Patents

Literature

47results about How to "Suitable for working at heights" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning machine suitable for various kinds of wall surfaces

ActiveCN107348915AClean adaptationIncrease the cleaning areaCarpet cleanersFloor cleanersEngineeringMechanical engineering

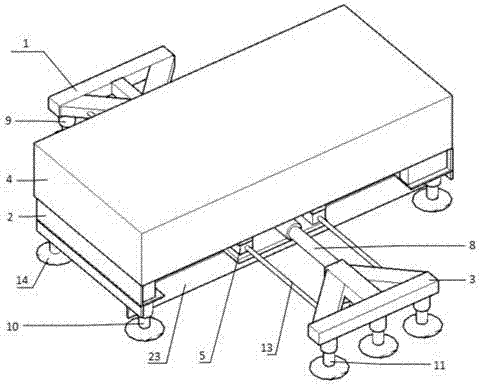

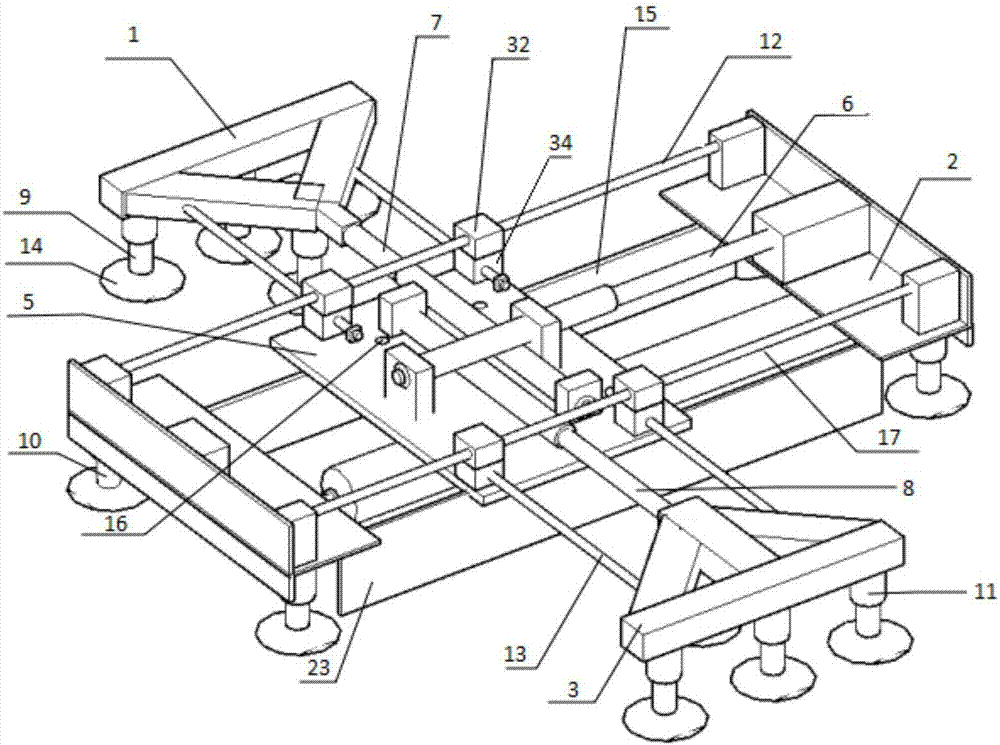

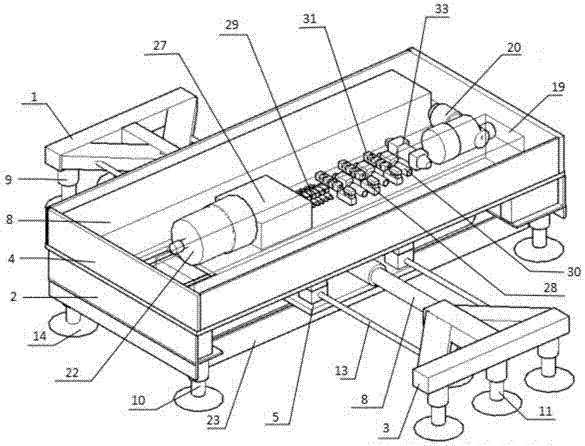

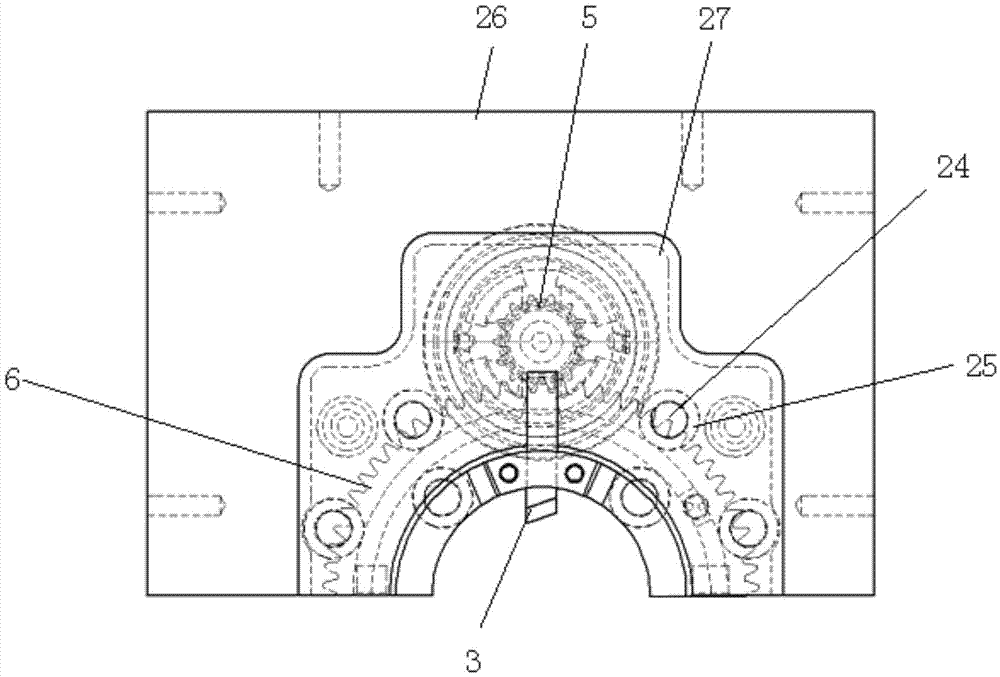

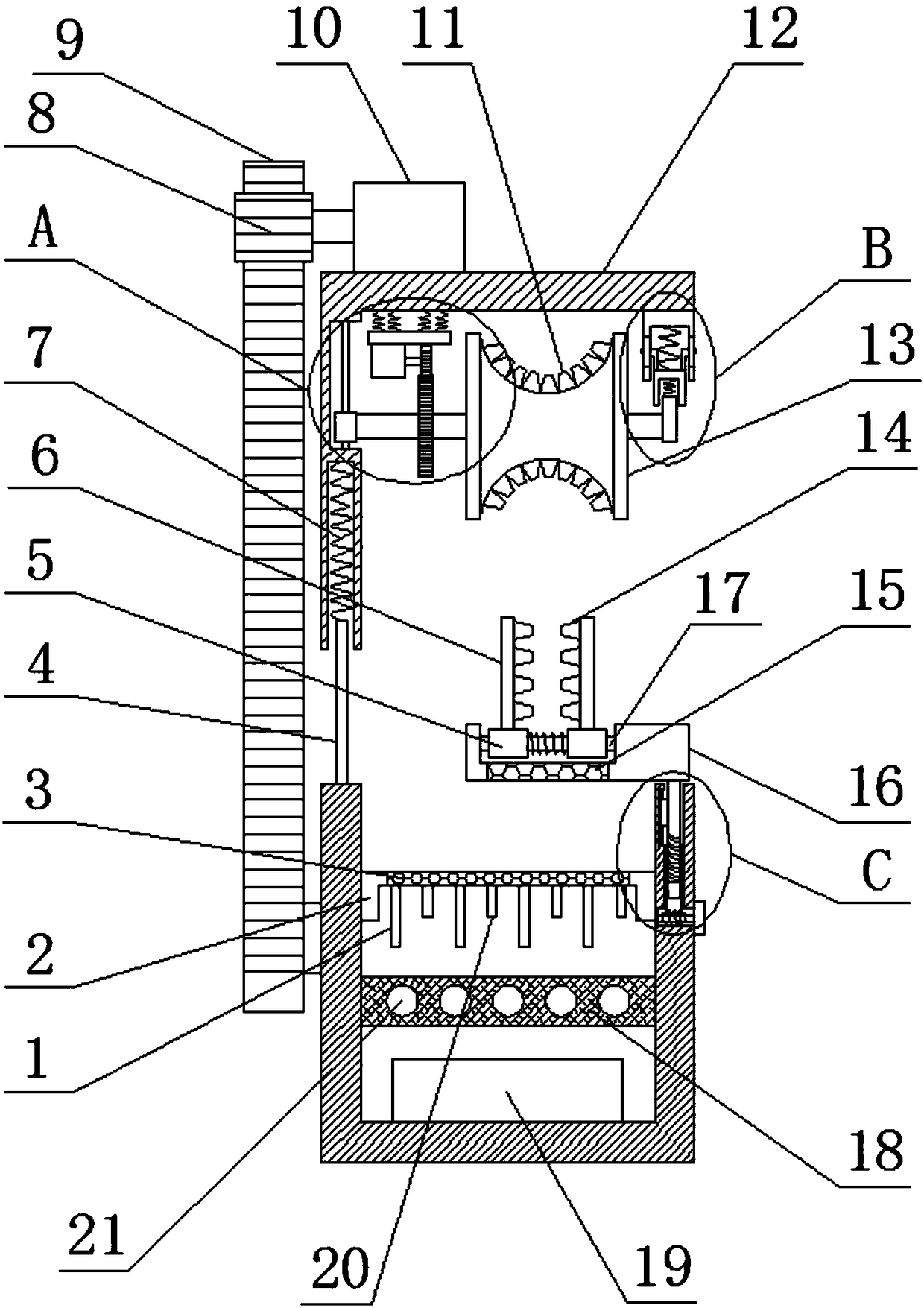

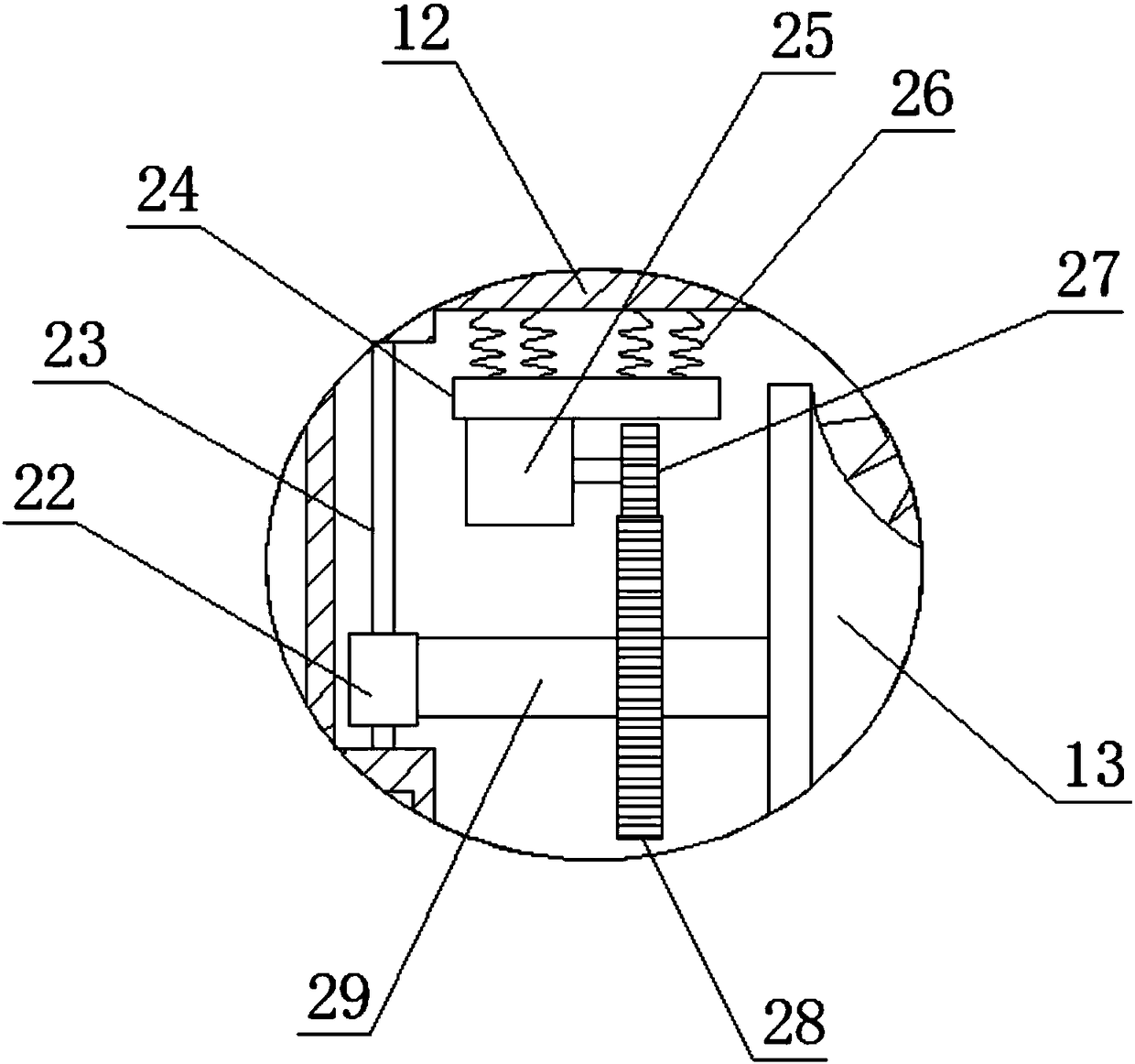

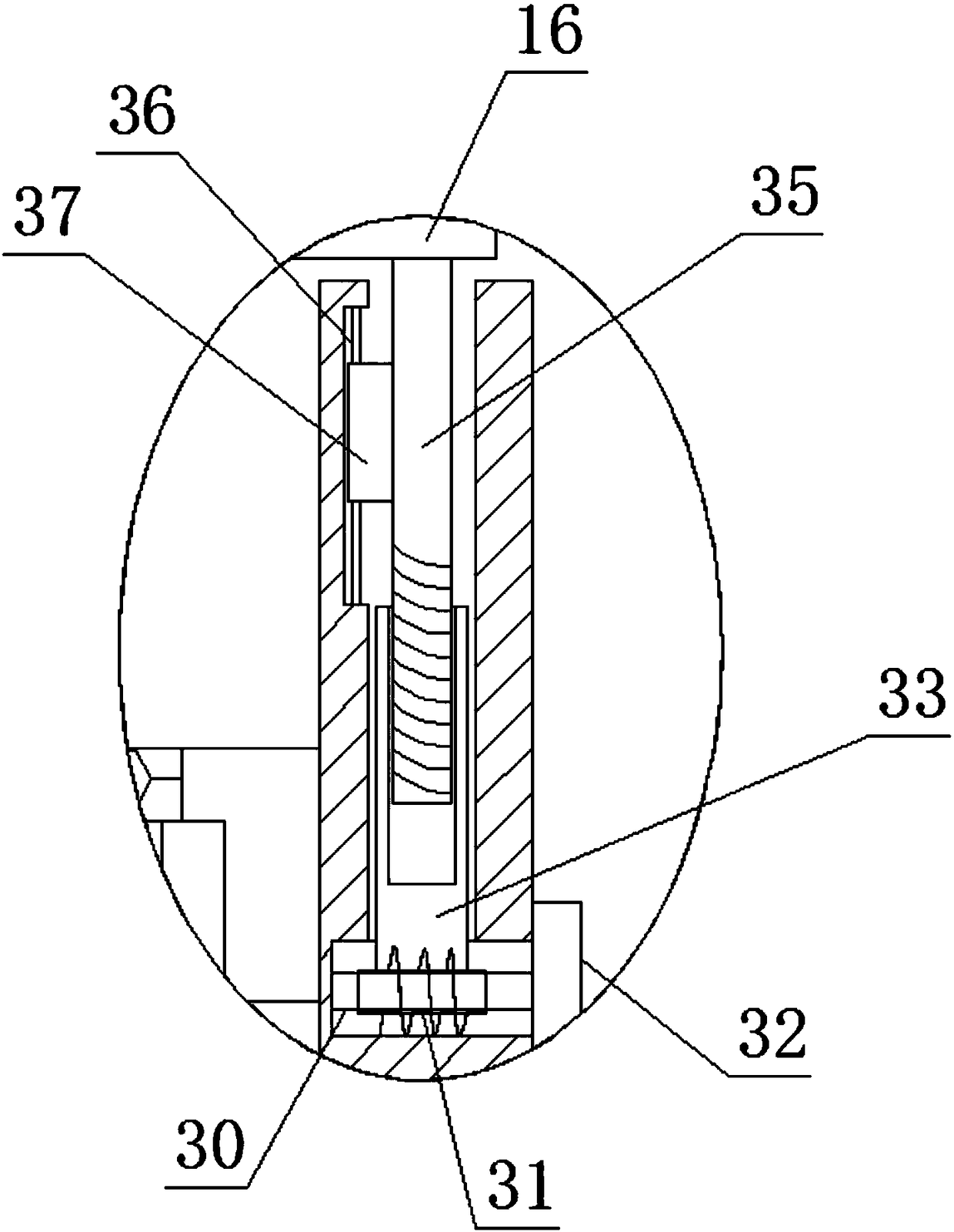

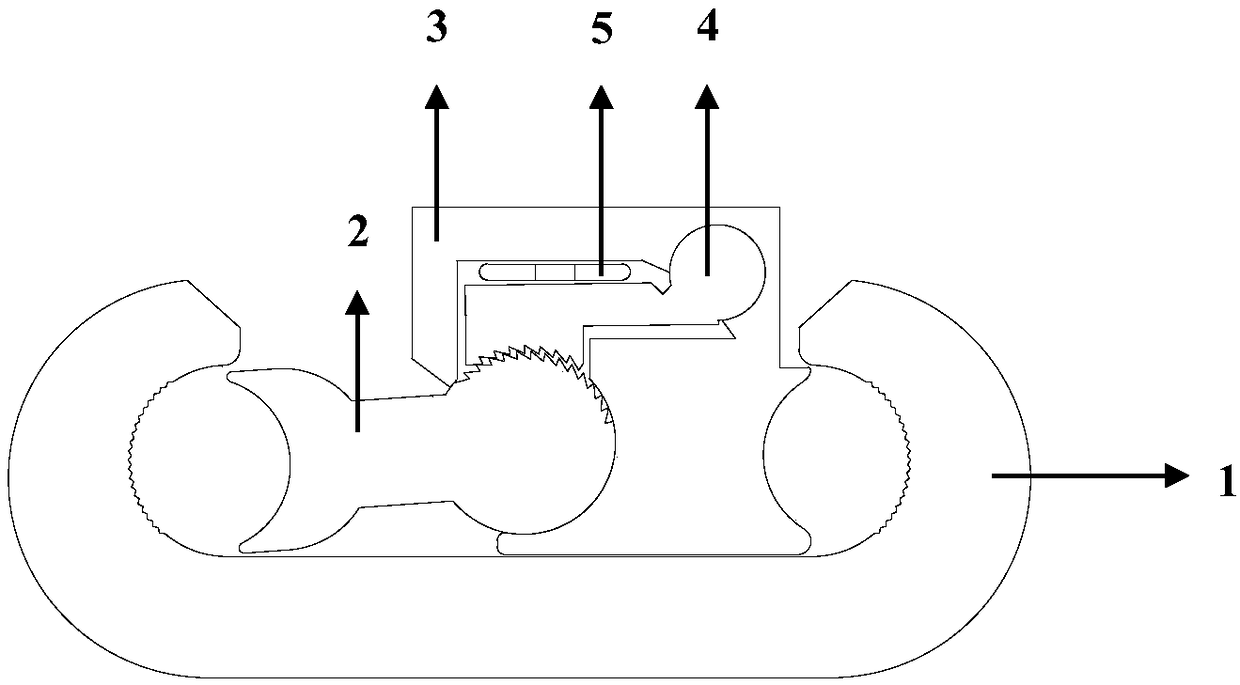

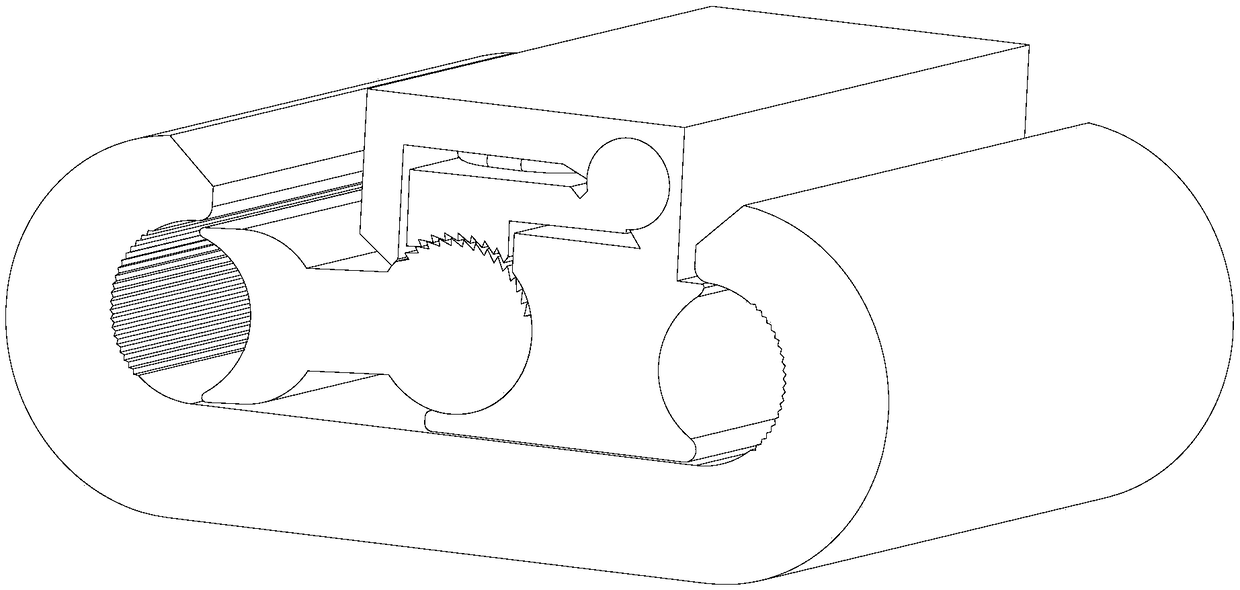

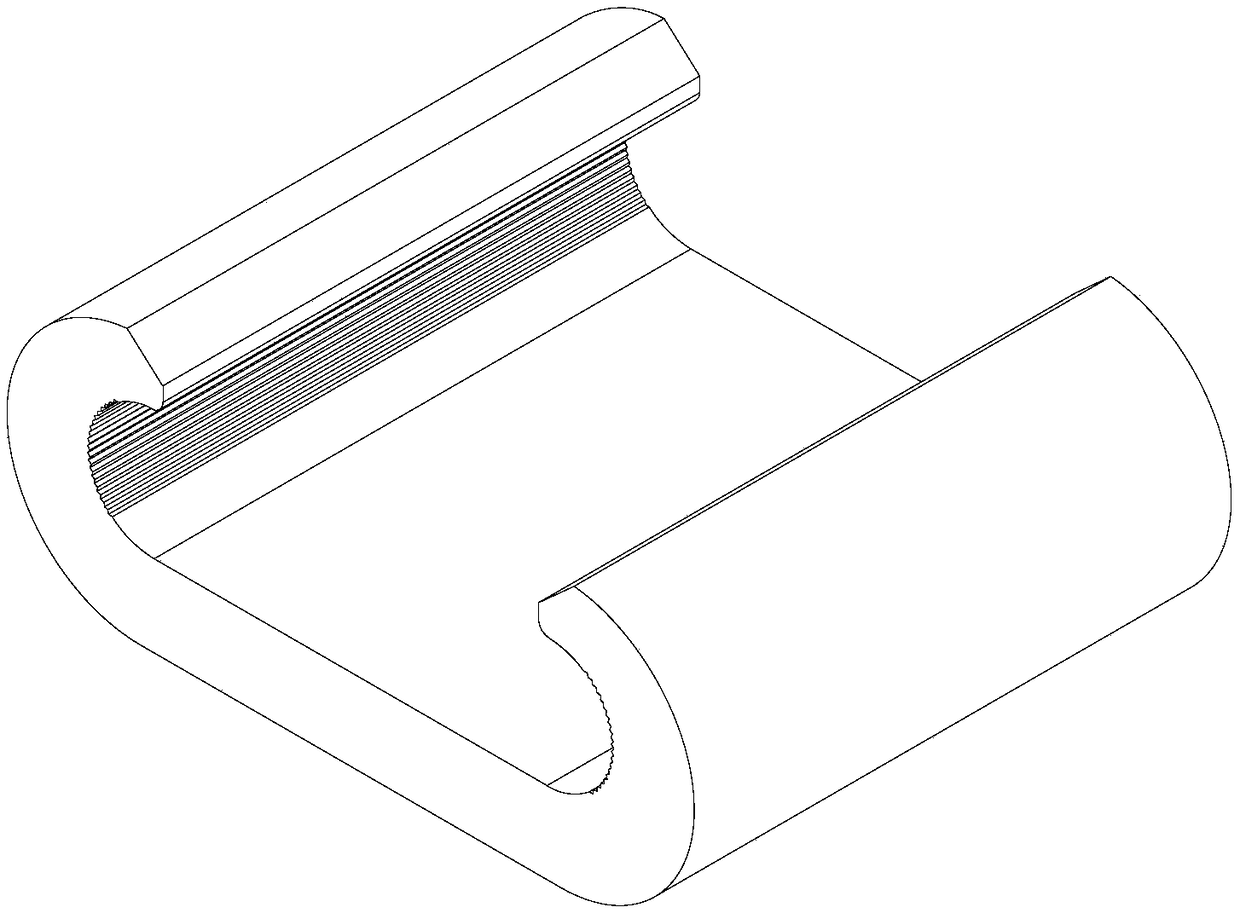

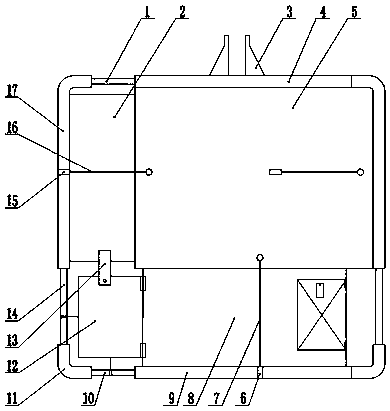

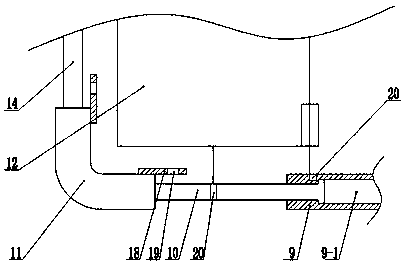

The invention relates to a cleaning machine suitable for various kinds of wall surfaces. The cleaning machine comprises a circulation cleaning assembly, an upper support, a middle support, a lower support, a bottom tray, an upward-downward movement mechanism, a leftward-rightward movement mechanism and a control assembly. The bottom tray is arranged in the middle of the middle support. The upper support and the lower support are symmetrically arranged on two sides of the middle support and connected with the bottom tray through the upward-downward movement mechanism. The leftward-rightward movement mechanism is arranged on the middle support and connected to the bottom tray. The upper support, the middle support and the lower support are all provided with adsorption assemblies. The circulation cleaning assembly is arranged on the middle support. The control assembly is connected with the circulation cleaning assembly, the upward-downward movement mechanism, the leftward-rightward movement mechanism and the adsorption assemblies. Compared with the prior art, the machine can automatically clean wall surfaces so that potential safety hazards are reduced, working efficiency is increased and resources are saved. Meanwhile, the conventional cleaning mode is changed, which facilitates life of people.

