Cantilever formwork for concrete construction and construction method thereof

A concrete and formwork technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of low comprehensive construction work efficiency, cumbersome construction process, and time-consuming, and achieve the effect of simple construction, strong versatility, and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

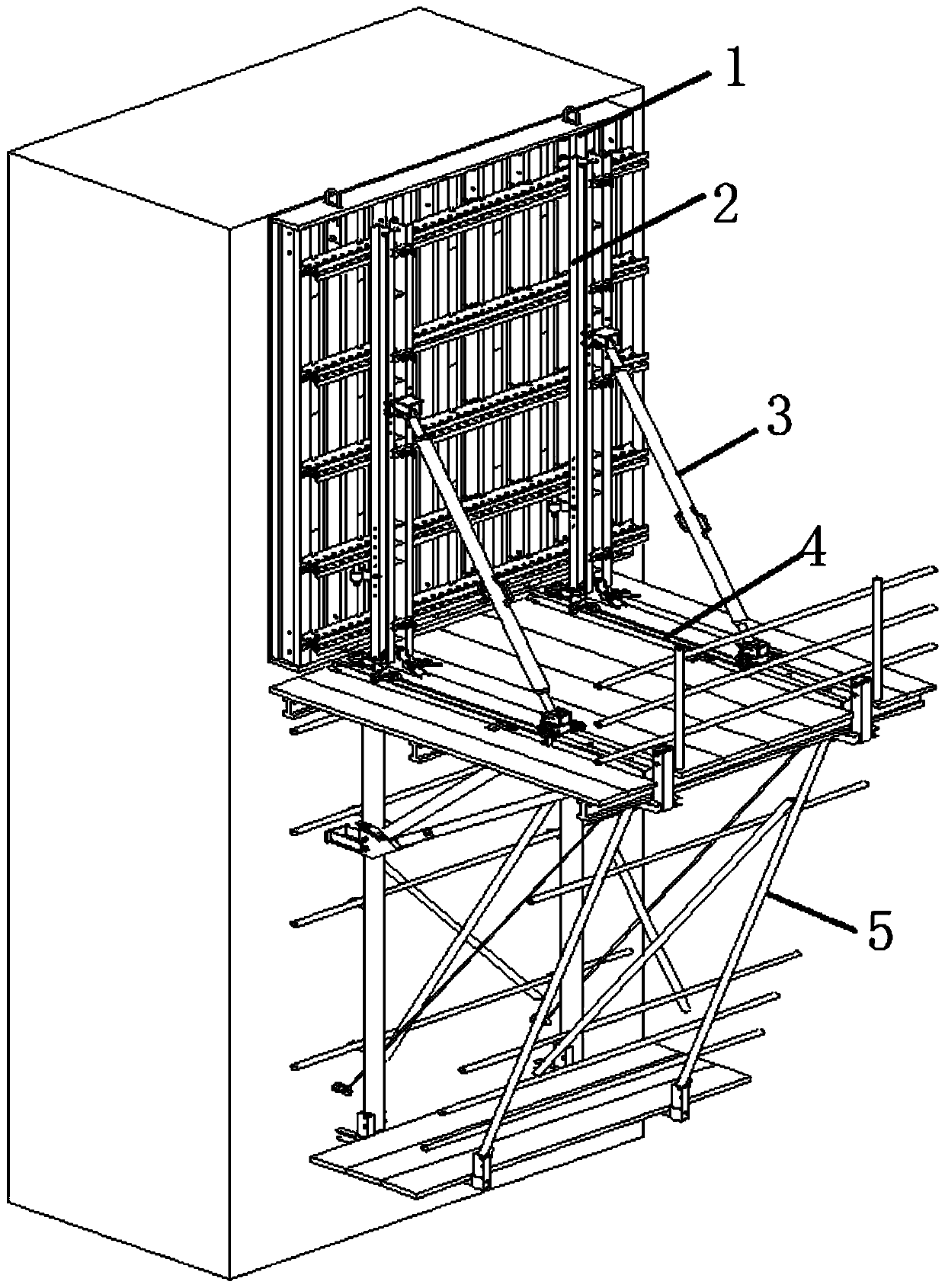

[0066] seefigure 1 , In this embodiment, a cantilever formwork for concrete construction includes a cantilever formwork bracket, an anchor assembly and a plane formwork.

