Rapid continuous construction method of single-compartment large-section cast-in-place frame-structure pipe gallery

A construction method and large-section technology, applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of long construction period, long installation and dismantling time, and many construction procedures, so as to solve the problems of many construction procedures and reduce construction rework. cost, avoid the effect of concrete misplacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a rapid and continuous construction method for single-cabin large-section cast-in-place frame pipe gallery. In order to make the purpose, technical scheme and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

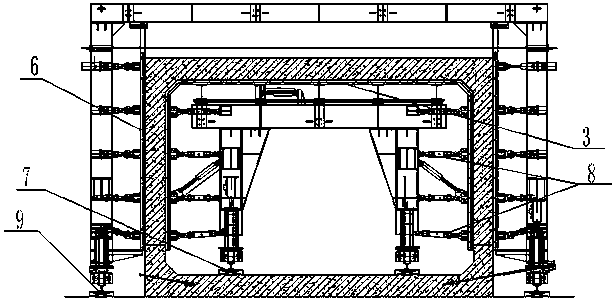

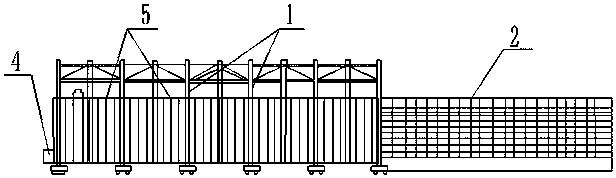

[0020] The invention provides a rapid and continuous construction method for single-cabin large-section cast-in-place frame pipe gallery, such as figure 1 and figure 2 As shown, it includes the following steps:

[0021] Step 1. Fine-tune the inner formwork on the inner mold trolley 3 and the outer formwork on the outer mold trolley 6 through the corresponding hydraulic rods 8, perform mold closing and adjustment, determine the structural size and line type, and then tie the roof reinforcement;

[0022] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com