Owner:SHANGHAI UNIV OF ENG SCI

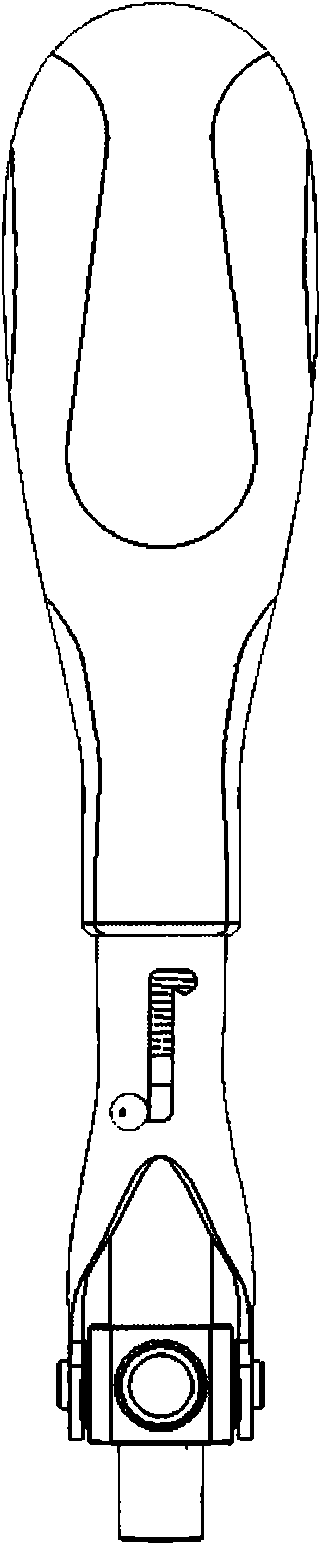

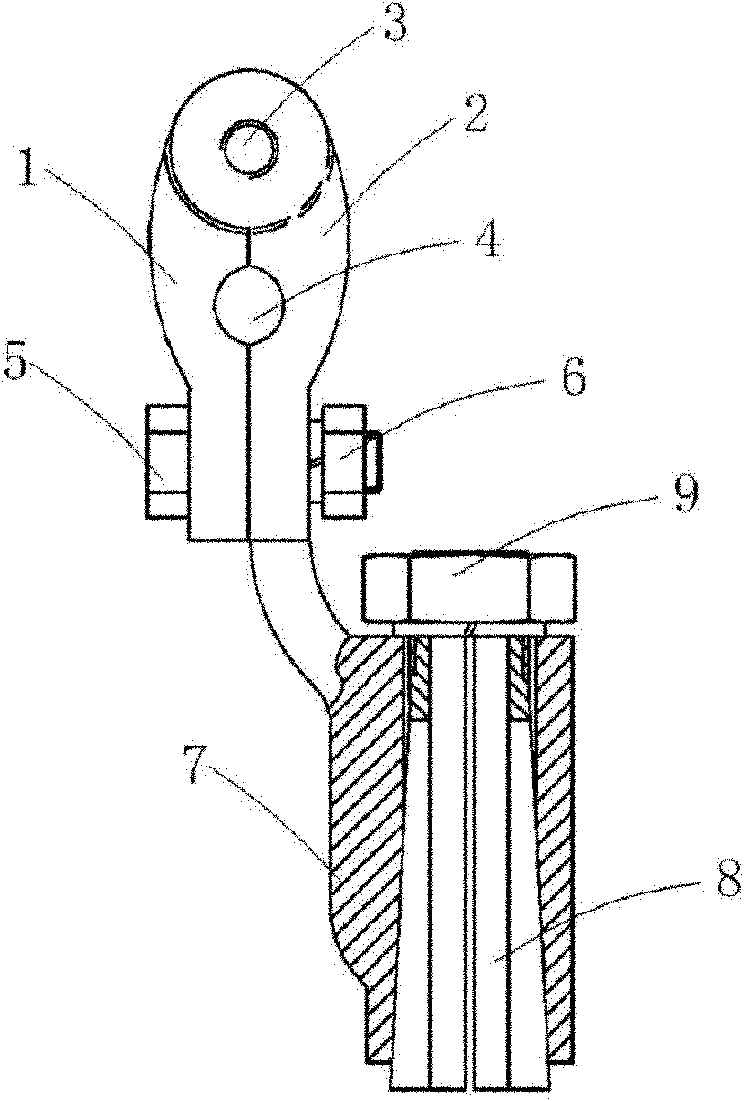

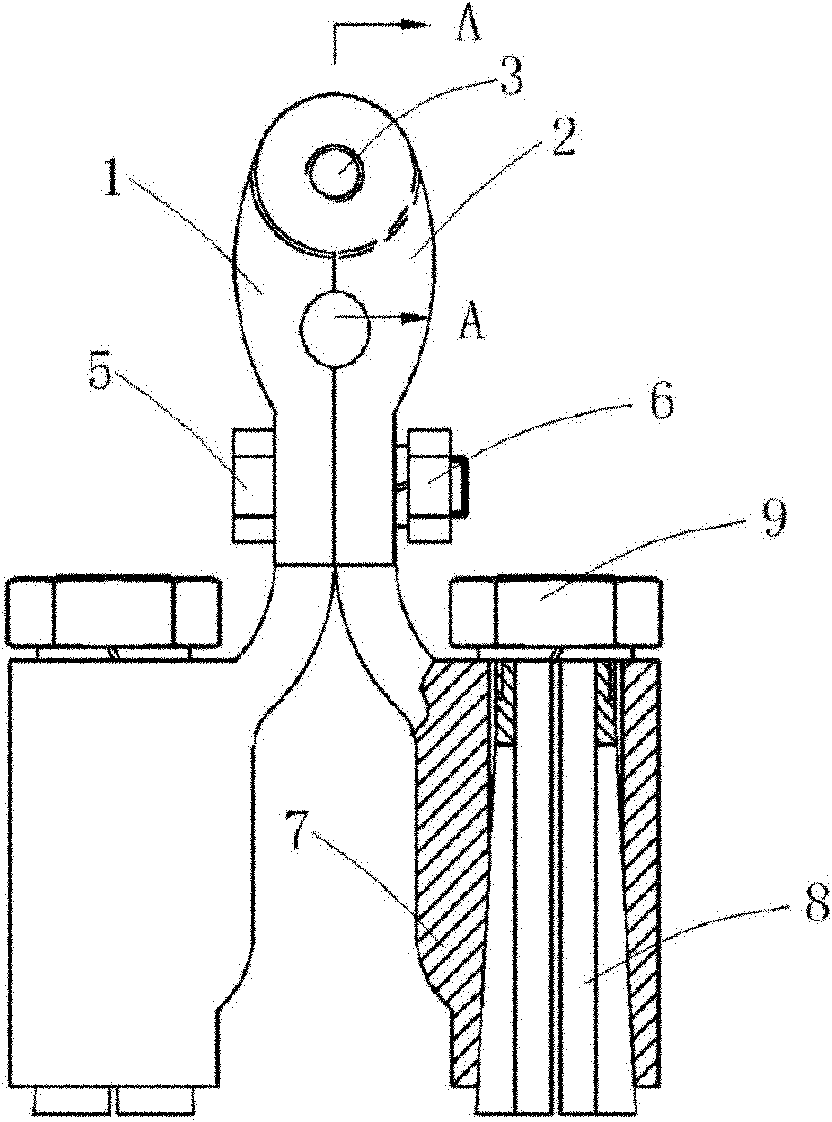

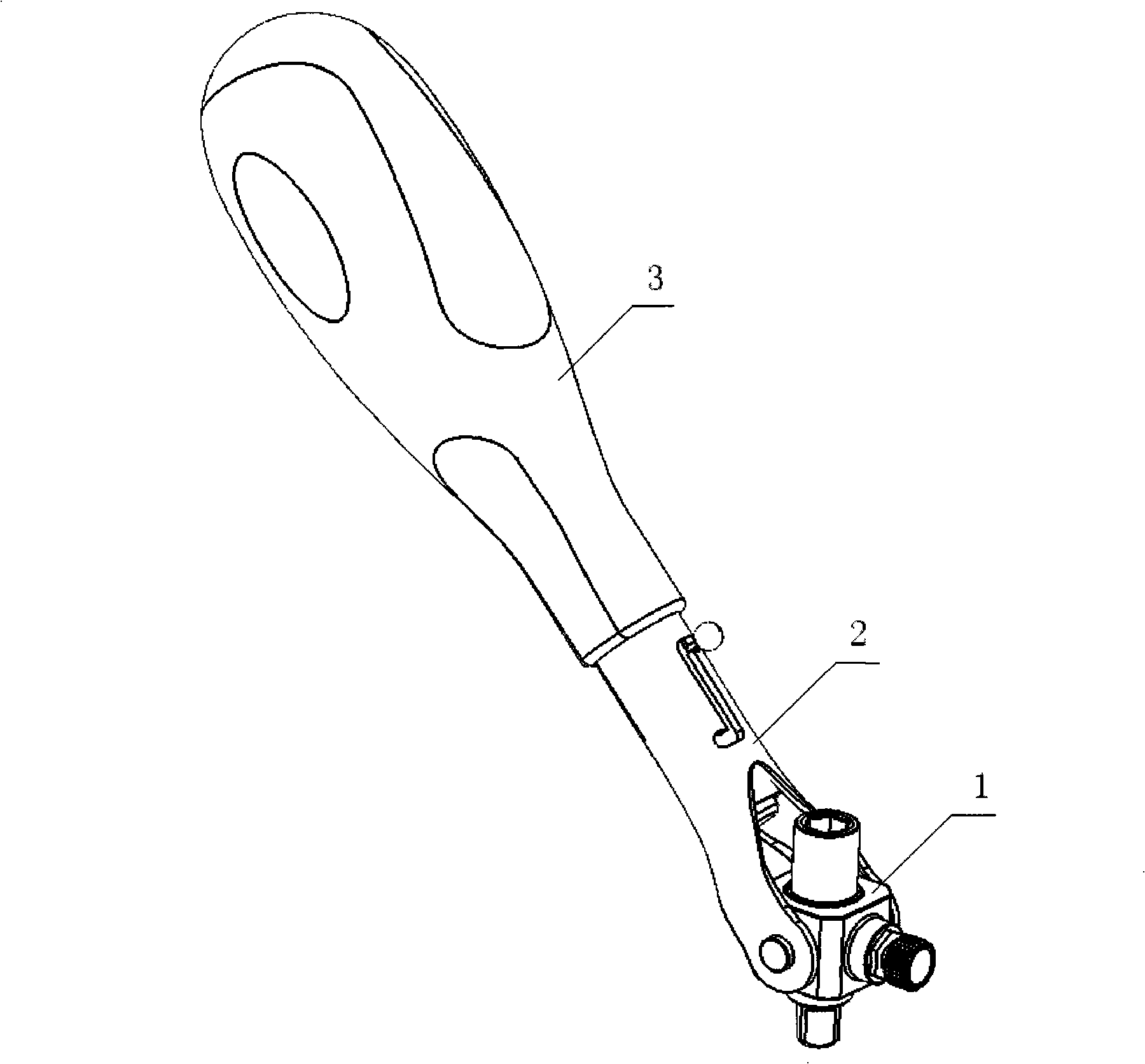

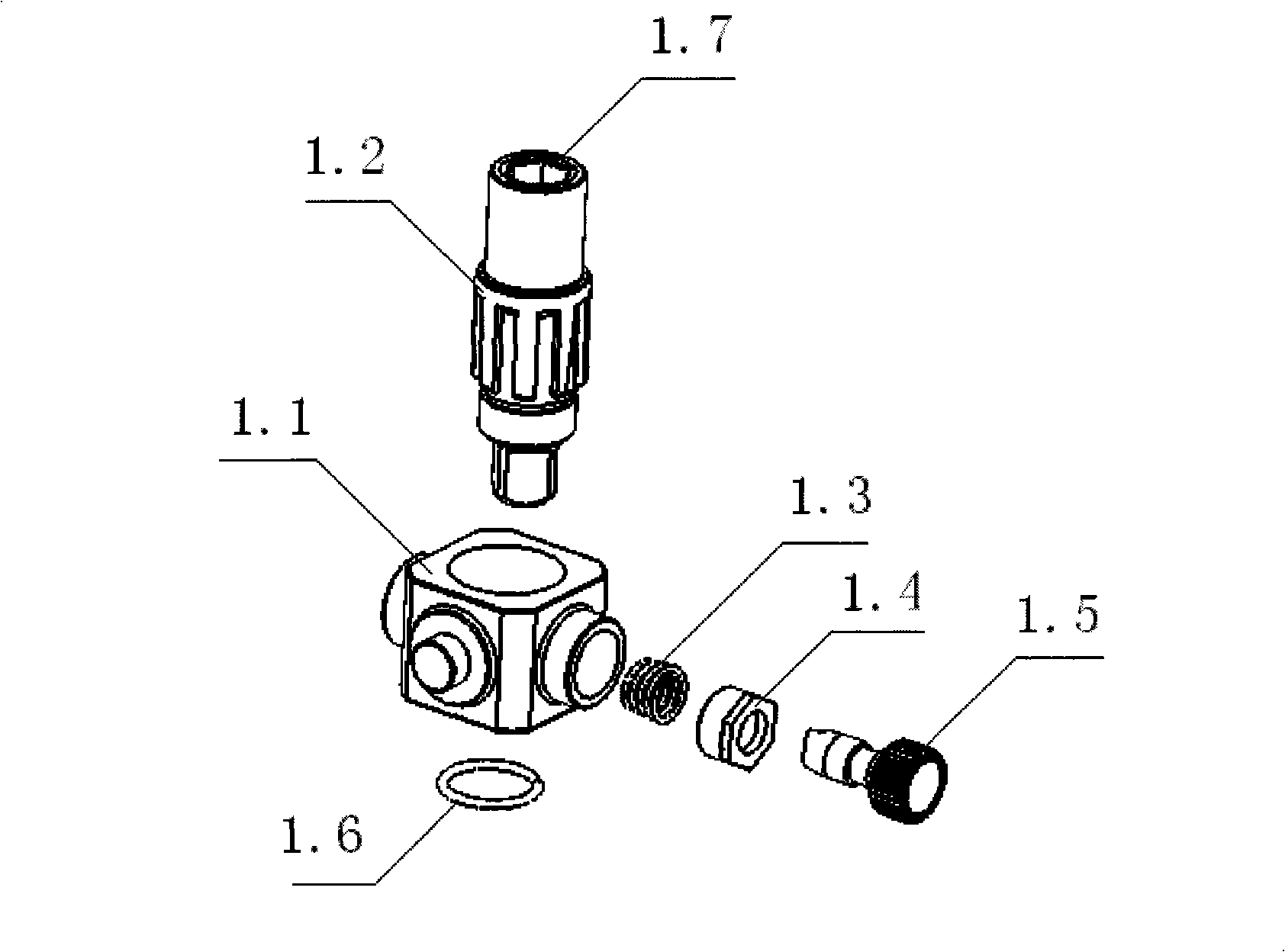

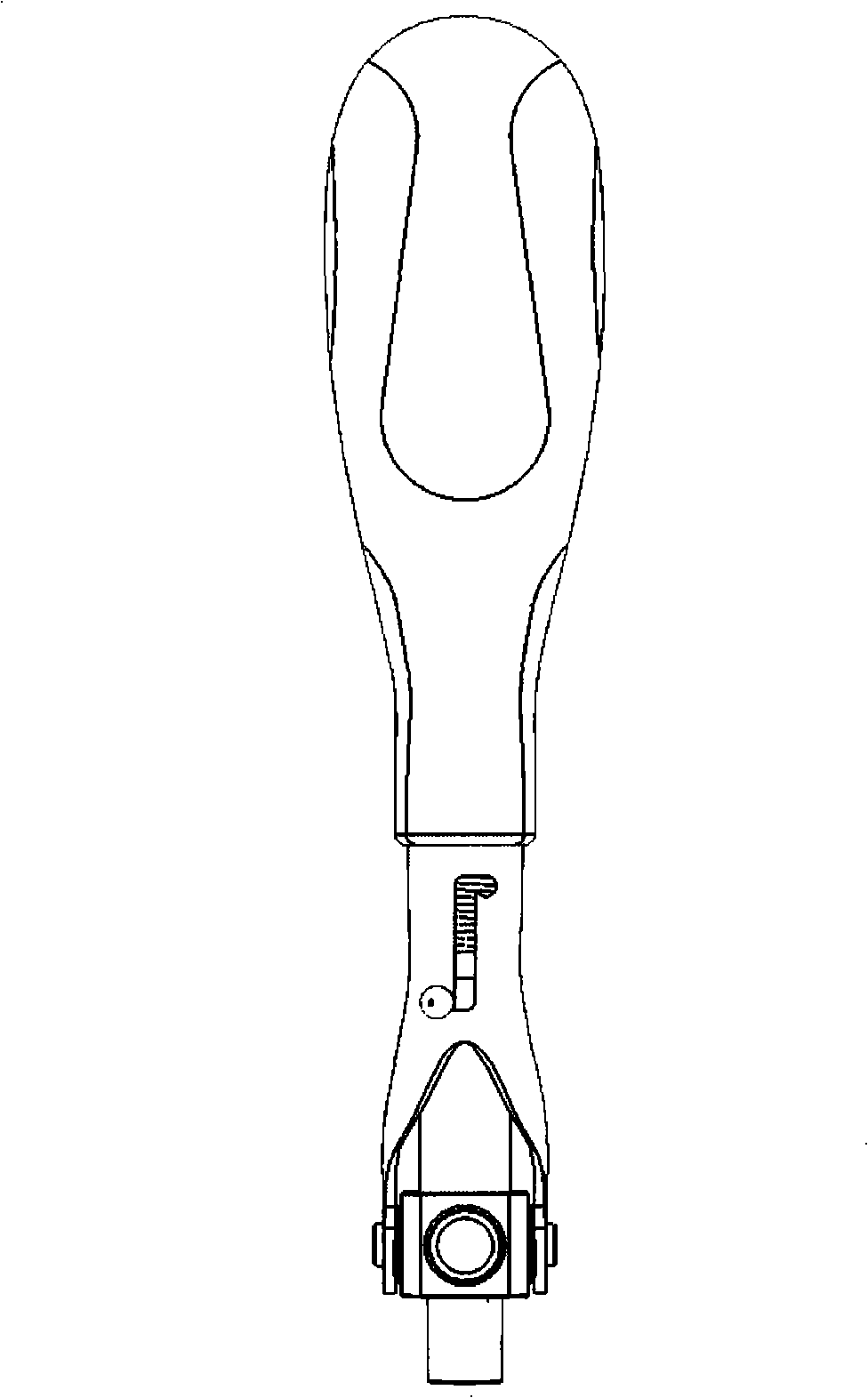

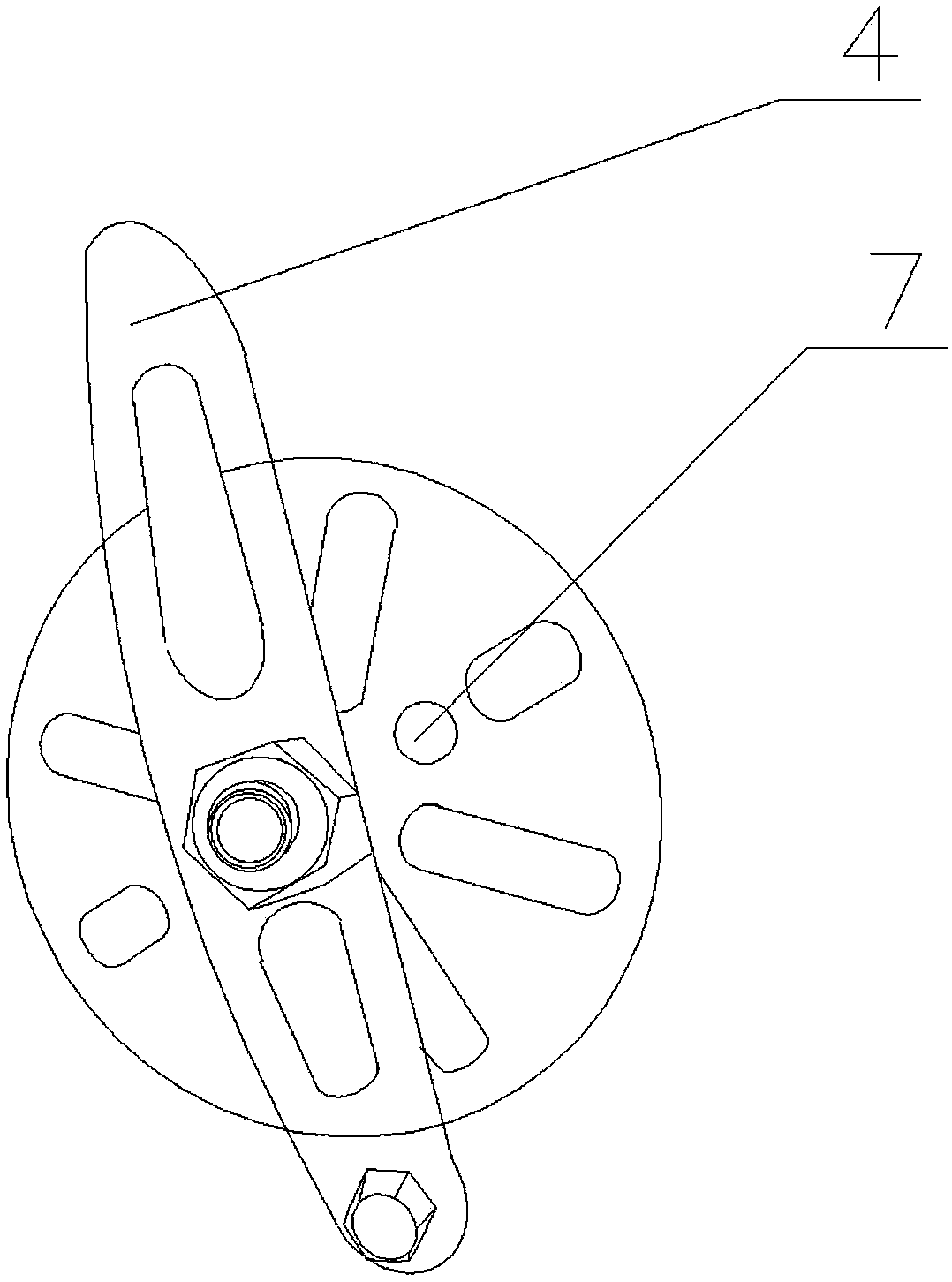

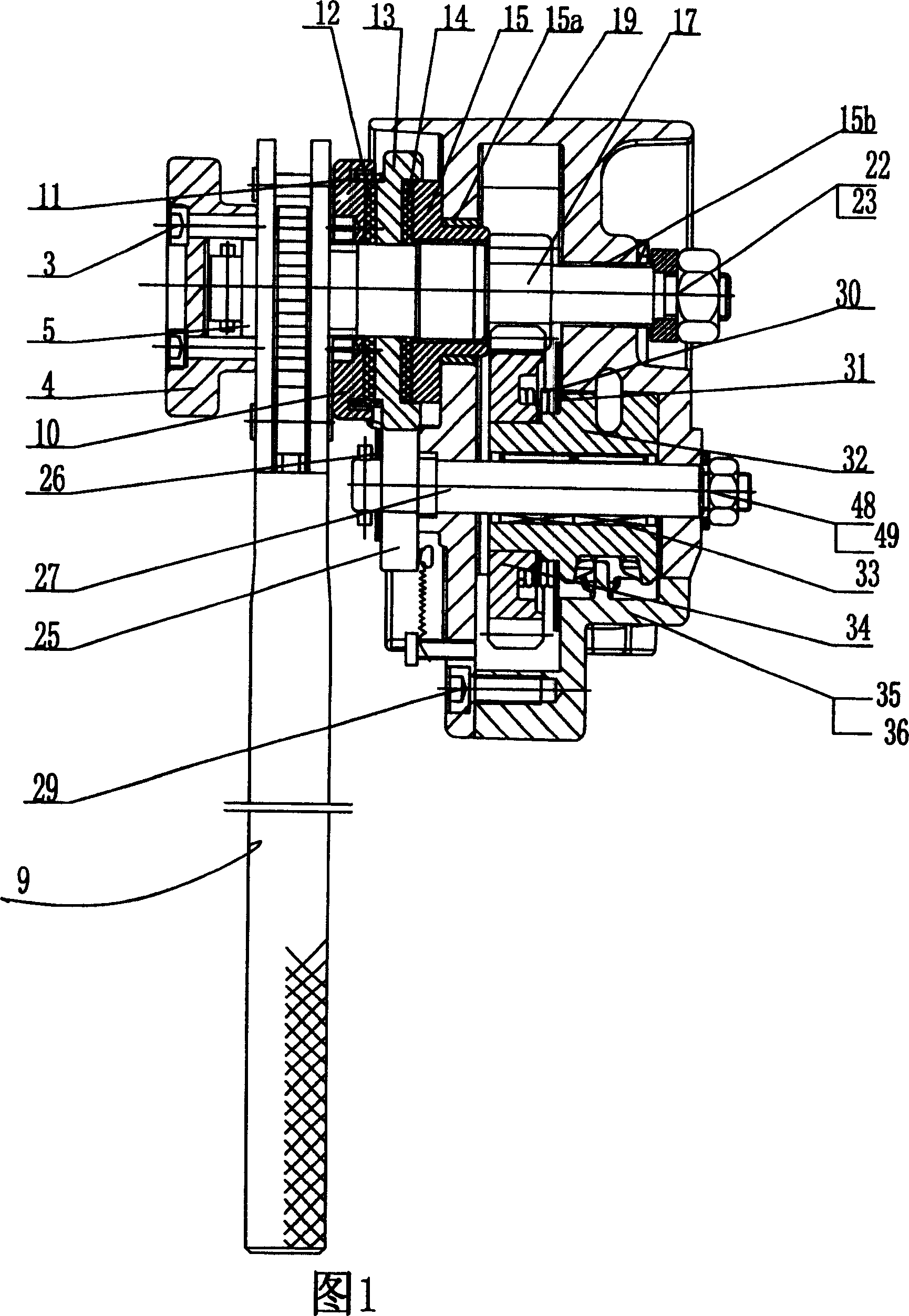

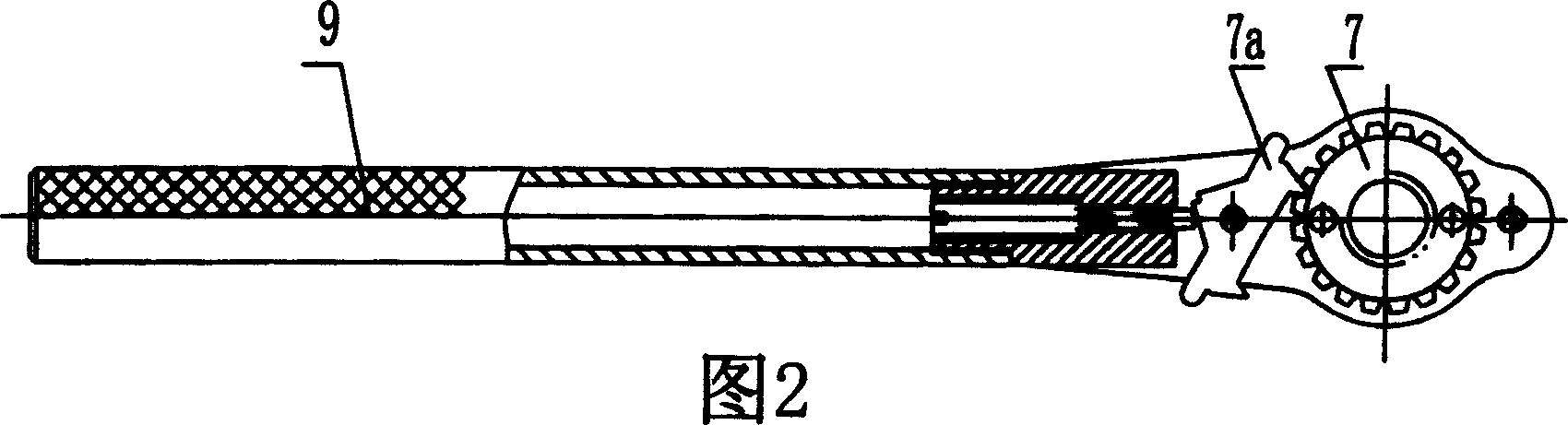

Multifunctional bolt turning tool ratchet handle

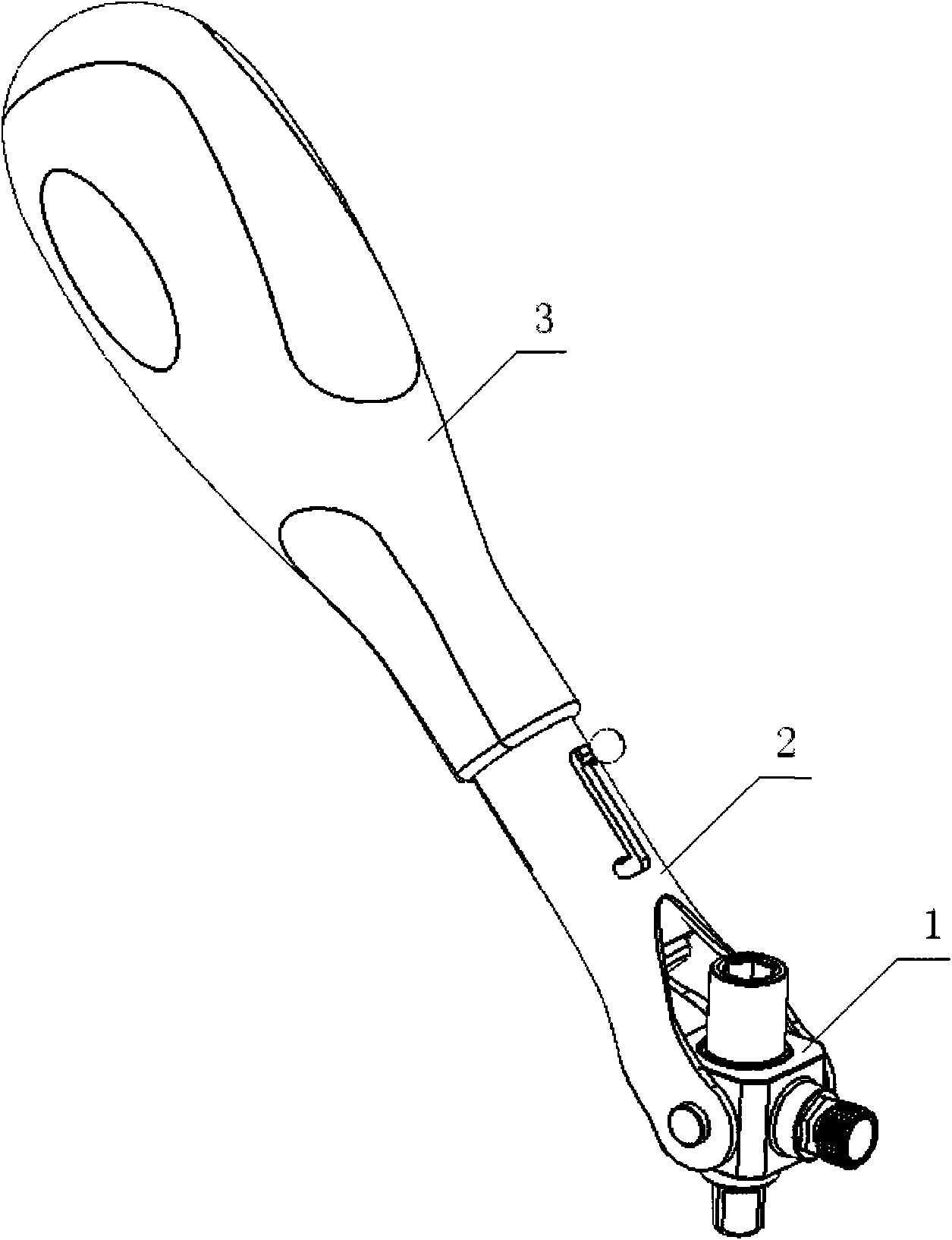

The invention relates to a multifunctional bolt turning tool ratchet handle, in particular to a multi-head multifunctional bolt turning tool ratchet handle which can rotate with 360 DEG and can be used as both screwdriver handle and sleeve spanner handle. The multifunctional bolt turning tool ratchet handle comprises a ratchet part, a handle body and a hand holding part, wherein the back end of the handle body is fixed with the hand holding part, the front end of the handle body is provided with the ratchet part capable of rotating with 360 DEG, the rotating central axis of the ratchet part is vertically intersected with the central axis of the handle, the outer edge of the ratchet part is distributed with a plurality of turning tool joints in radial shape, and the central axes of the turning tool joints and the central axis of the handle are in the same plane. The multifunctional bolt turning tool ratchet handle in the invention is combined with the ratchet bolt turning tool and the ratchet sleeve spanner in the existing technology together and is integrated with multiple specifications of bolt turning tool joints integrally to make up the defects in the existing technology, such as single linking form, single using mode, limited angle adjusting, and inconvenient using and carrying.

