formwork of wall columns and construction method of overall-type formwork

An integral formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems that the formwork joints at the joints of walls and columns are not dense, and the construction quality is difficult to control effectively. , to achieve the effect of being conducive to repeated use, shortening the construction period, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

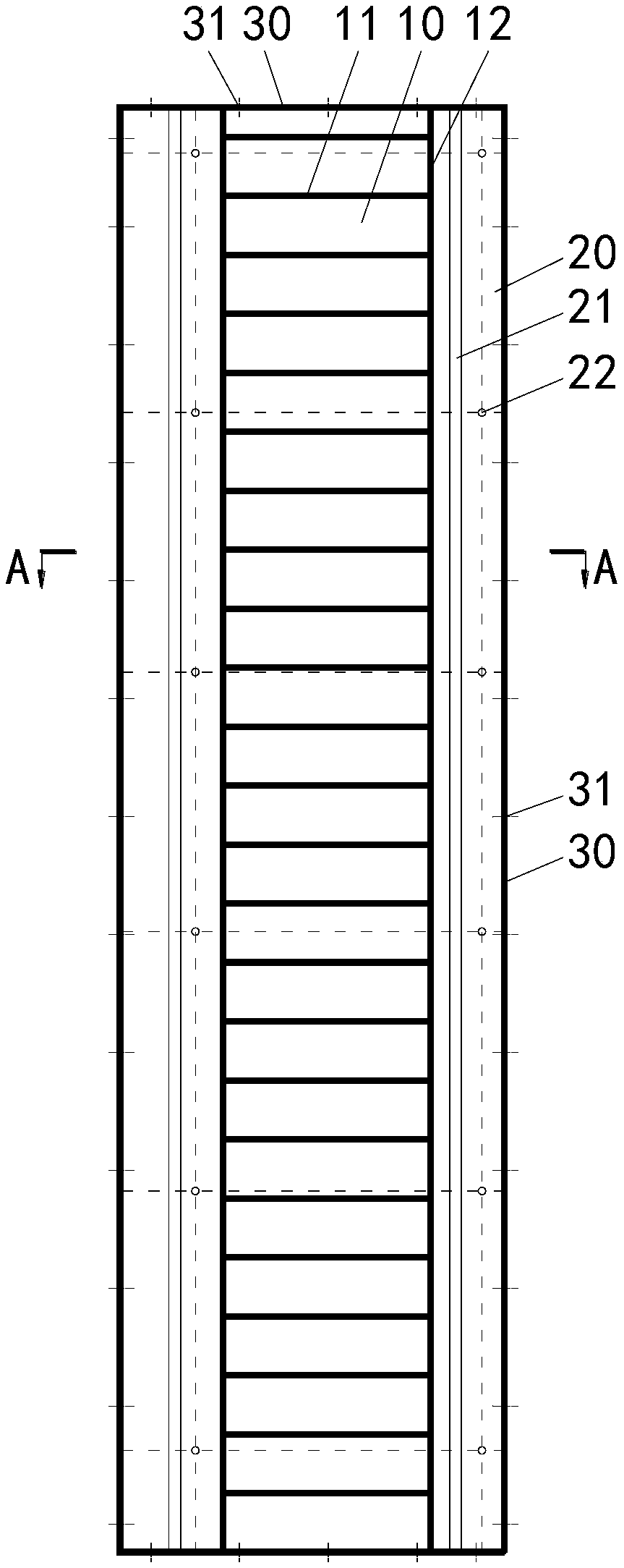

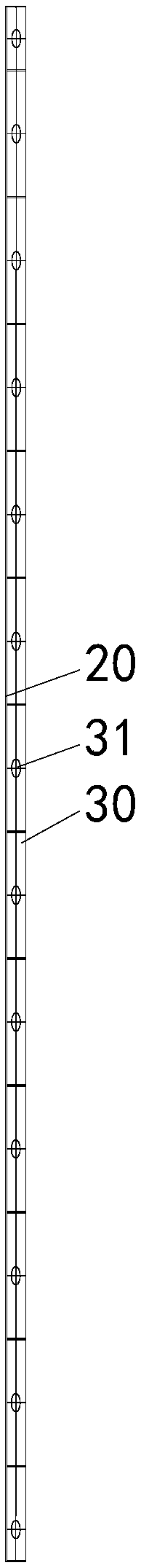

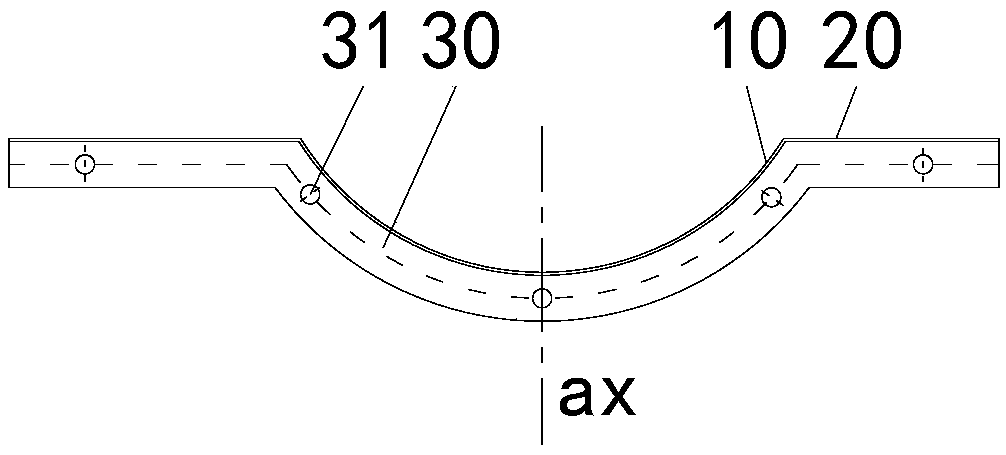

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention. For the convenience of description, the "up" and "down" described below are consistent with the directions of up and down in the drawings, but this should not be a limitation of the technical solution of the present invention.

[0031] In this embodiment, the construction of an underground sewage treatment plant is taken as an example. The floor height is 6.4m, and the number of diversion walls is relatively large. Splicing is carried out to implement the concrete pouring construction of the diversion wall. Combine below Figure 1 to Figure 4 Illustrate the integral formwork of the wall column of the present invention, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com