Patents

Literature

37results about How to "Reduce the amount of error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

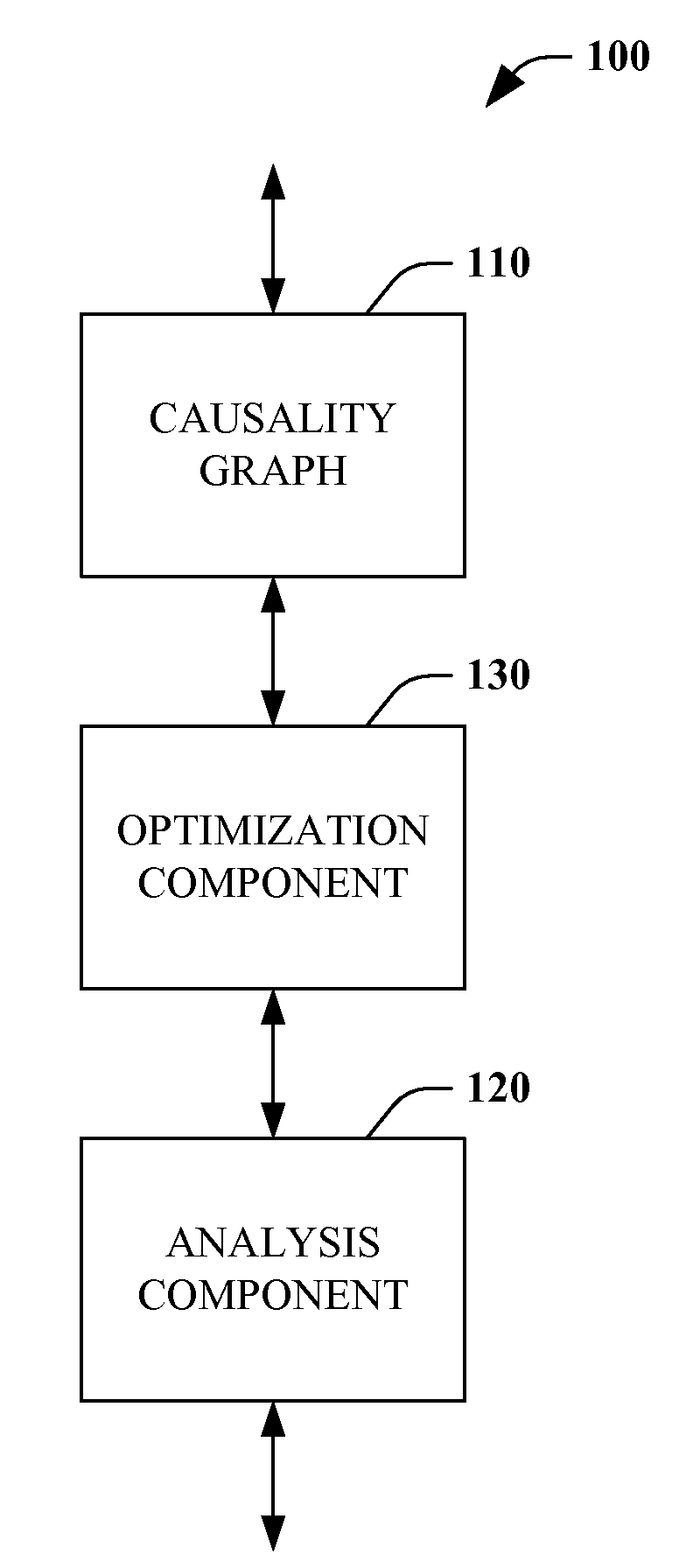

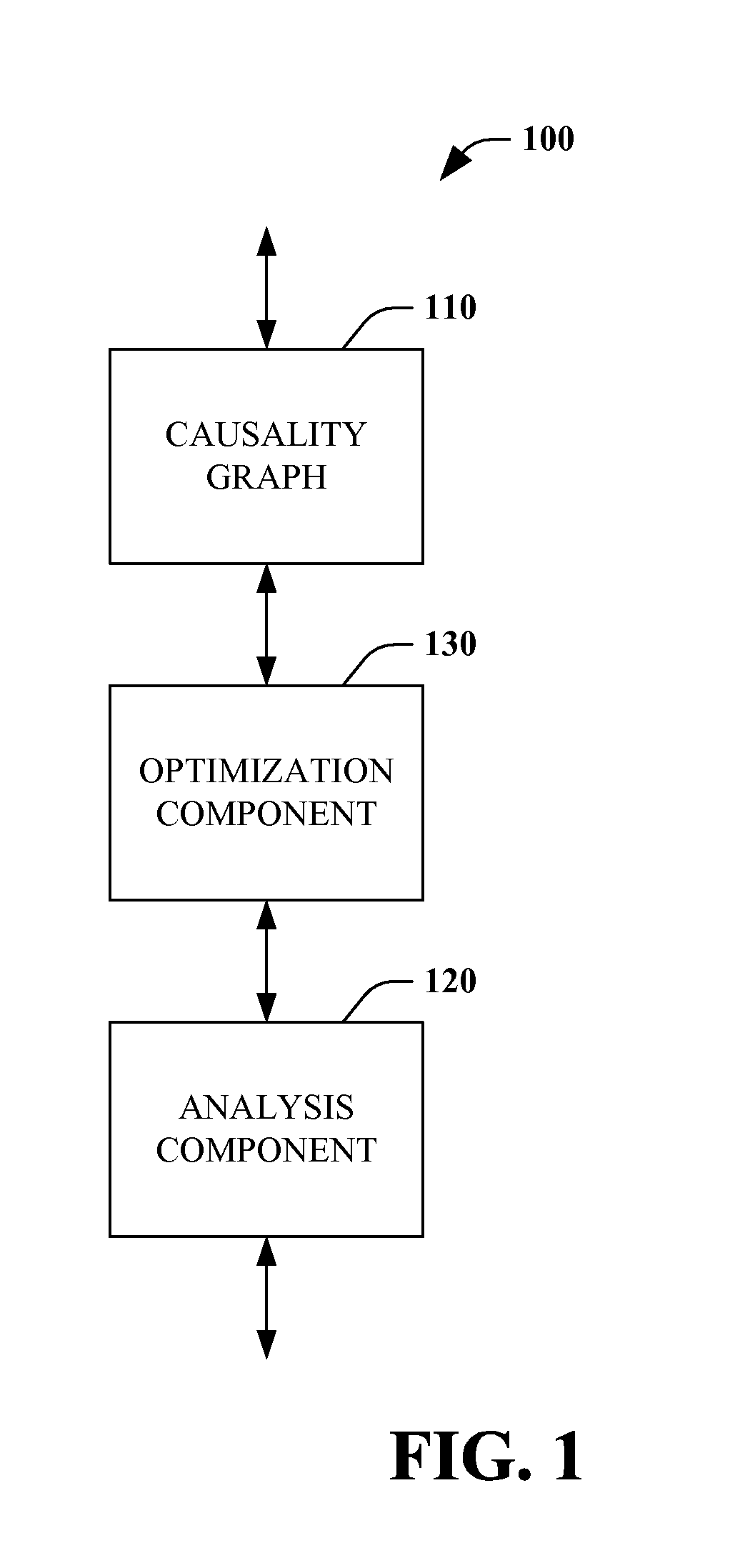

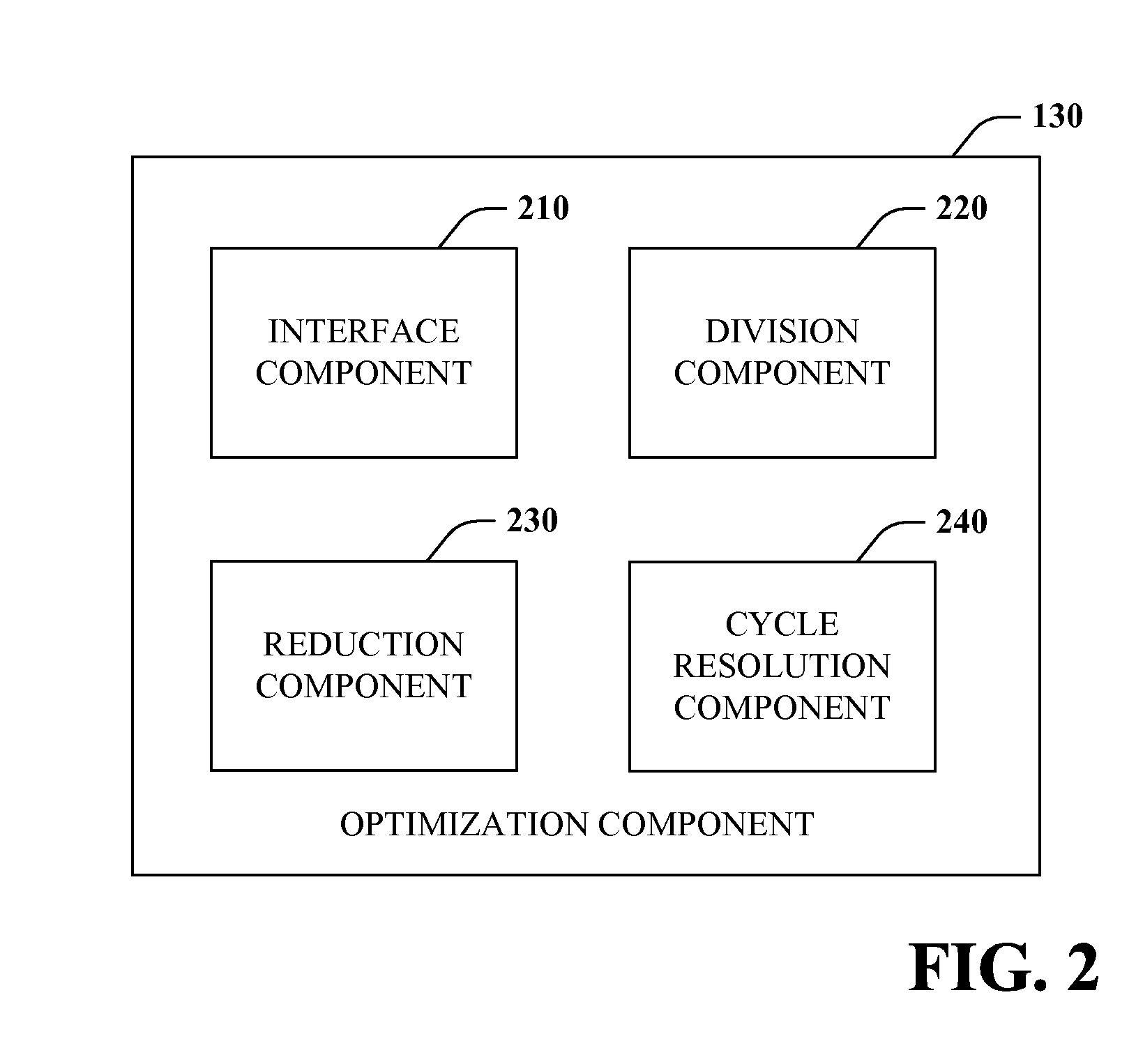

Root cause analysis optimization

InactiveUS20090327195A1Reduce in quantityEasy to operateKnowledge representationInference methodsTheoretical computer scienceRoot cause analysis

Root cause analysis is augmented by providing optimized inputs to root cause analysis systems or the like. Such optimized inputs can be generated from causality graphs by creating sub-graphs, finding and removing cycles, and reducing the complexity of the input. Optimization of inputs enables a root cause analysis system to reduce the number of iterative cycles that are required to execute probable cause analysis, among other things. In one instance, cycle removal eliminates perpetuation of errors throughout a system being analyzed.

Owner:MICROSOFT TECH LICENSING LLC

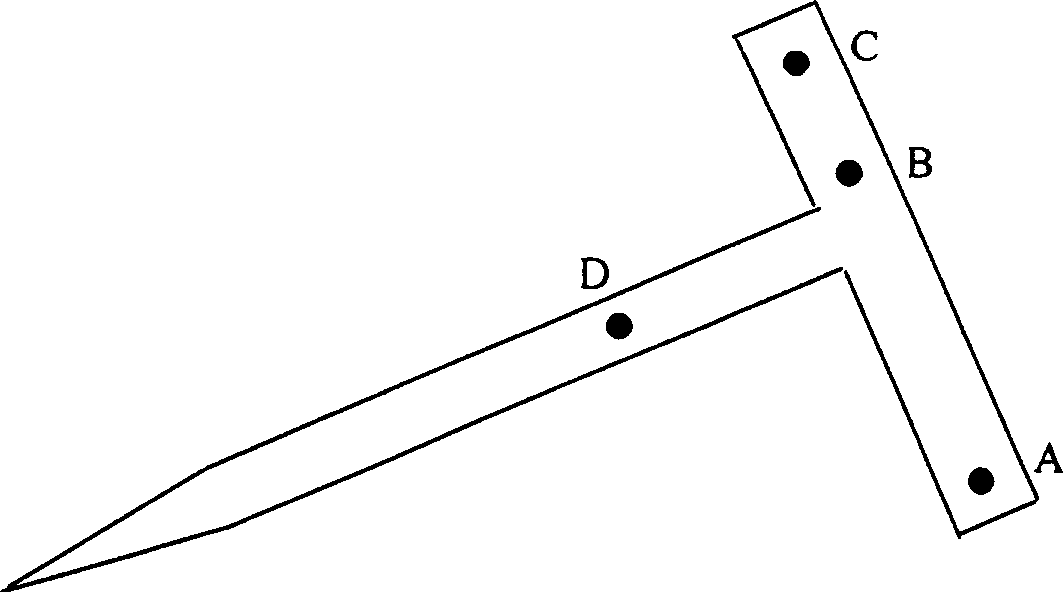

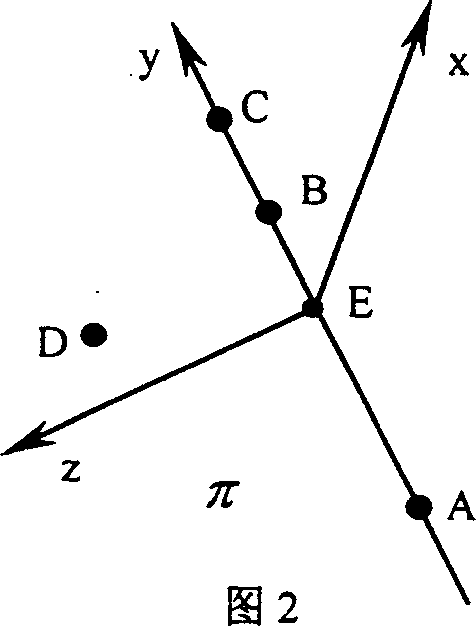

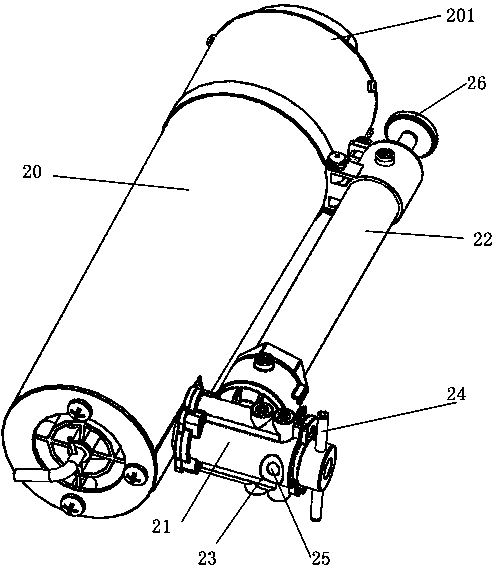

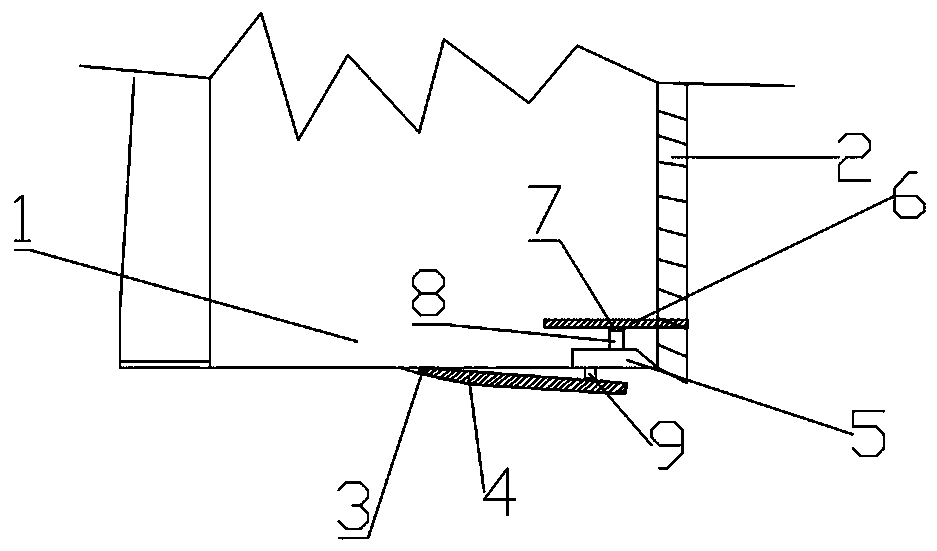

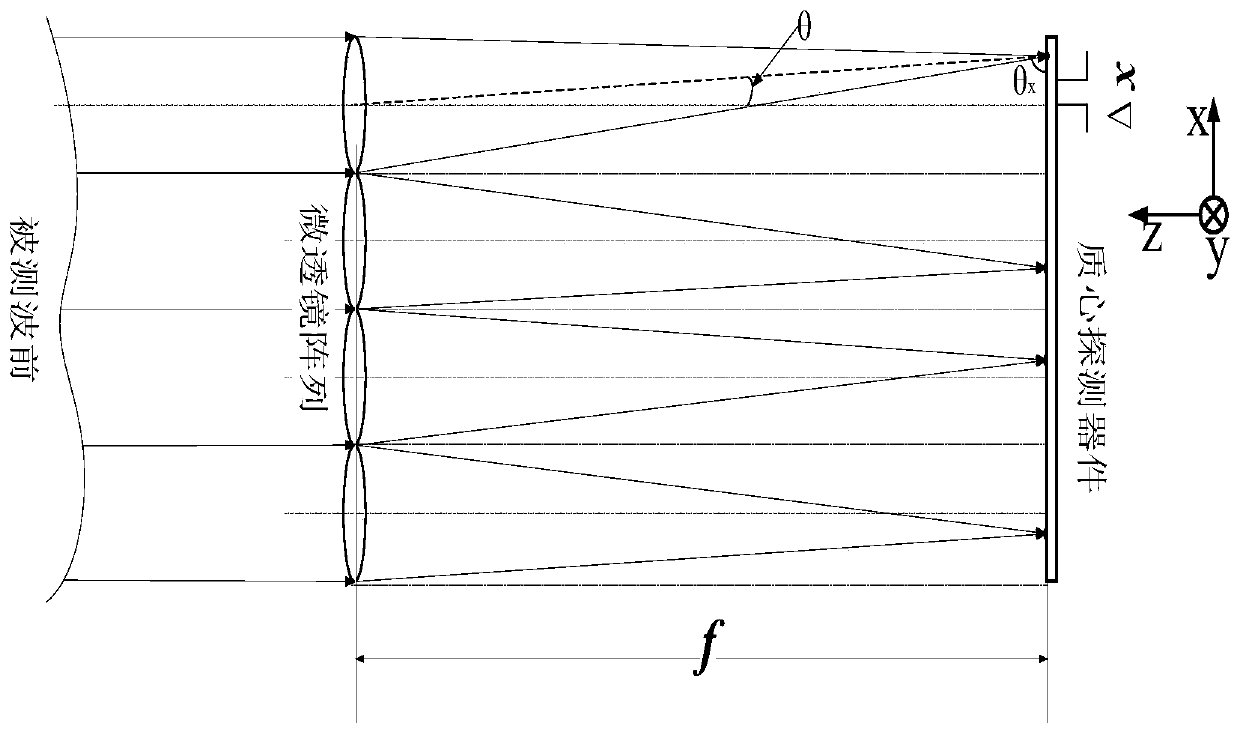

Method for connecting space object positioned by visible marking points

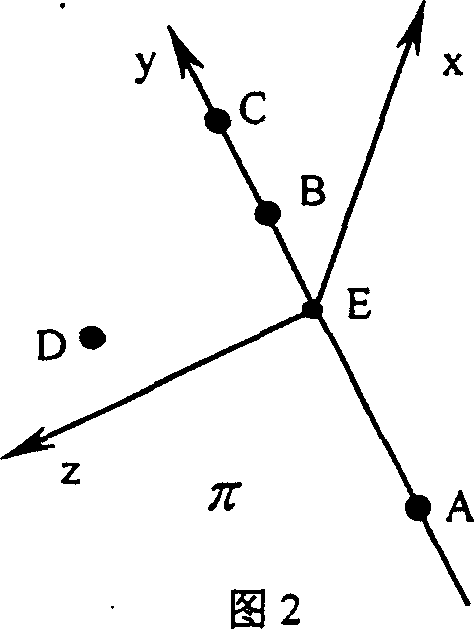

InactiveCN1559356ASource of control errorReduce the amount of errorDiagnosticsSurgerySurgical operationSpace object

A method for using visual marker point to locate the 3D object to be connected includes such steps as creating a coordinate system of probe by 4 marker dots, determining the coordinate of probe tip in the coordinate system, calculating the relation between the coordinate systems of world and probe, and coordinate transforming to obtain the coordinate information of probe tip in world coordinate system.