Owner:南通海迈五金有限公司

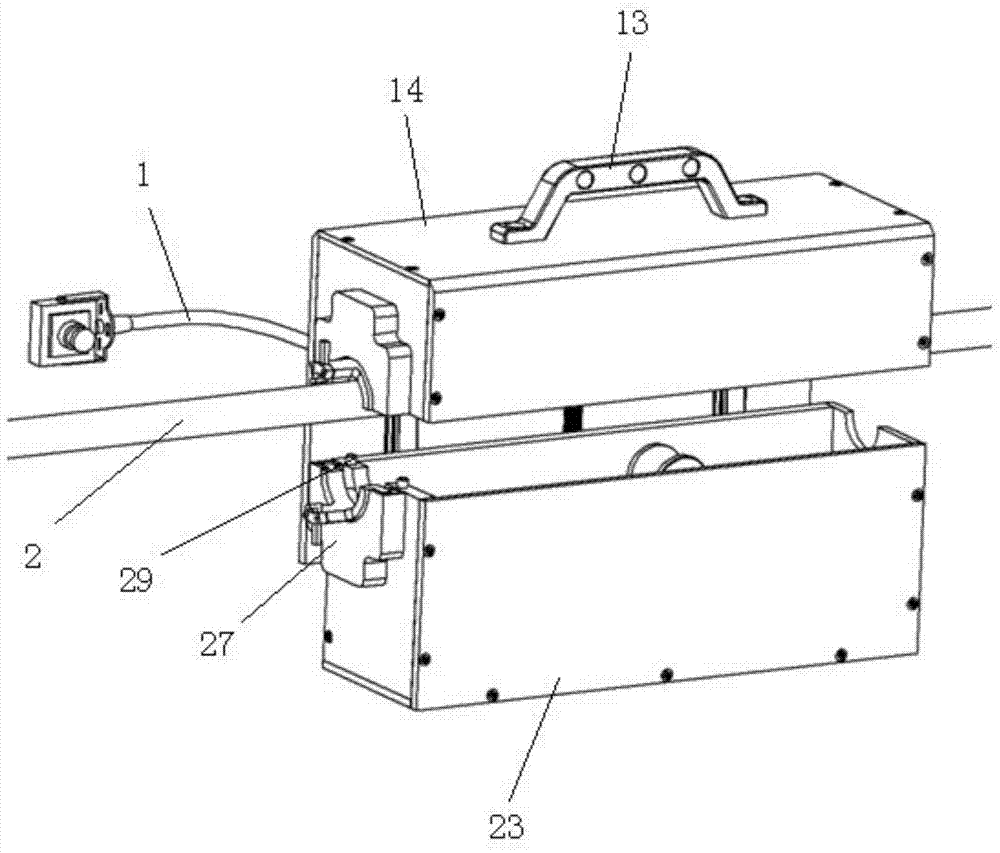

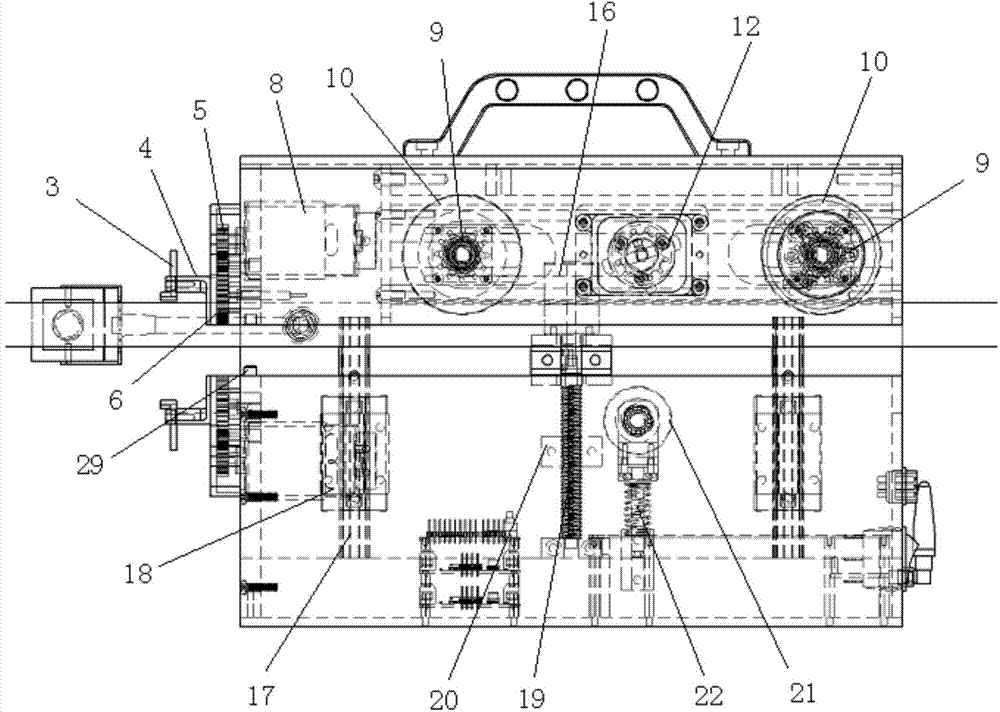

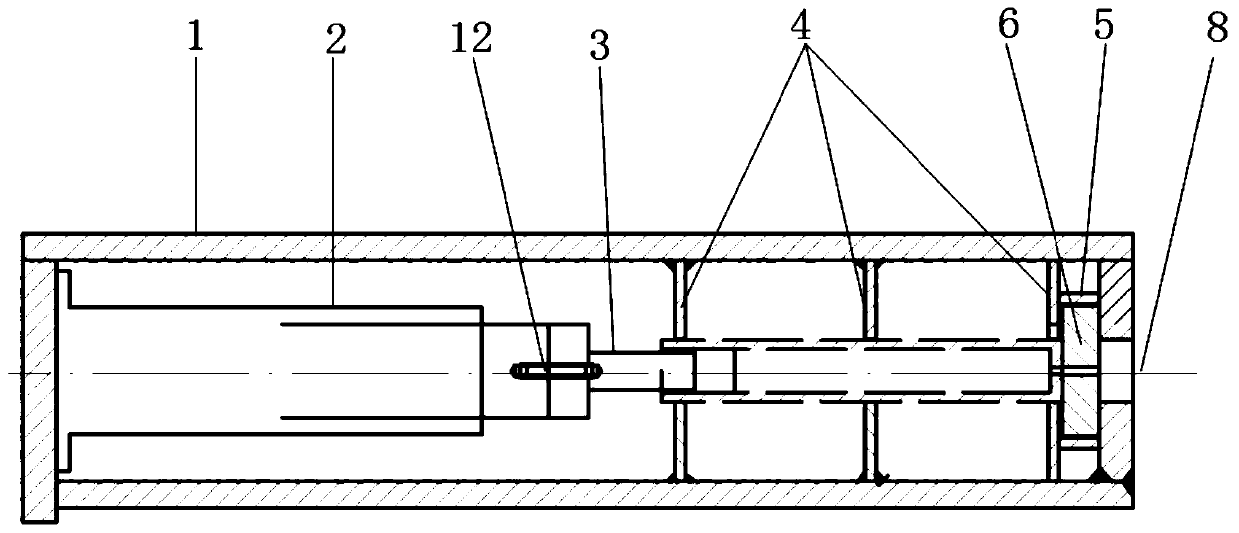

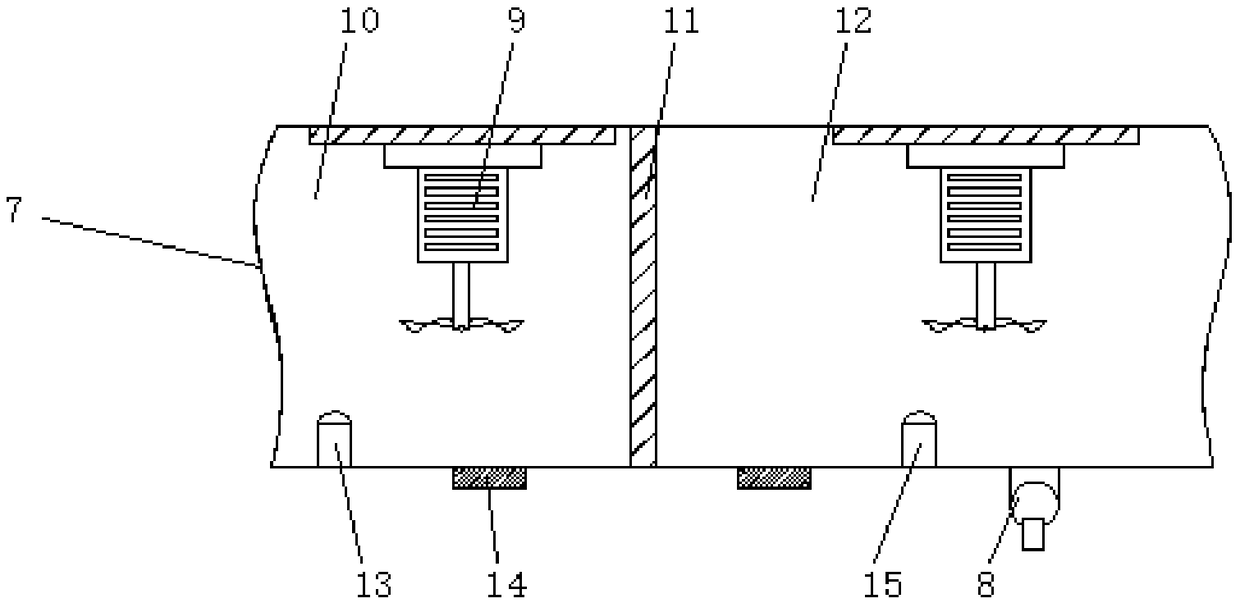

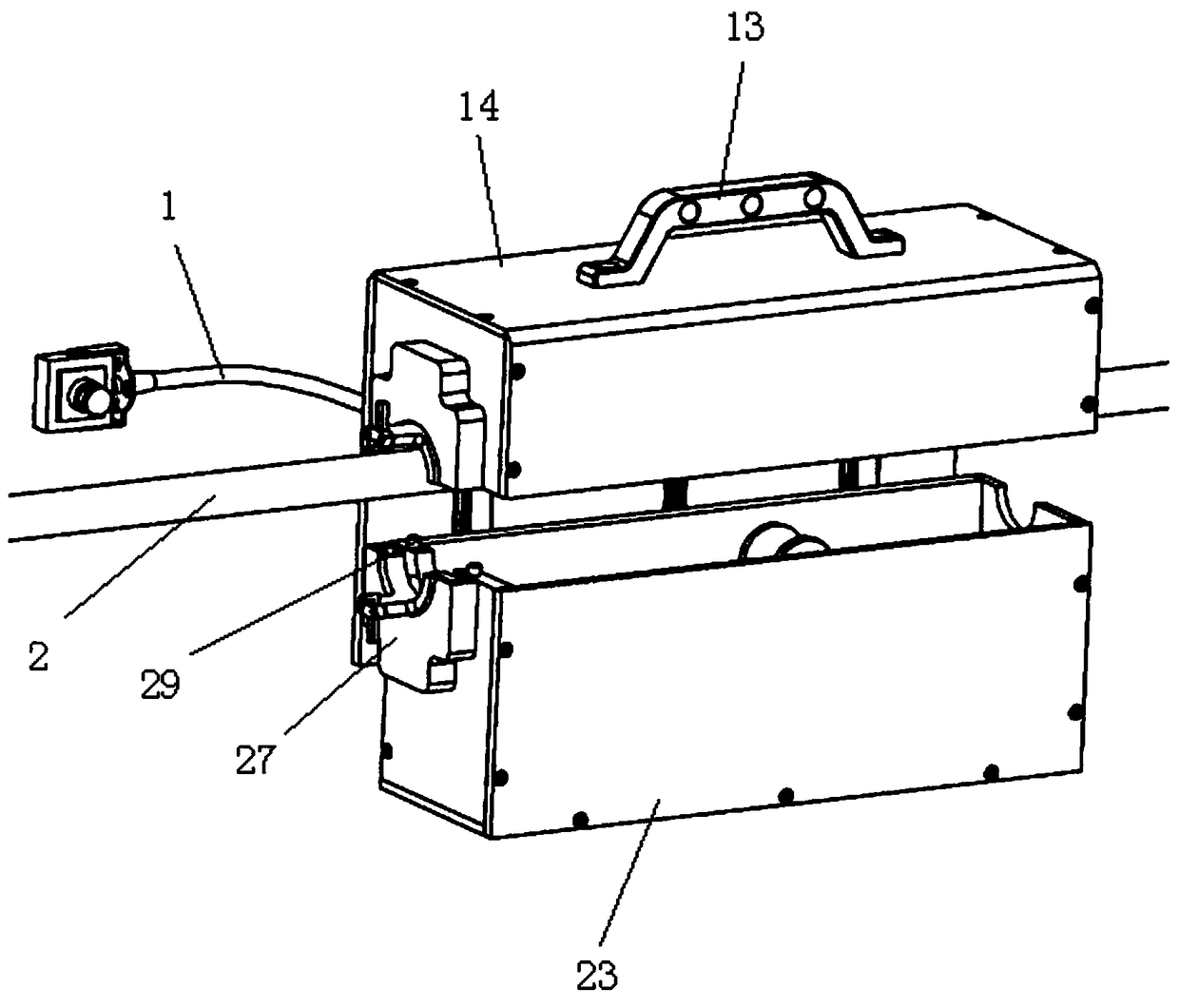

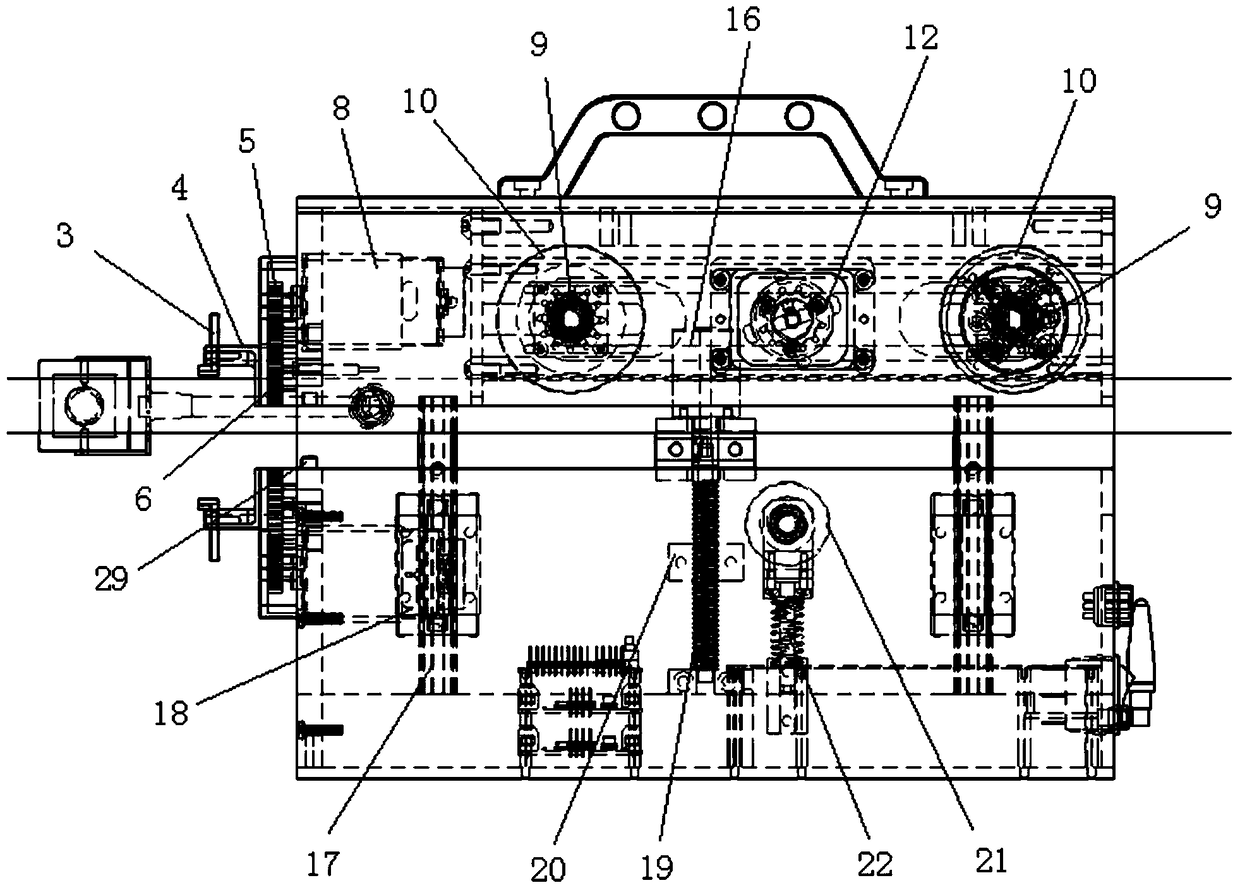

High-tension cable de-icing machine

ActiveCN104716612ACompact structureReduce volumeOverhead installationAcquisition apparatusHigh tension line

The invention discloses a high-tension cable de-icing machine which comprises a split type box. A de-icing high-tension cable penetrates through the box along a semicircular hole, a de-icing mechanism is arranged at one end of the box, and the de-icing mechanism comprises a geared motor, a driving gear and a driven gear, wherein the driving gear and the driven gear are meshed with each other. The driven gear is formed by combining two semicircular gears, and tools are arranged on the end face of the driven gear. A walking driving mechanism and a gear motor are arranged in the box, and an output shaft of the gear motor is connected with driving chain wheels and driven chain wheels through chains. Each driven chain path shaft is sleeved with a polyurethane wheel, and the polyurethane wheels are pressed on the high-tension cable to be de-iced to move forward in a rolling mode along the cable. The high-tension cable de-icing machine further comprises remote video collecting equipment, a lifting mechanism and a pressurizing mechanism. After the de-icing machine is hung on the cable through an insulating rod, a lower box body is driven by the lifting mechanism to be combined together with an upper box body, and the box can achieve the function of fixing other parts and the function of supporting. The de-icing machine is compact in structure, small in size, low in weight and suitable for working high above the ground.

Owner:NANJING HYDRAULIC RES INST

Cable deicing device

ActiveCN108471100AReasonable structural designCompact structureOverhead installationDrive motorEngineering

The invention discloses a cable deicing device comprising an upper casing and a lower casing. A first circular cavity is formed in the lower end of the upper casing; a connecting rod arranged at the upper end of the lower casing is arranged in the first circular cavity and is fixedly connected to the inner wall of the first circular cavity by a first elastic device. A first drive motor is arrangedat the upper end of the upper casing; a first gear is fixedly connected to the tail end of the output shaft of the first drive motor; a rack is fixedly connected to the side wall of the lower casing;and the first gear and the rack are engaged mutually. Besides, a guiding groove is formed in the inner wall of the upper casing; a guide rod is arranged in the guiding groove; the two ends of the guide rod are fixedly connected to the inner wall of the guiding groove; and a guiding block sleeves the guide rod and is connected with the guide rod movably. The cable deicing device having advantagesof reasonable structural design, simple operation, compact structure, small size, reduced material usage, and light mass is suitable for work high above the ground.