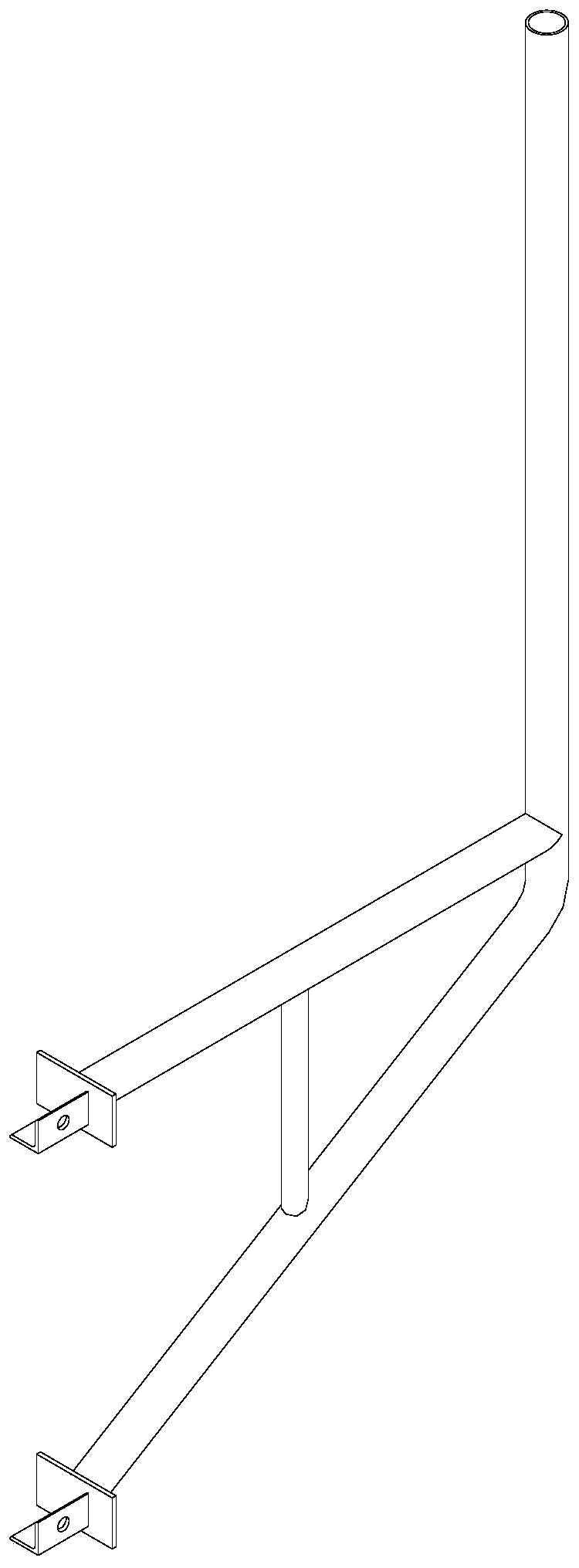

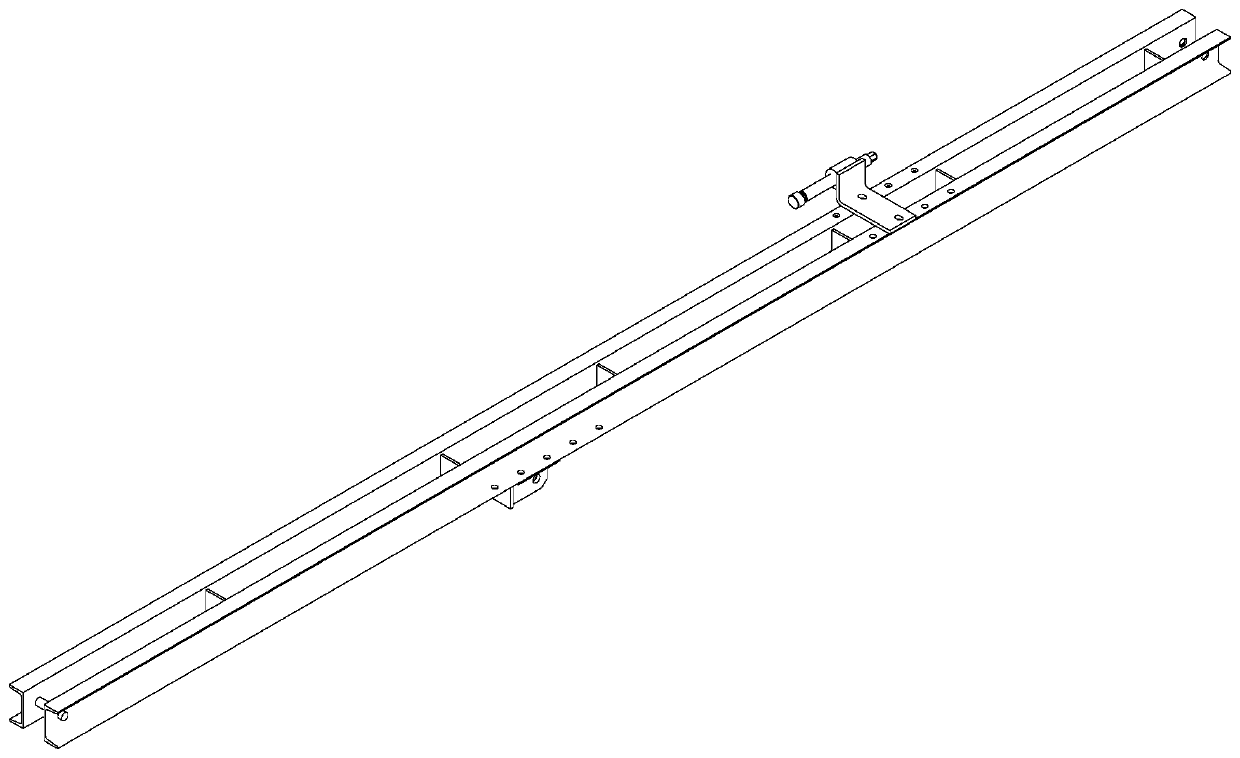

[0067] see Figure 2-6 As shown, the cantilever formwork support includes a cantilever 1, a main back corrugated 2, a diagonal brace 3, a main beam tripod 4 and a hanging platform 5, the bottom of the main beam tripod 4 is connected to the hanging platform 5, and the hanging platform 5 is formed by The set suspension platform beam and the suspension platform pole vertically arranged on the side are composed of the main back corrugated 2 installed on the upper end of the main beam tripod 4, the main back corrugated 2 is vertically arranged, the side of the main back corrugated 2 is connected to the diagonal support, and the diagonal support A diagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com