Owner:SHANGHAI JIAO TONG UNIV

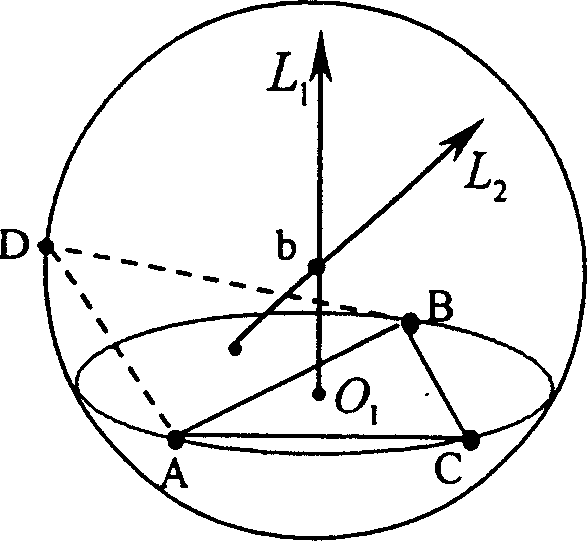

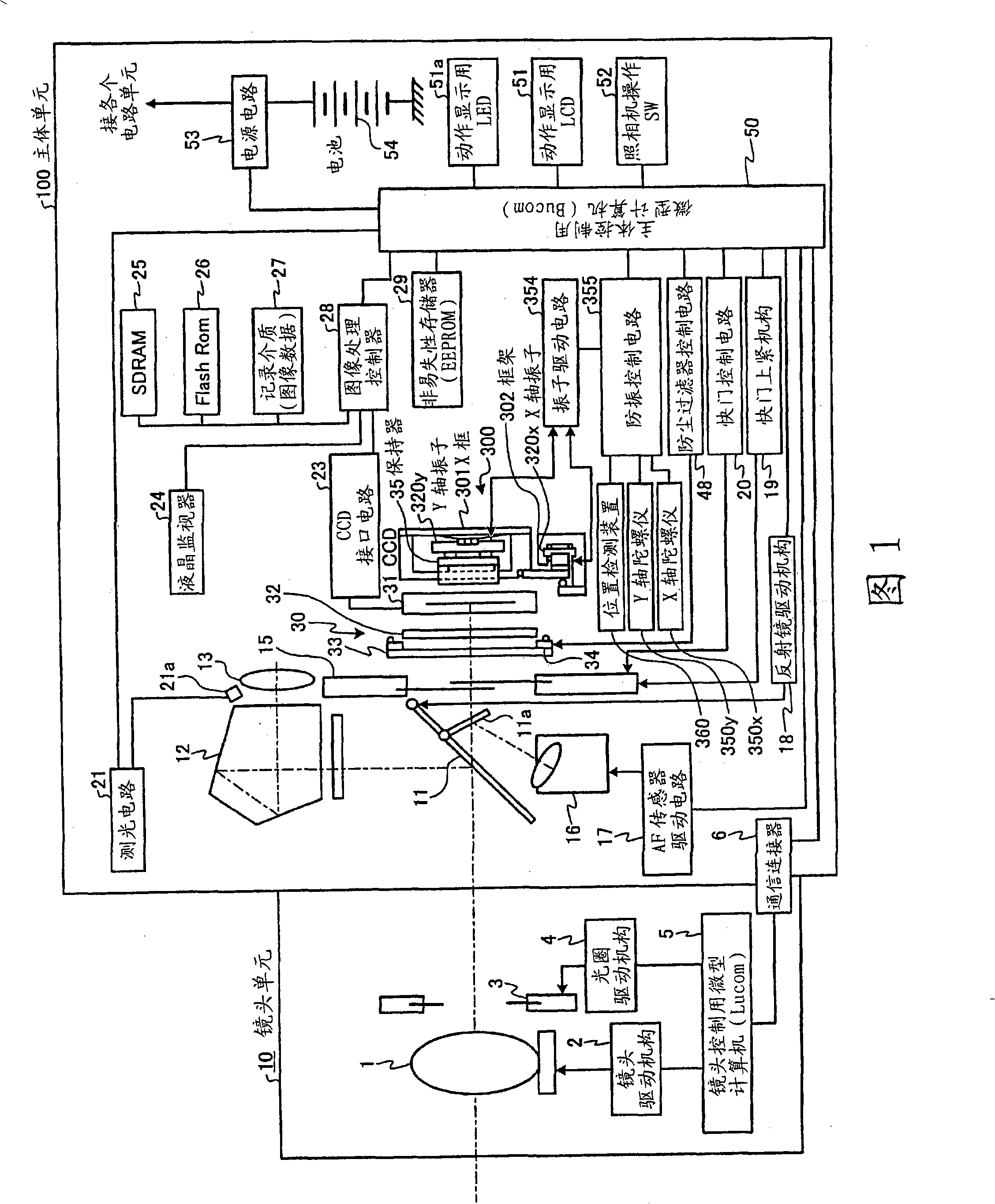

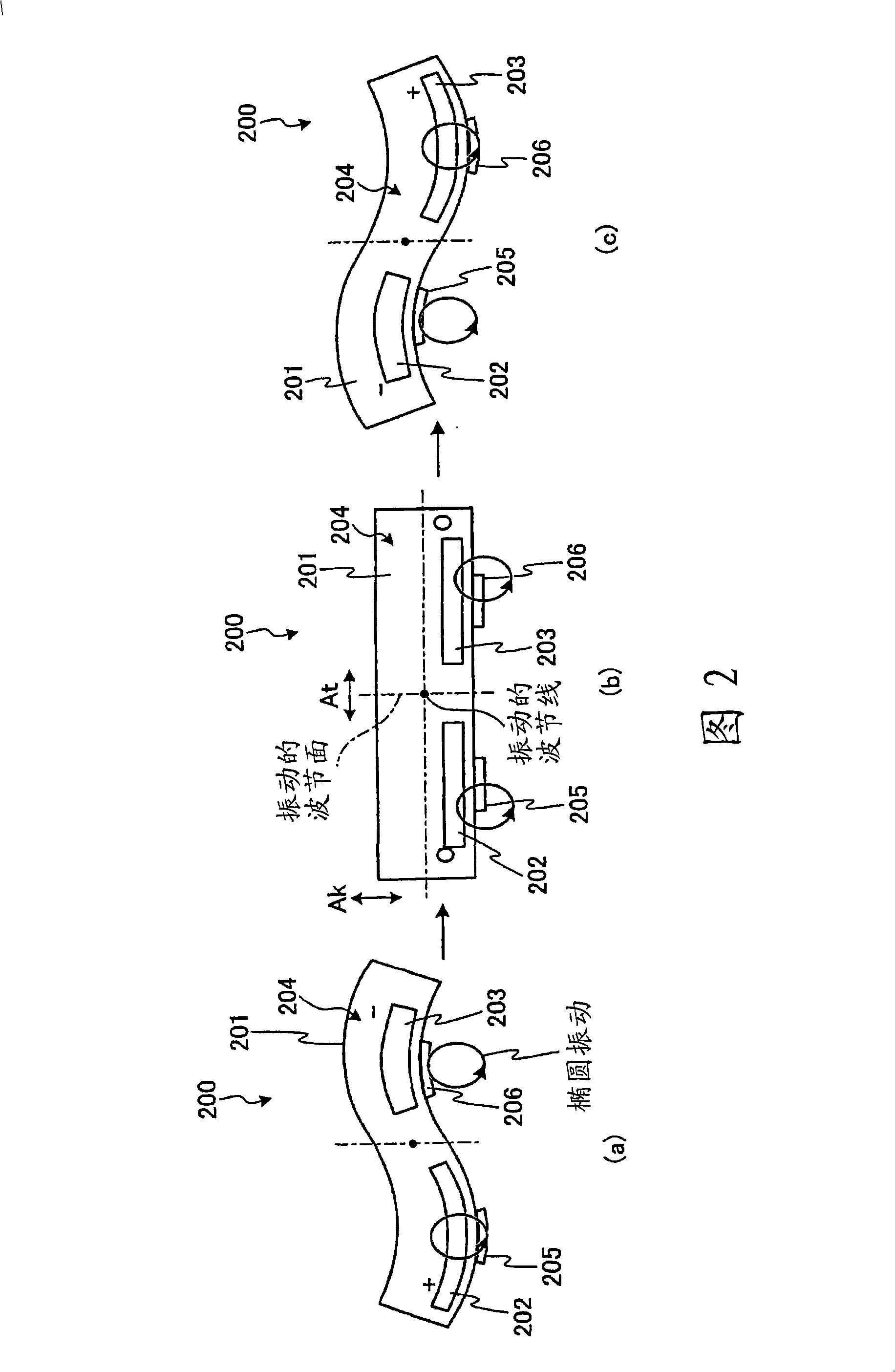

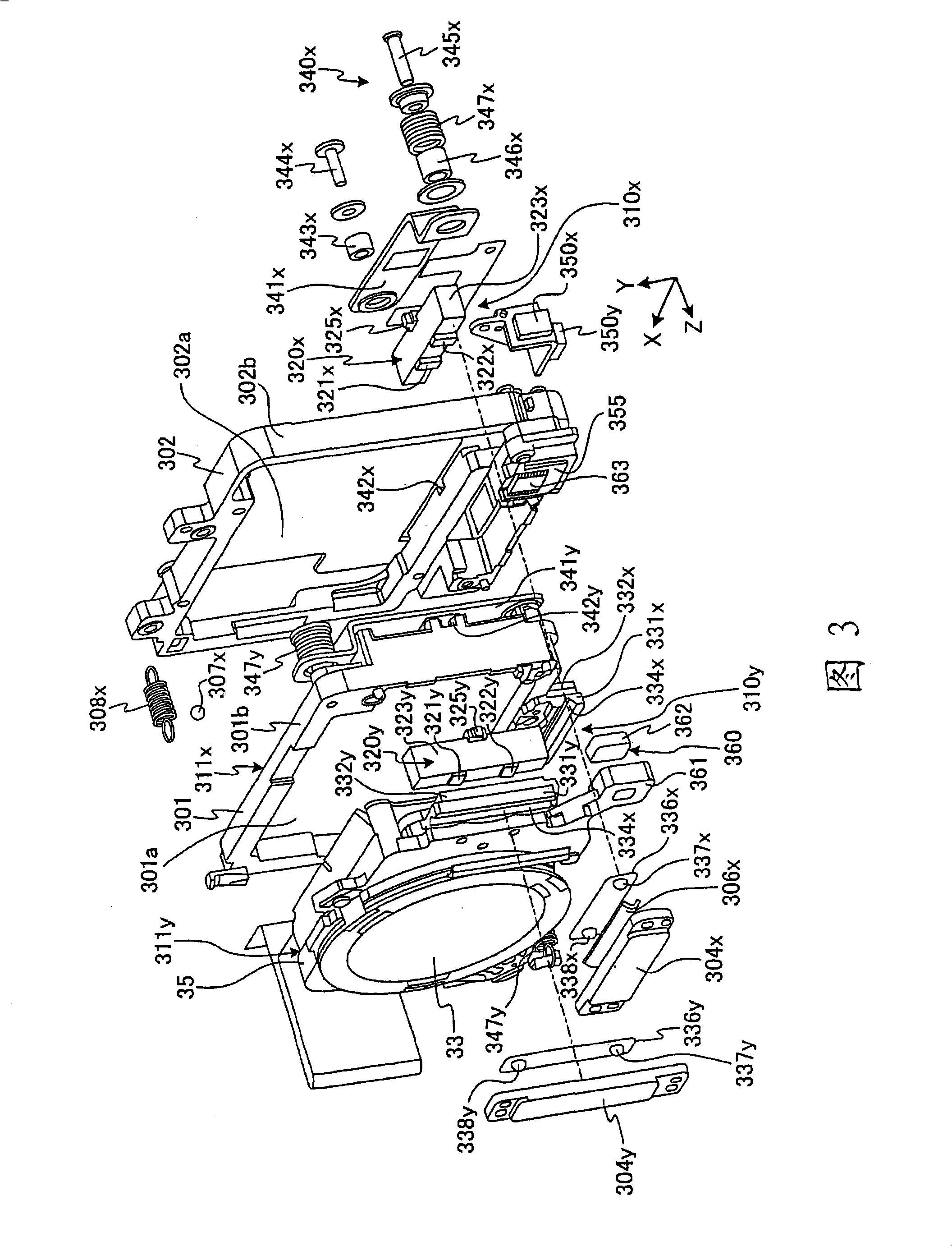

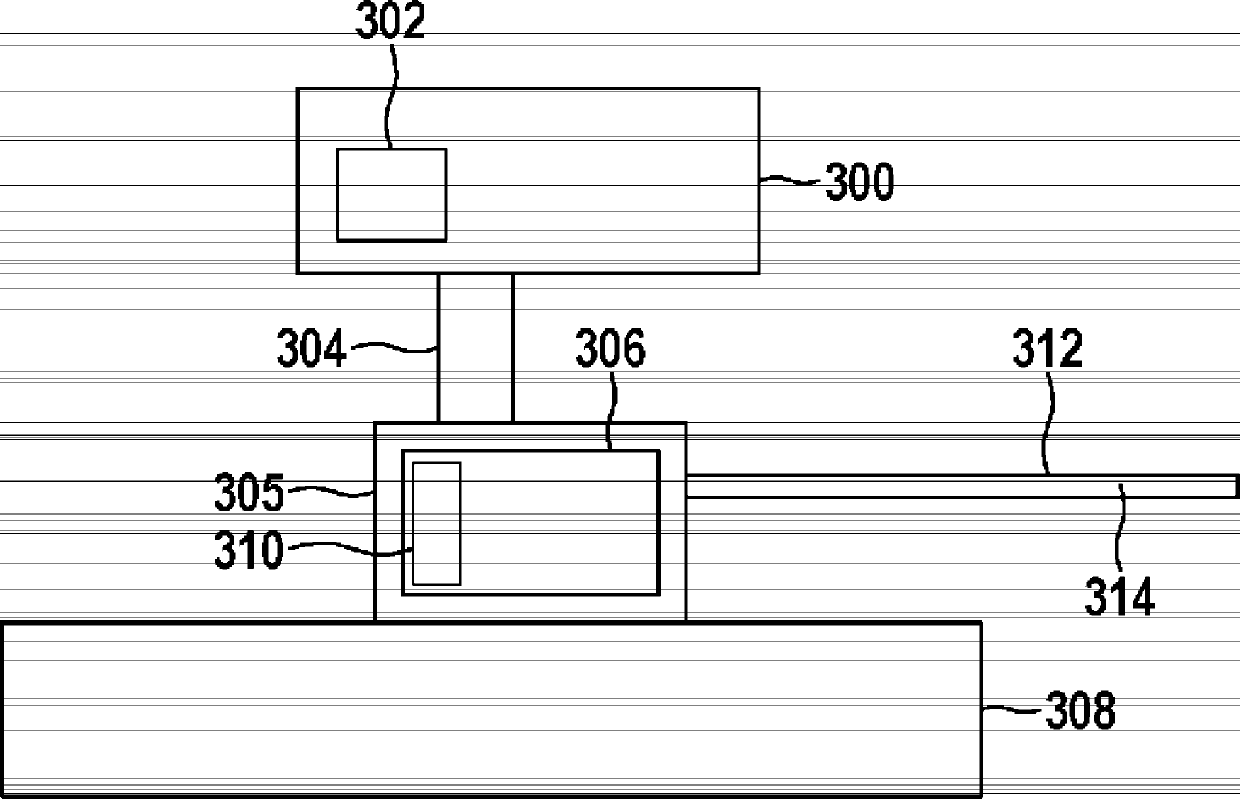

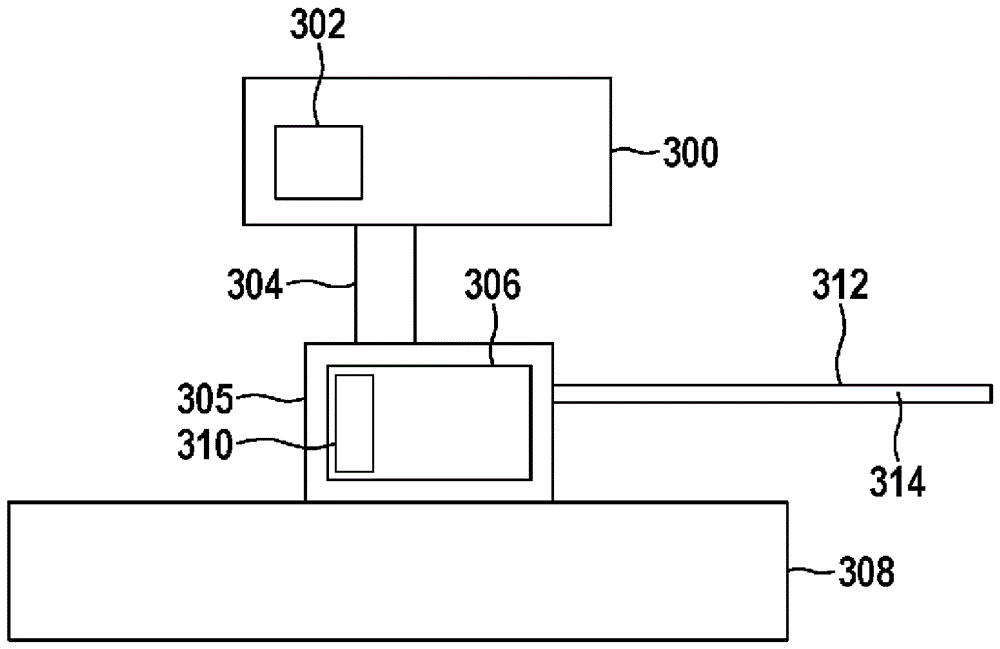

Image stabilizer

InactiveCN101335492AGuaranteed miniaturizationReduce the amount of errorPrintersPiezoelectric/electrostriction/magnetostriction machinesLocation detectionMiniaturization

The present invention provides a shake correcting device, which can ensure the device miniaturization and accurately detect the relative position of a camera shooting element. An X-axis actuator (320x) and a Y-axis actuator (320y) are arranged near respective positions of fictitious intersection points (P) at length directional axis (Lx, Ly) but not intersection, a position detecting component for detecting the relative position of CCD(31) is arranged in areas (E) containing fictitious intersection points (P) and surrounded by each one end of the X-axis actuator (320x) and the Y-axis actuator (320y), thus the device can be ensure miniaturization by a dead space generated by the arrangements of the X-axis actuator (320x) and the Y-axis actuator (320y). Furthermore, the present invention can reduce error quantity by arranging the position detecting component near the position of CCD(31), and accurately detect the relative position of CCD(31).

Owner:OLYMPUS CORP

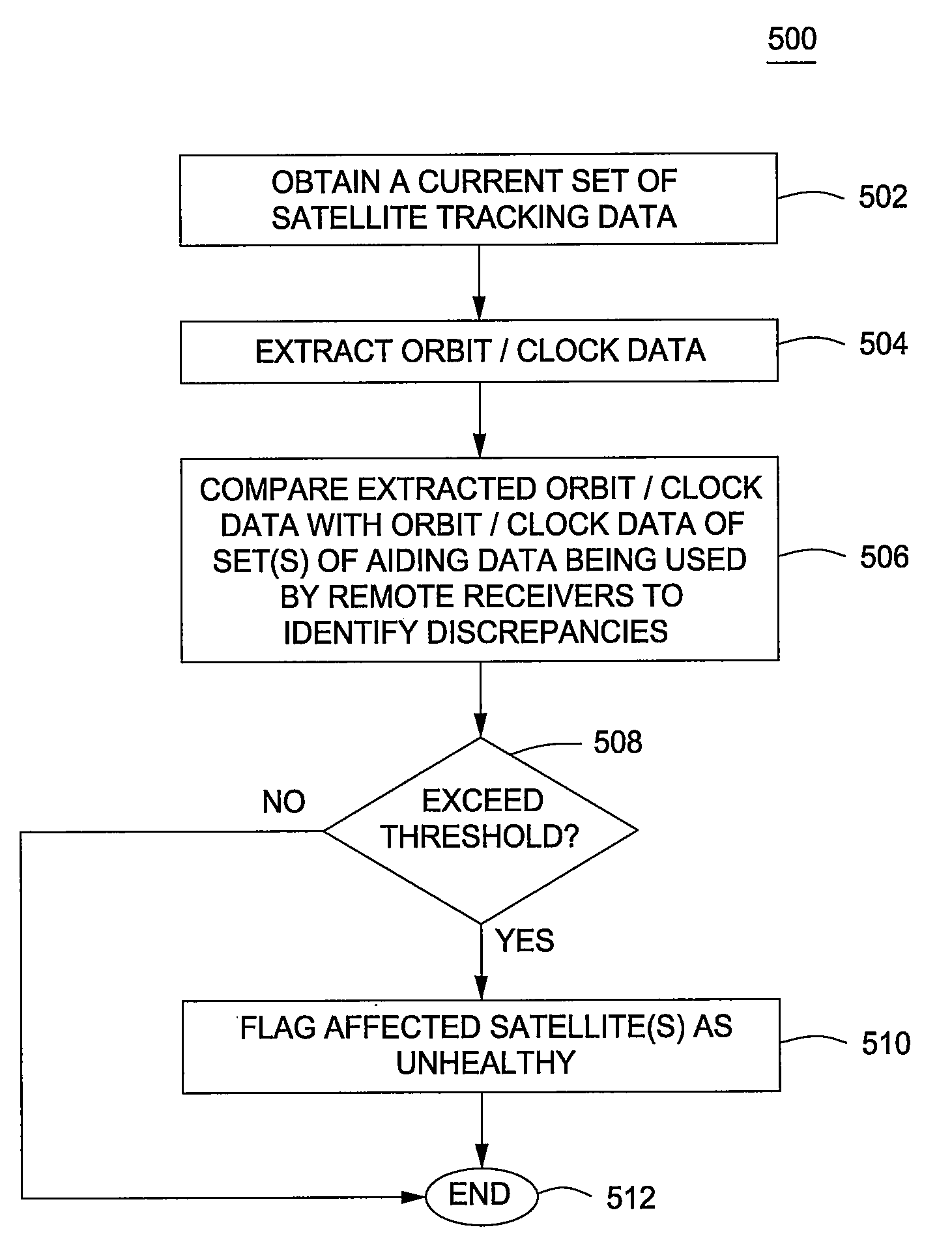

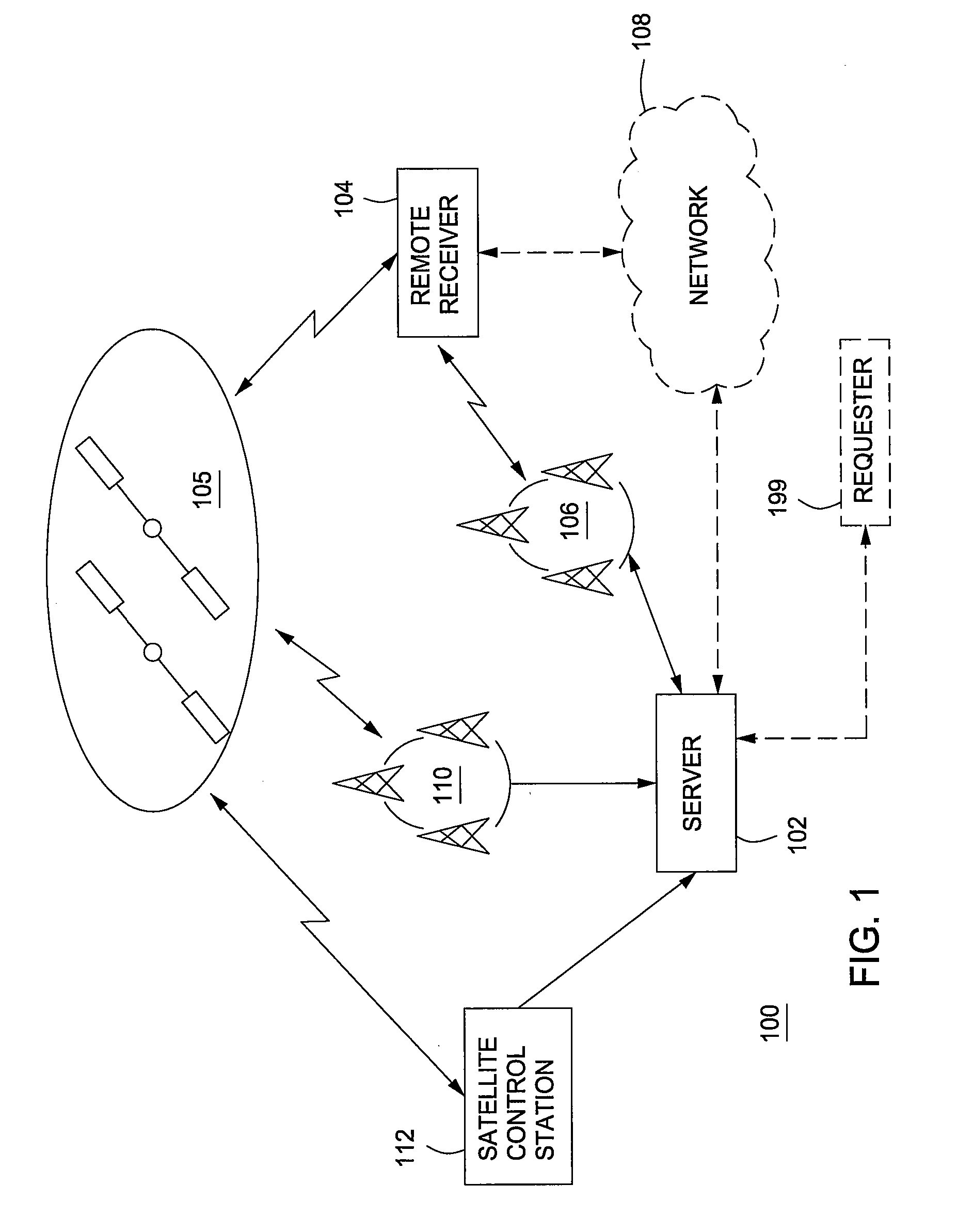

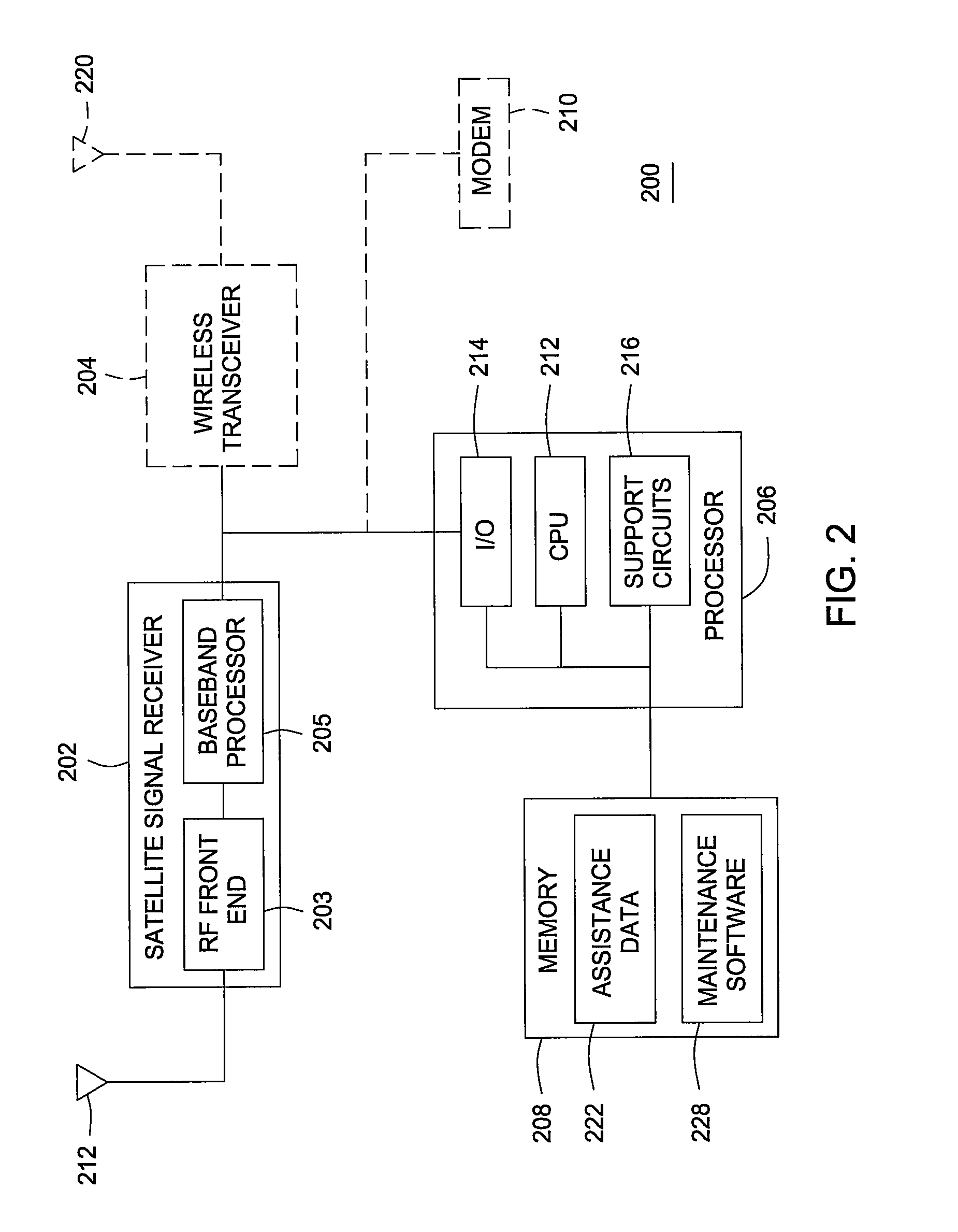

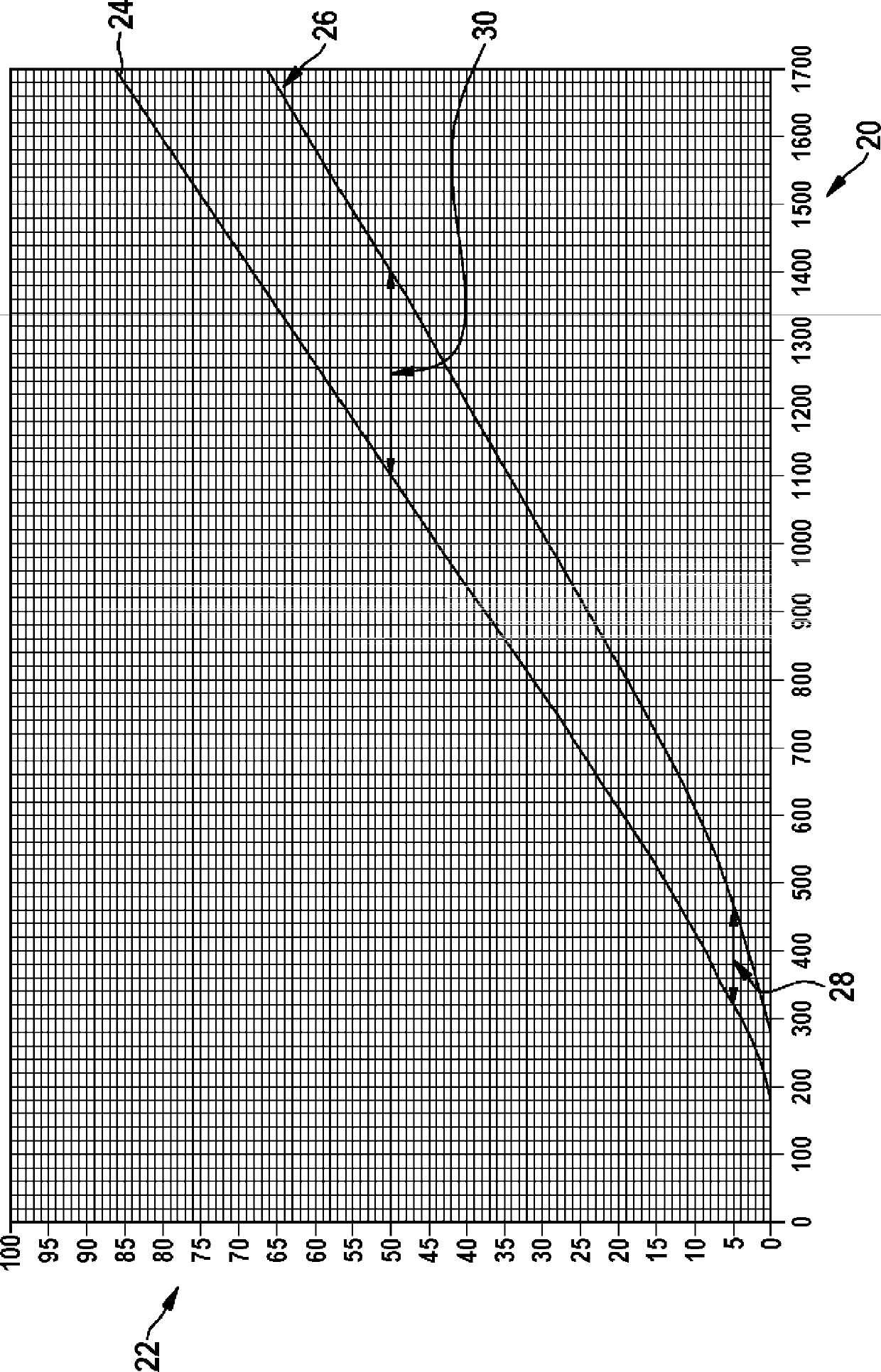

Method and apparatus for improving accuracy and/or integrity of long-term-orbit information for a global-navigation-satellite system

InactiveUS20080125971A1Improve accuracyReduce the amount of errorNavigation instrumentsSatellite radio beaconingEphemerisOrbit

A method and apparatus for monitoring a configuration of satellites to maintain integrity of LTO information in a GNSS receiver of a GNSS or other positioning system is described. The method may include obtaining broadcast ephemeris transmitted from at least one satellite of a constellation of satellites; comparing the broadcast ephemeris to long-term-orbit information available to a global-navigation-satellite receiver; and causing the global-navigation-satellite receiver to not use the long-term-orbit information when the long-term-orbit information does not correspond to the broadcast ephemeris.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