Owner:山东智汇新谷科技企业孵化器有限公司

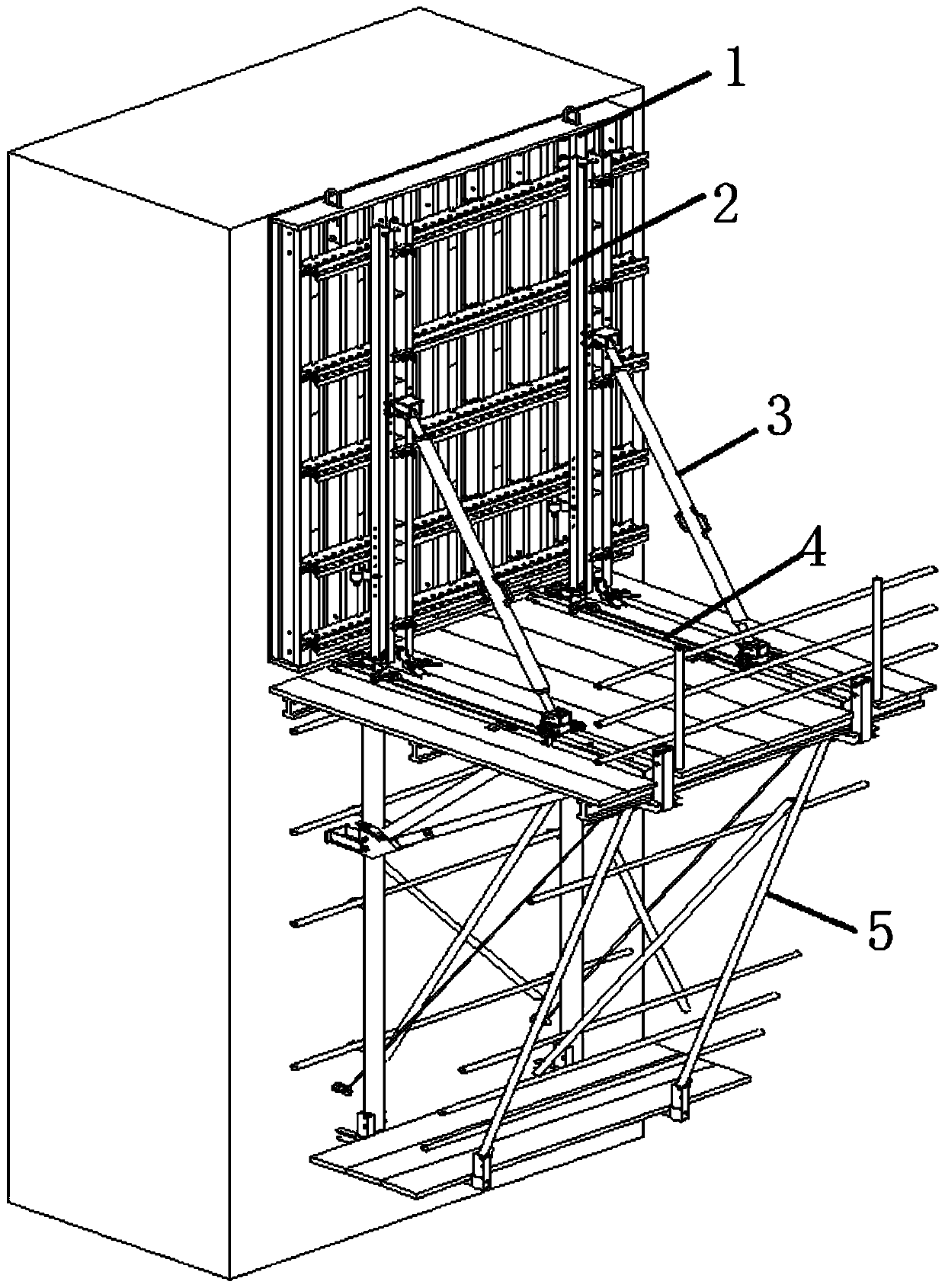

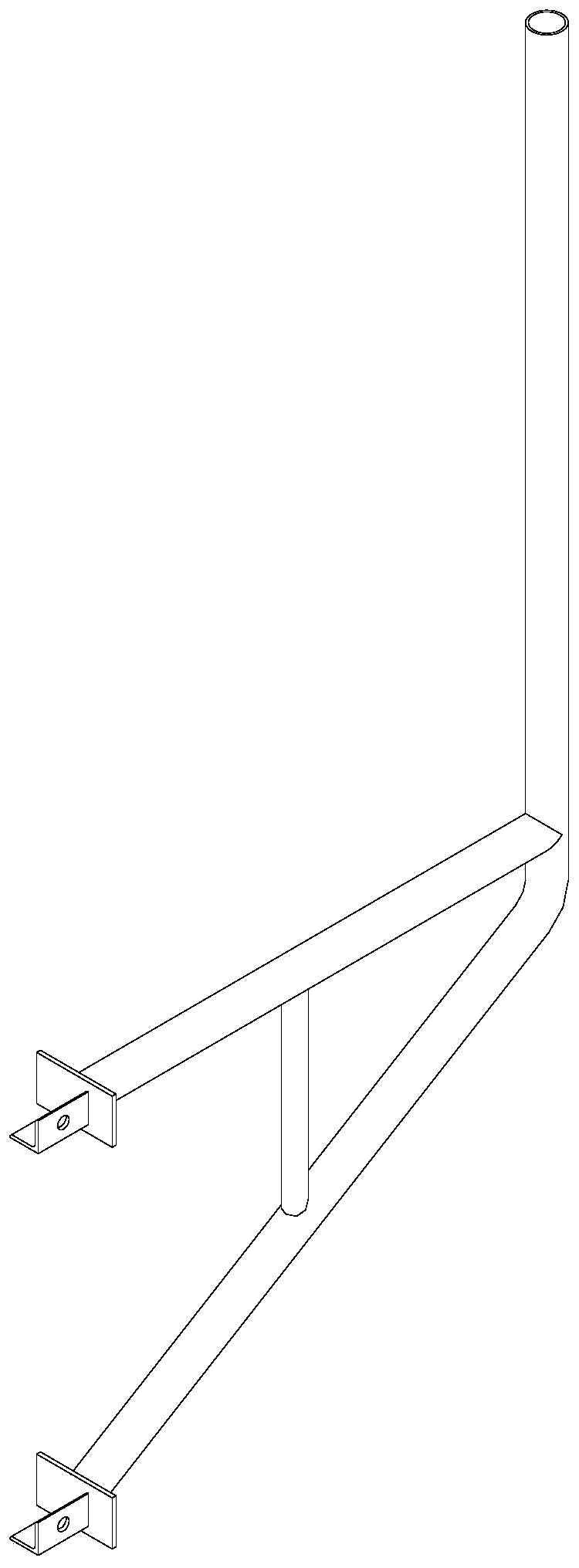

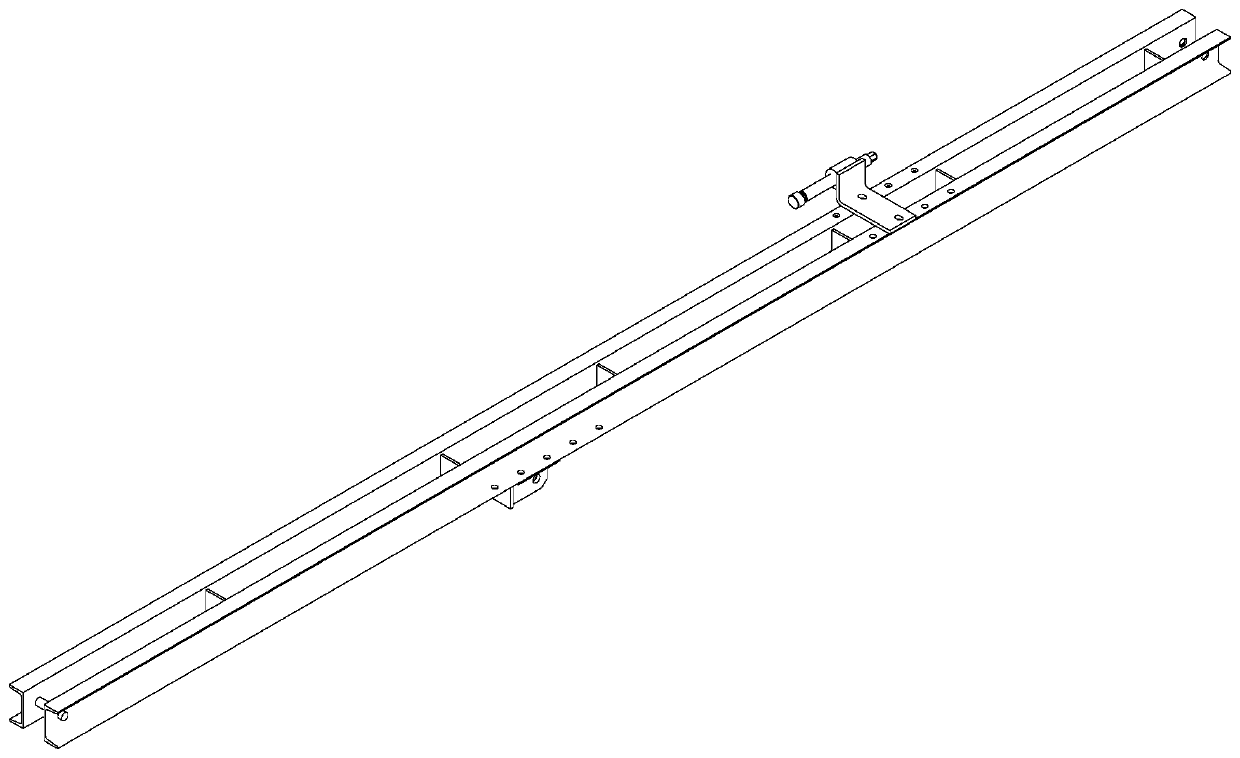

Cantilever formwork for concrete construction and construction method thereof

InactiveCN109989348AEasy constructionFast constructionBridge erection/assemblySurface finishFalsework

The invention discloses a cantilever formwork for concrete construction and a construction method thereof, and belongs to the technical field of bridge construction. The problems that construction iscomplicated, cost is high and concrete surface smoothness is low when the outer surfaces of all supporting columns of a bridge are constructed are solved. The cantilever formwork comprises a cantilever formwork support, an anchoring assembly and a planar formwork and is a single-sided wall body climbing formwork used for formwork construction of concrete linings and other structures of dams, piers, concrete retaining walls, tunnels and underground plants, the formwork is easy and rapid to construct and economical, the concrete surface is smooth, the support, the formwork and construction loadsare all borne by an embedded piece assembly, no scaffold needs to be additionally erected, and the formwork is suitable for aloft operation; by means of an anchoring device, the formwork is closely attached to a concrete wall surface, and mortar leakage and slab end faulting are prevented; an inclined strut is arranged on the cantilever support, and the perpendicularity of the formwork can be conveniently adjusted; all connectors are standard, universality is high, and a hanging platform is arranged at the lower portion of the formwork and can be used for assembling and disassembling embeddedpieces and processing the concrete surface.

Owner:中交中南工程局有限公司 +1

Hinge type middle jointing clamp

InactiveCN102170051APowerfulLow costClamped/spring connectionsMultiple conductors connectorEngineeringBase station

The invention discloses a hinge type middle jointing clamp which comprises a hinge structure, an elastic taper sleeve, a hexagonal nut, a spring spacer and the like, wherein two jointing seats form the hinge structure through bolts. The hinge type middle jointing clamp disclosed by the invention can be divided into various types according to the different line diameters of single-end and double-end jointing clamps and a main line rope connected with the single-end and double-end jointing clamps, and is suitable for the jumper connection of the T-shaped joints of lines, the bus and isolating switch of a base station and the like. Compared with the traditional T-shaped jointing clamp, the hinge type middle jointing clamp disclosed by the invention has the advantages of rapidness and convenience in installation and the like.

Owner:国网安徽广德县供电有限责任公司

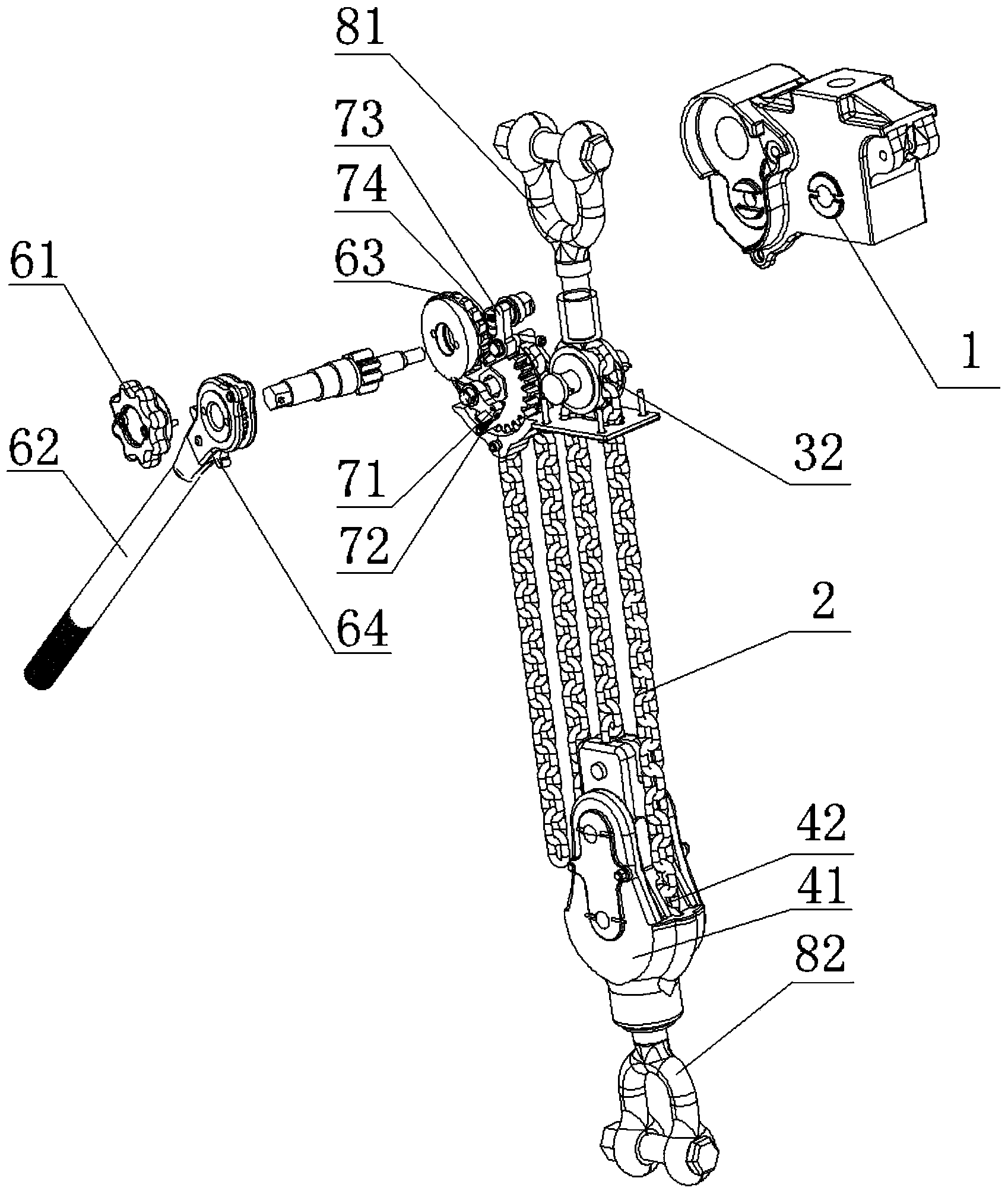

Lever pulley block convenient to use

The invention discloses a lever pulley block convenient to use. The lever pulley block comprises a main body shell, a ratchet wrench device, a driven sprocket device, a glasal plate assembly and a chain assembly, wherein an anti-reversal gear transmission mechanism and a sprocket transmission mechanism are arranged in the main body shell; the chain assembly comprises three rows of chains; a small sprocket mechanism is arranged in the main body shell; the driven sprocket device comprises a big sprocket mechanism; the small sprocket mechanism comprises a first shell and a fixed pulley arranged in the first shell; the big sprocket mechanism comprises a second shell and a moveable pulley arranged in the second shell; a first chain hole and a second chain hole are formed in the bottom of the main body shell; one ends of the chains are arranged at the upper end of the second shell, and the other ends of the chains sequentially bypass the fixed pulley and the moveable pulley in a surrounding manner, pass through the first chain hole, surround the main shaft of the sprocket transmission mechanism and pass through the second chain hole. The invention has the advantages that the lever pulley block is simple and compact in structure, less susceptible to deformation, flexible and handy to use, convenient and safe, and is applicable to aloft operation.

Owner:王震

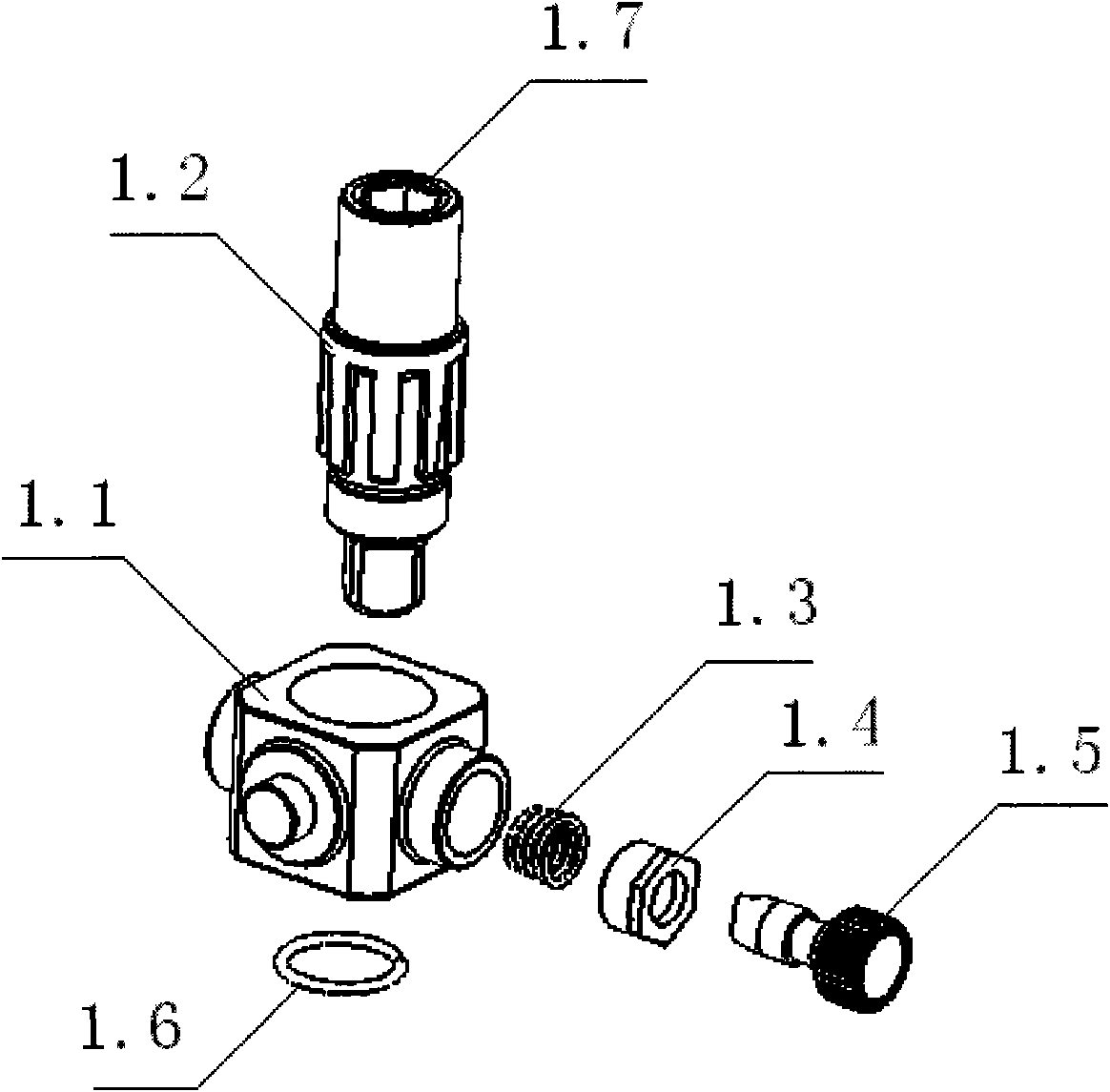

Electric-melted pipeline press-fitting process, press-fitting tool and press-fitting tool manufacturing process

PendingCN113635258ADifficult and easy to affectSize Difficulty AffectedMetal-working hand toolsPipe fittingPipe

An electric-melted pipeline press-fitting process comprises the following steps of performing oxide layer removing and polishing operation on the surface of an electric-melted pipeline inserting part, polishing an extremely thin surface layer, and keeping the cylindricity precision of the polished part basically unchanged; selecting a pressing disc, an electric-melted direct pipe fitting, an elbow pressing frame and a tee pressing frame pressing tool which are matched with the pipeline and the pipe fitting which are to be assembled, and mounting the pipeline and the pipe fitting on the pressing tool; and synchronously rotating a nut, and driving the pipeline and the pipe fitting to move oppositely in a relative spiral rotation mode to finish spiral press-fitting assembly of the pipeline and the pipe fitting. And then electrifying and welding are conducted. The invention further relates to a press-fitting tool and a manufacturing method of the press-fitting tool; after the press-fitting tool is used, the welding quality can be guaranteed through the assembly interference magnitude of the electric-melted pipeline and the pipe fitting, the welding quality cannot be affected by the small interference magnitude, and the threshold value of the interference magnitude is much larger than that of the prior art; and the press-fitting tool has the advantages that the whole device is simple, the operation is convenient, the process is suitable for space-limited and high-altitude environment operation, and the application range is wide.

