Fabricated rapid repairing method for building pavement

A repair method and assembled technology, which is applied in road repair, construction, road construction reinforcements, etc., can solve the problems of heavy traffic impact and long maintenance time of concrete roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

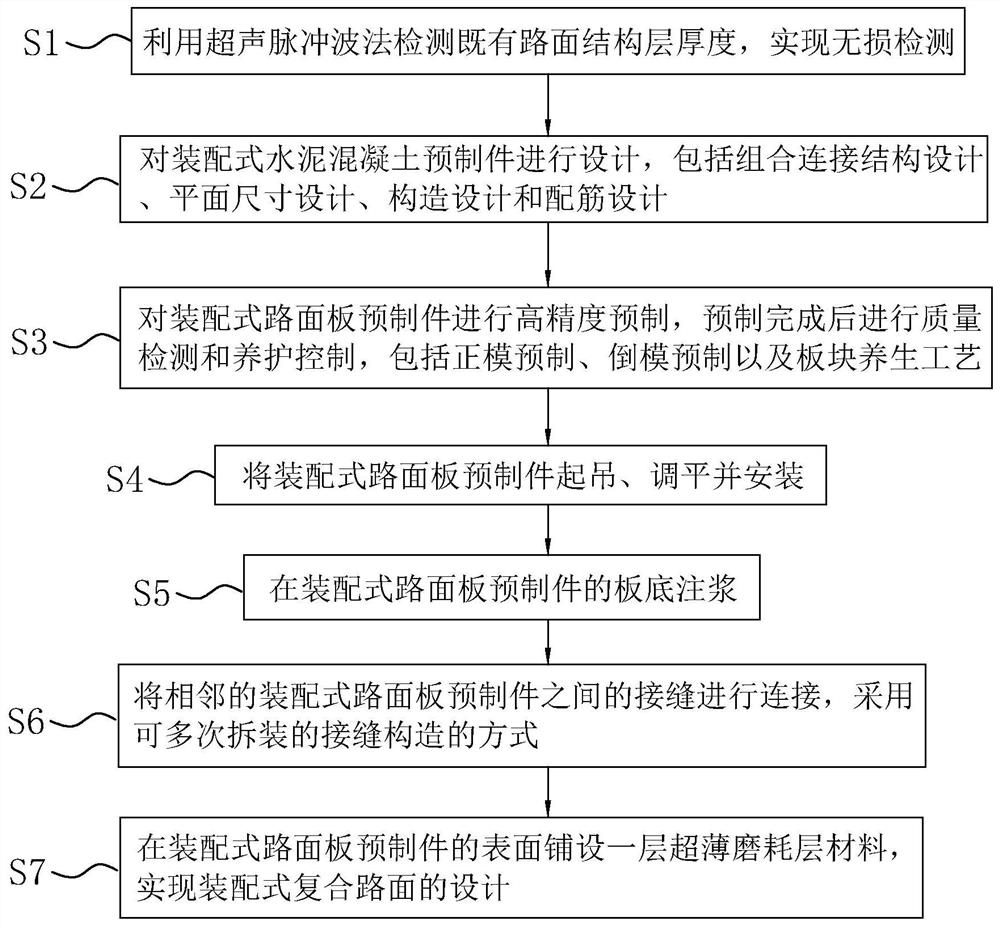

[0036] A kind of building pavement assembled type rapid repair method, refer to figure 1 shown, including the following repair steps:

[0037] S1. Use the ultrasonic pulse wave method to detect the thickness of the existing pavement structure layer to achieve non-destructive testing. The non-destructive testing can also use 3D laser scanning measurement and depth camera 3D measurement to perform 3D elevation digital detection of the existing pavement.

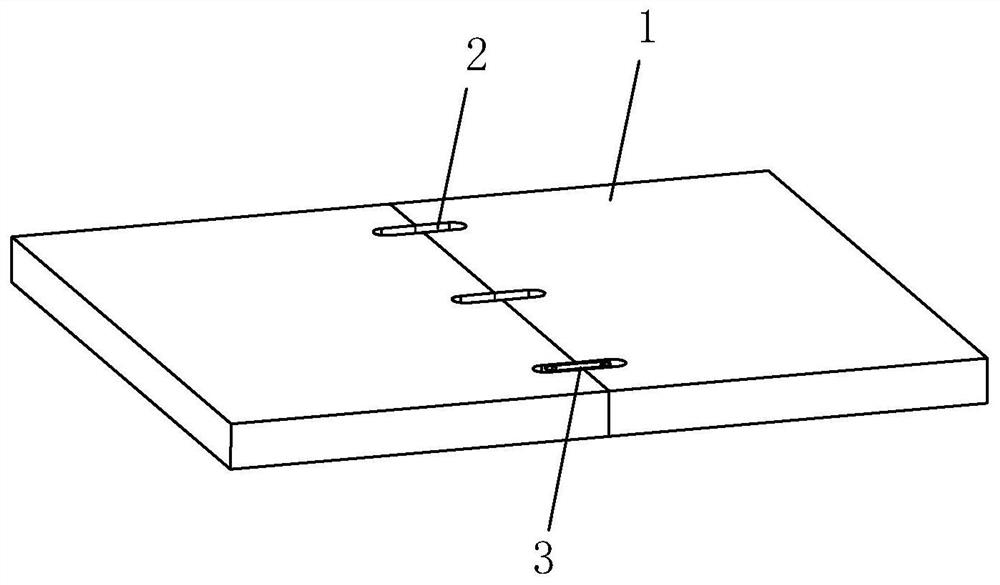

[0038] S2. Design the prefabricated cement concrete parts, including combined connection structure design, planar size design, structural design and reinforcement design; where the combined connection structure is to connect the joints between the prefabricated pavement slabs structure, such as figure 2 As shown, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com