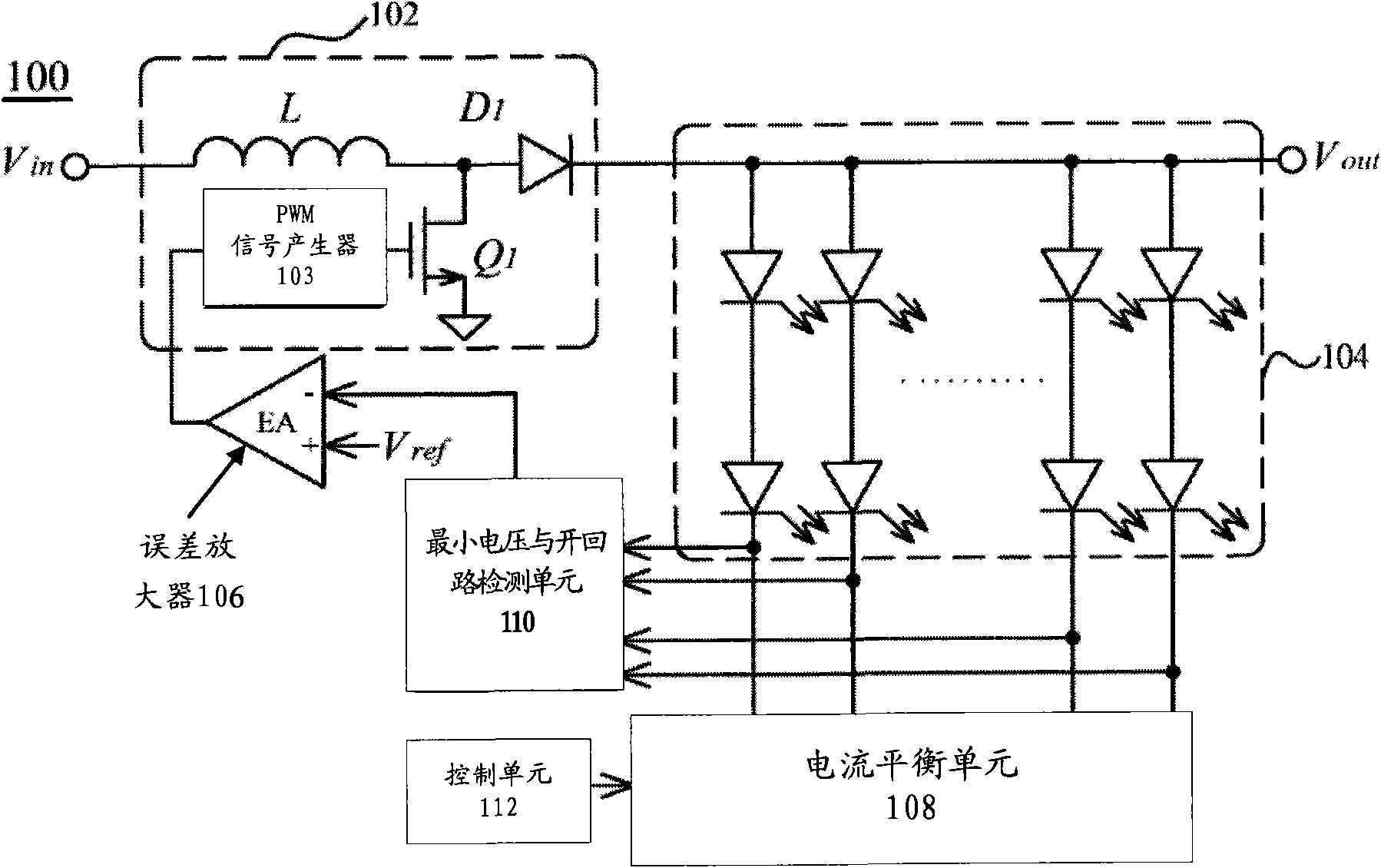

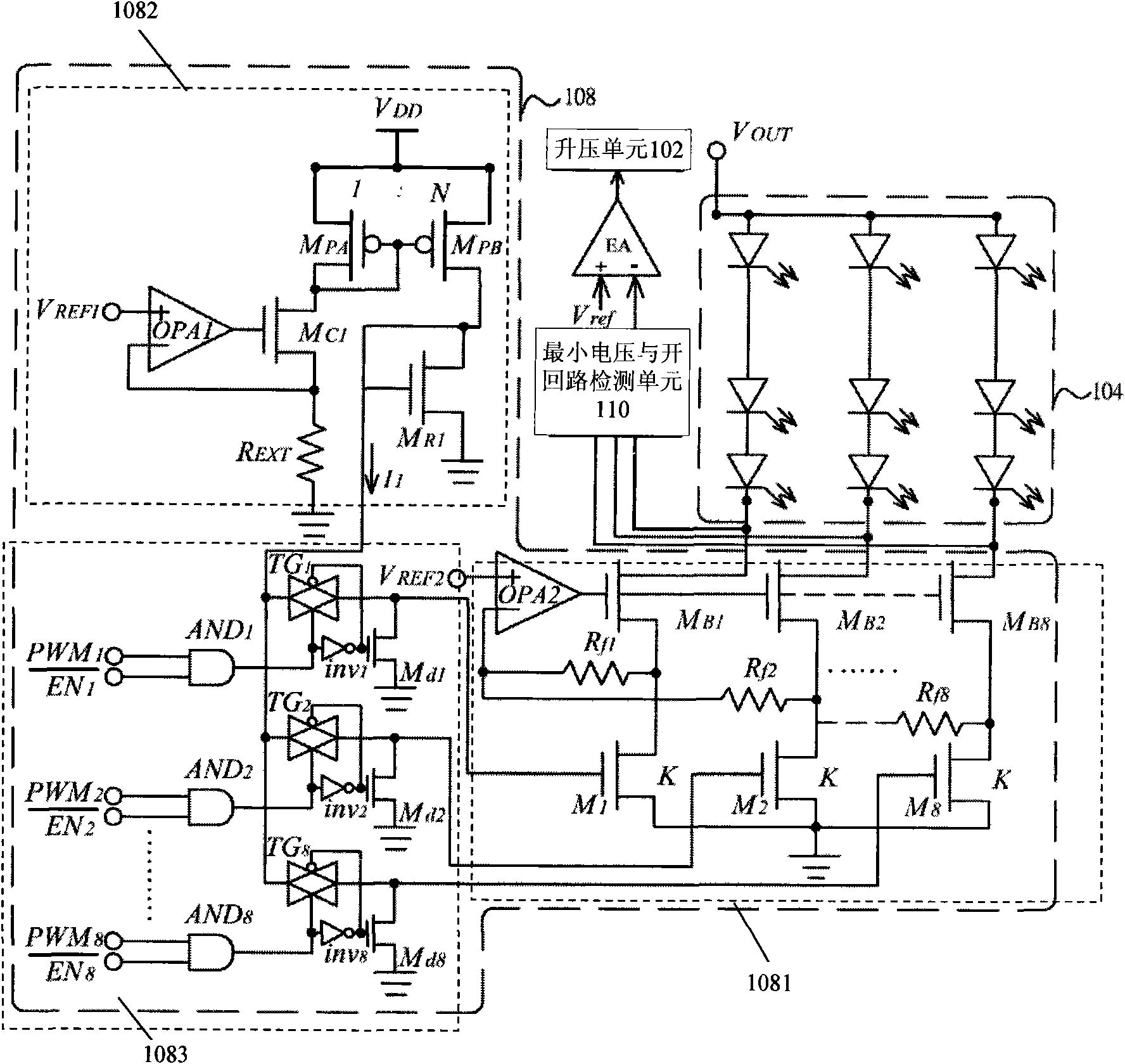

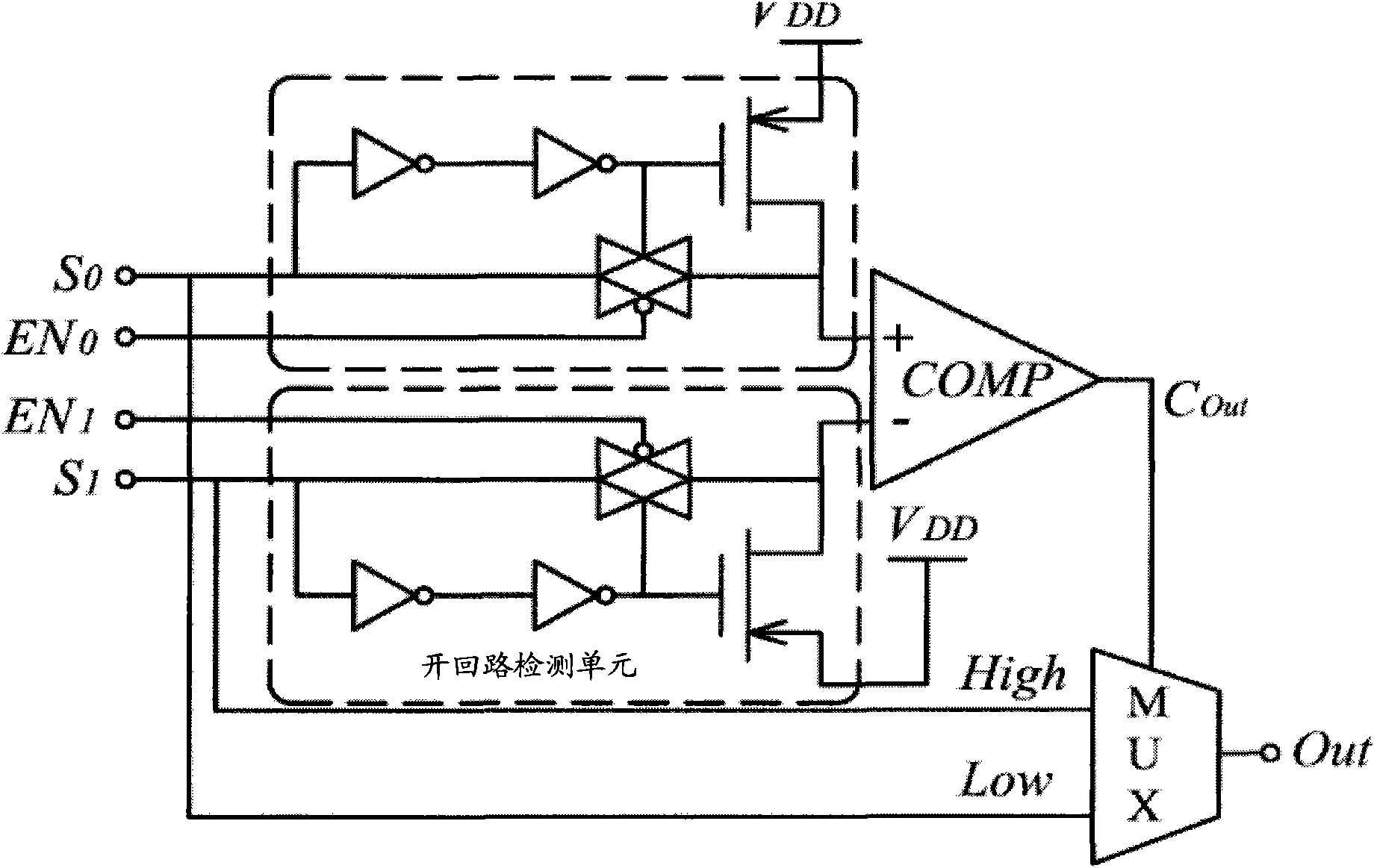

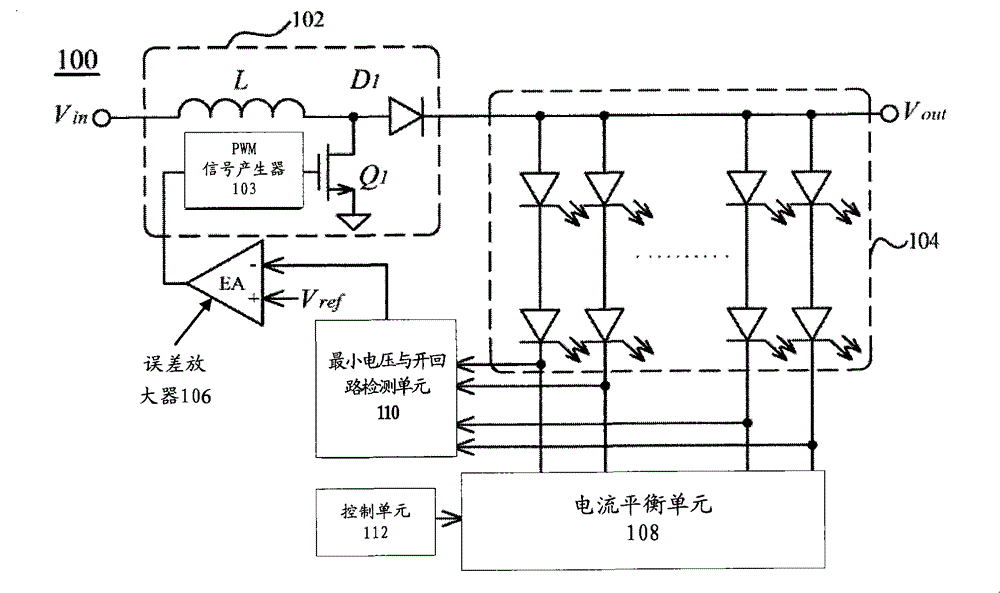

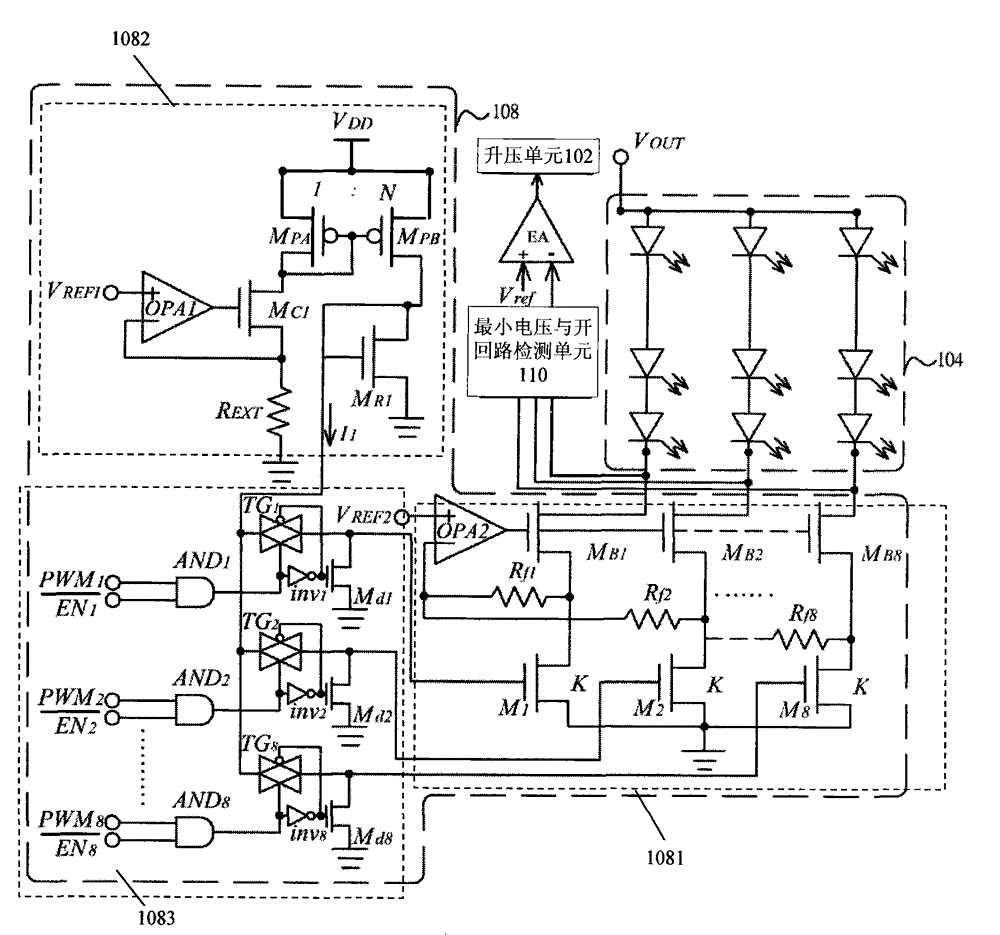

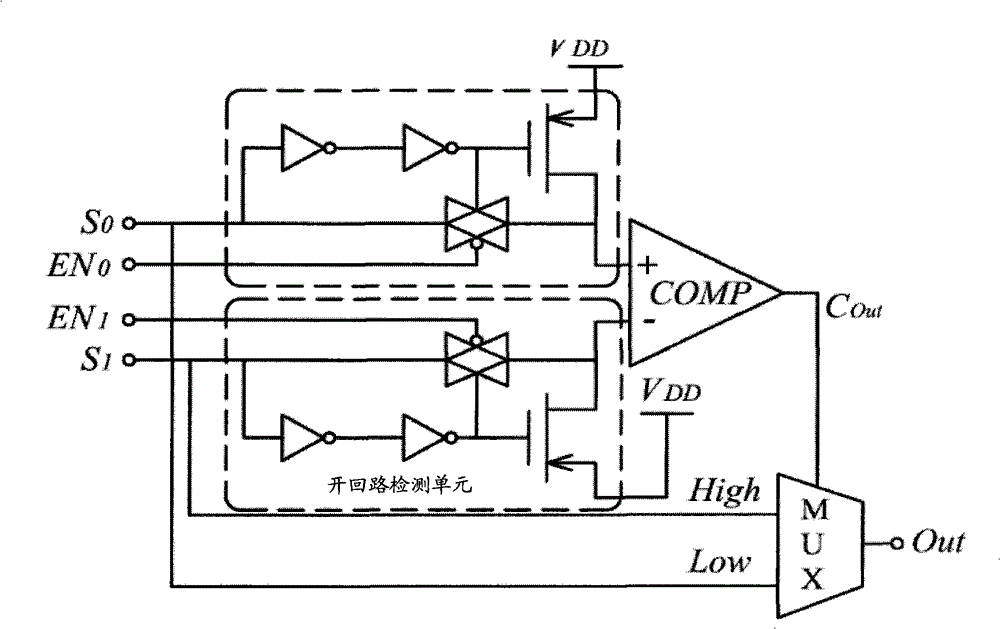

Current balancing circuit and backlight module with same

InactiveCN101854758AReduce the amount of errorImprove reliabilityPoint-like light sourceElectric circuit arrangementsPower flowControl unit

The invention relates to a current balancing circuit and a backlight module with the same. The current balancing circuit comprises a current balancing unit, a control unit and a detection unit, wherein the current balancing circuit is coupled to a plurality of light-emitting units so as to stabilize the current of the plurality of light-emitting units not be influenced by input voltage; the detection unit is coupled to the plurality of light-emitting units and the current balancing unit so as to be beneficial to detecting the minimum operation voltage of the light-emitting units; and the control unit is coupled to the current balancing unit so as to control the operation of the light-emitting units.

Owner:华映视讯(吴江)有限公司 +1

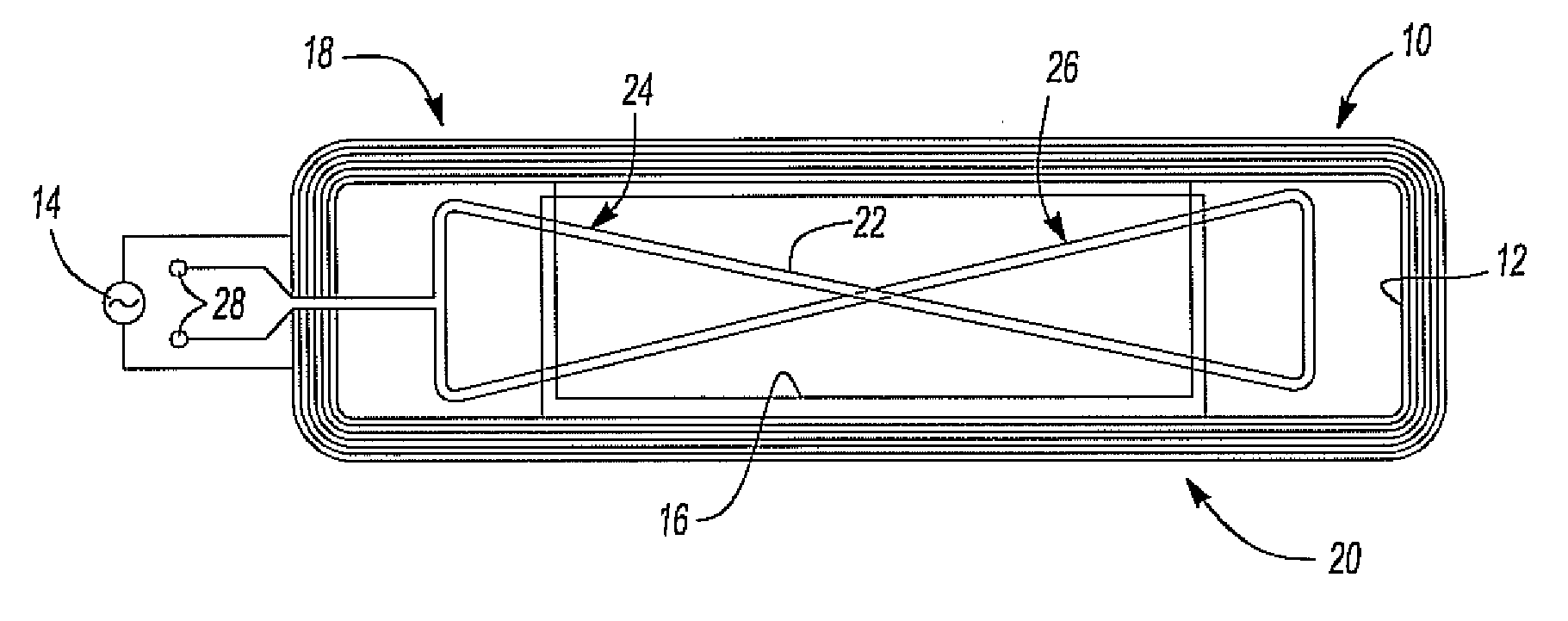

Linear inductive position sensor

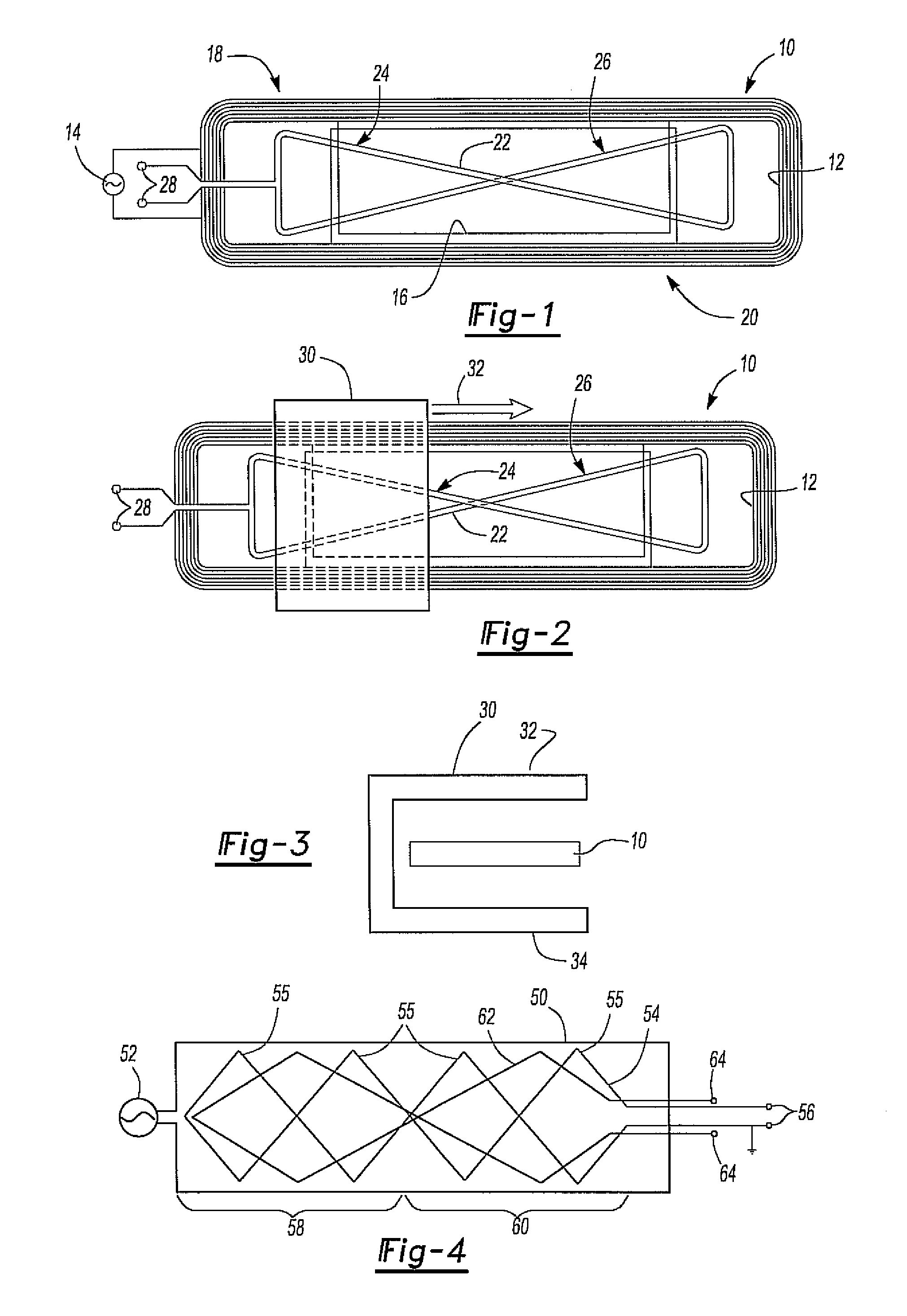

ActiveUS20090256555A1Easy to manufactureReduce the amount of errorElectric/magnetic position measurementsUsing electrical meansElectricityTransmitter coil

A linear position sensor having a transmitter coil which generates electromagnetic radiation when excited by a source of electrical energy and wound in a first direction. A receiver coil is contained within the transmitter coil and the receiver coil includes both a first loop wound in a first direction and a second loop wound in the opposite direction. A coupler element linearly moves along a first direction relative to the transmitter coil which varies the inductive coupling between the transmitter coil and the receiver coil as a function of the linear position of the coupler element to thereby vary the electrical output signal from the receiver coil when excited by the transmitter coil. The first and second loops of the receiver coil are linearly aligned with each other along the first direction.