Owner:江西铜业集团(贵溪)防腐工程有限公司

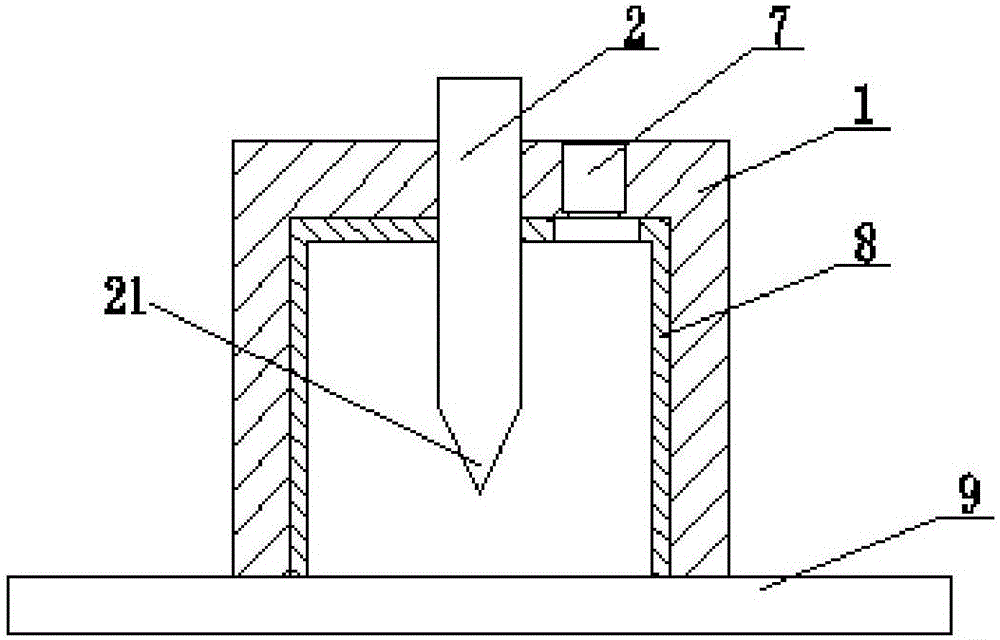

Portable and movable laser drilling and cutting equipment

InactiveCN106514013ARealize the combinationSuitable for working at heightsLaser beam welding apparatusHead movementsHigh power lasers

The invention provides portable and movable laser drilling / cutting equipment. The portable and movable laser drilling / cutting equipment comprises a laser machining head movement rack, a laser machining head, an ultra-long transmission cable, an optical fiber laser, a portable control device and a shielding gas device. The laser machining head has a focal depth adjustment function and the like and can be used for machining high-hardness and high-tenacity thick metal plates. The ultra-long transmission cable is internally provided with a circuit control cable, a shielding gas path, optical fibers and the like and connected to the laser machining head, the laser, the portable control device, the shielding gas device and the like. The portable control device has the function of controlling starting and stopping of gas supply, the light emitting power and time of the laser, the movement track of the laser machining head and the like and is convenient to move. In addition, a protection cover can protect the safety of operators. The portable and movable laser drilling / cutting equipment creatively combines laser drilling / cutting with long-distance high-power laser transmission and is suitable for working aloft; and focal depth can be adjusted, and the equipment can be used for machining thick metal plates; and the portable and movable laser drilling / cutting equipment is convenient to move, high in applicability, high in safety, and convenient to use and popularize.

