Novel damping bearing block mechanism

A bearing seat and bearing technology, which is applied in the field of mechanical structure, can solve the problems of large radial error, poor elasticity, wear of the fit gap between the slender shaft and the bearing, etc., and achieve the wear of the fit gap between the slender shaft and the bearing Less, overcome the poor elasticity, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

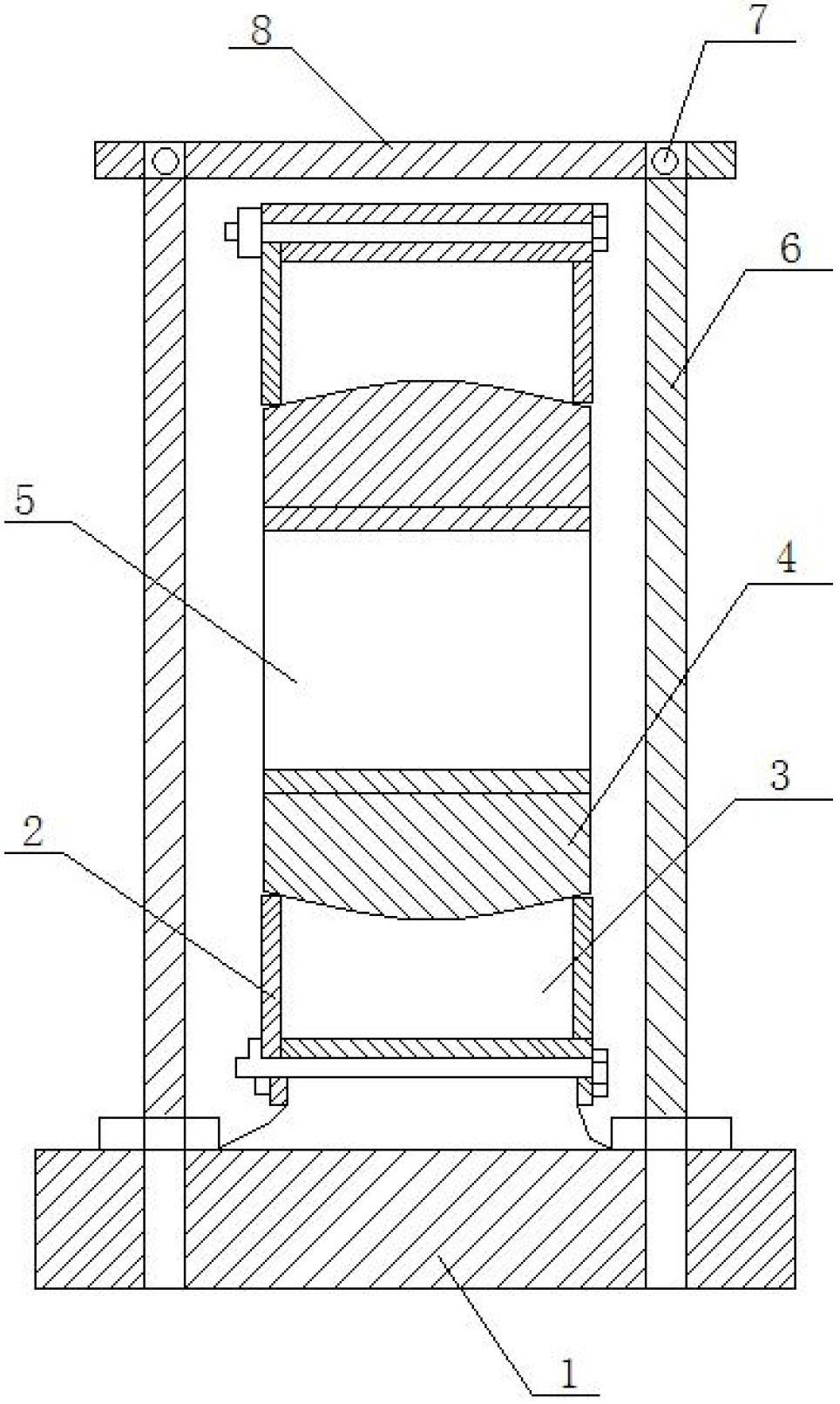

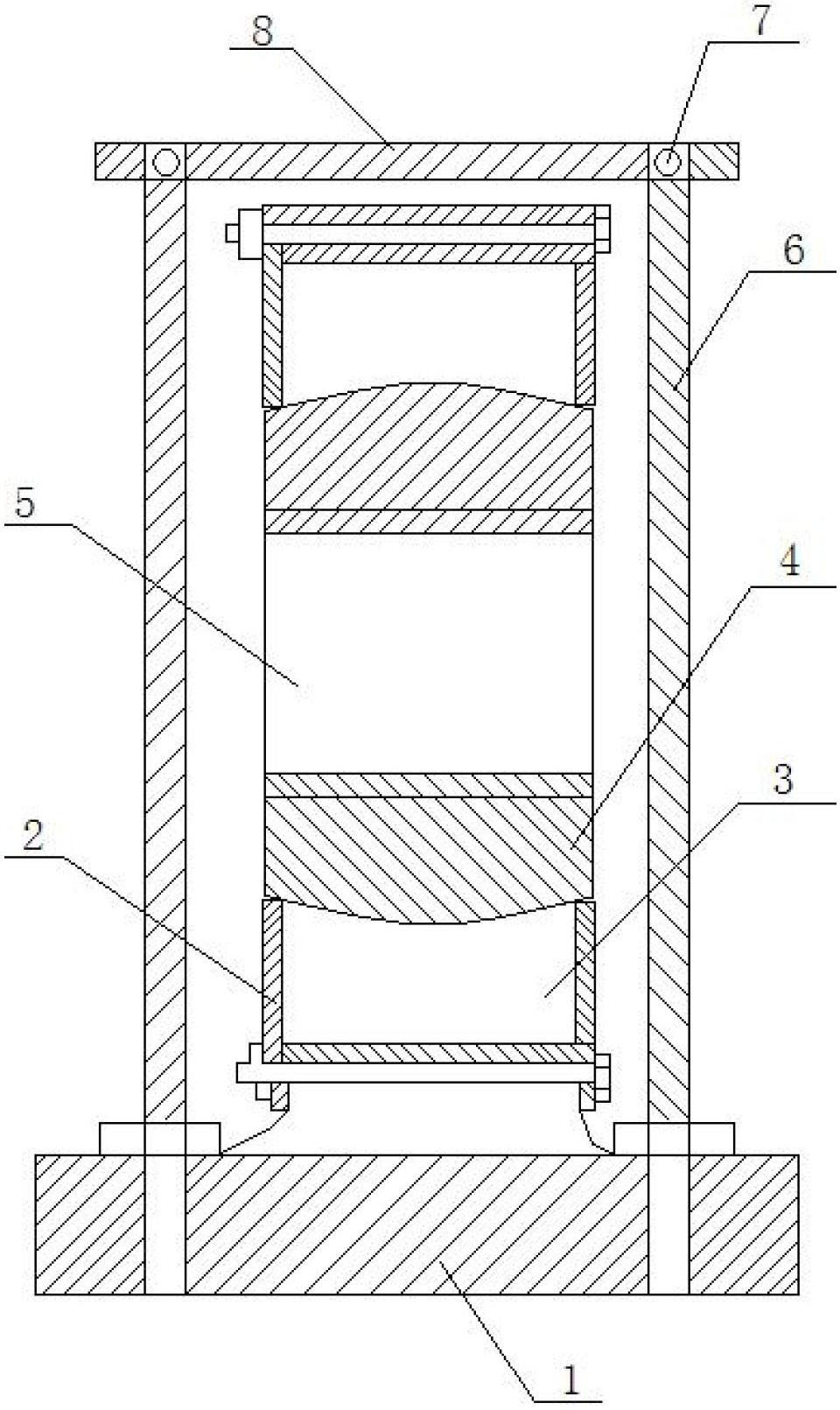

[0010] The damping bearing mechanism has a double-layer guard frame (6), and the double-layer guard frame (6) is a three-dimensional rectangle. Bearings (5) are installed in the inner cavity of the protective frame (6), and the bearings (5) are connected with the double-position spherical bushing (4), and the bearing (5), the double-position spherical bushing (4) and the silica gel The fiber damping rings (3) are combined and loaded into the holes of the base (1), and the two-body cover (2) is respectively installed on the base (1) through bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com