Owner:KSR IP HLDG

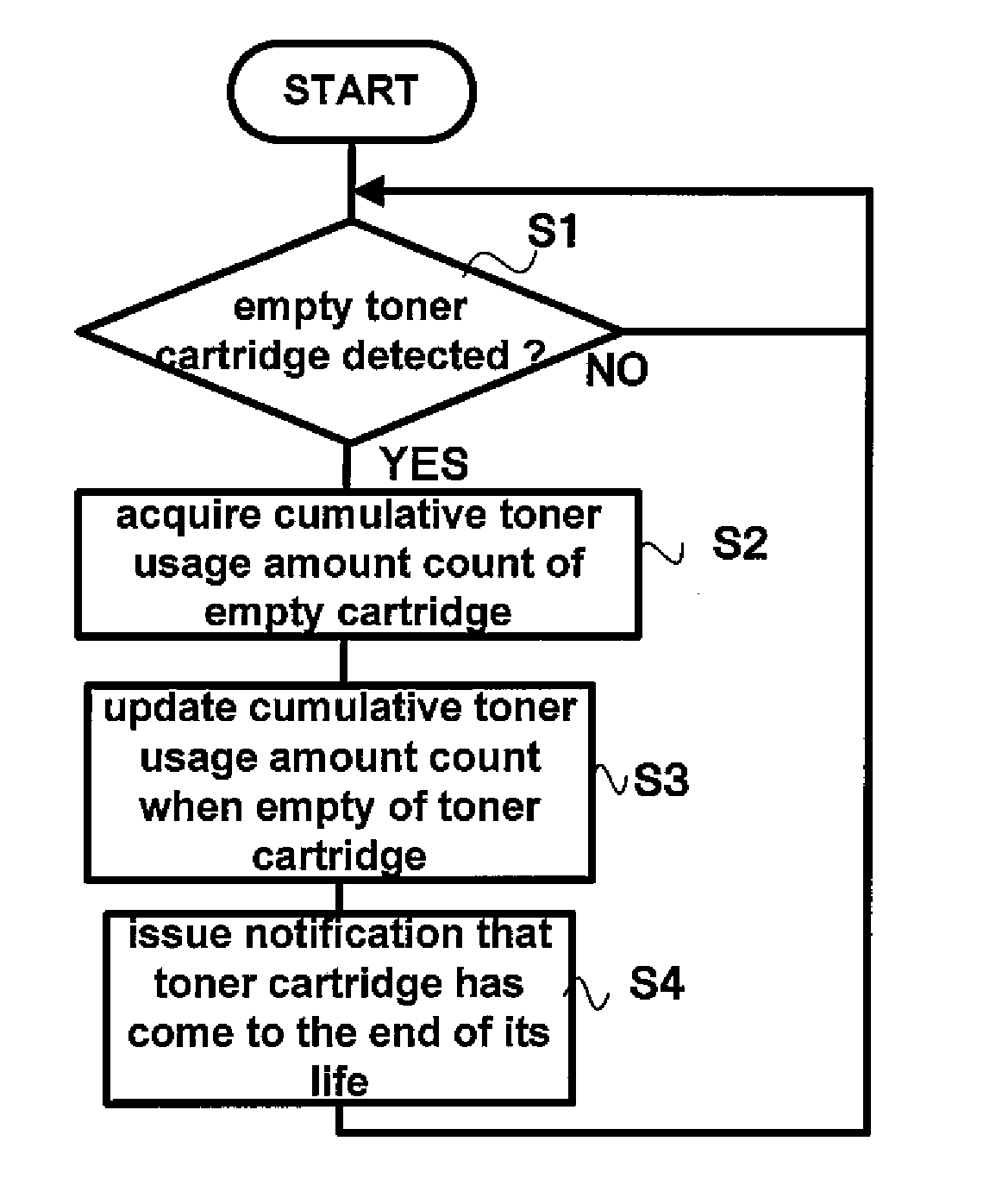

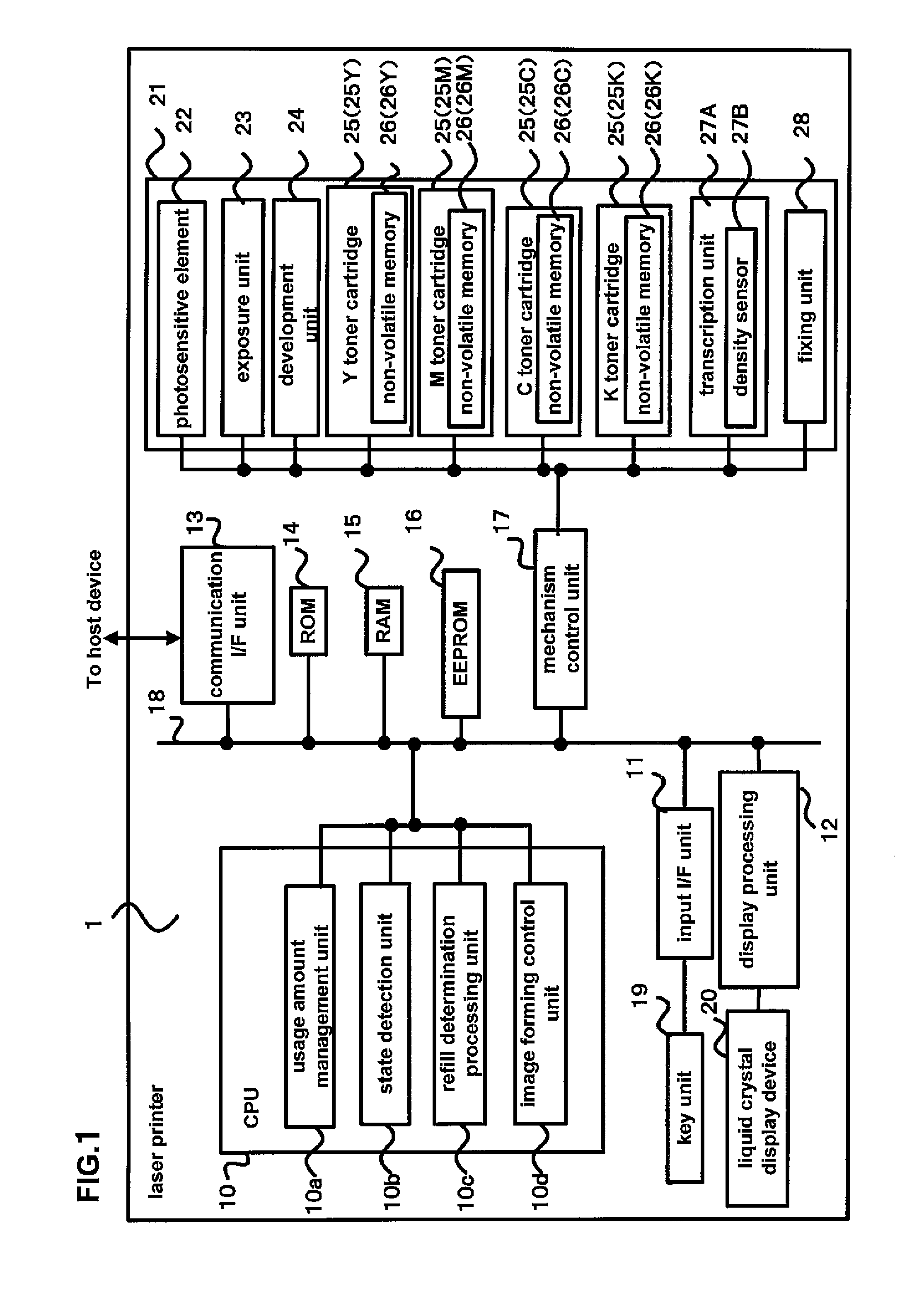

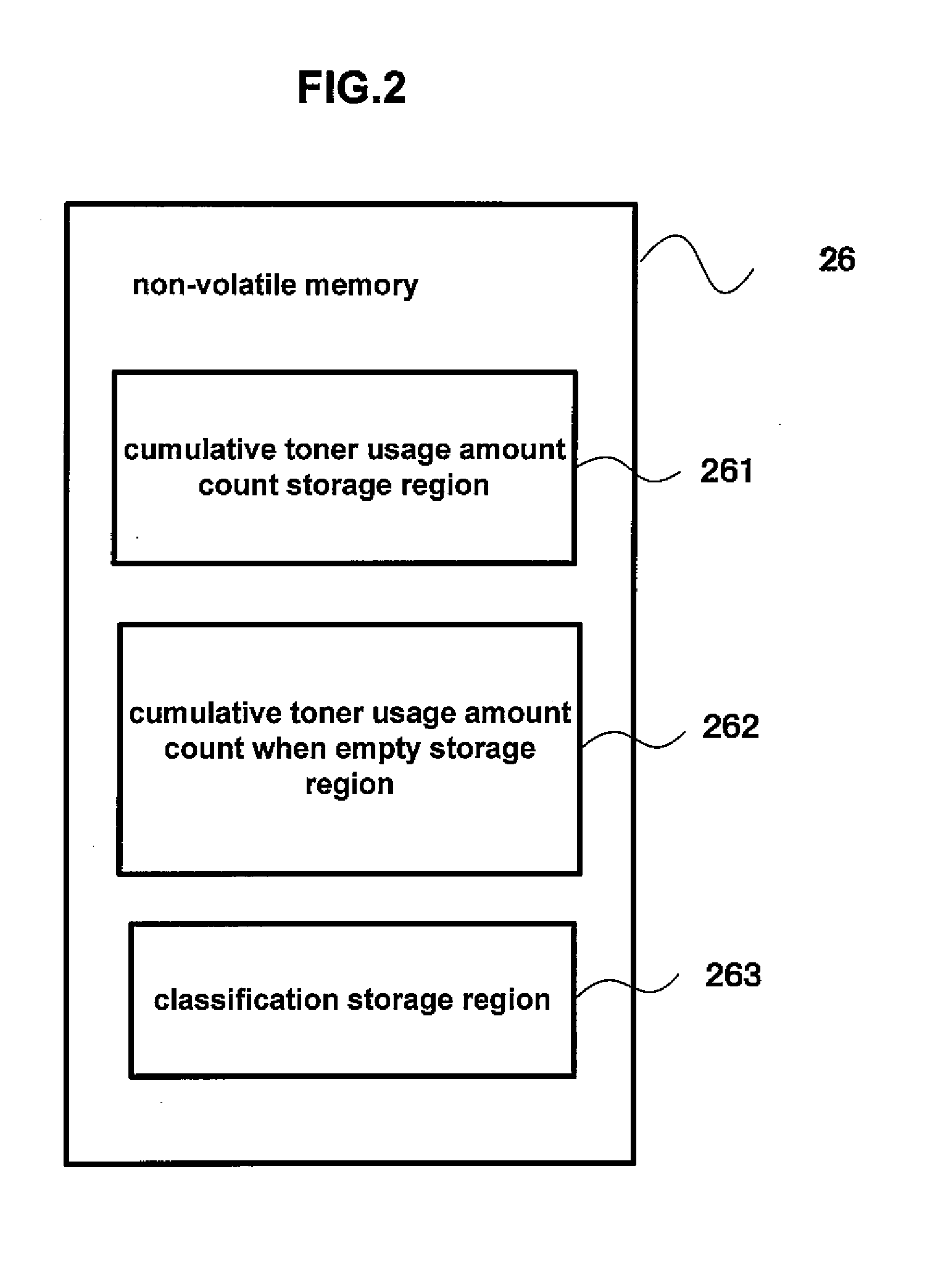

Image Forming Device

ActiveUS20090034995A1Reduce the amount of errorUnauthorized useElectrographic process apparatusImage formationComputer science

An image forming device to which can be installed an image forming material cartridge which contains an image forming material, and which has a non-volatile memory from which data can be read and to which data can be written, includes a counter which approximately counts the image forming material usage amount of the image forming material cartridge, and generates an image forming material usage amount count; a state detector which detects a predetermined state in which it is inferred that the amount of the image forming material in the image forming material cartridge is low; a storage unit which stores amount of change information which specifies the amount of change of the image forming material usage amount count from the time point that the predetermined state was detected until the present in the non-volatile memory of the image forming material cartridge; and a determination unit which determines whether or not the image forming material cartridge is a refilled product, based upon the amount of change of the image forming material usage amount count and upon a first threshold value.

Owner:SEIKO EPSON CORP

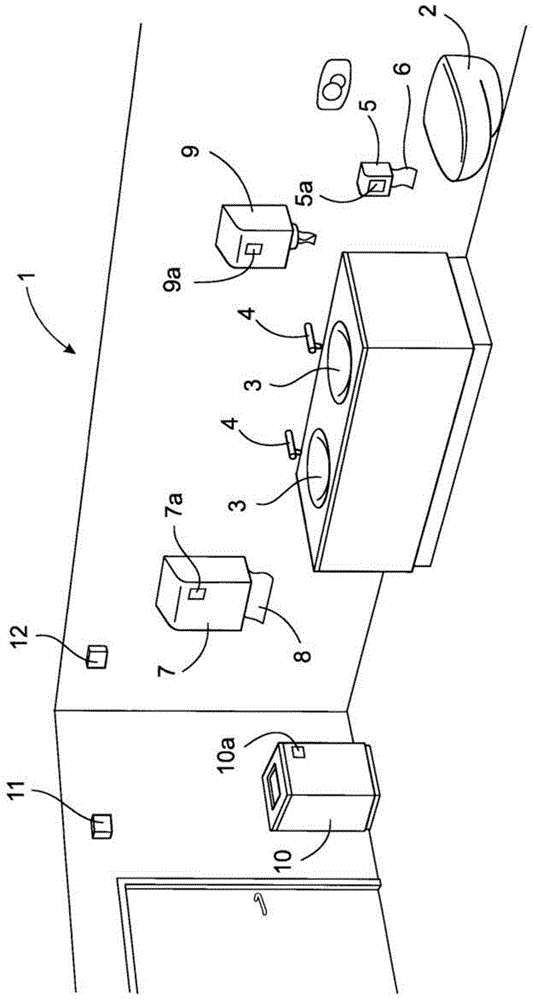

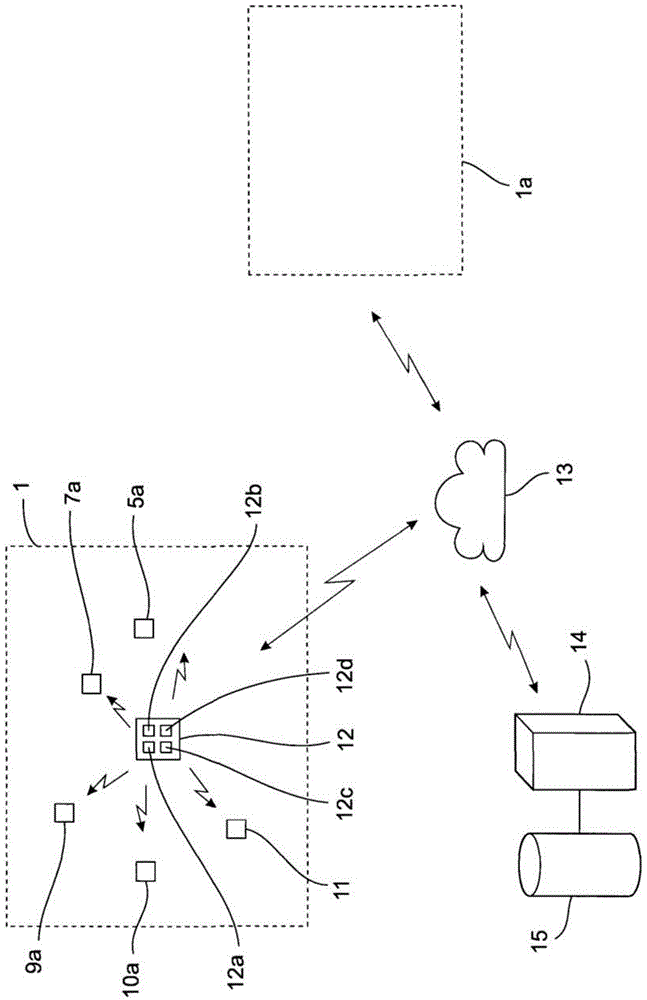

System and method for data collection and monitoring of defined space

ActiveCN104603805ALow costReduce loadTelemetry/telecontrol selection arrangementsAlarmsMonitoring systemEngineering

P41202191PCT00 2012-08-3 20 ABSTRACT: The invention relates to a data collection and monitoring system for a defined space (1) within a public or commercial facility, comprising: a plurality of sensors (5a, 7a, 9a, 10a, 11) of which at least one sensor (5a, 7a, 9a) is arranged for monitoring the level of a consumable in connection with said space (1); and a data collecting unit (12) arranged for wirelessly communicating with said sensors (5a, 7a, 9a, 10a, 11) and furthermore arranged for communicating with a central server (14) associated with a storage medium (15). The storage medium (15) is adapted for storing and monitoring data related to said space (1). The invention is arranged so that said data collecting unit (12) is arranged for minimizing the amount of data transmitted, by transferring data from said sensors (5a, 7a, 9a, 10a, 11) to said central server (14) upon a status change of at least one of said sensors (5a, 7a, 9a, 10a, 11).

Owner:ESSITY HYGIENE & HEALTH AB

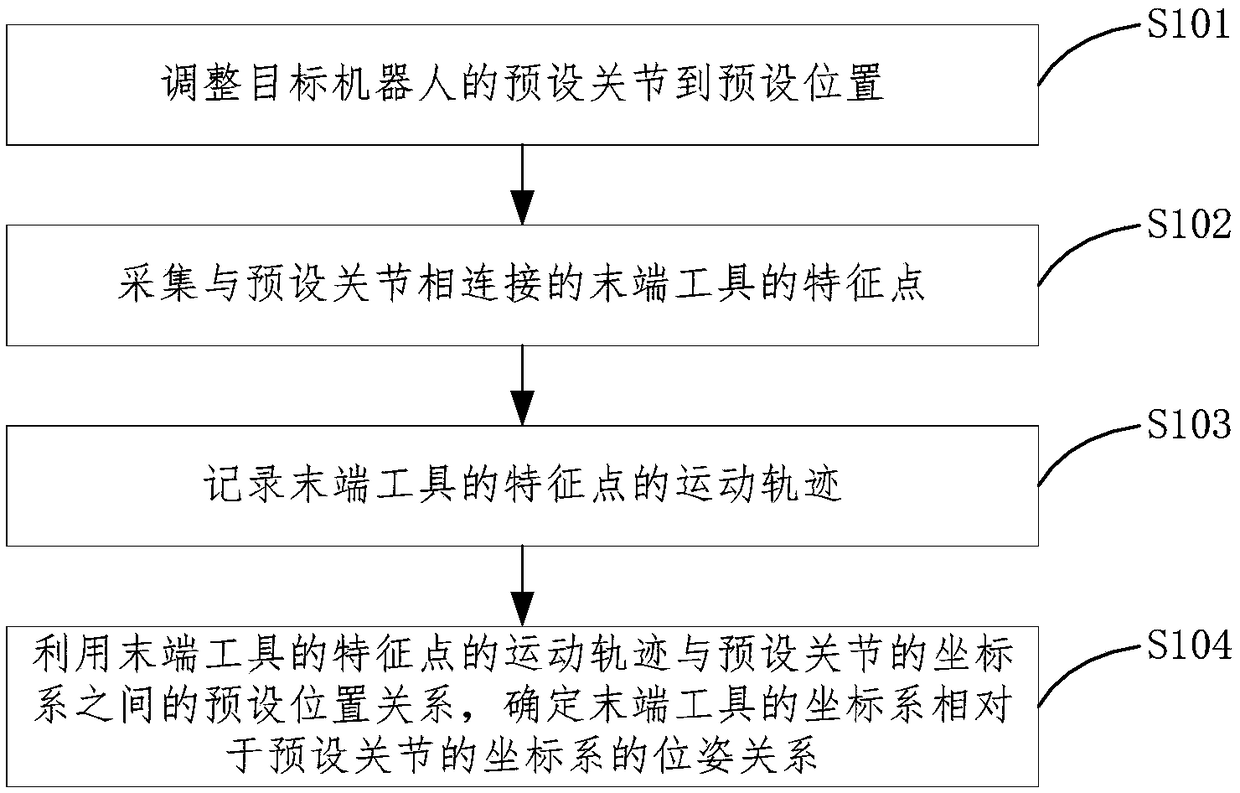

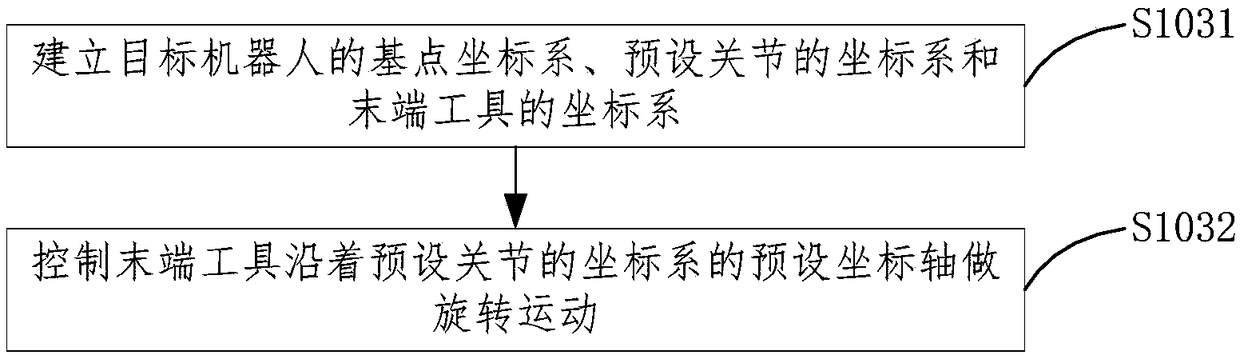

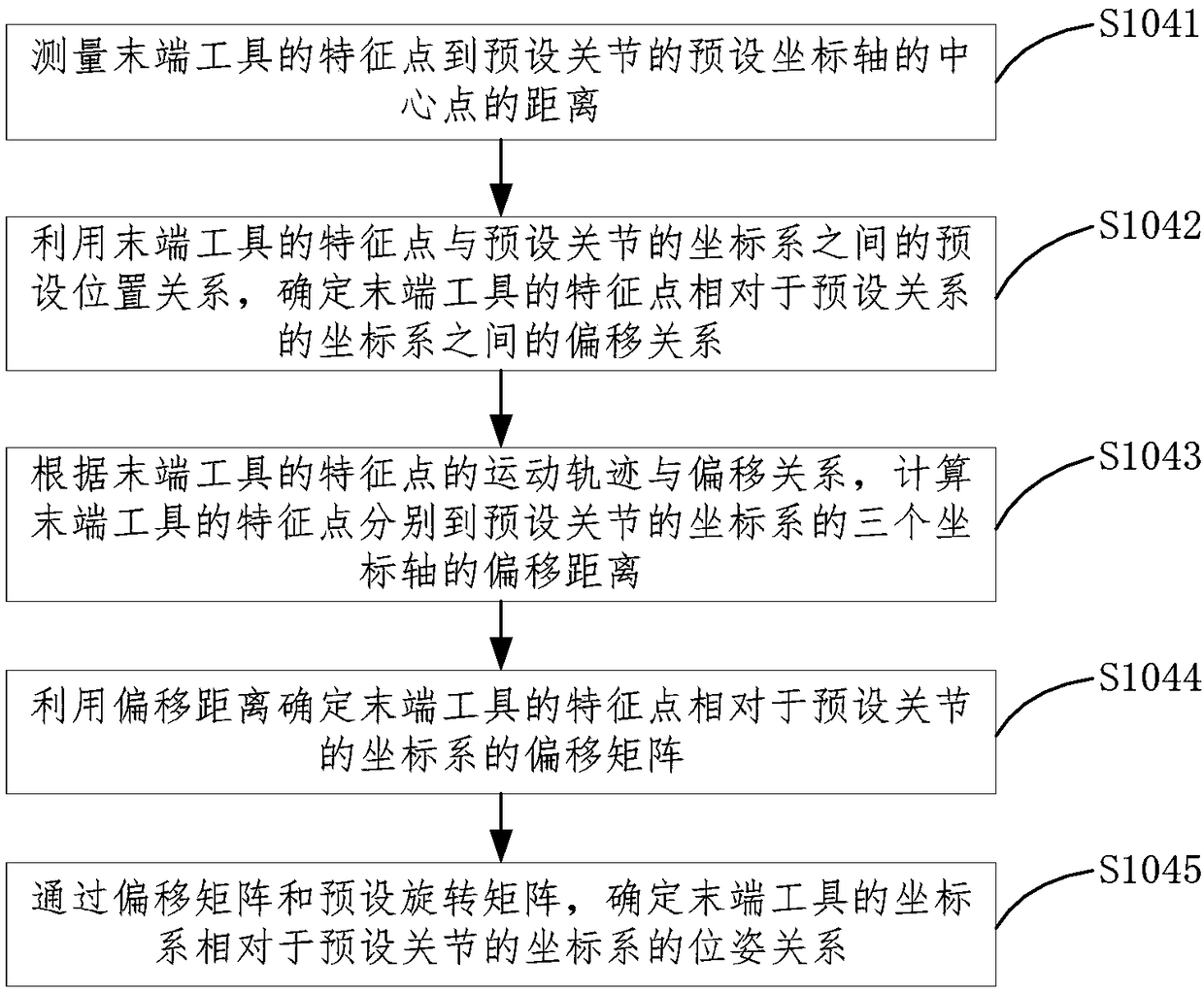

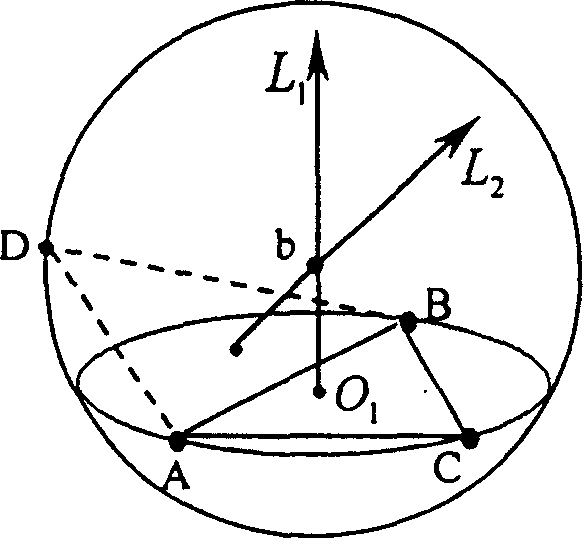

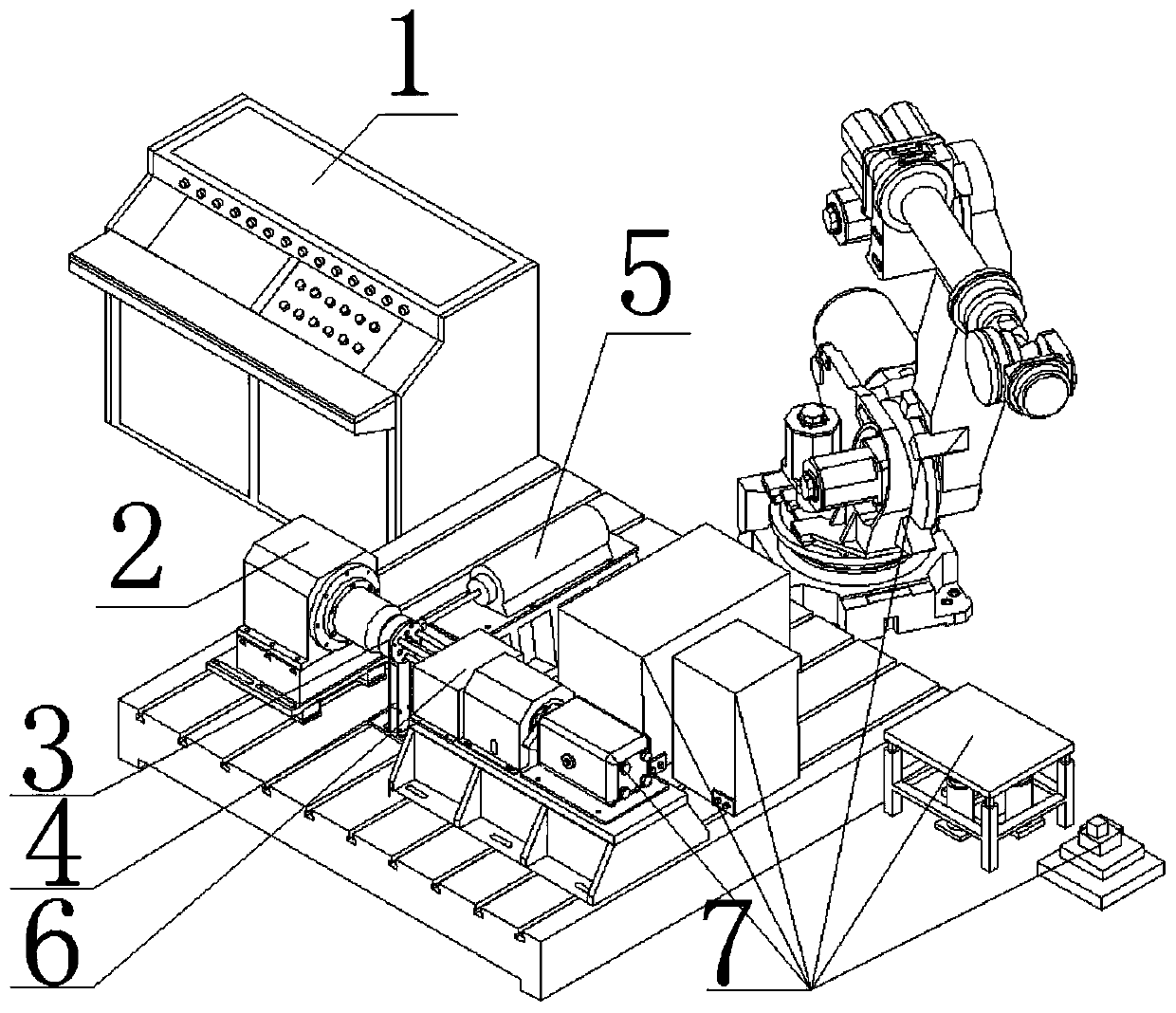

Calibrating method and device of tool coordinate system as well as computer-readable storage medium

ActiveCN109304713ASimple calculationReduce computing power requirementsProgramme-controlled manipulatorComplex calculationComputer science

The invention relates to a calibrating method and device of a tool coordinate system as well as a computer-readable storage medium. The calibrating method comprises the following steps: adjusting a preset joint of a target robot to a preset position; acquiring a feature point of an end-of-arm tooling connected with the preset joint; recording a motion trail of the feature point of the end-of-arm tooling; and determining the pose relation, of a coordinate system of the end-of-arm tooling, relative to a coordinate system of the preset joint, by using the preset position relation between the motion trail of the feature point of the end-of-arm tooling and the coordinate system of the preset joint. According to the technical schemes of the embodiments of the invention, neither changing of the posture of the target robot for many times nor complex calculation formulas are needed, the calibration process of the tool coordinate system and the calculation process of the calibration algorithm are simplified, the need of the calibration on calculation capacity is lowered, the calibration efficiency is improved, the number of introduced relevant error amounts is reduced, and the calibration precision is increased.

Owner:GREE ELECTRIC APPLIANCES INC

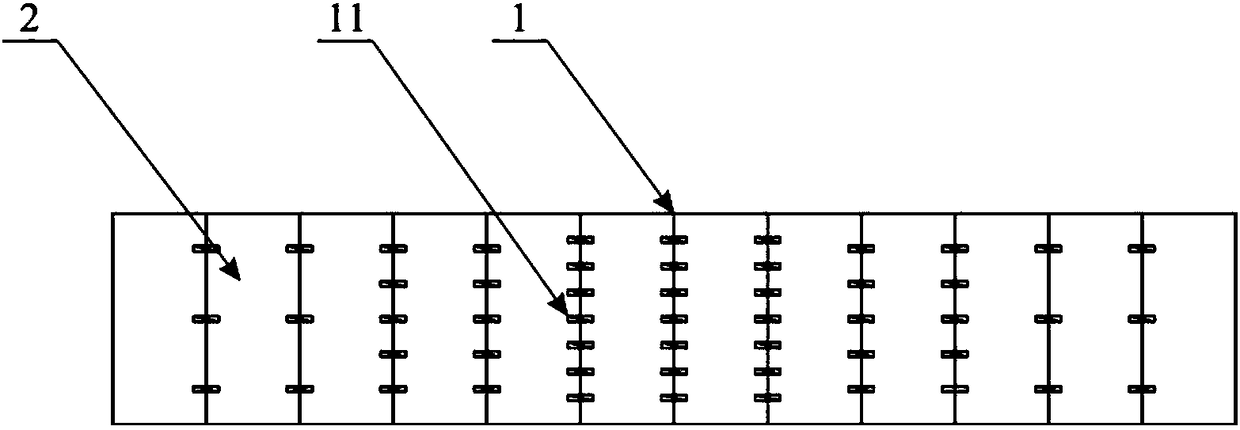

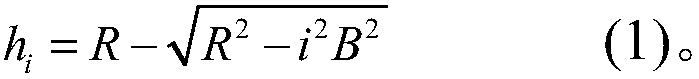

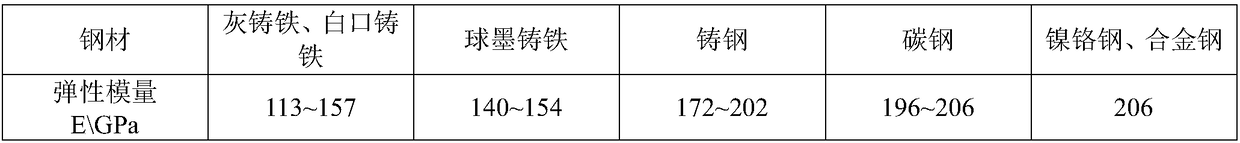

Shield tunnel segment lining structure of stratum junction section and design method

ActiveCN108571328AIncrease stiffnessAvoid failure damageUnderground chambersSustainable transportationStress concentrationEngineering

The invention discloses a shield tunnel segment lining structure of a stratum junction section and a design method. The shield tunnel segment lining structure comprises a junction section, conventional pipe sections are arranged on the two sides of the junction section, and the rigidity of a longitudinal joint bolt between every two adjacent segment rings on the junction section is higher than therigidity of each longitudinal joint bolt of the conventional pipe sections. The design method comprises the steps of establishing a longitudinal finite element numerical calculation model of a shieldtunnel, taking tunnel lining segments as concrete segments, and calculating the longitudinal sediment amount and the longitudinal deformation curve radius generated by the stratum junction section. According to the shield tunnel segment lining structure and the design method, the problem that in the prior art, the longitudinal deformation of a shield tunnel segment lining structure of the soft-hard stratum junction section is too large, the non-uniform stress is concentrated, and inter-ring longitudinal joints are damaged can be effectively solved.