Owner:HARGLO APPLIED LASER TECH INST CO LTD

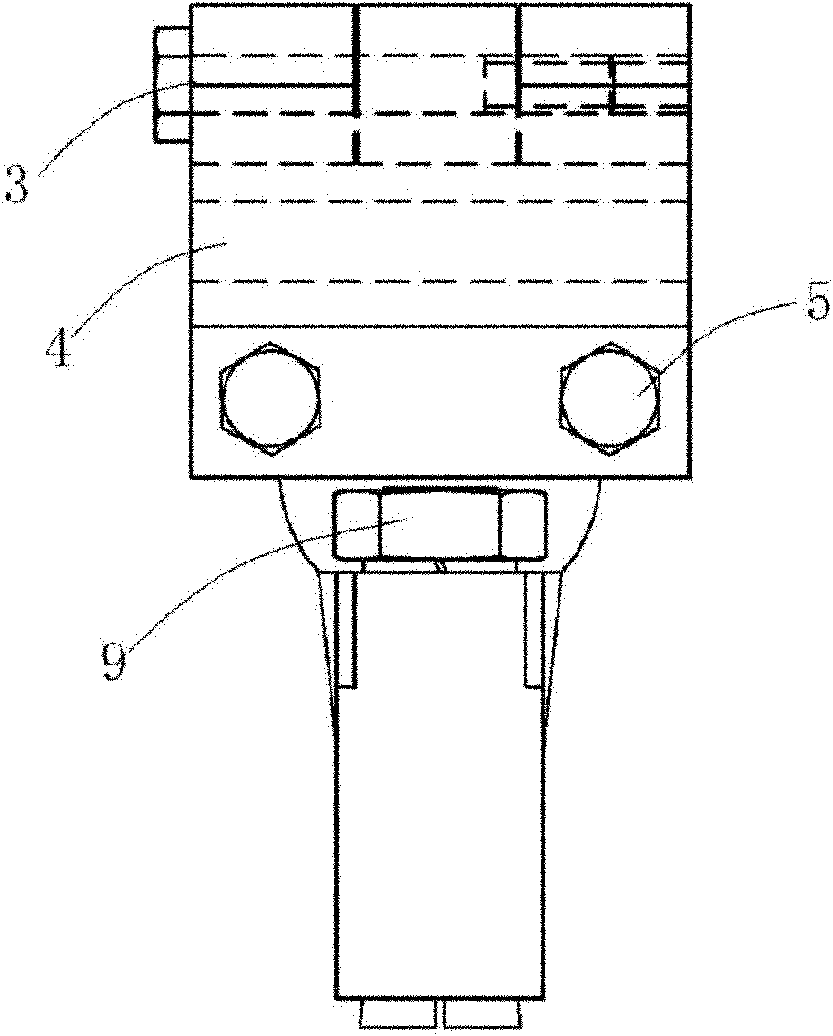

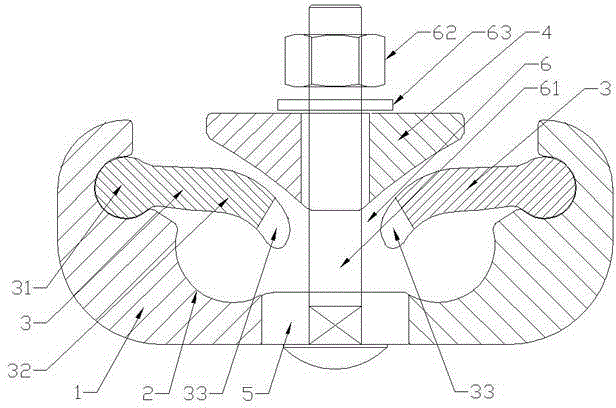

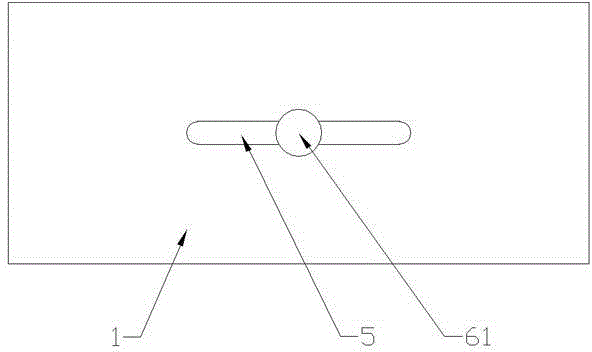

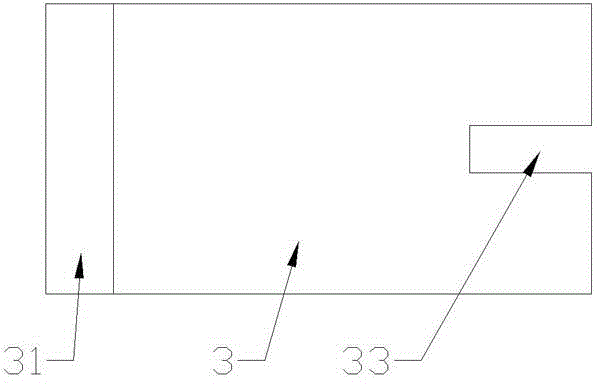

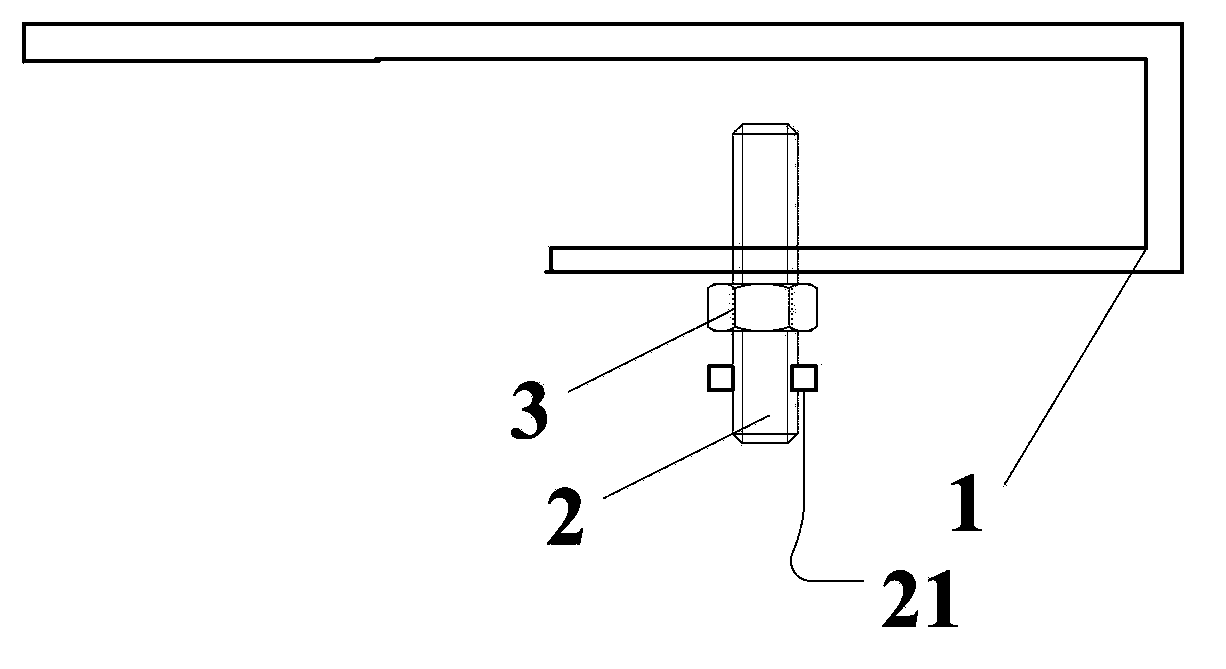

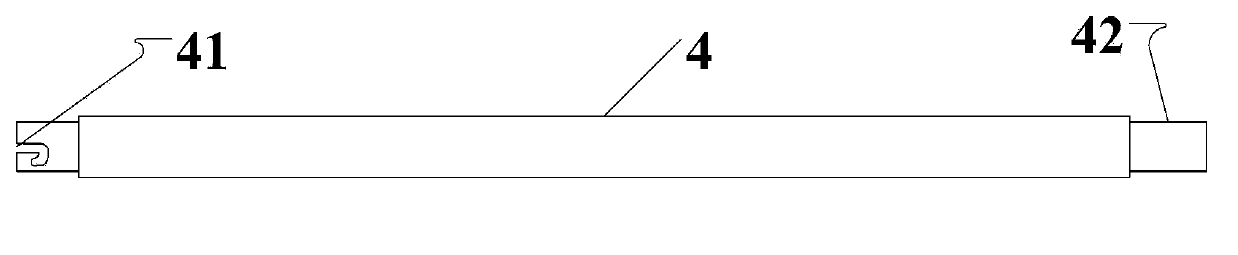

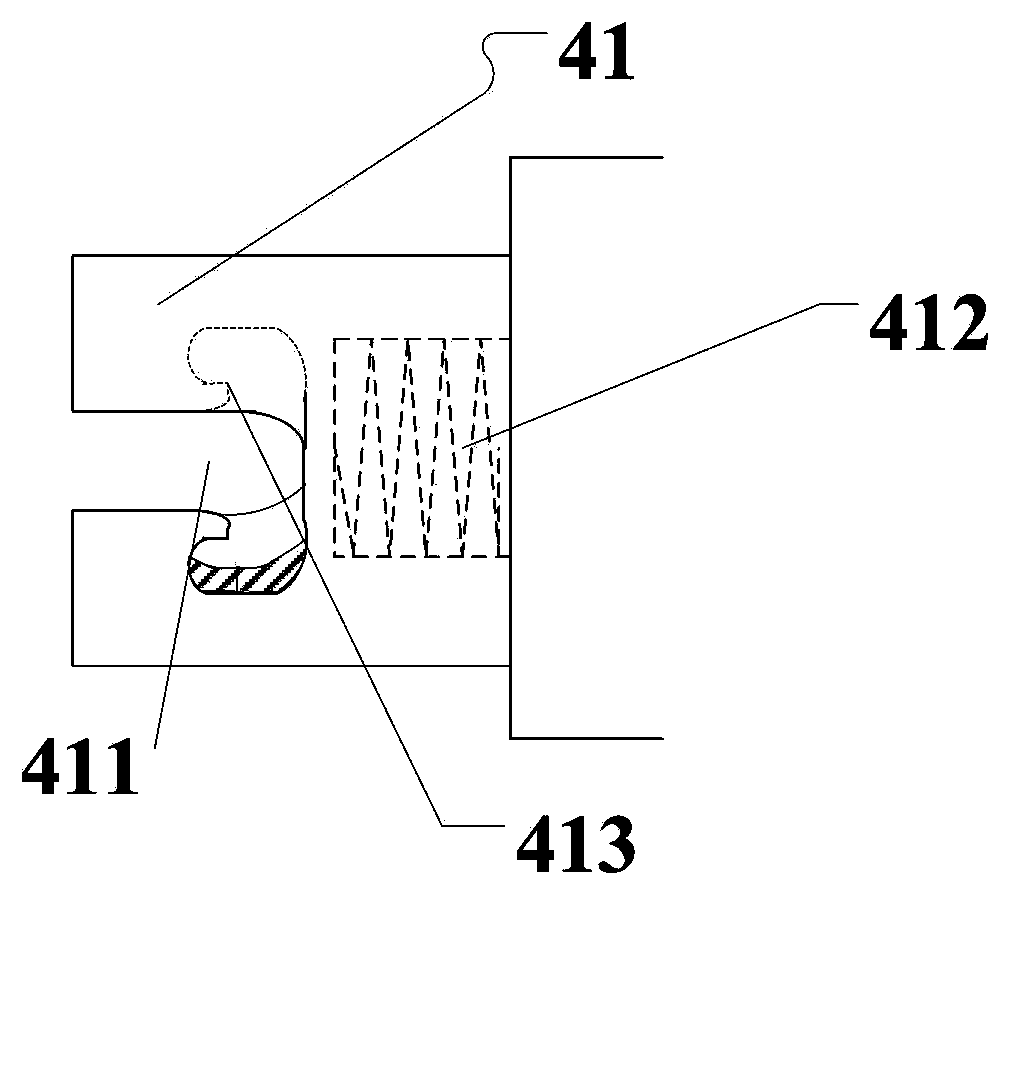

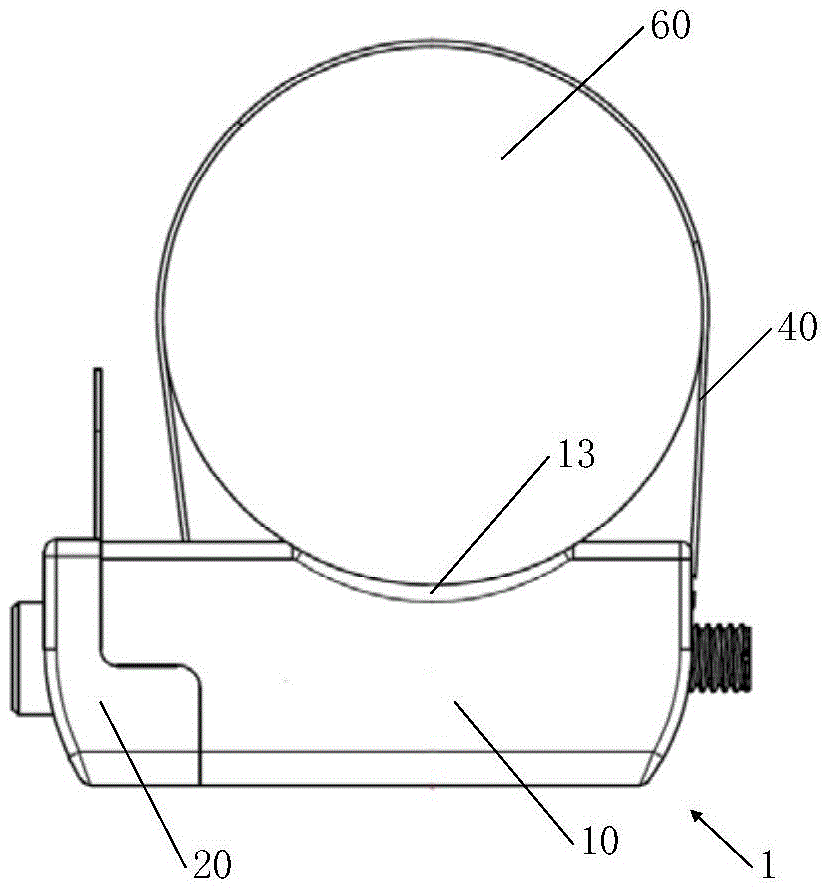

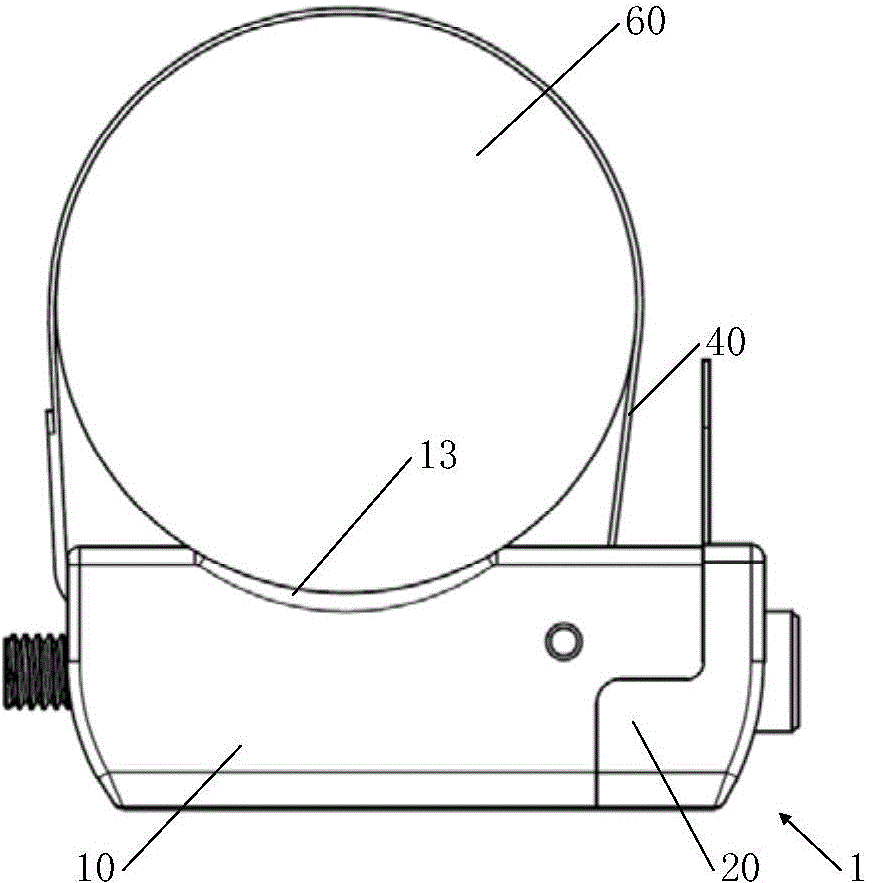

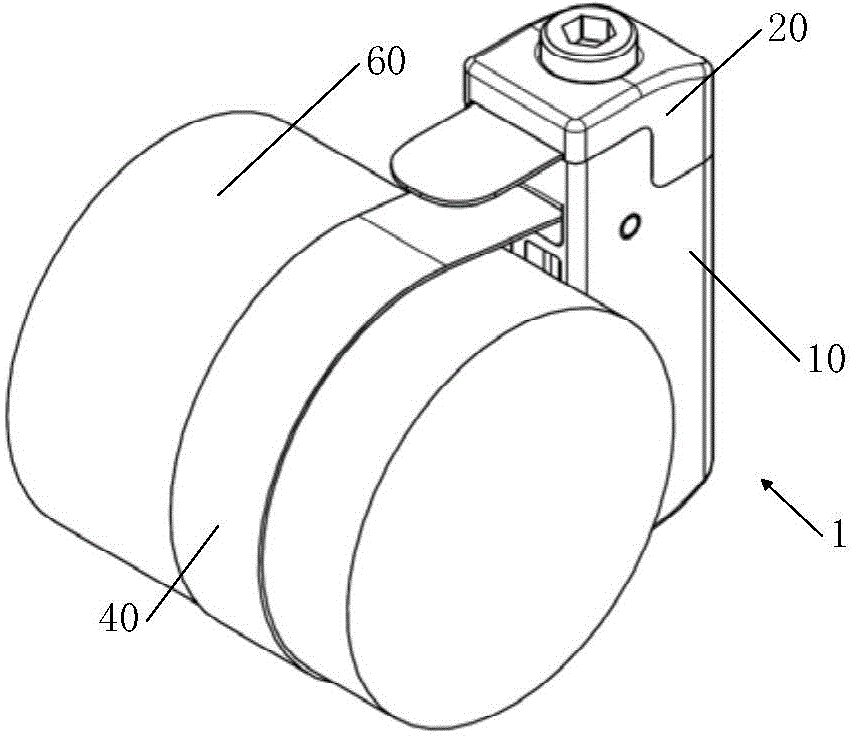

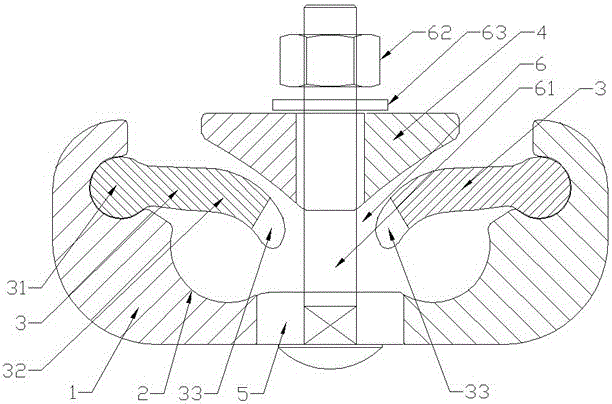

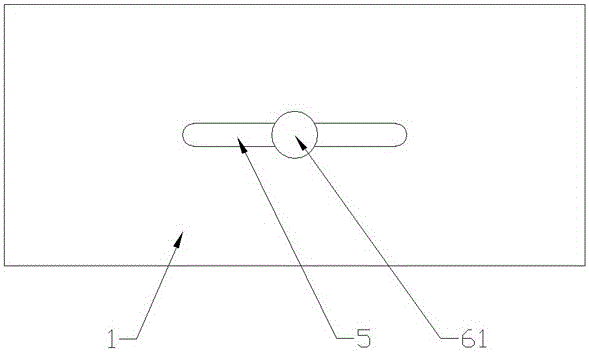

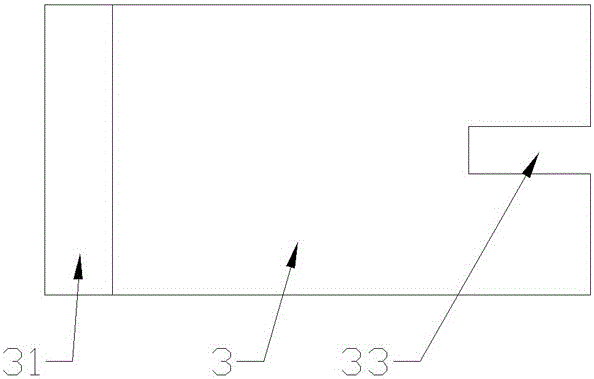

General connecting cable clamp

ActiveCN104701648ASimple structureSolve easy feverElectric connection structural associationsClamped/spring connectionsEngineeringElectrical and Electronics engineering

The invention aims to provide a general connecting cable clamp which is simple in structure, safe and reliable and capable of being suitable for connecting guide wires with different diameters. The general connecting cable clamp comprises a cable clamp body (1), wherein a cable slot (2) is formed in the cable clamp body (1); a hinged block (3) is hinged at one side of the cable slot (2); the cable clamp further comprises a pressing block (4), a long-strip-shaped through hole (5) penetrating through the cable clamp body (1) and a bolt device (6) of the pressing block (4), the pressing block (4) presses the hinged block (3) and drives the hinged block (3) to press a guide wire in the cable slot (2). The general connecting cable clamp can be applied to the electric equipment field.

Owner:ZHUHAI ZHONGLI ELECTRICAL EQUIP

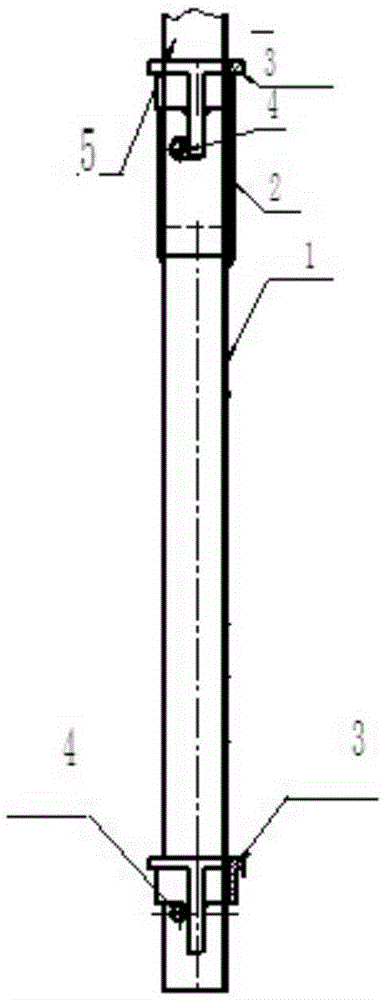

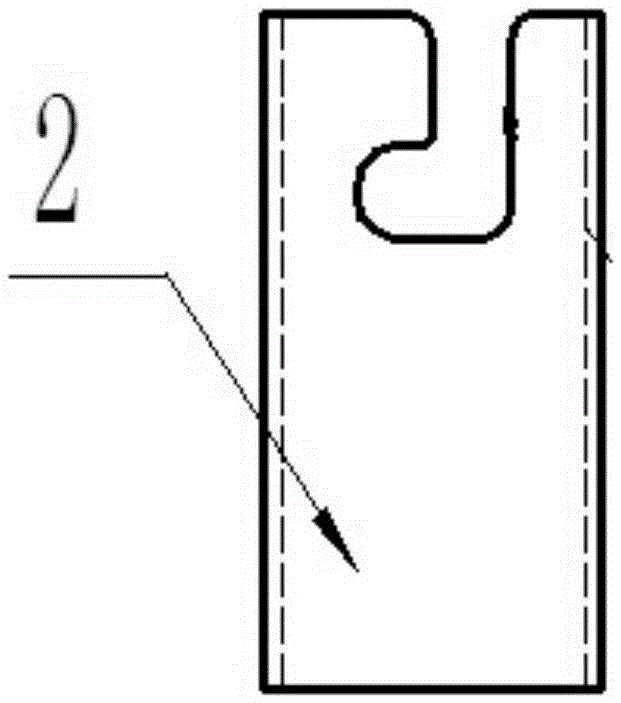

Mounting method and fast connection locking mechanism for vertical rods of steel pipe scaffolds

ActiveCN105239768AQuick lockReduce on-site installation processScaffold connectionsLocking mechanismEngineering

The invention provides a fast connection locking mechanism for vertical rods of steel pipe scaffolds. A pair of symmetrical notch slide ways fixed in length and width is arranged at one end of a lock notch sleeve of the locking mechanism, the bottom of a notch is provided with two semicircular lock notches after 90-degree rotation, and the semicircular lock notches sleeve the upper end of one vertical rod and are positioned and firmly welded onto the vertical rod to form the fixed lock notch sleeve. A pair of symmetrical lock fasteners in fixed length and width is arranged on a sleeve lock fastener and sleeves the lower end of the vertical rod, and a lock nail is inserted into a positioning hole in the lower end of the vertical rod to prevent the sleeve lock fastener from slipping so as to form a vertically slidable sleeve lock fastener. The invention further provides a method of using the fast connection locking mechanism for fast connection locking of the vertical rods. The fast connection locking mechanism for the vertical rods of the steel pipe scaffolds has the advantages that firstly, at most eight transverse rods, including diagonal pulling rods, can be overlapped at any angle in 360-degree horizontal direction of a vertical rod lock disk without direction limits; secondly, quick locking in connection of the vertical rods can be realized, and accordingly reduction of onsite mounting procedures, convenience in mounting and demounting and low time consumption are realized, and the fast connection locking mechanism is more suitable for aloft work.

Owner:天津市隆宝钢管有限公司

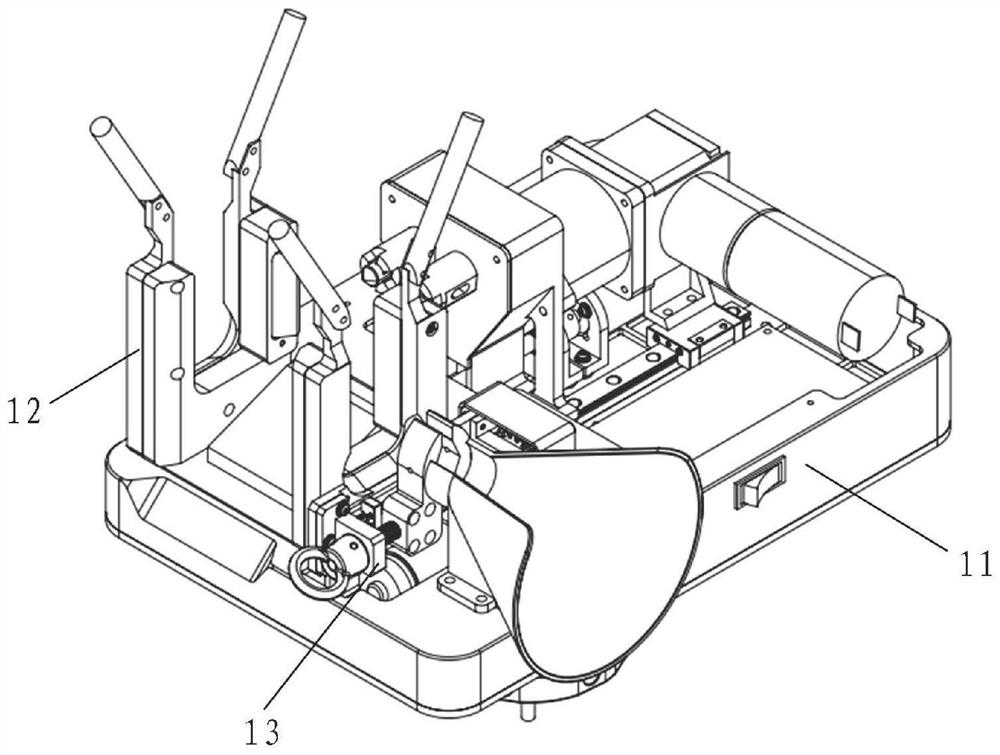

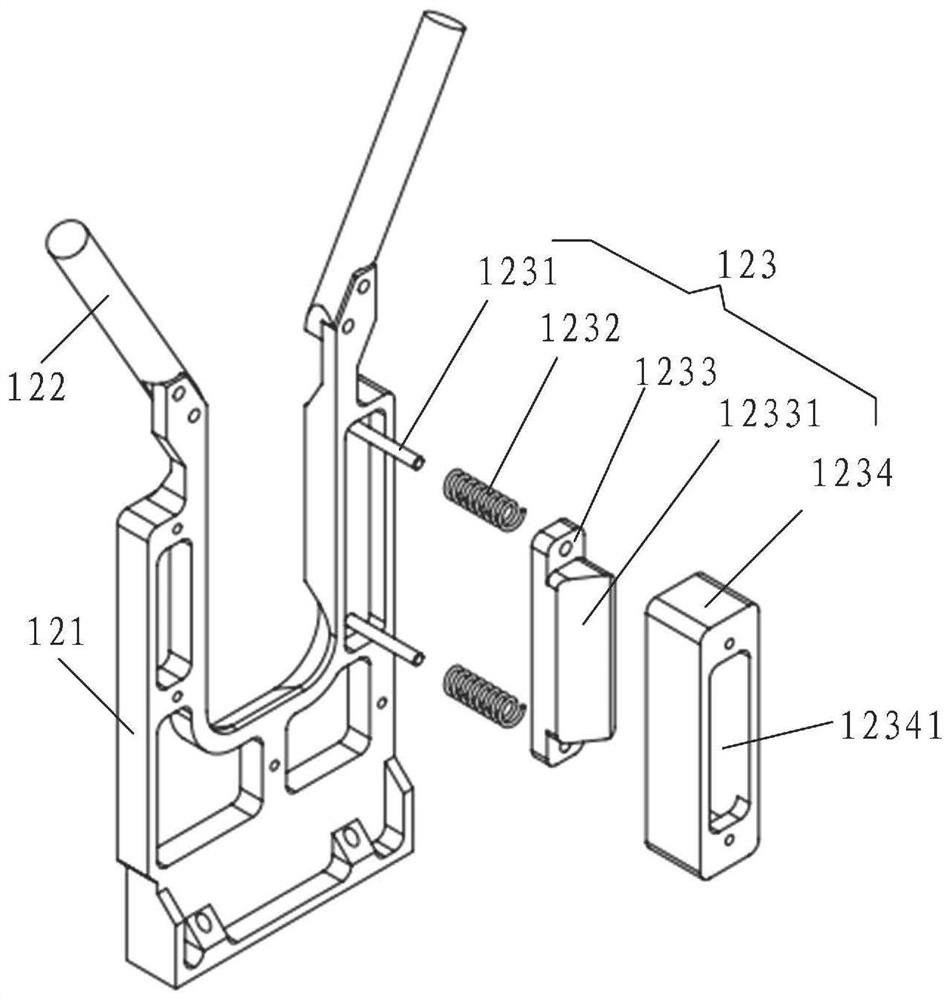

Live-line work robot lead lap joint device and lap joint method

PendingCN114552497ALower requirementReduce power and weightBus-bar installationManipulatorLap jointEngineering

