Cover grabbing and screwing device

A technology of grasping and capping heads, applied in screw caps and other directions, can solve problems such as affecting production work and product quality, high working frequency of capping machines, inaccurate centering of capping machines, etc., to improve the accuracy of centering and The effect of connection strength, avoidance of deviation, and improved alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

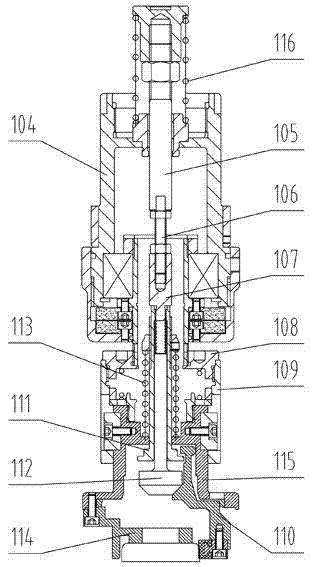

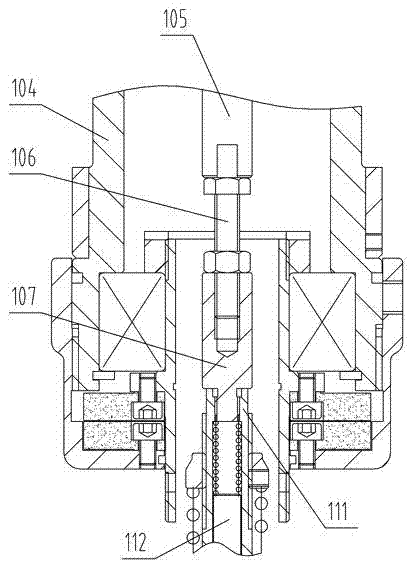

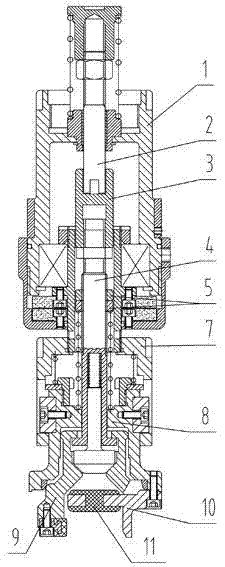

[0011] A capping and capping device, comprising a capping head housing 1 and a connecting shaft 2 that transmits a downward movement, the capping head housing 1 is provided with a connecting screw 3 whose outer wall is close to the inner wall of the mandrel of the capping head housing 1, Both the top surface and the bottom surface of the connecting screw 3 are provided with concave holes, and the concave holes on the bottom surface are provided with internal threads. 4. The upper end of the ejector screw 4 is provided with an external thread and is connected and fixed with the concave hole on the bottom surface of the connecting screw 3. The outer wall of the ejector screw 4 is equipped with two nuts 5 that are pressed against each other, and there is also a screw that drives the ejector screw 4 to rise. Back-moving spring 6, the two ends of back-moving spring 6 are respectively connected the nut 5 of the lower end outside the push rod screw rod 4 and the main body of the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com