Owner:SOUTHWEST JIAOTONG UNIV +1

Automobile refinishing paint weight-volume mixed toning method

ActiveCN109173827ASimple structureAccurate measurementRotary stirring mixersTransportation and packagingMasterbatchLacquer

In order to solve the technical prejudice, the present invention provides an automobile refinishing paint weight-volume mixed toning method with accurate color masterbatch matching. The method comprises the following steps: (1) finding a refinishing paint weight formula; (2) converting a corresponding refinishing volume formula according to the refinishing paint weight formula and the measured color masterbatch proportion; (3) calculating the type of the required color masterbatch as well as the required volume and weight for each color masterbatch; (4) finding a color masterbatch barrel corresponding to any one of the color masterbatch A according to the desired type of masterbatch, and taking a large part V1of the required volume V for the color masterbatch A, and weighing M1; subtracting M1 by the weight M2 required by the color masterbatch to obtain the weight M2, converting the weight M to the volume V2 according to the color masterbatch proportion measured in the step (2), and taking the color masterbatch A having the volume of V2 to complete the material taking of the color masterbatch A; and (5) according to the method in the step (4), sequentially taking the other color masterbatch; and mixing and stirring the acquired color masterbatch.

Owner:ZHENGZHOU SANHUA TECH & IND

Method for connecting space object positioned by visible marking points

InactiveCN1256072CSource of control errorReduce the amount of errorDiagnosticsSurgerySpace objectComputer science

Owner:SHANGHAI JIAOTONG UNIV

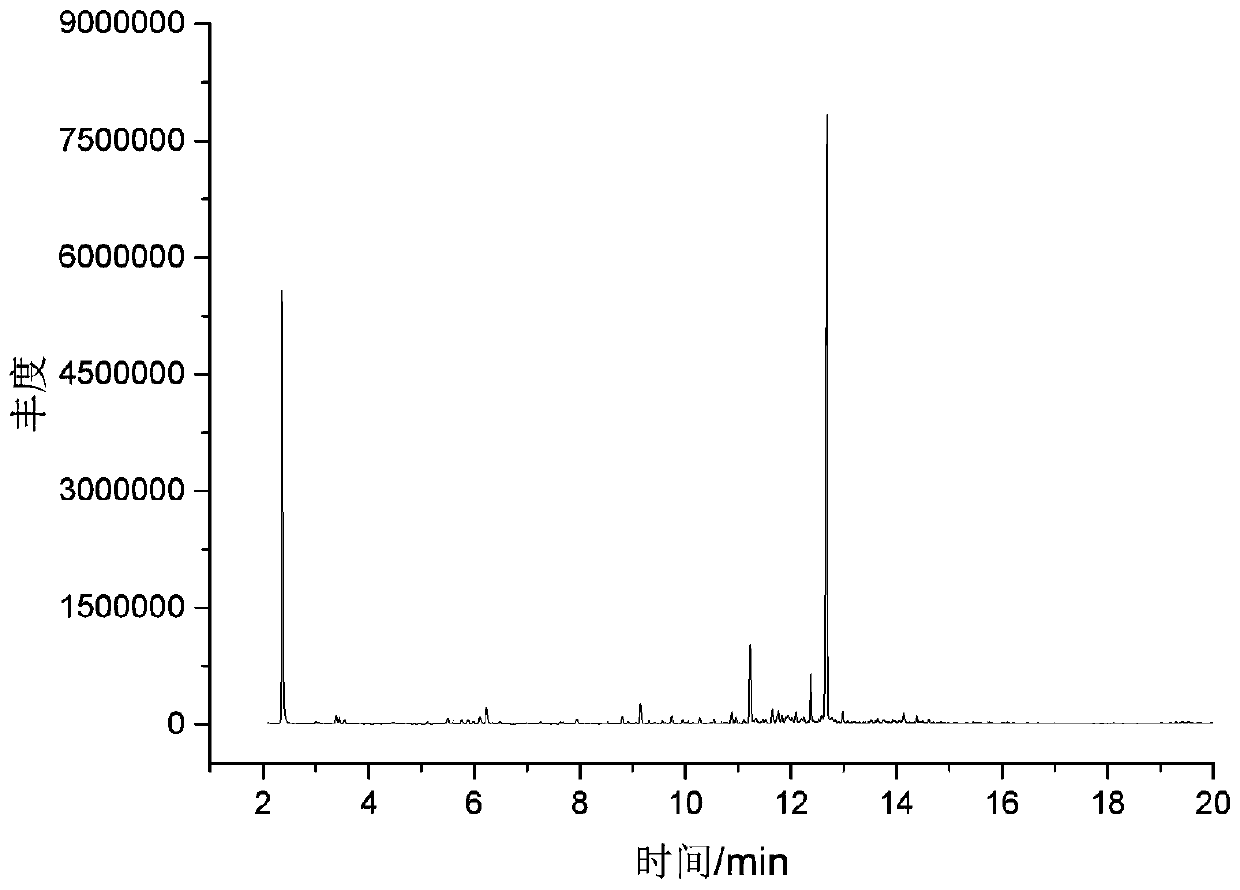

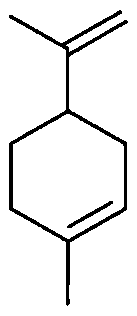

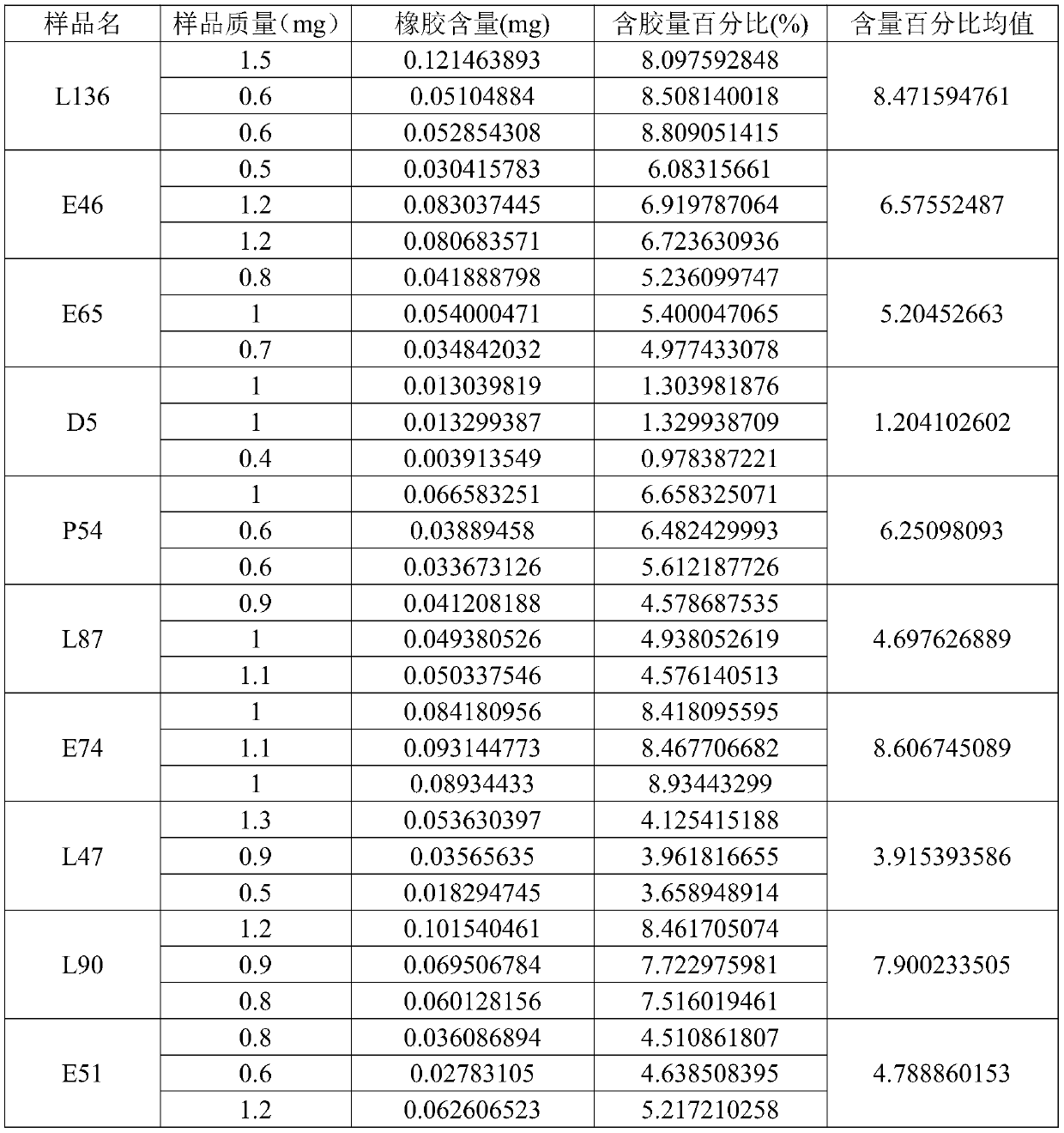

Testing method of content of rubber in dandelion rubber grass

PendingCN111443146AReduce the amount of errorSmall reproducibilityComponent separationGas liquid chromatographicAgricultural engineering

The invention provides a testing method of content of rubber in dandelion rubber grass, comprising the following steps: preparing a sample of a standard substance of dandelion rubber, making a standard curve, testing the sample to be tested, and calculating the rubber content. First the standard substance of the dandelion rubber is prepared and a calibration substance after splitting is determined, a pyrolysis temperature of a pyrolysis instrument and a programmed temperature of a gas chromatograph are set, and the standard substance is put into a pyrolysis gas chromatography-mass spectrometerfor sample testing, after the sample is tested, a chromatogram is obtained, and the standard curve is made by using the peak area of the calibration substance; and then the actual sample to be testedis put into a pyrolysis gas chromatograph for measurement, and the peak area of the calibration substance of the actual sample is substituted into the standard curve to acquire the rubber content ofthe actual sample. The testing method provided by the invention has good repeatability and high accuracy, and can be used for rubber content detection of the dandelion rubber grass.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for determining a property of a fuel

ActiveCN103403329AThe injection volume is the sameClear measurementElectrical controlInternal combustion piston enginesSolenoid valveEngineering

The invention relates to a method for determining at least one property of a fuel, in which method a closed period of an armature of a solenoid valve, which moves through the fuel, is measured in at least one triggering period, and a factor is determined on the basis of the measured closed period, which factor represents the at least one property of the fuel.

Owner:ROBERT BOSCH GMBH

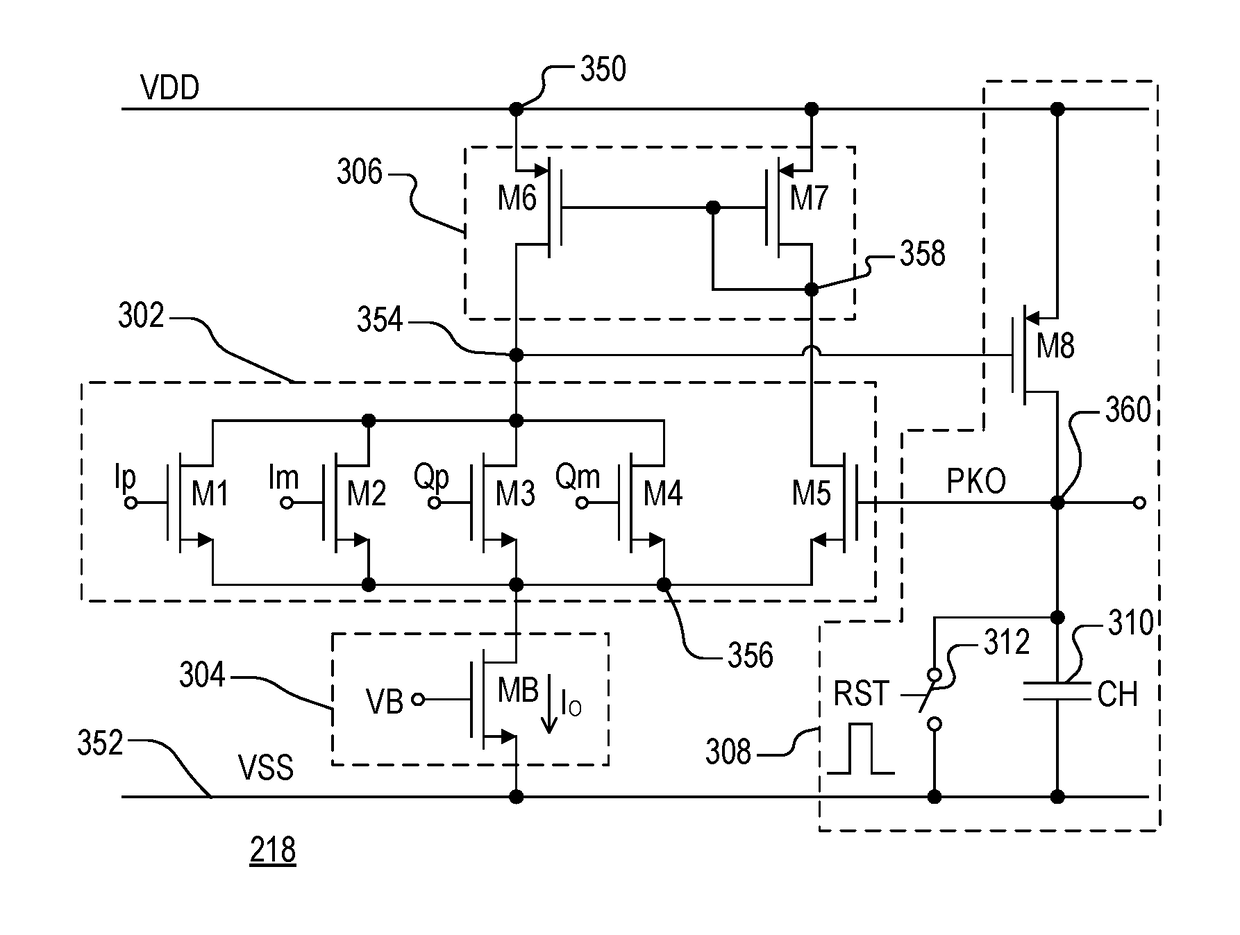

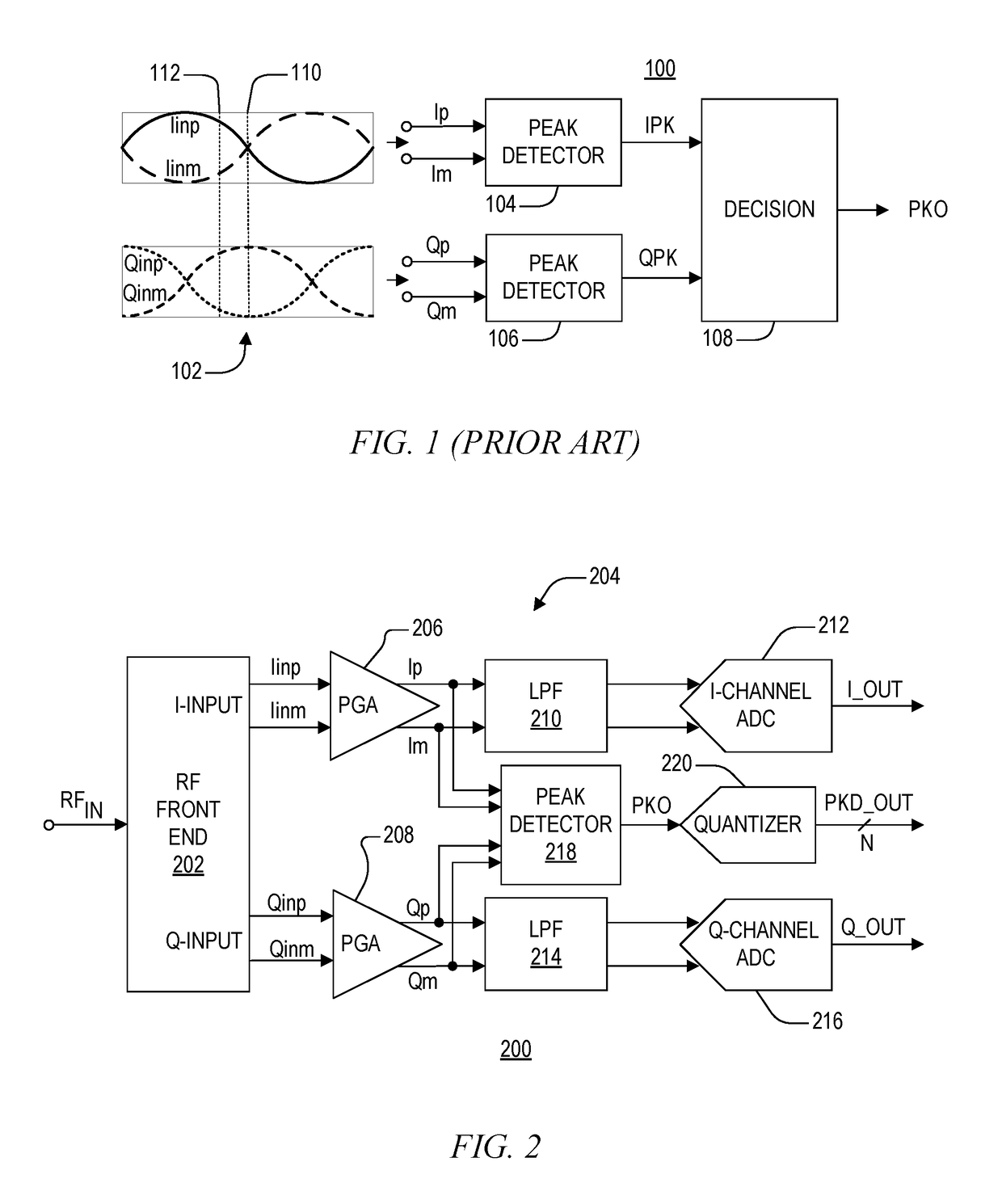

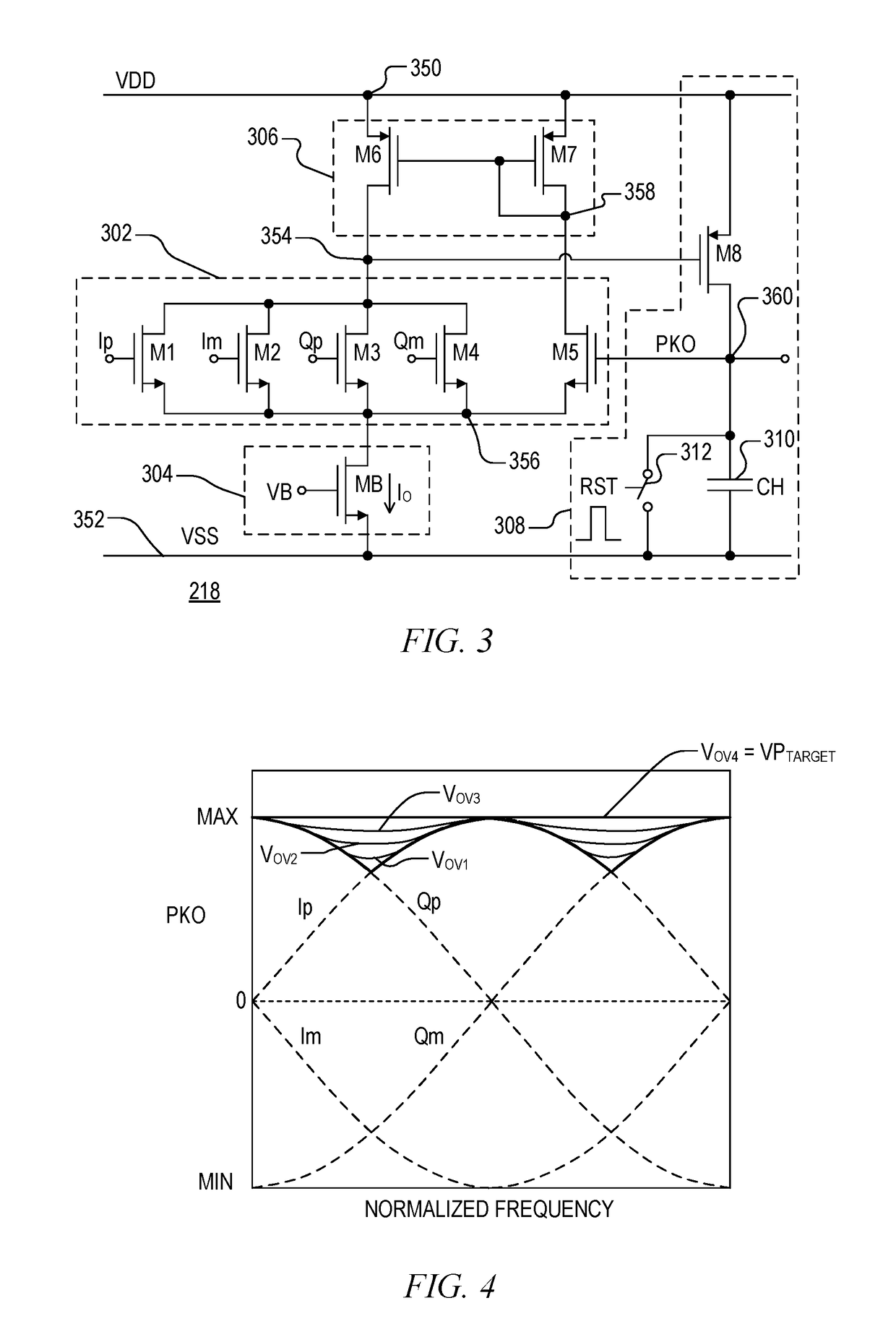

Low power compact peak detector with improved accuracy

ActiveUS10033364B1Error minimizationReduce the amount of errorGain controlAc/pulses peak value measurementsPeak valuePeak detection

A peak detector including an input circuit with five same-sized transistors, in which four of the input transistors are coupled in parallel between a control node and a bias node and receive a corresponding one of two in-phase signals and two quadrature signals. The fifth transistor is coupled between a current node and the bias node and has its control terminal coupled to an output node. A bias circuit establishes a predetermined bias current that flows through the five input transistors. A current mirror mirrors the current through the fifth transistor from the current terminal into the four parallel-coupled input transistors via the control node. An output circuit charges a peak capacitor based on voltage developed at the control terminal of the fifth transistor. The peak detector is low power and compact and detects the actual peak of the input signal with greater accuracy compared to a conventional peak detector.