The invention discloses a hot-line work robot lead lap joint device and method. The device comprises a wiring tool and a wire clamp. The wiring tool comprises a rack, a wire clamp mounting mechanism, a lead clamping mechanism and a wire clamp tightening mechanism, the wire clamp mounting mechanism and the lead wire clamping mechanism are arranged at the front end above the rack side by side, and the wire clamp tightening mechanism is arranged at the rear end above the rack; the wire clamp comprises a front side part and a rear side part, the front side part and the rear side part are connected through at least one pair of bolts, and a bus groove and a lead groove for a bus and a lead to pass through are formed between the front side part and the rear side part; the wire clamp mounting mechanism is used for clamping a wire clamp; the lead enters the lead groove of the wire clamp from the lead guide groove and then is clamped by the lead clamping mechanism; the wire clamp tightening mechanism comprises two screwdriver head assembly units and a screwdriver head driving unit, wherein the two screwdriver head assembly units are designed side by side. According to the invention, the wire clamp nut can be uniaxially and asynchronously screwed, the wiring tool and the wire clamp can be automatically separated after screwing, and the power consumption is low.

Owner:福建大观电子科技有限公司

Cable terminal fastener

InactiveCN106655022ALabor-saving and fast bending and pressingSuitable for working at heightsSuspension arrangements for electric cablesApparatus for joining/termination cablesFastenerEngineering

The invention discloses a cable terminal fastener, which comprises a wire pressing body, a movable pressure block and a compression screw, wherein the top and the bottom of the wire pressing body are oppositely arranged; the movable pressure block is located between the top and the bottom of the wire pressing body and is opposite to the bottom; wire clamping structures for clamping a cable in a fit manner are arranged at the bottom of the wire pressing body and on the lower surface of the movable pressure block respectively; the compression screw vertically passes through a threaded hole in one side of the movable pressure block and is in threaded connection with the threaded hole; two ends of the compression screw are rotationally connected with the top and the bottom of the wire pressing body respectively; the reciprocating motion of the movable pressure block relative to the bottom of the wire pressing body can be adjusted through rotating the compression screw; and the wire pressing body is provided with a limiting mechanism for limiting the movable pressure block to prevent the movable pressure block from rotating relative to the wire pressing body. According to the cable terminal fastener, the labor can be saved, the end of the cable around a street code insulator can be quickly bent and pressed together and the position of a tightening tool does not need to be moved during operation, so that the operation space and the operation difficulty are reduced.

Owner:GUANGZHOU PANYU CABLE WORKS

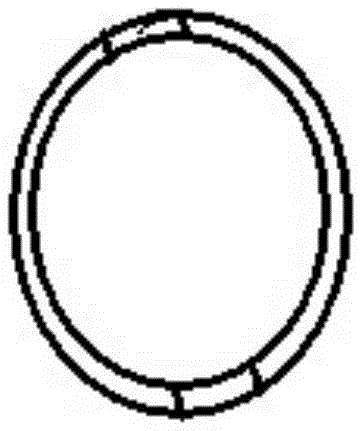

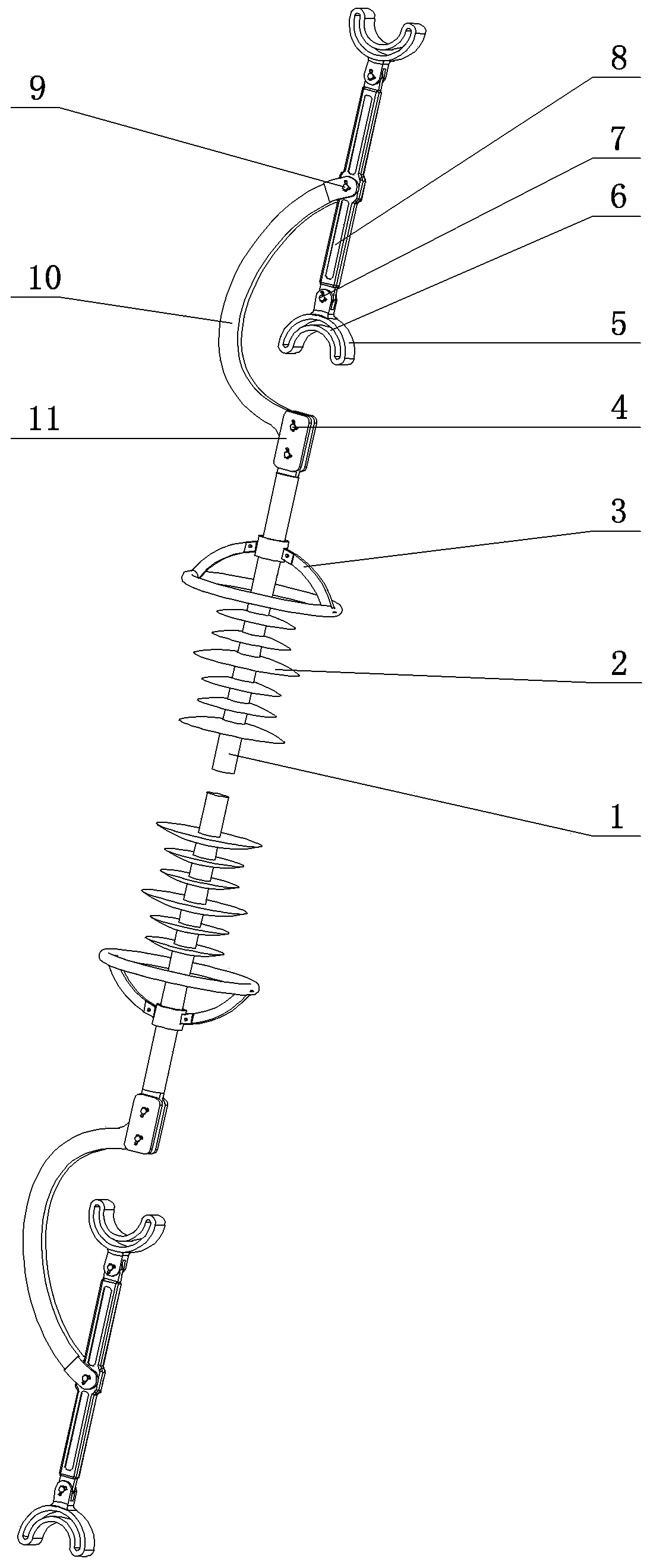

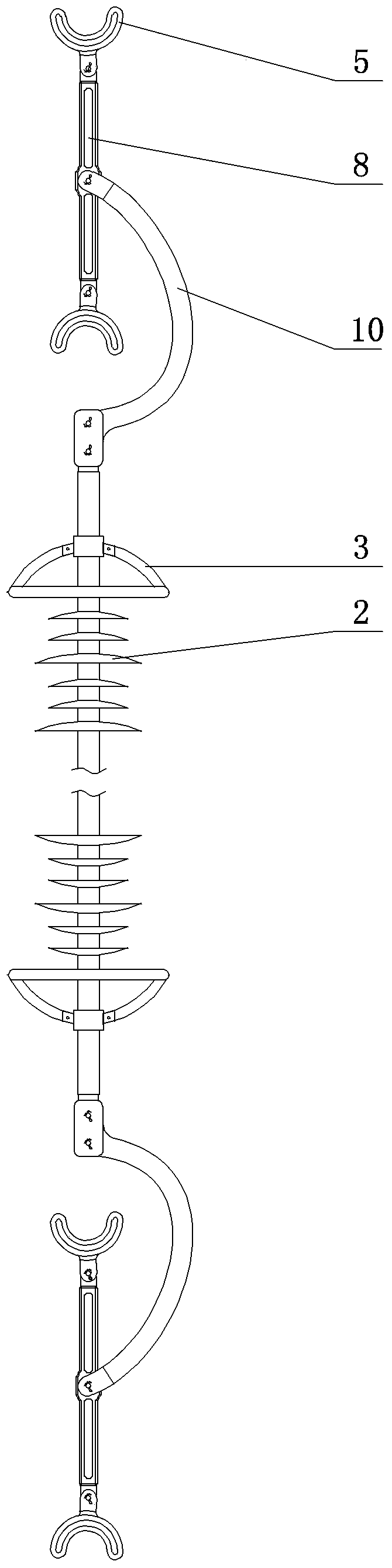

Pre-twisted spacer

InactiveCN107845995ANo damageImprove grip strengthMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsEngineeringStructuring element

A pre-twisted spacer bar belongs to the technical field of spacer devices for overhead wires of power transmission lines, and in particular relates to a pre-twisted spacer bar. The invention provides a pre-twisted spacer bar which can improve the stress performance between the spacer bar and the conductor and is easy to install. The present invention includes a support rod, and its structural points are wire clips arranged at both ends of the support rod. There are pre-twisted wires in the inner thread; the inner end of the clamp is a connecting splint, and the connecting splint and the end of the support rod are provided with a connecting hole correspondingly. There is a horizontal positioning hole on the top, and a positioning pin is inserted in the positioning hole; the middle part of the support rod is connected with one end of the arc-shaped rotary arm through a pin shaft, and the other end of the arc-shaped rotary arm is fixed with the connecting plate at the end of the mandrel, and the mandrel There are umbrella skirt groups on both sides, and a pressure equalizing ring is arranged on the mandrel near the end of the mandrel.

