Control device for preventing duct piece staggering and shield tail postures for TBM

A control device and shield tail technology, applied in shaft equipment, well shaft lining, tunnel lining, etc., can solve the problems of shield tail brush failure, delay of construction period, segment misplacement, etc., achieve simple assembly process, reduce the amount of misplacement, Minimize the effect of staggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and specific embodiments.

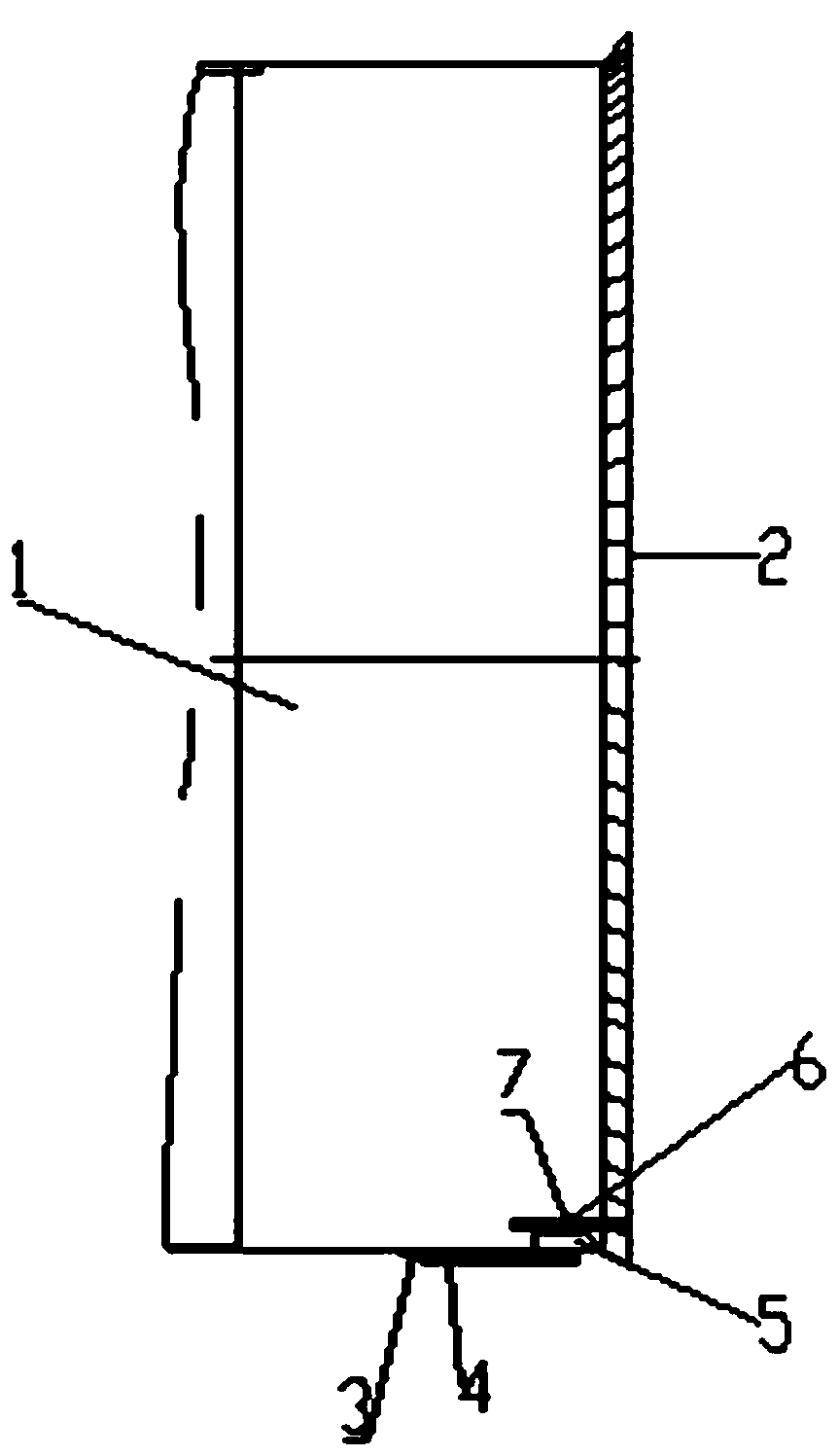

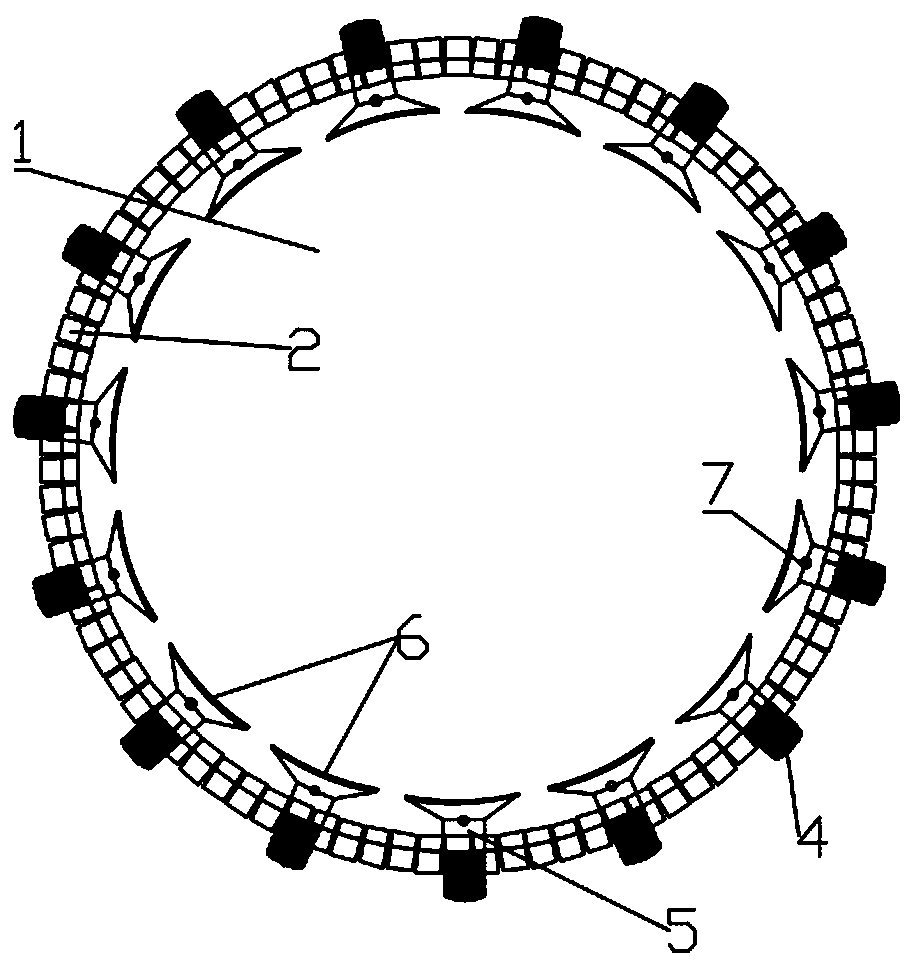

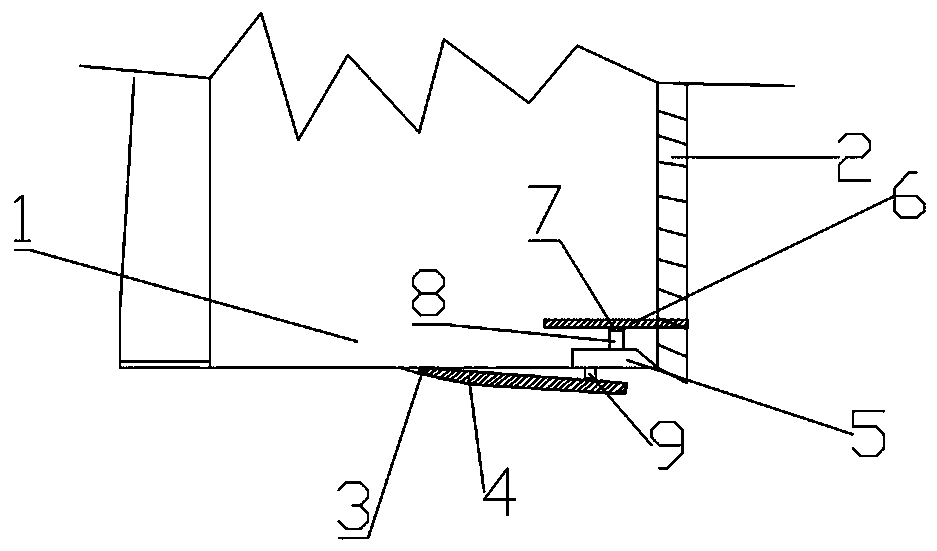

[0020] Such as Figure 1-4 As shown, the TBM of the present invention uses a control device for preventing the misalignment of tube segments and the posture of the shield tail. There are fifteen control devices, which are evenly distributed on the shield tail behind the shield tail brush in a manner of surrounding the axis of the shield tail. The outer circular surface; the control device includes a streamlined wear plate 4 with one end hinged on the outer circular surface of the shield tail at the rear of the shield tail brush, and a shield body attitude disposed on the other end of the streamlined wear plate facing the inner surface of the shield tail The adjusting oil cylinder 9, the oil cylinder connecting plate 5 arranged on the telescopic rod end of the shield body attitude adjusting oil cylinder 9, and the tube piece support plate 6 arranged on the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com