Owner:SILICON LAB INC

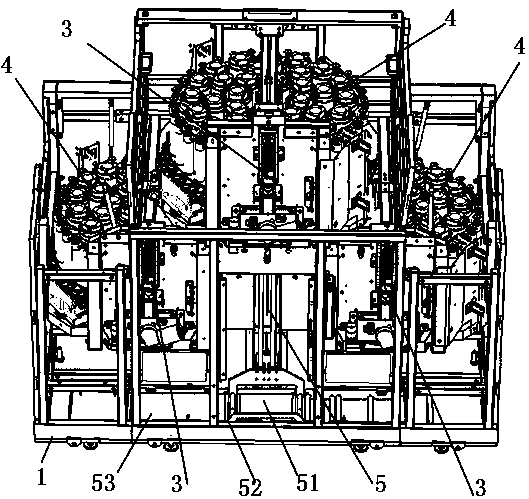

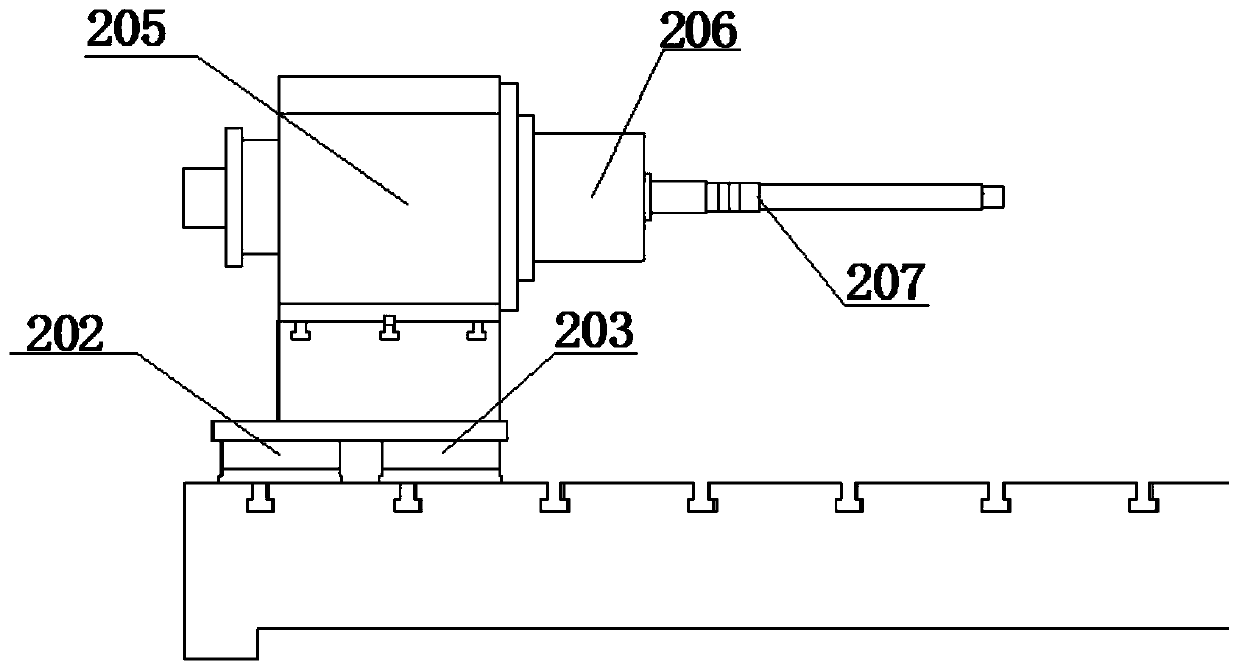

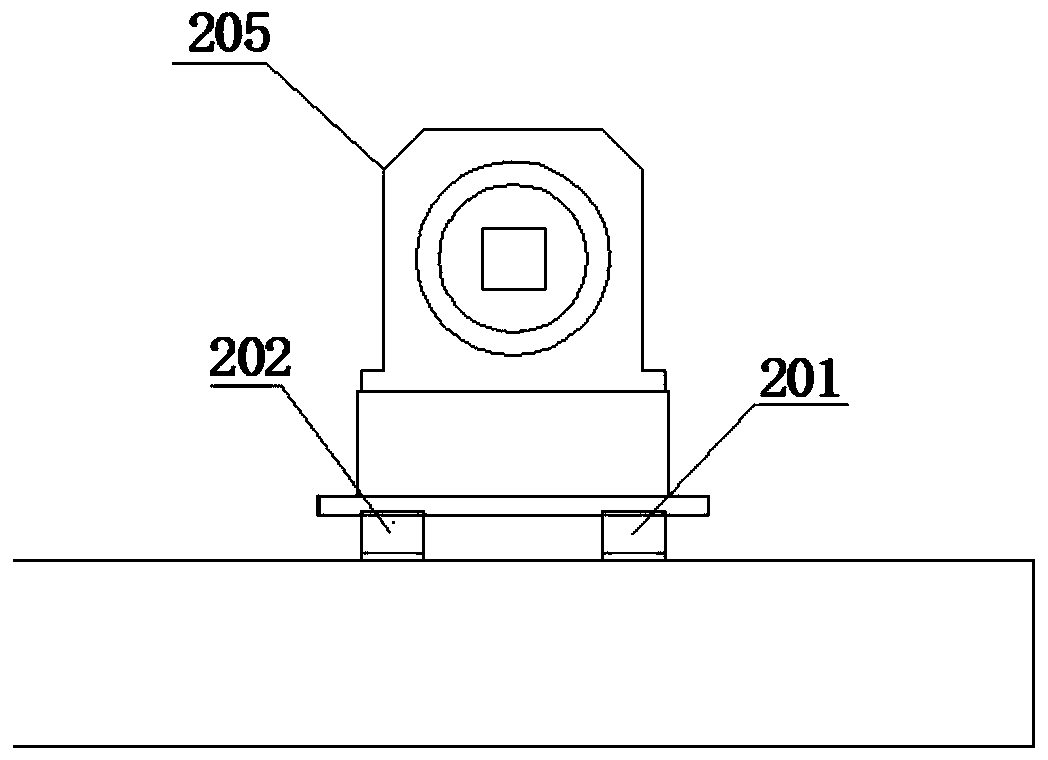

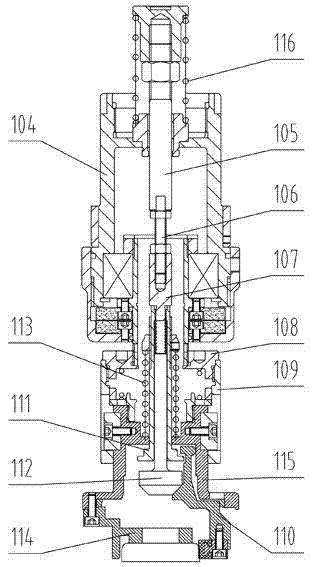

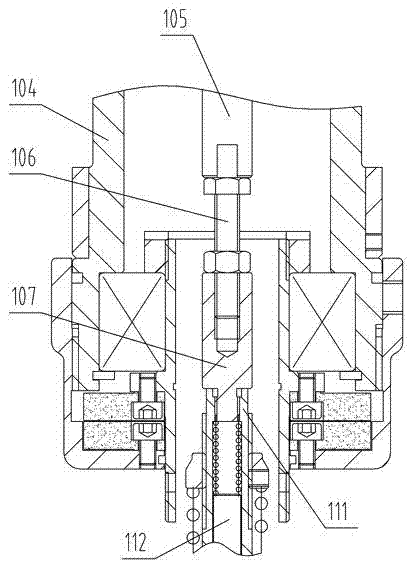

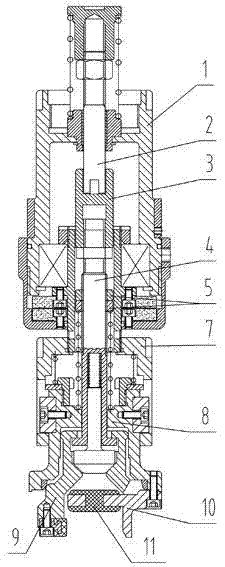

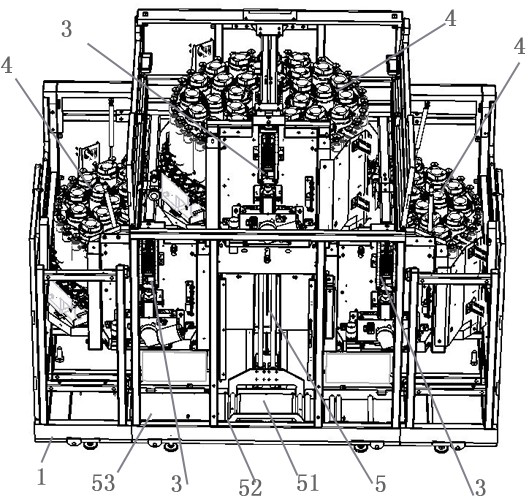

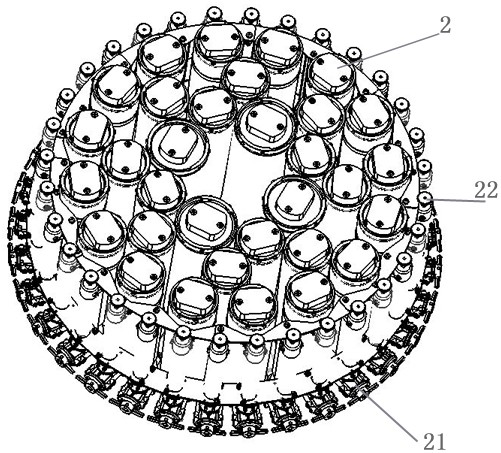

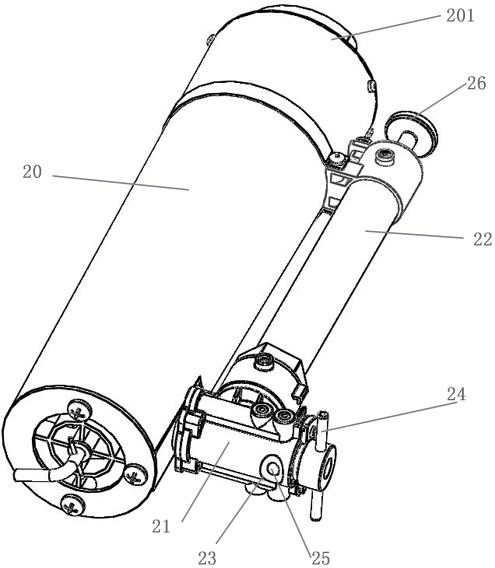

Electric spindle reliability test device based on synchronous hydraulic cylinder drive loading

PendingCN111238810ANo eccentricityAvoid failureMachine part testingHydraulic cylinderNumerical control

The invention discloses an electric spindle reliability test device based on synchronous hydraulic cylinder drive loading. The device comprises a main shaft clamping part, a loading unit part, a loading unit supporting part, a main radial loading part, an axial loading part and a torque loading part, the main shaft clamping part comprises a dowel bar; the loading unit part comprises a loading unitmain body and spherical grooves from No.1 to No.5; the loading unit supporting part comprises a first loading head; the main radial loading part comprises a No.2 loading head; the axial loading partcomprises loading heads from No.3 to No.5; and the torque loading part comprises a hydraulic pump and a torque transmission testing device. the electric spindle reliability test device is suitable fortwo common spindles in the reliability test of the numerically-controlled machine tool spindle, the test cost is reduced, and the device has universality; and axial, radial and torque loading can becarried out in a sequential, and separate and synchronous loading manners are performed, which is closer to the actual working condition of the main shaft, so that the steps of disassembling and assembling the test bed due to different loading are reduced, and the time is saved.

Owner:JILIN UNIV

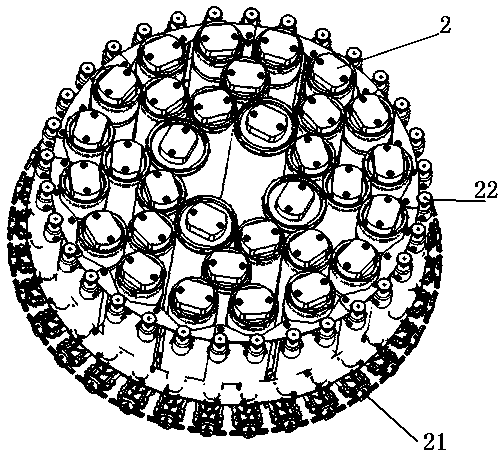

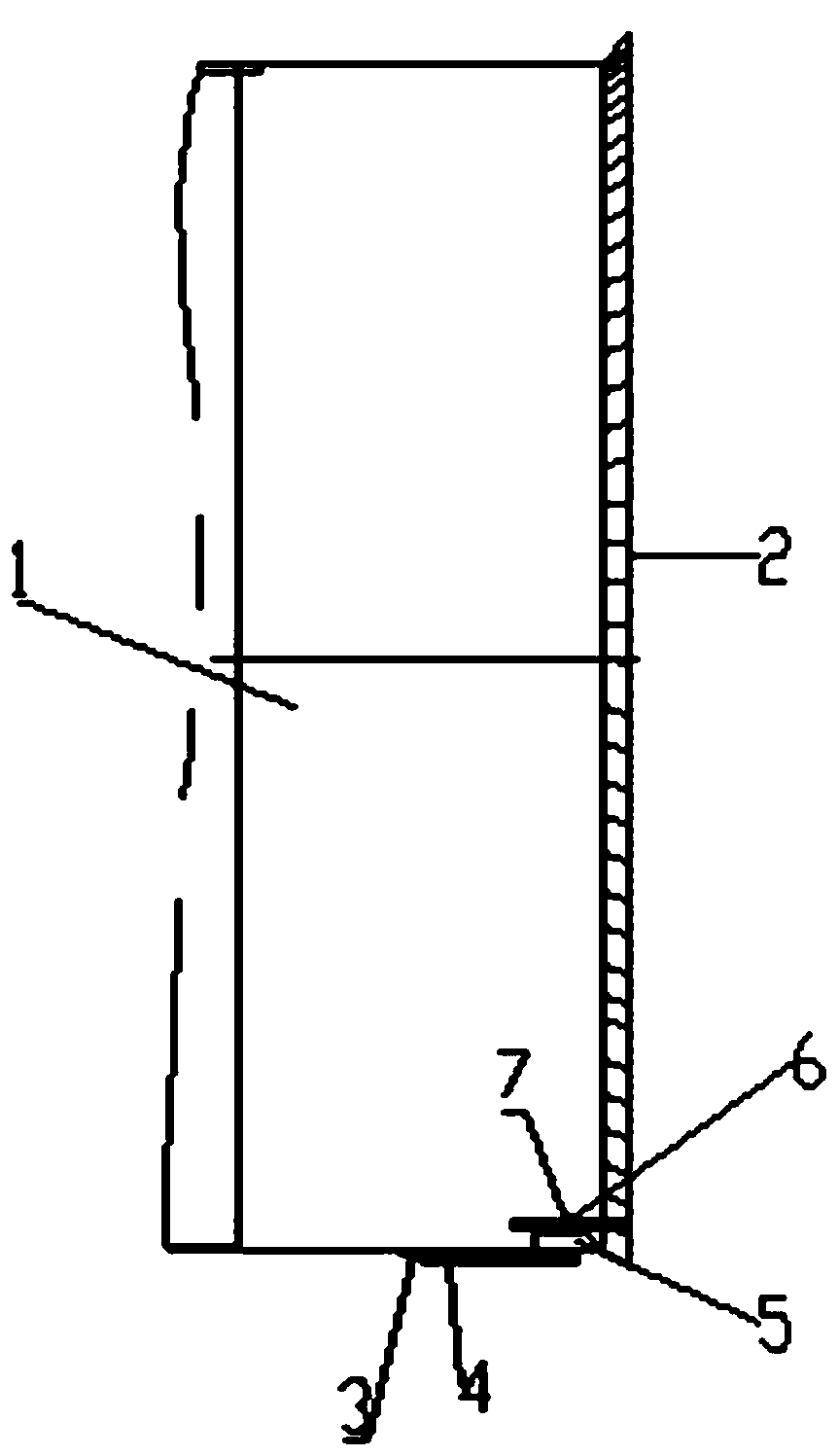

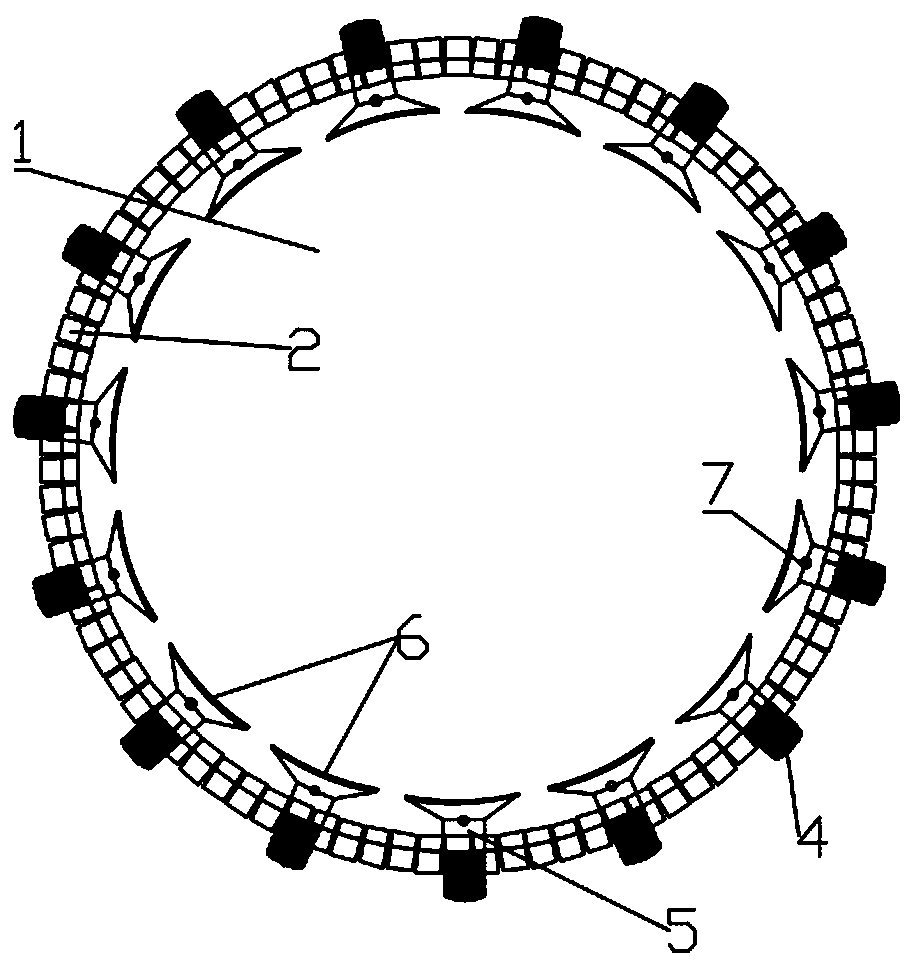

Control device for preventing duct piece staggering and shield tail postures for TBM

PendingCN109751055AAvoid wrong stationPlay a buffer roleUnderground chambersTunnel liningEngineeringTunnel boring machine

The invention discloses a control device for preventing duct piece staggering and shield tail postures for a tunnel boring machine (TBM). A plurality of the control devices are uniformly distributed on an excircle surface of a shield tail at the rear part of a shield tail brush in a manner of surrounding the axis of the shield tail; each control device comprises a streamline wear-resisting plate,a shield body posture adjusting oil cylinder, an oil cylinder connecting plate and a pipe piece supporting plate; the upper surface of the oil cylinder connecting plate is stopped in the shield tail through the shield tail outer shell; the upper surface of the duct piece supporting plate is an arc-shaped concave surface; the circle center of a circle defined by the upper surfaces of all the duct piece supporting plates coincides with the circle center of the cross section of the shield tail; the bottom of the duct piece supporting plate is hinged to the telescopic rod end of the duct piece posture adjusting oil cylinder, and the hinged point of the duct piece supporting plate and the telescopic rod end of the duct piece posture adjusting oil cylinder coincides with the symmetric center line of the arc inward-concave face of the upper surface of the duct piece supporting plate.

Owner:SHENZHEN METRO GROUP +2

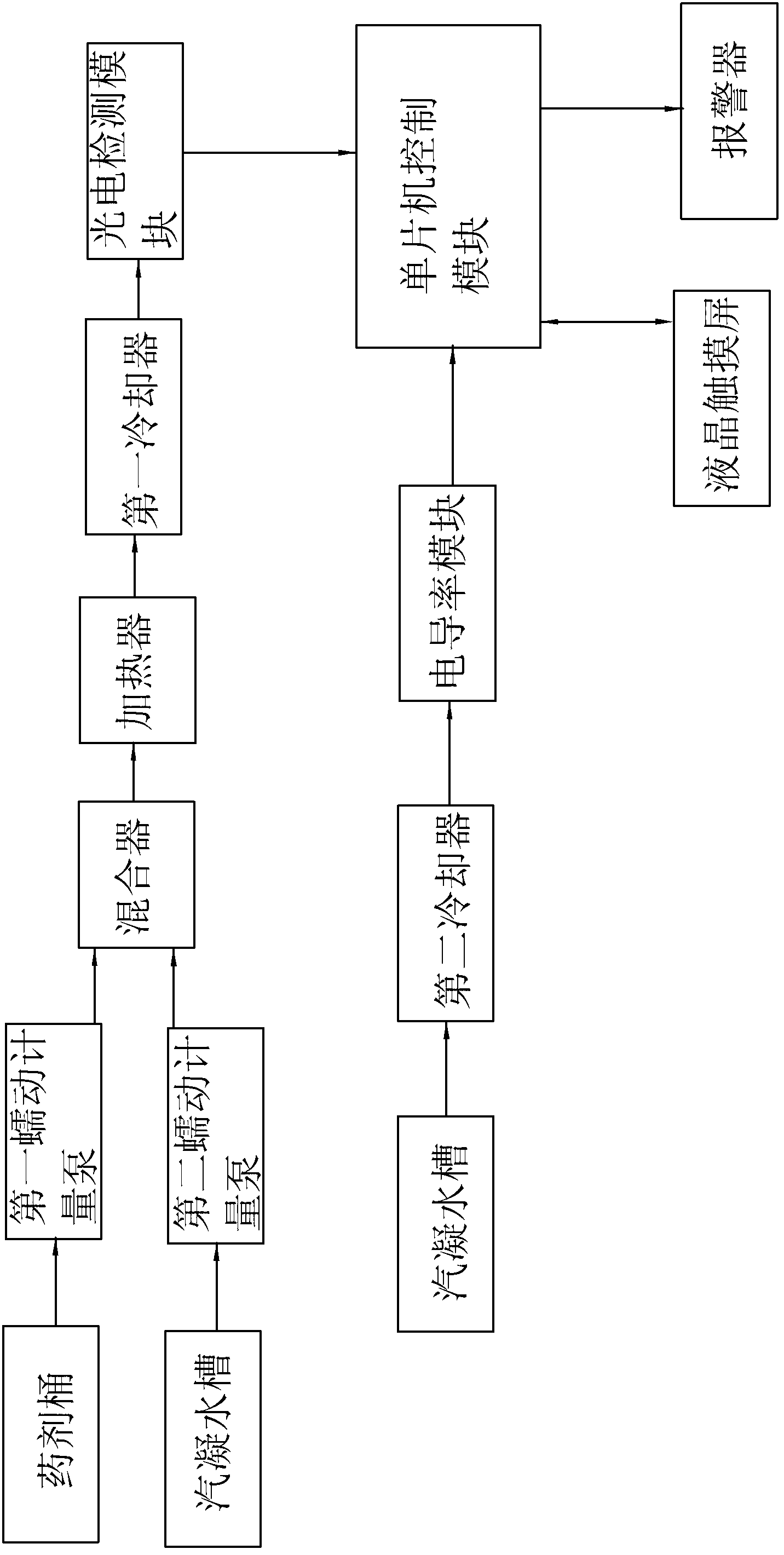

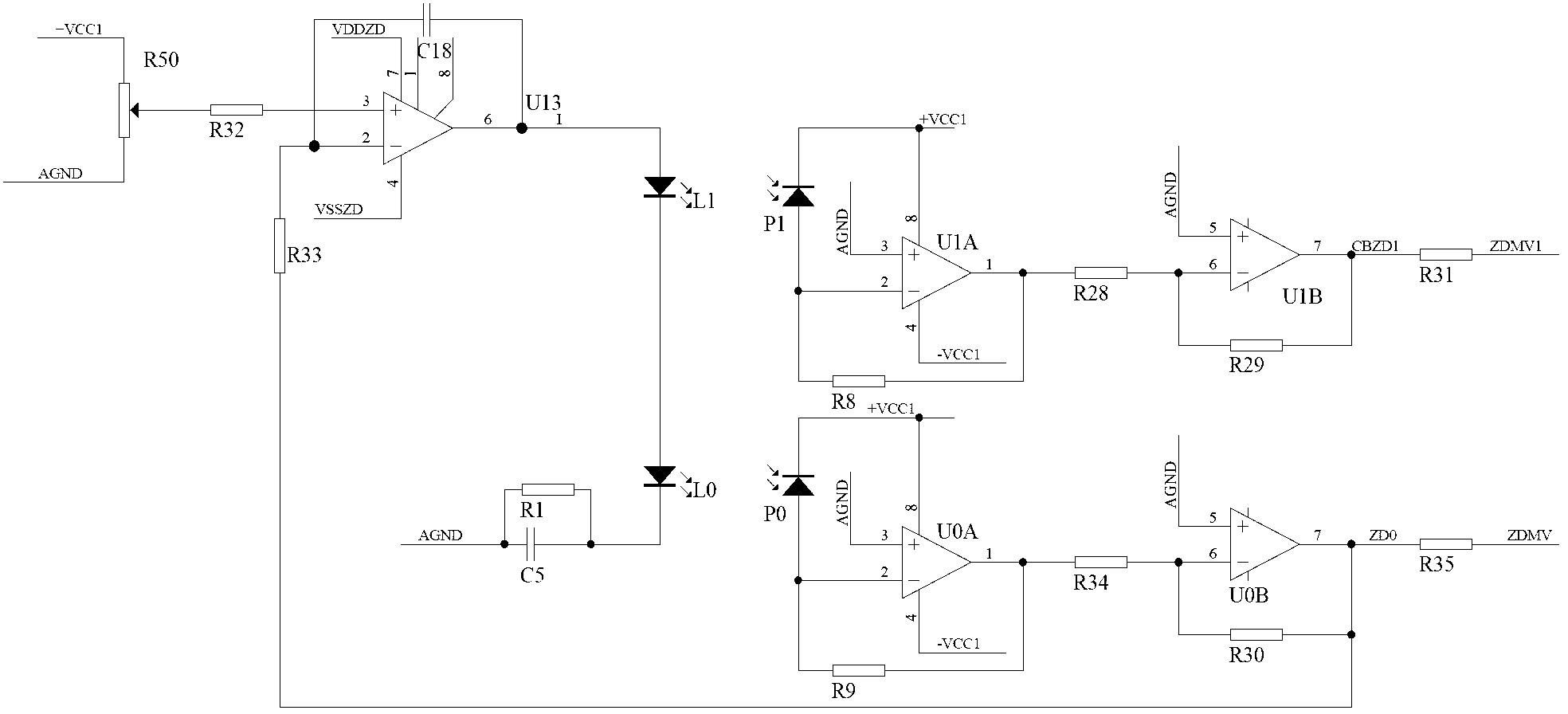

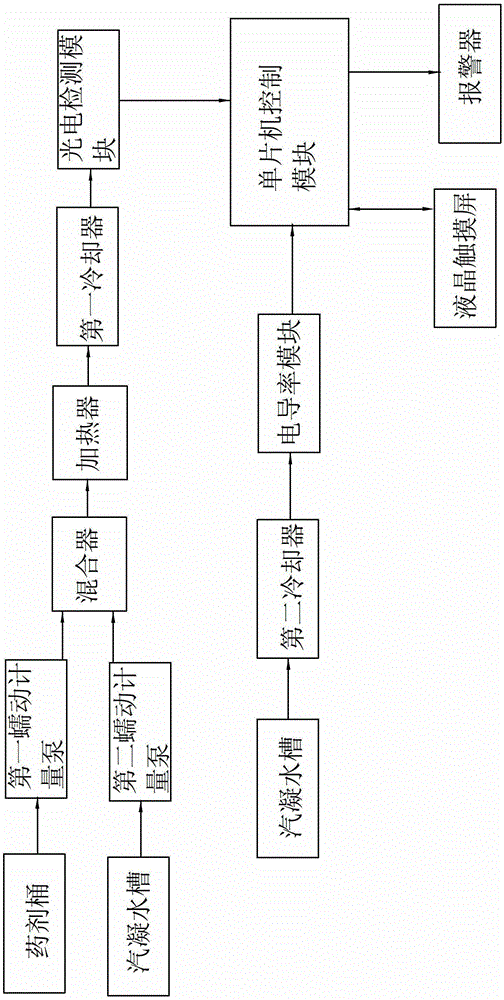

Icro-sugar online measuring system and measuring method thereof

ActiveCN103234964AContinuous monitoring of sugar contentPromote absorptionMaterial analysis by observing effect on chemical indicatorReaction temperatureEngineering

The invention discloses a micro-sugar online measuring system and a measuring method thereof. The online measuring system includes a pretreatment device, a photoelectric detection module and a single-chip microcomputer control module. The output end of the pretreatment device is connected to the photoelectric detection module, the output end of which is connected to the single-chip microcomputer control module. The pretreatment device comprises a mixer, a heater and a first cooler that are connected in order. The outlet of the first cooler is connected to the input end of the photoelectric detection module. The heater is a lightwave infrared heater. The system and the method provided in the invention utilizes a photoelectric detecting technique to conduct micro-sugar content online measurement, the measuring accuracy is high, and at the same time, the lightwave infrared heater is employed to heat a mixed solution of steam condensate and ammonium molybdate, the heating efficiency is high, temperature rise is very fast, and the mixed solution of steam condensate and ammonium molybdate can be heated to a reaction temperature within several seconds to tens of seconds, so that the measurement time is greatly shortened, continuous monitoring of the sugar content in the steam condensate can be guaranteed, and potential safety hazards of production can be solved.

Owner:QINZHOU CHUANGHUA IND CONTROL EQUIP

Current balancing circuit and backlight module with same

InactiveCN101854758BReduce the amount of errorImprove reliabilityPoint-like light sourceElectric circuit arrangementsPower flowControl unit

Owner:华映视讯(吴江)有限公司 +1

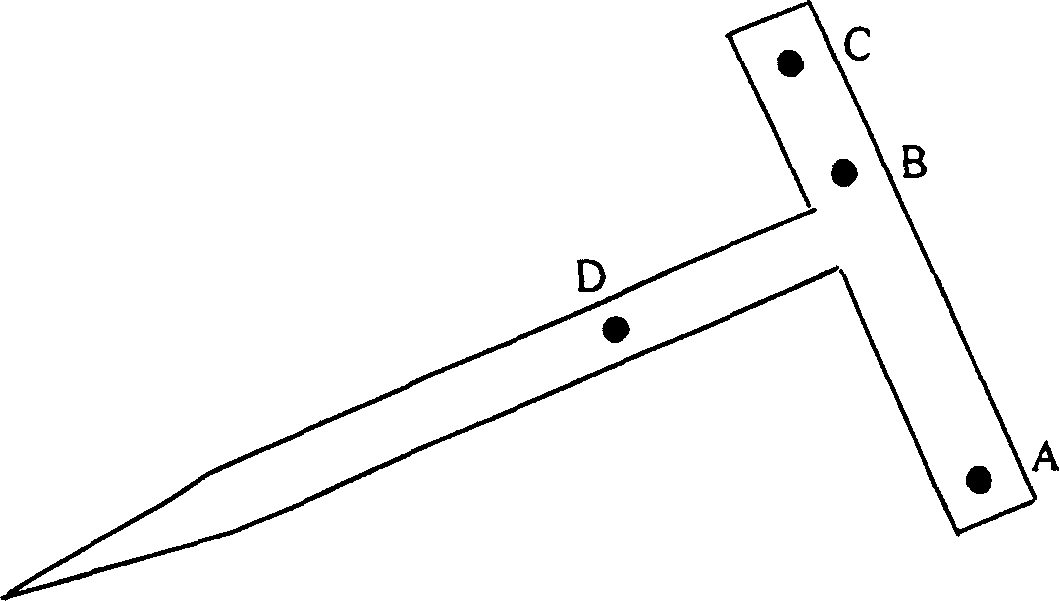

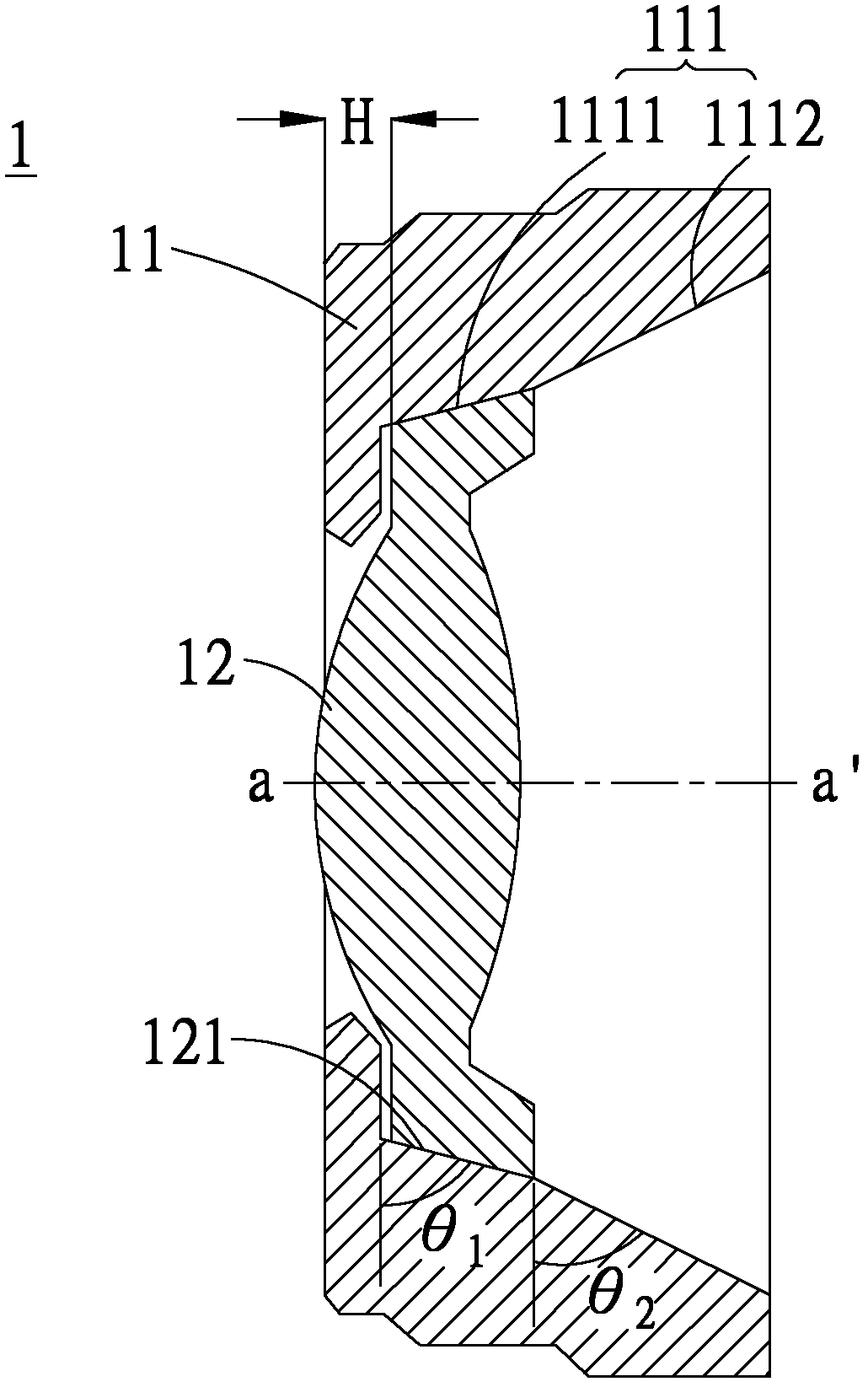

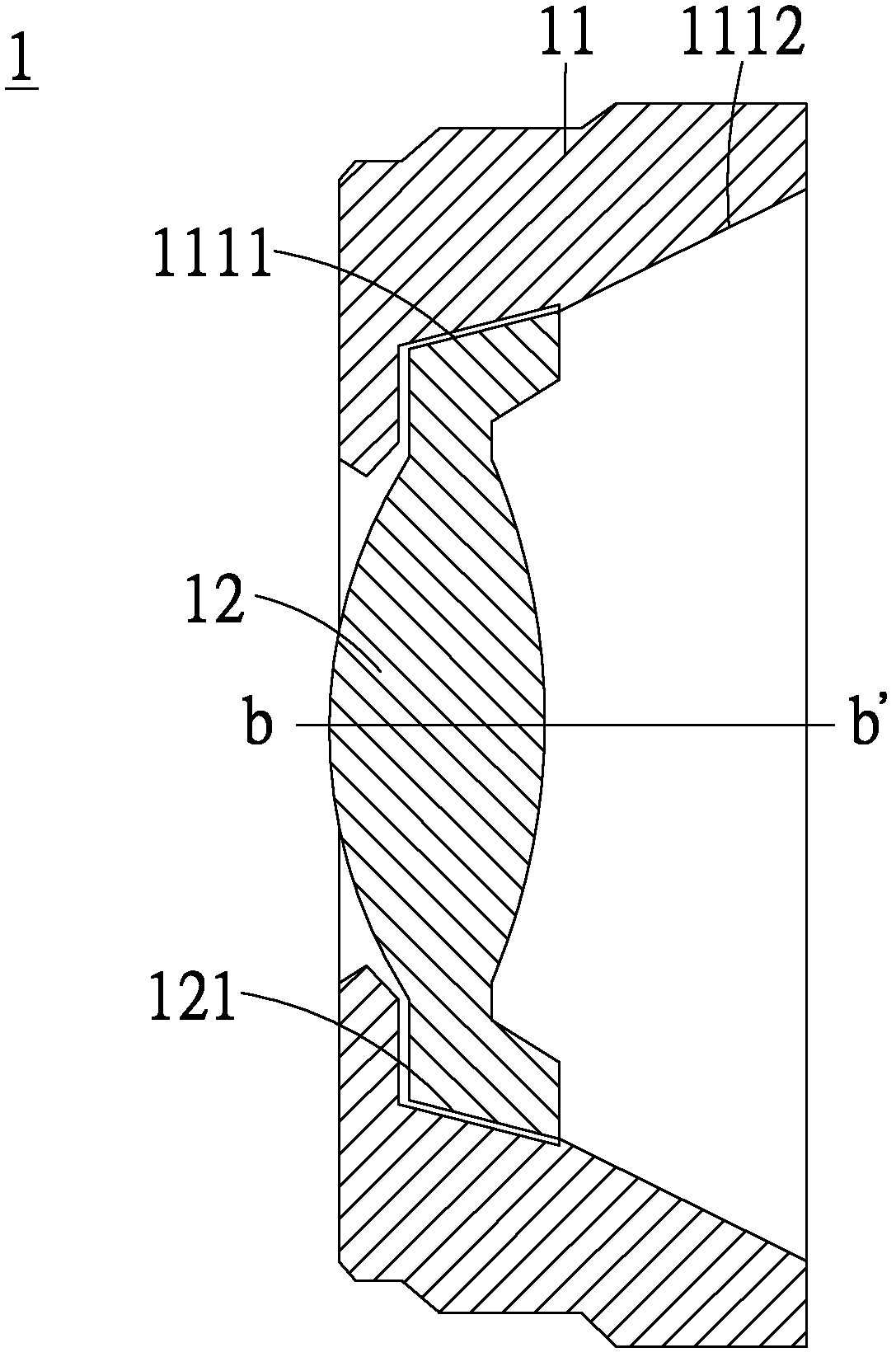

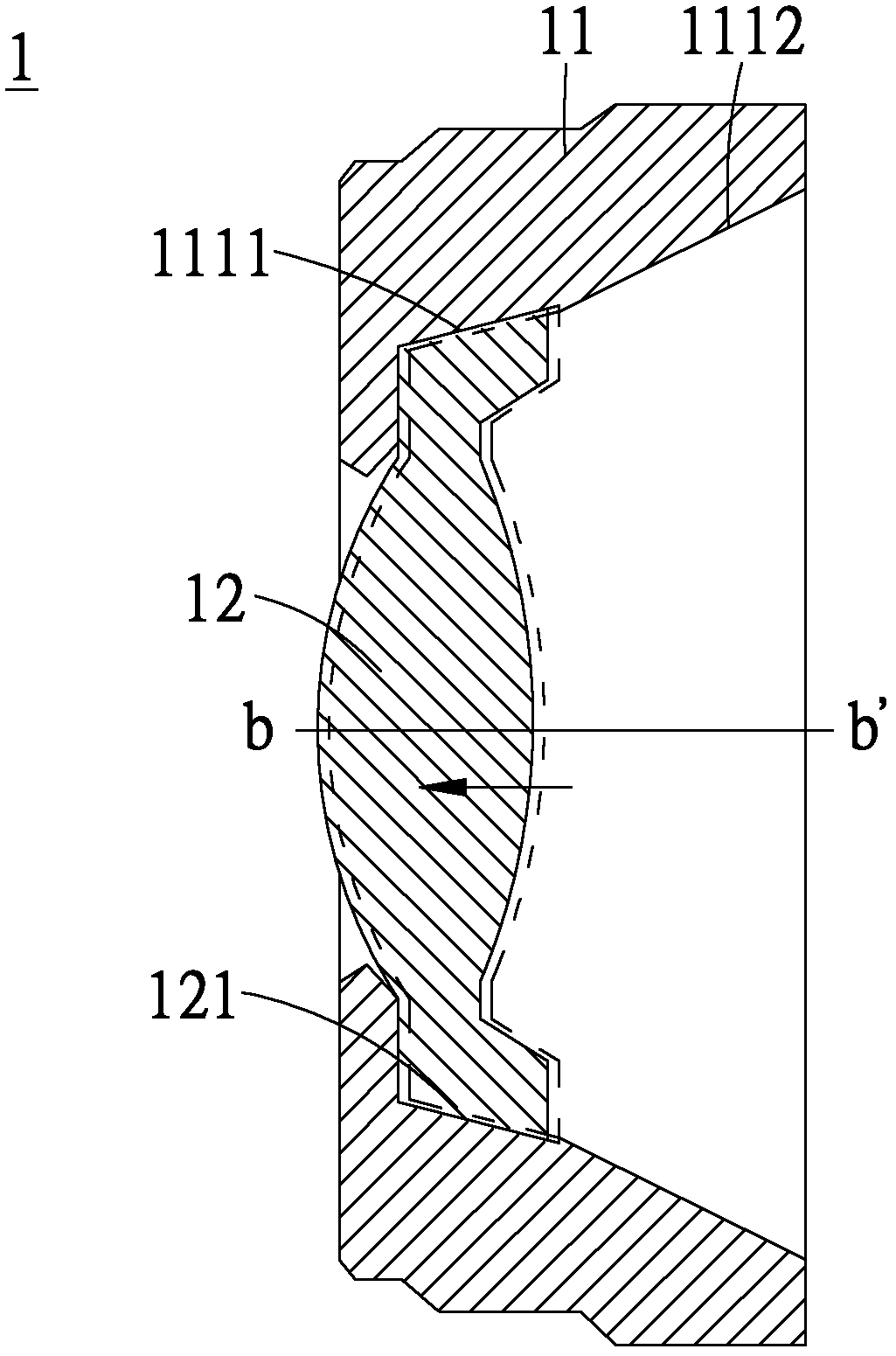

Lens structure and camera device

InactiveCN103376525AReduce the amount of errorPrevent looseningMountingsCamera body detailsCamera lensOptical axis

The invention provides a lens structure, including a lens cone which is of a tubular structure and possesses inner sidewalls unparallel with a center shaft; and a lens, wherein a side relative to an optical axis between two sides corresponds with the inner sidewall to form a joint side, and the lens is buckled to the inner sidewall through the joint side so as to be buckled in the lens cone. The beneficial effects are that the lens structure can substantially reduce error amount generated in assembling and avoid lens looseness and inaccurate centering when lens inner sidewalls are worn; meanwhile, inaccurate centering in assembling can be avoided when the lens is prepared by glass materials; inner sidewalls in a lens cone and lens sides can be prevent from squeezing in a process of assembling and clamping the lens cone and the lens; inaccurate centering of each lens in a whole lens group can be avoided when a lens looses.

Owner:ALTEK CORP

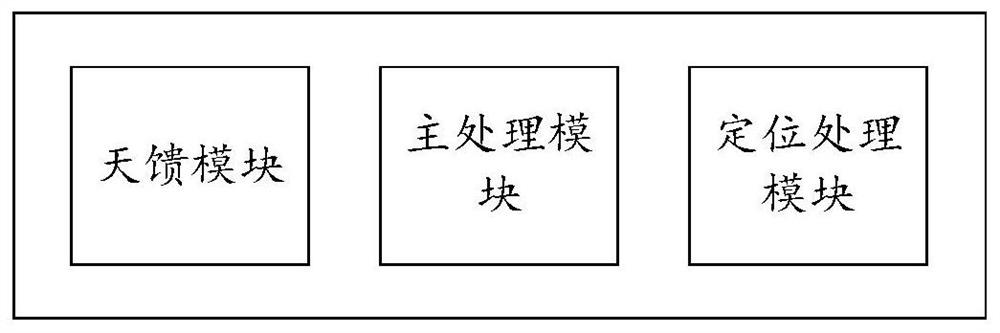

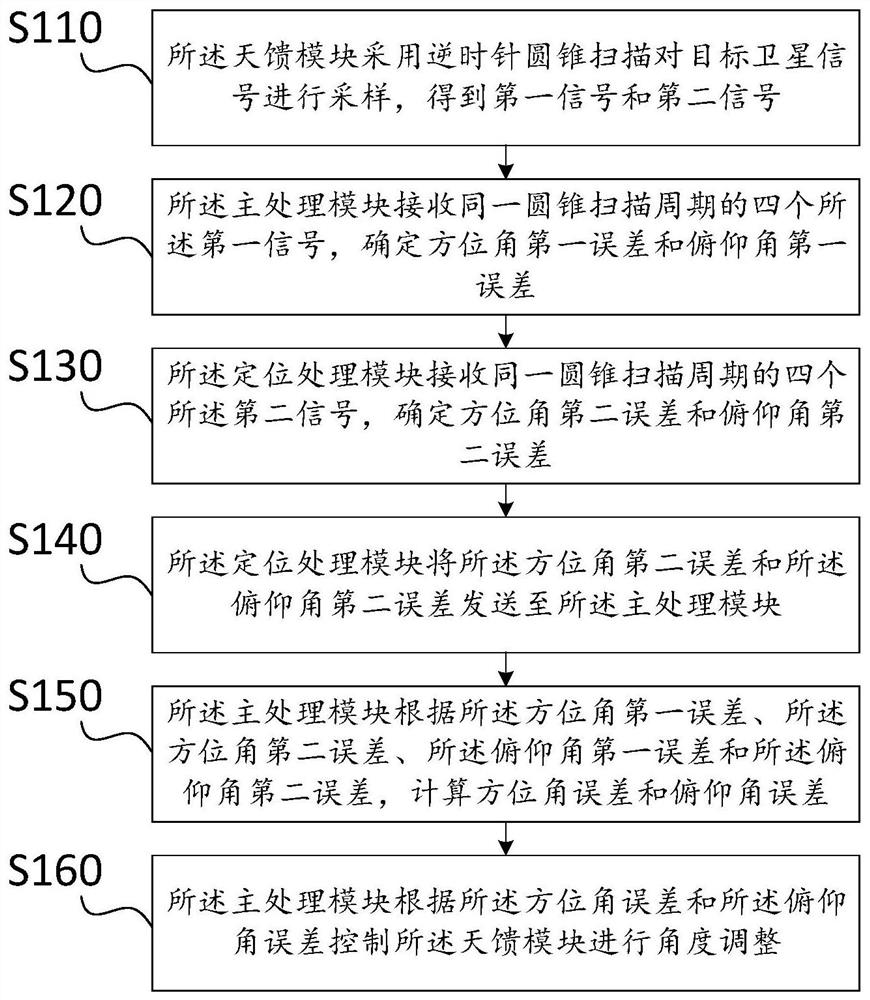

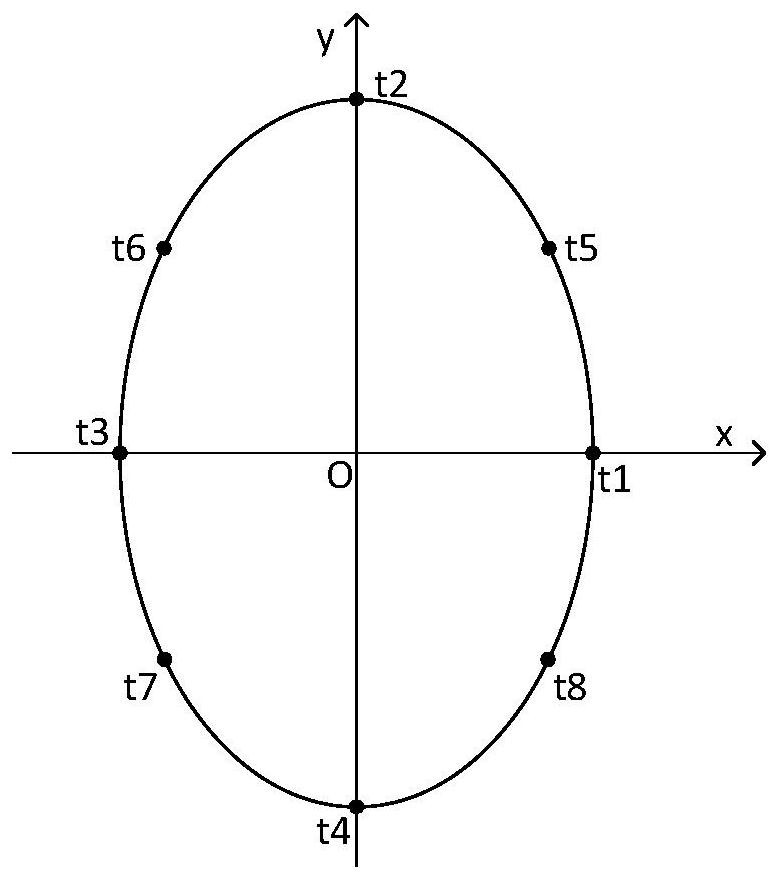

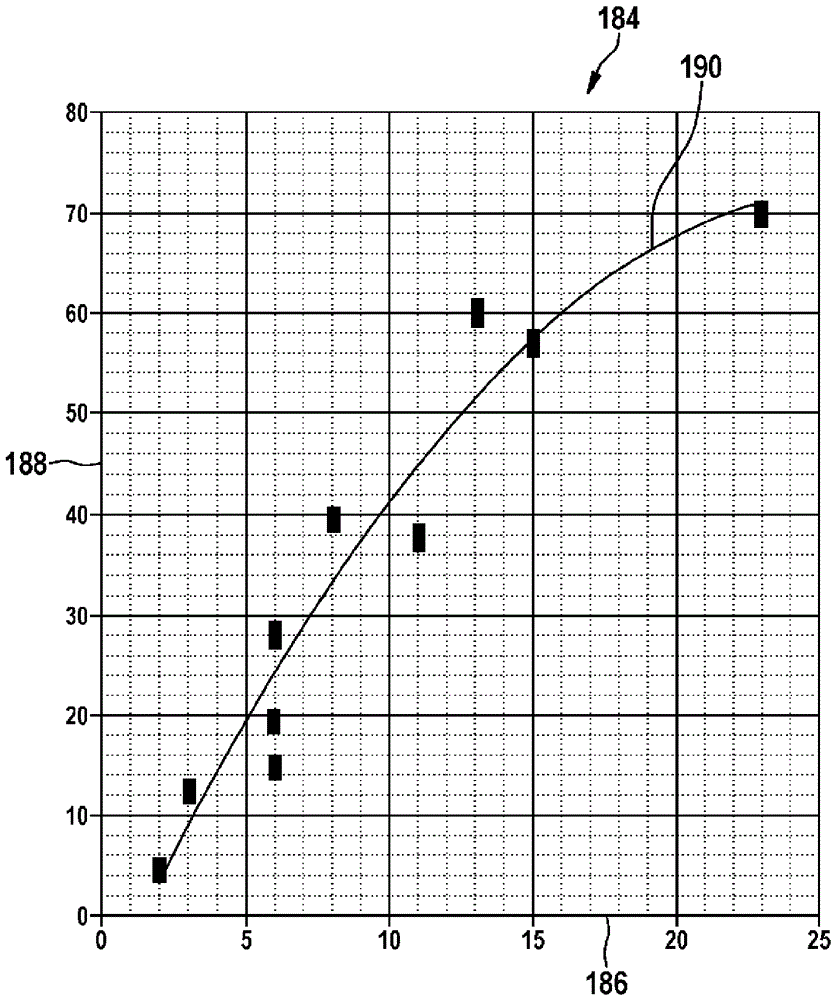

Ship-borne three-axis antenna satellite automatic tracking method, system and device and storage medium

ActiveCN113917949AImprove control efficiencyQuick solveControl using feedbackAntennasControl theoryAntenna feeder

The invention discloses a ship-borne three-axis antenna satellite automatic tracking method, and relates to the technical field of ship-borne antenna control. Signals of a target satellite are received through antenna feeder information, two groups of periodic signals with a certain time interval are obtained, and the two groups of periodic signals are respectively sent to the main processing module and the positioning processing module for processing. The main processing module and the positioning processing module are combined with a pre-measured signal voltage amplitude and a modulation degree caused by a unit error angle to obtain two groups of angle errors, and the two groups of obtained angle errors are combined to obtain a final adjustment angle; the embodiment of the invention further provides a corresponding automatic tracking system and device and a storage medium, the calculation amount in the ship-borne antenna angle control process can be effectively reduced, meanwhile, the calculation precision of angle adjustment is effectively improved, and therefore the control efficiency of the ship-borne antenna is improved.

Owner:广州辰创科技发展有限公司

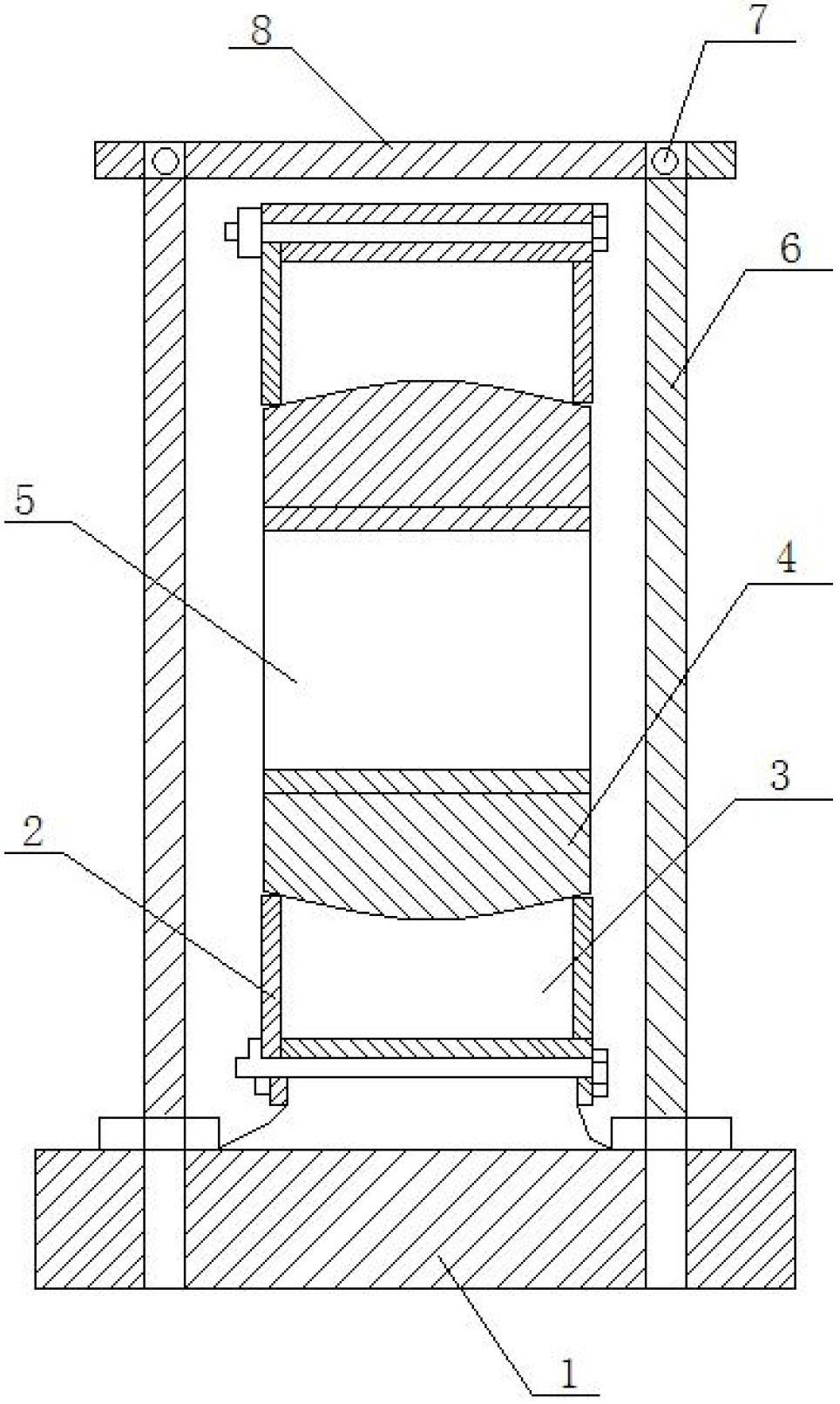

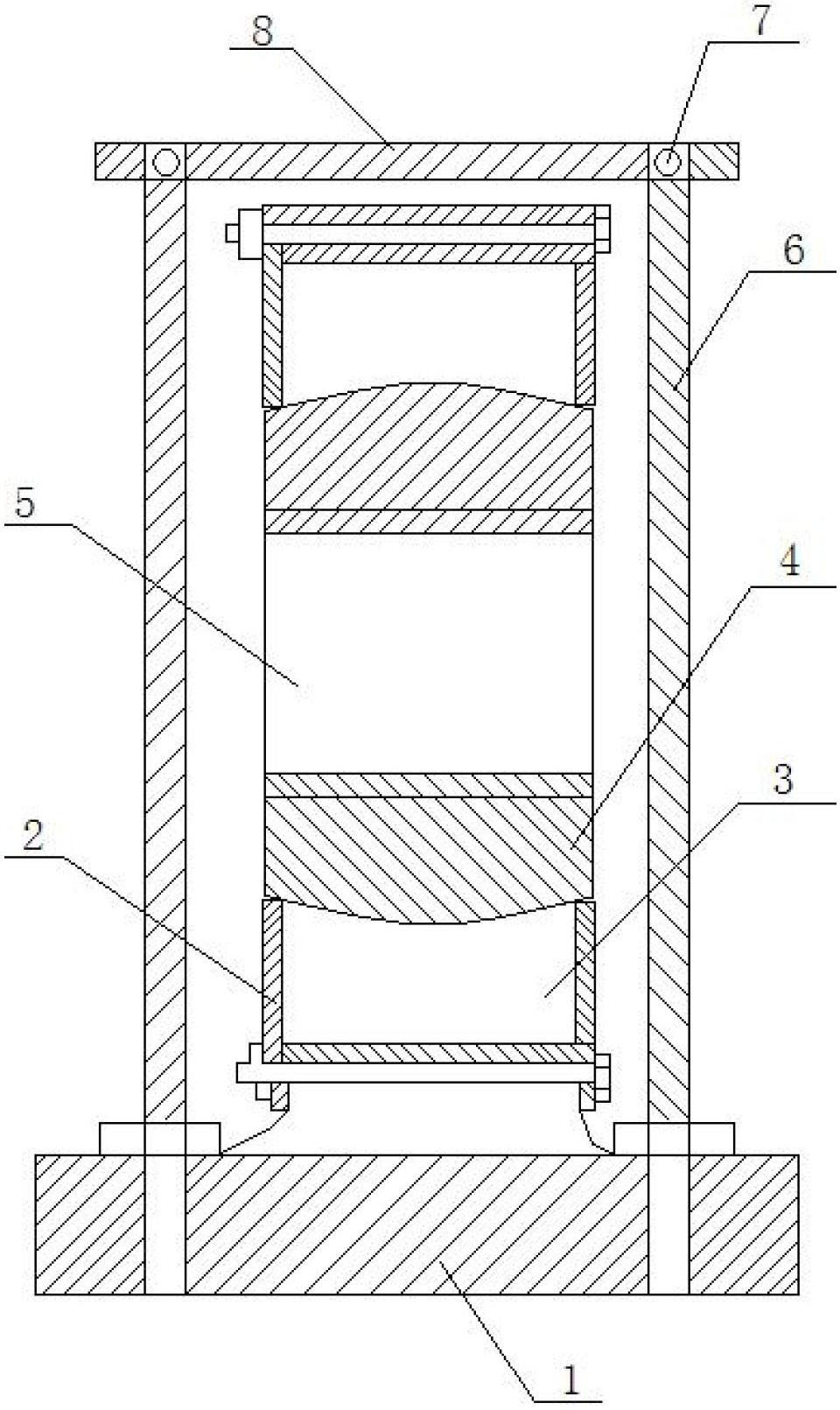

Novel damping bearing block mechanism

InactiveCN102661320AReduce wearOvercome elasticityElastic bearingsBearing unit rigid supportFiberEngineering

A novel damping bearing block mechanism comprises a double-layer stereoscopic rectangular guard frame, the double-layer guard frame is mounted on a base and fixed by hinge pins, a bearing is mounted in an inner cavity of the double-layer guard frame and connected with a double-position spherical shaft sleeve, the bearing, the double-position spherical shaft sleeve and a silicon fiber damping ring are combined and are mounted in a hole of the base, and a double-body shielding cover is mounted on the base by bolts. The novel damping bearing block mechanism has the advantages that a damping effect is good, errors are fewer, the service life is long, and a fit clearance between a slender shaft and the bearing is rarely abraded.

Owner:韩士军

Cover grabbing and screwing device

ActiveCN103663316AReduce gapImprove connection strengthThreaded caps applicationEngineeringMechanical engineering

The invention relates to a cover grabbing and screwing device. A connecting shaft used for lifting and moving and an ejector rod screw sleeved with an ejector rod are arranged in a cover head screwing assembly. Motion is transmitted by the connecting shaft and the ejector rod screw through a connecting screw. Holes are formed in the top face and the bottom face of the connecting screw respectively and the holes are connected with the connecting shaft and the ejector rod screw respectively. The outer wall of the connecting screw is tightly attached to the inner wall of a mandrel of a cover head screwing shell. The outer wall of the ejector rod screw is further provided with two nuts abutting against each other. A reset spring is arranged between the nut located at the lower end and a cover grabbing body. According to the cover grabbing and screwing device, the connecting strength is high, the centering accuracy is good, the production efficiency and the product quality can be improved, the production efficiency and the product quality are further improved due to the arrangement of the double nuts outside the ejector rod screw, and the grabbing force of cover grabbing fingers is made adjustable.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

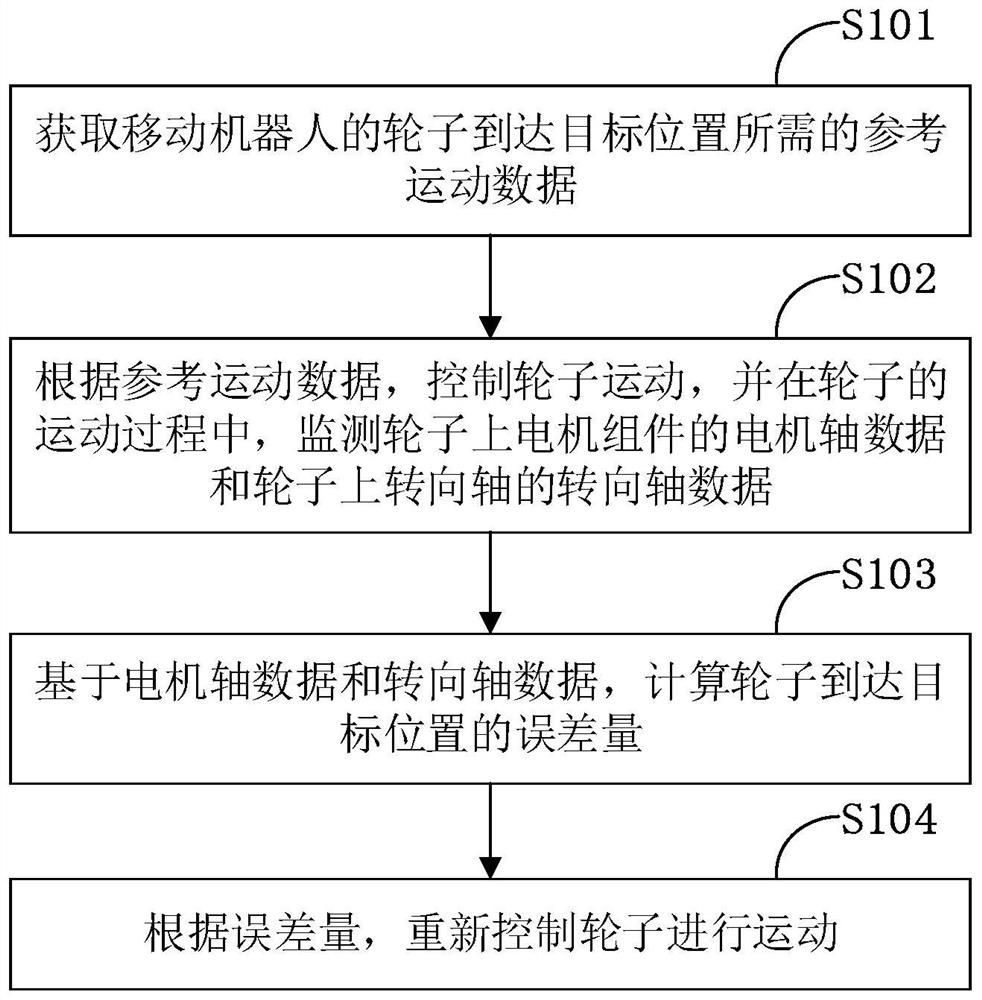

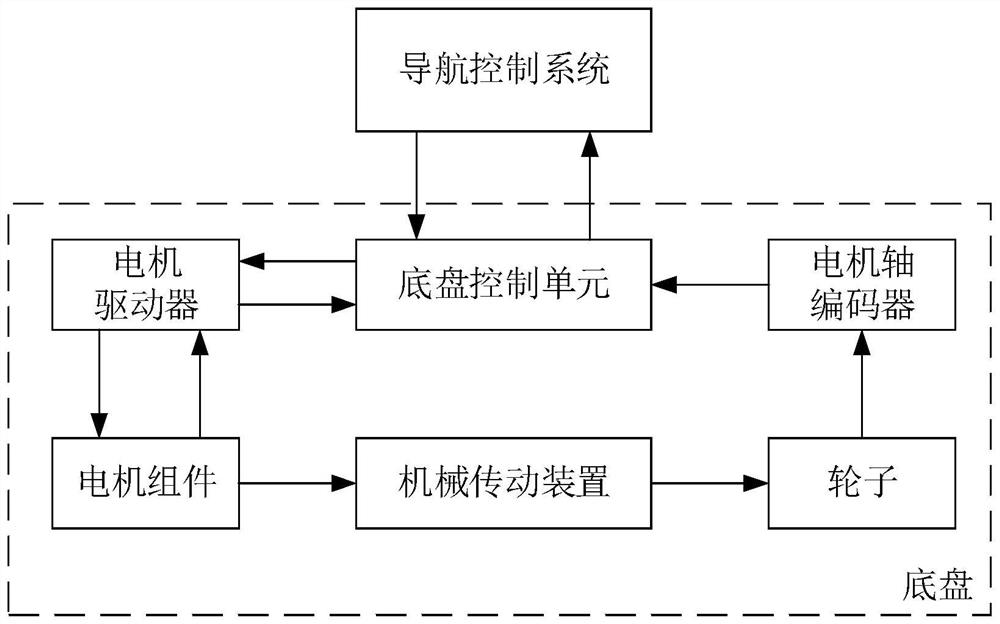

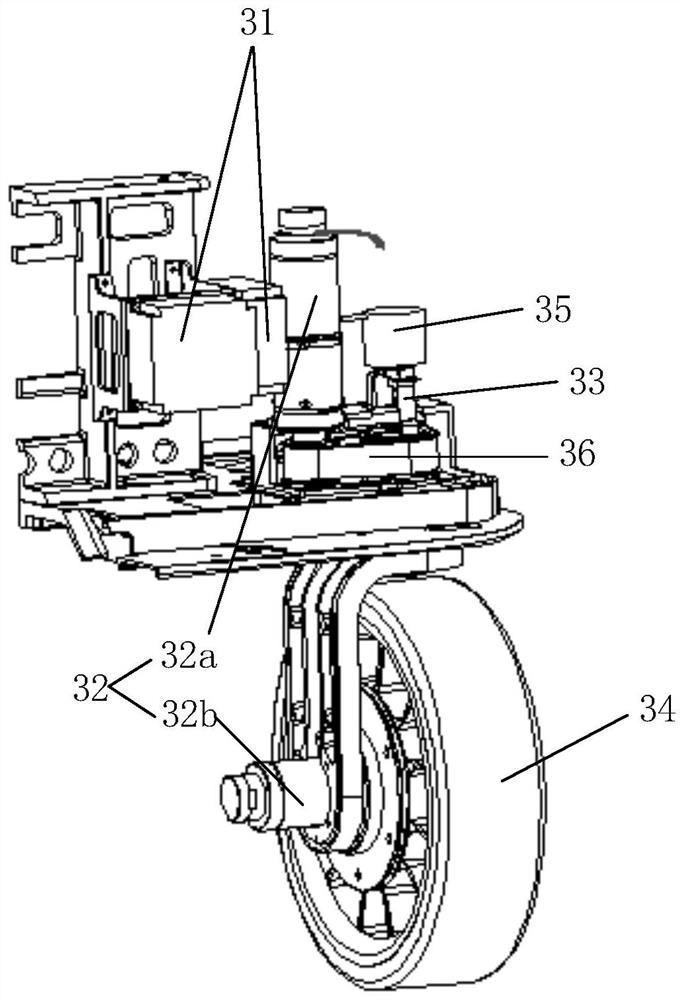

Control method and device of mobile robot, mobile robot and medium

PendingCN114368277AHigh steering precisionConsistent movementSpeed controllerMotor depositionSimulationElectric machinery

The invention is suitable for the technical field of equipment control, and provides a control method and device of a mobile robot, the mobile robot and a medium. The control method of the mobile robot specifically comprises the following steps: acquiring reference motion data required by a wheel of the mobile robot to reach a target position; according to the reference motion data, controlling the wheel to move, and monitoring motor shaft data of a motor assembly on the wheel and steering shaft data of a steering shaft on the wheel in the motion process of the wheel; based on the motor shaft data and the steering shaft data, the error amount of the wheel reaching the target position is calculated; and re-controlling the wheels to move according to the error amount. According to the embodiment of the invention, the steering precision of the mobile robot can be improved.

Owner:UBTECH ROBOTICS CORP LTD

Method for determining the properties of a fuel

ActiveCN103403329BThe injection volume is the sameClear measurementElectrical controlInternal combustion piston enginesEngineering

The invention relates to a method for determining at least one property of a fuel, in which the closing duration of an armature of a solenoid valve which moves through the fuel is measured during at least one actuation period, and is determined from the measured closing duration. A factor representing at least one property of the fuel is obtained.

Owner:ROBERT BOSCH GMBH

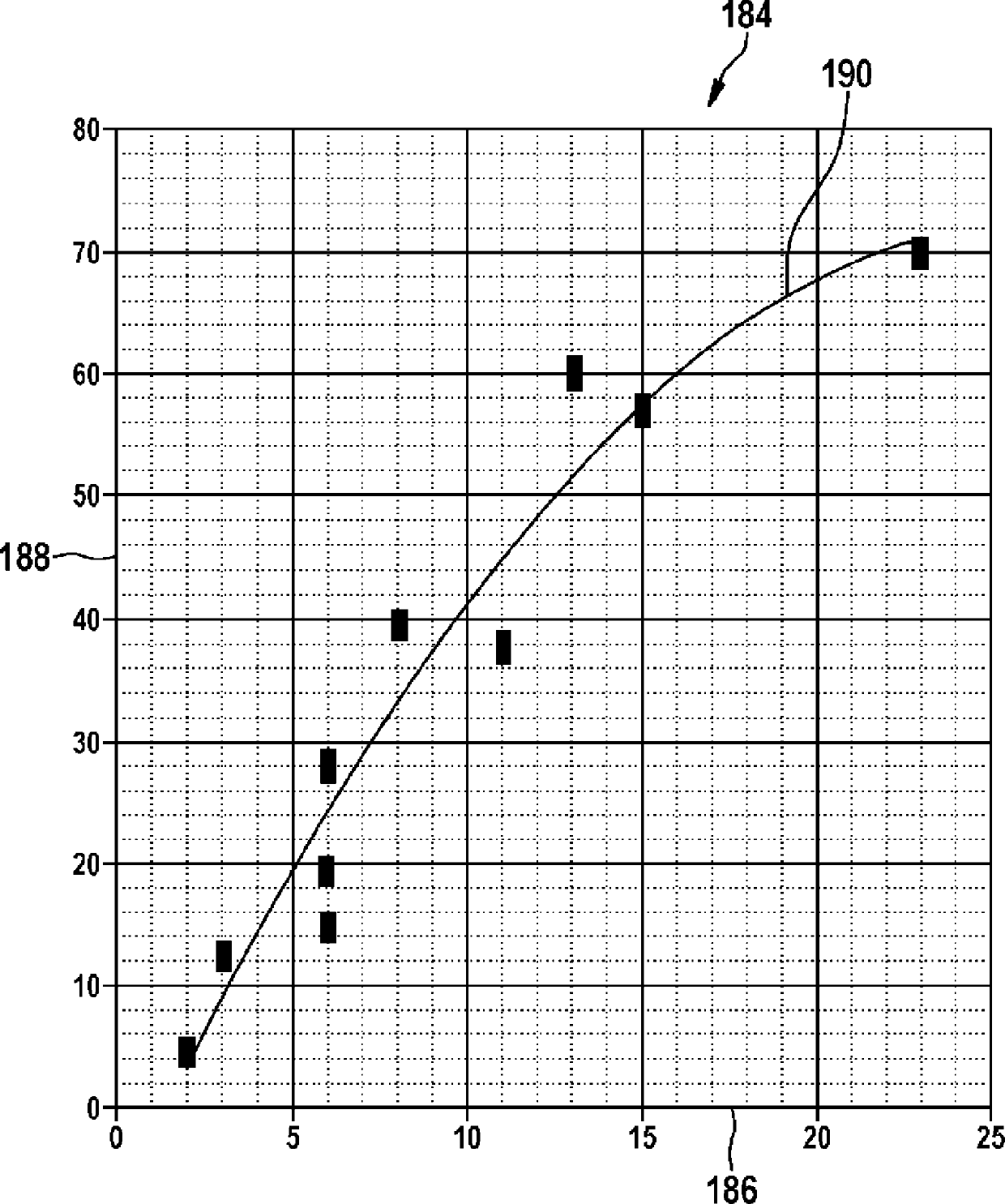

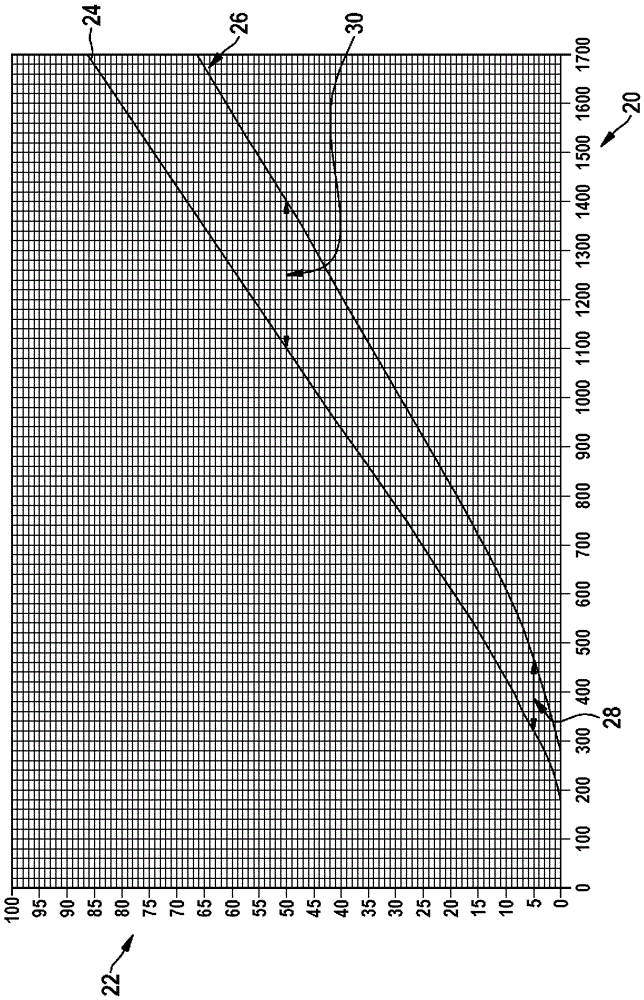

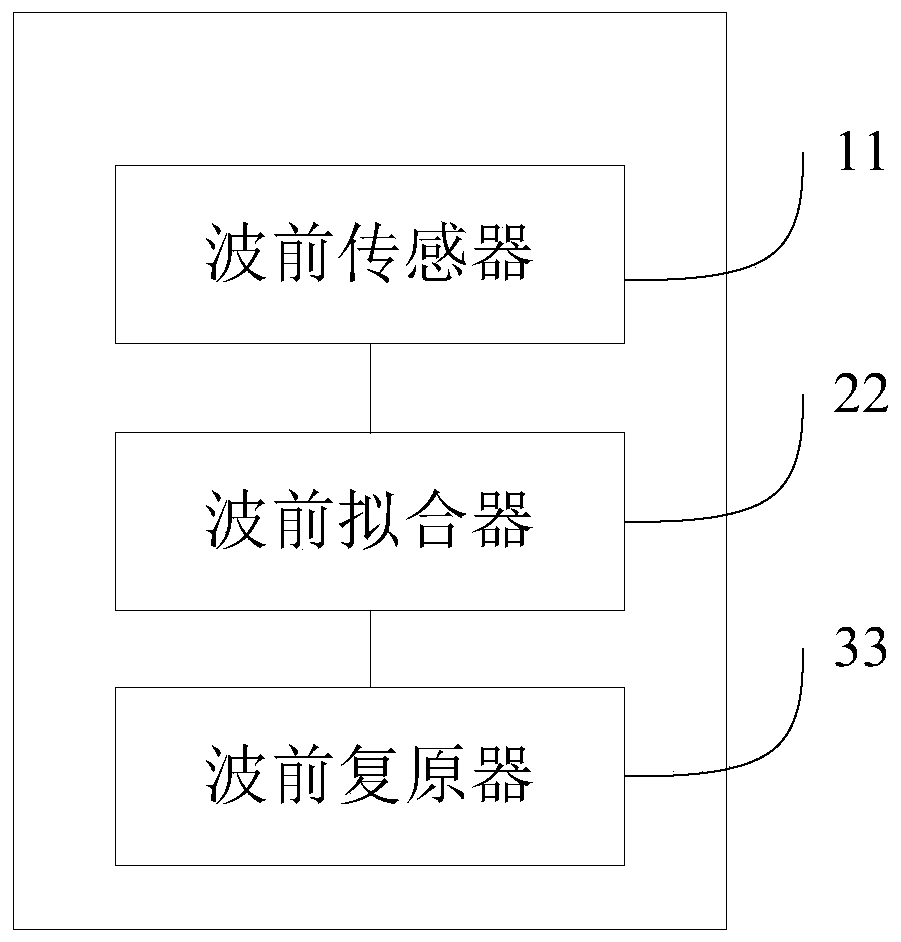

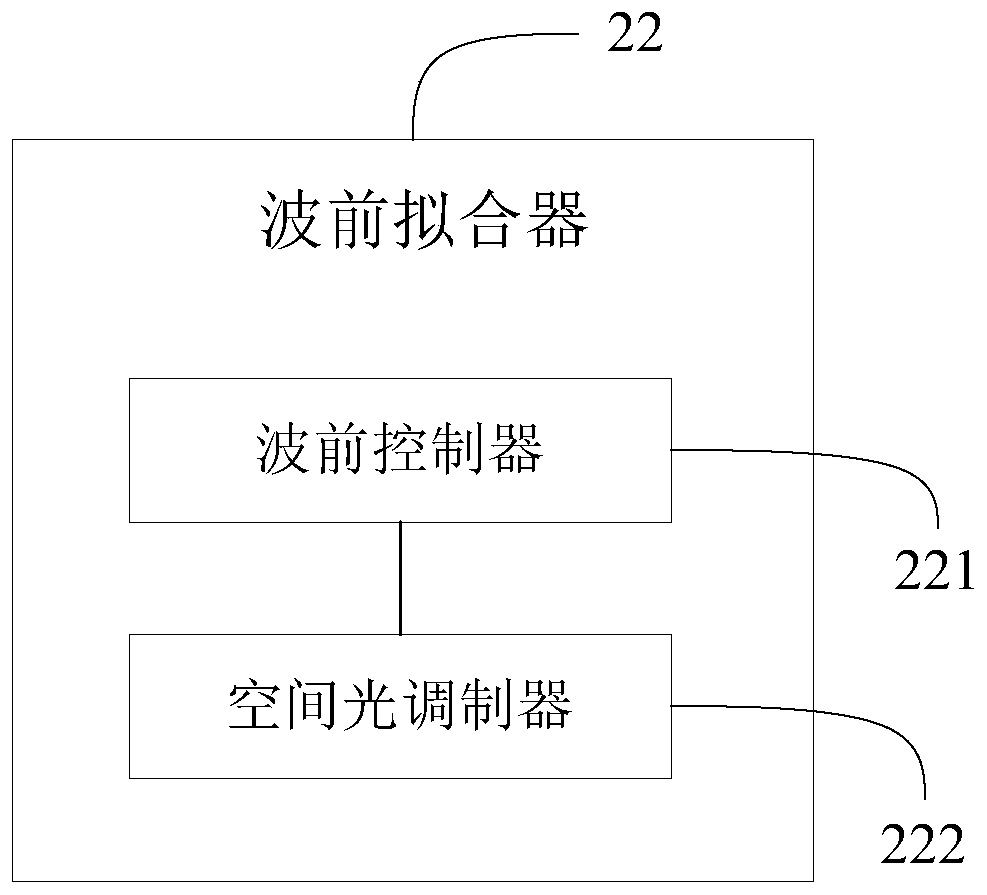

A Wavefront Sensor Based on Adaptive Fitting

ActiveCN106482838BHigh precisionHigh precision measurementOptical measurementsWavefront sensorLight spot

The invention provides a wavefront sensor based on adaptive fitting. The wavefront sensor comprises a wavefront sensor, a wavefront fitting device and a wavefront recovery device. The wavefront sensor is used for receiving to-be-detected wavefront and carrying out segmentation and gathering processing on the to-be-detected wavefront so as to obtain a light spot array. The wavefront fitting device is used for carrying out recovery processing on the light spot array so as to obtain recovery wavefront and carrying out space iteration fitting processing on the recovery wavefront so as to obtain recovery wavefront compensation quantity reaching a stable value. The wavefront recovery device is used for carrying out recovery processing on the recovery wavefront compensation quantity which has reached the stable value so as to obtain recovery wavefront with high precision. The wavefront sensor carries out cycle measurement on error quantity subjected to compensation fitting under the effects of the wavefront fitting device, so when the cycle index is increased, error quantity fluctuations are reduced, the measurement precision is improved and high-precision measurement of the recovery wavefront is achieved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Weight-volume mixing method for car refinish paint

ActiveCN109173827BSimple structureAccurate measurementRotary stirring mixersTransportation and packagingMasterbatchEngineering

In order to solve the technical prejudice, the present invention provides a weight-volume mixing method for automotive refinish paint with accurate color masterbatch, which includes the following steps: (1) Find the weight formula of the refinish paint used; (2) According to the weight formula of the refinish paint and The measured color masterbatch specific gravity is converted to the corresponding repair paint volume formula; (3) Calculate the type of color masterbatch required and the volume and weight required for each color masterbatch; (4) Find any one of the color masterbatches according to the required color masterbatch type For the color masterbatch barrel corresponding to masterbatch A, take more than half of the volume V required by color masterbatch A 1 , weighing M 1 ; Subtract M from the weight M required by the color masterbatch 1 The resulting weight M 2 Calculate the volume V according to the specific gravity of the color masterbatch measured in step (2) 2 , take the volume as V 2 Complete the retrieving of color masterbatch A; (5) complete the retrieving of other color masterbatches in sequence according to the method in step (4); mix and stir the obtained color masterbatch.

Owner:ZHENGZHOU SANHUA TECH & IND

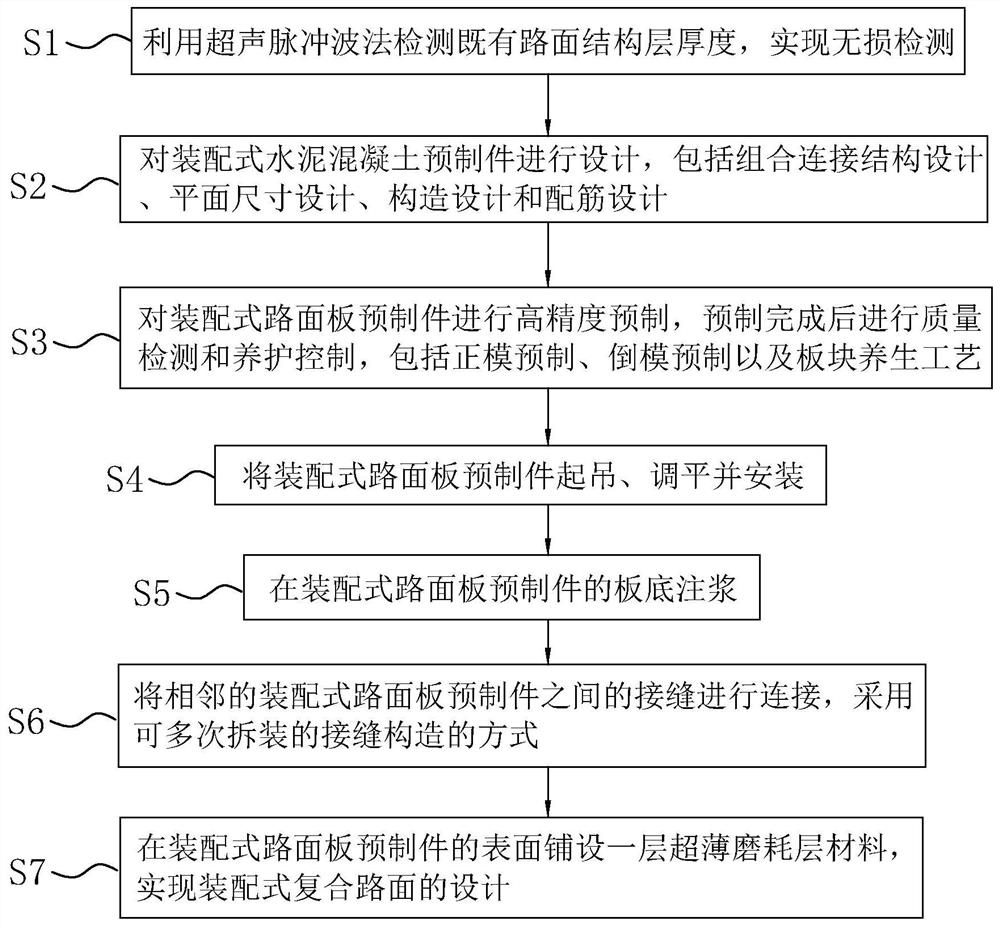

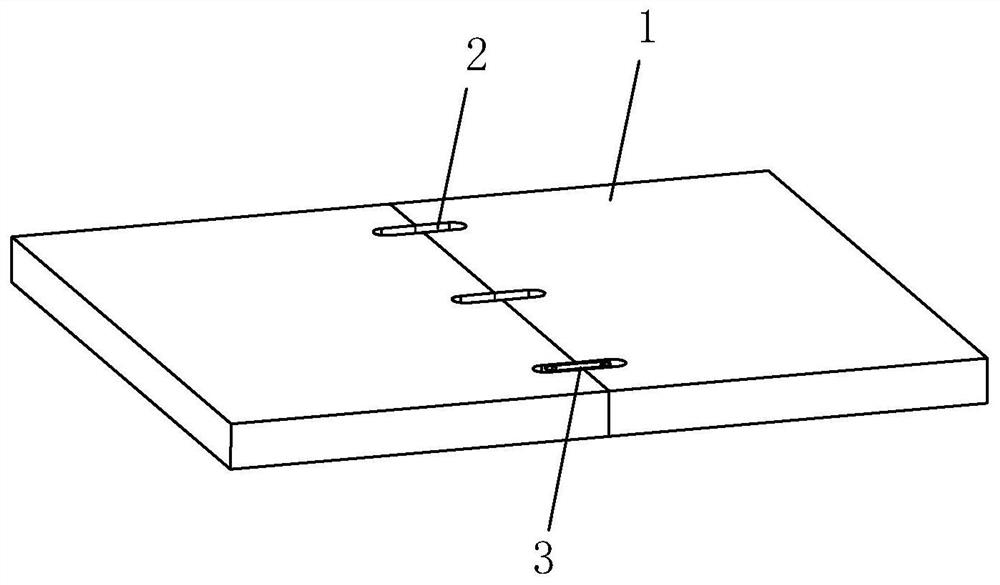

Fabricated rapid repairing method for building pavement

InactiveCN113215914ALow seam widthReduce the amount of errorPaving reinforcementsIn situ pavingsCement MaterialPulsed wave

The invention relates to the technical field of road surface construction, discloses a fabricated rapid repairing method for a building pavement, and solves the technical problem that the influence on normal traffic is large due to the fact that the current road blocking time is too long. The method comprises the following repairing steps: S1, detecting the thickness of an existing road surface structure layer by utilizing an ultrasonic pulse wave method to realize nondestructive detection; S2, designing a fabricated cement concrete prefabricated part; S3, performing high-precision prefabrication on the fabricated pavement slab prefabricated part; S4, hoisting, leveling and installing the fabricated pavement slab prefabricated part; S5, performing grouting on the slab bottom of the fabricated pavement slab prefabricated part; S6, connecting joints between the adjacent fabricated pavement slab prefabricated parts; and S7, laying a layer of ultra-thin wearing layer material on the surface of the fabricated pavement slab prefabricated part. According to the technical scheme, the purpose of shortening the road blocking time is achieved by utilizing a newly designed rapid repairing method.

Owner:江西省宏顺建筑工程有限公司

Method for measuring rotational inertia of steam turbine generator set

ActiveCN110207893AOvercome the unfavorable factors of large dynamic speed errorPhysical concepts are clearStatic/dynamic balance measurementGeneral functionEngineering

The invention discloses a method for measuring the rotational inertia of a steam turbine generator set. On the basis of the technical way of sinusoidal wave counting of a local rotating disk gear recording signal, 1-ms-level high-precision dynamic rotor rotating speed is calculated and then the rotational inertia of a steam turbine generator set is calculated based on the rotating speed. Therefore, an overcome of large dynamic rotating speed error in the conventional rotating speed measurement method is overcome. The employed instruments and equipment are conventional ones and the employed data processing software is conventional function software. The method has advantages of clear physical concept, simple operation, and high measurement accuracy.

Owner:ZHEJIANG ZHENENG ELECTRIC POWER +1

On-line measurement system and method for micro-sugar content

ActiveCN103234964BContinuous monitoring of sugar contentPromote absorptionMaterial analysis by observing effect on chemical indicatorMicrocontrollerReaction temperature

Owner:QINZHOU CHUANGHUA IND CONTROL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com