Owner:STATE GRID LIAONING ELECTRIC POWER CO LTD SHENYANG POWER +1

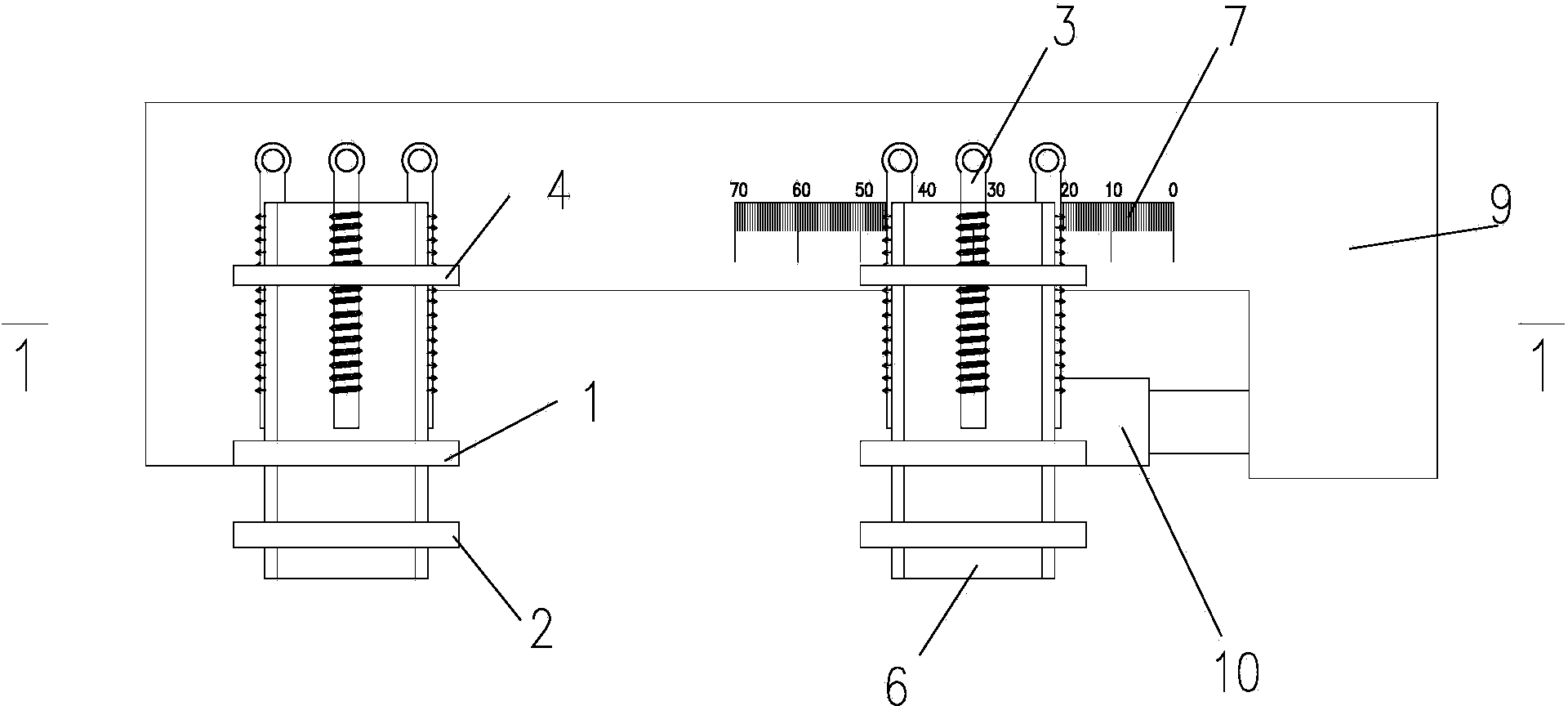

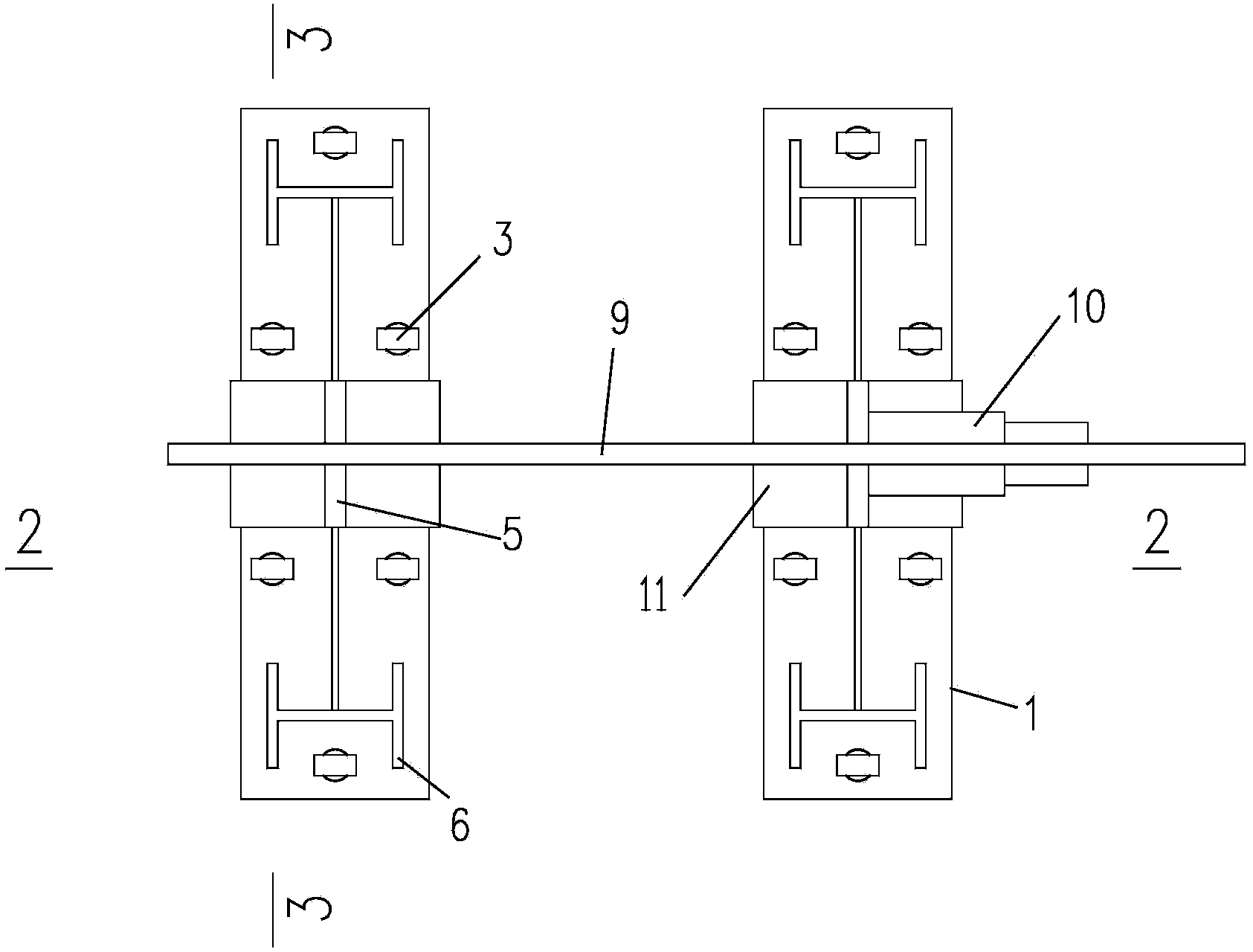

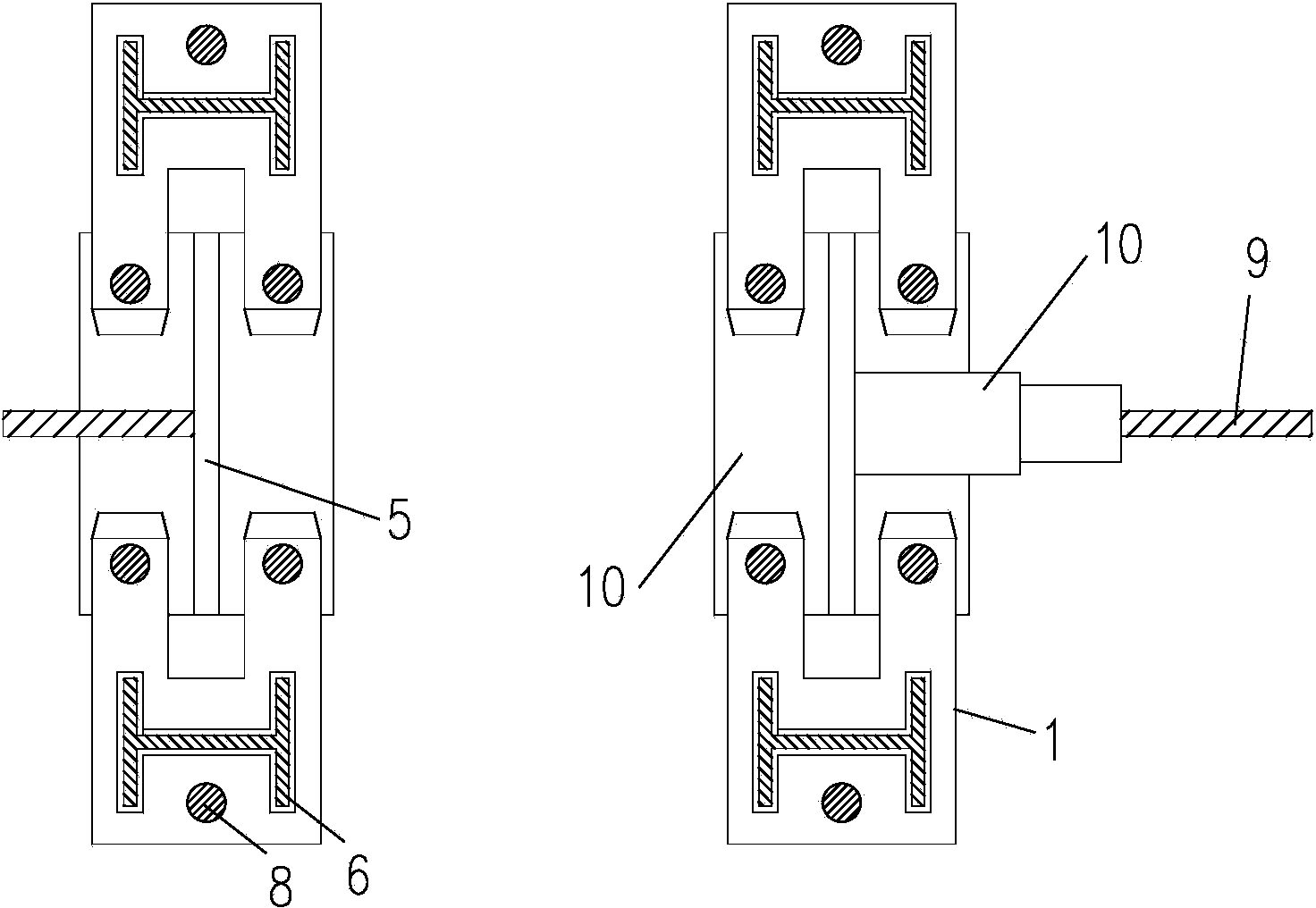

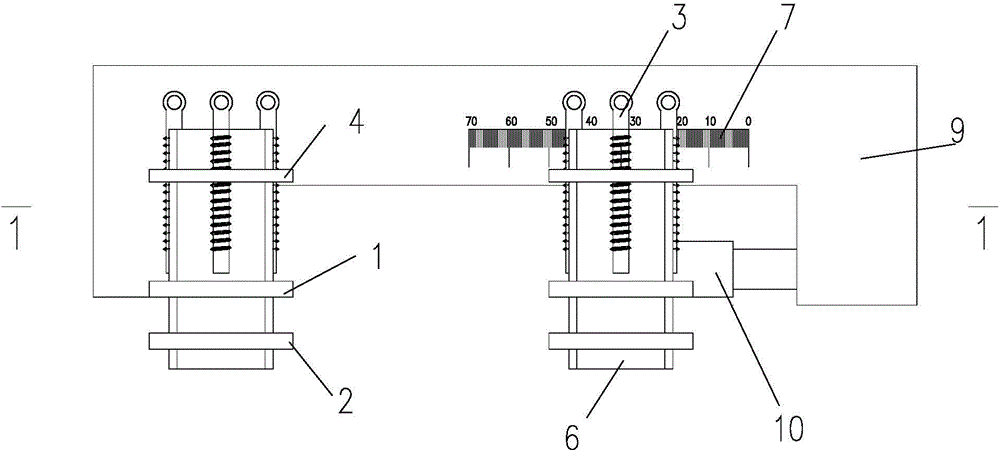

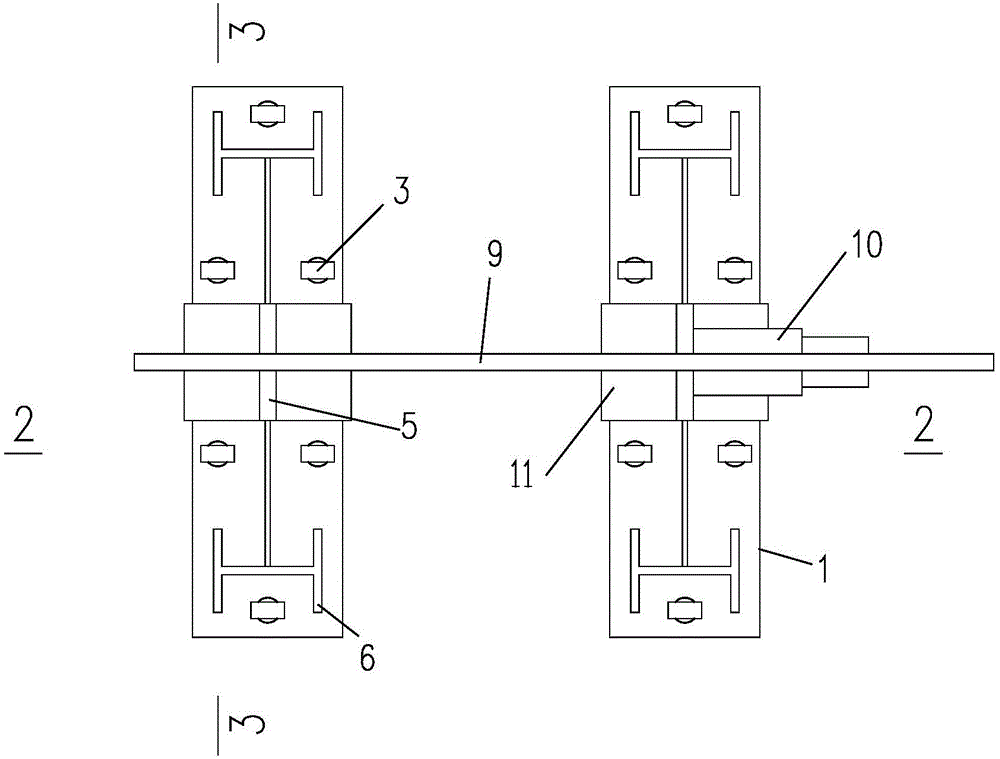

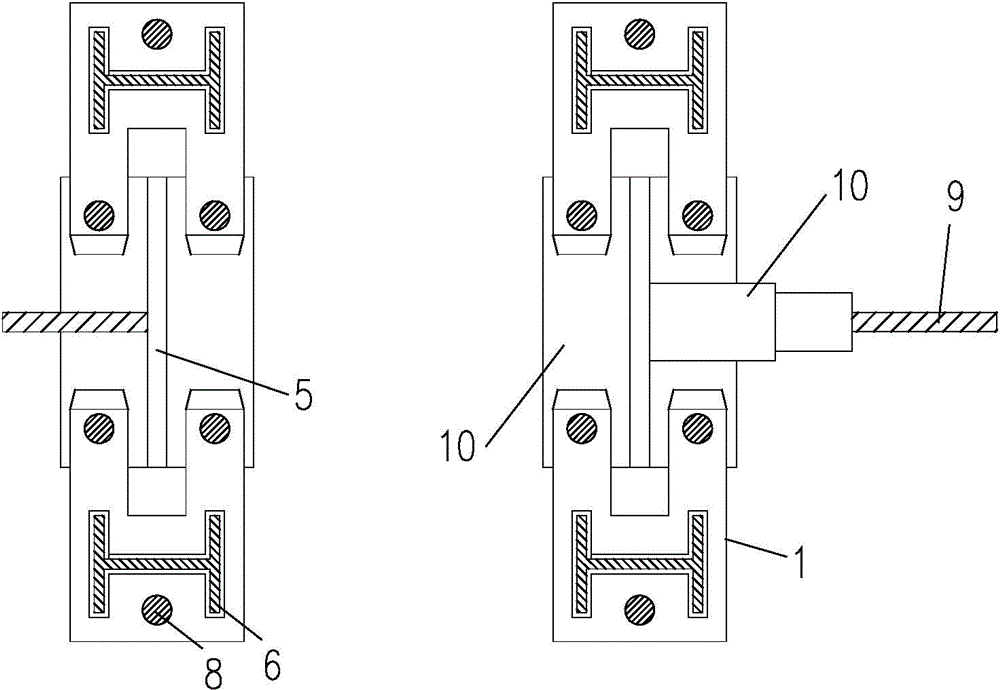

H-type steel beam installation gap adjusting device and use method thereof

ActiveCN103835516ASimple structureEasy to operateBuilding material handlingStructural engineeringOperation safety

The invention relates to an H-type steel beam installation gap adjusting device and a use method of the H-type steel beam installation gap adjusting device. The H-type steel beam installation gap adjusting device comprises two bases, a C-type draw arm, a clamping mechanism and a jack, wherein the C-type draw arm is arranged on the outer sides of the two bases in a crossing mode, the jack is arranged between one base and the C-type draw arm, and the clamping mechanism is fixed to one base through a puller bolt. The use method comprises the following steps that the bases are manufactured, the clamping mechanism and the C-type draw arm are installed, the jack is installed on the adjusting side, the puller bolt penetrates through a fixed adjusting plate to be tightly jacked in a groove of a sliding clamping plate, the jack is started, the two ends of an H-type steel beam draw close inwards under the driving of the clamping mechanism, and the adjusting distance can be visually read from an adjusting ruler above the C-type draw arm. Compared with the prior art, the H-type steel beam installation gap adjusting device and the use method have the advantages that the structure is simple, operation is convenient, the adjusting interval is visual, safety of prior structural design is not affected, labor is saved, operation safety is ensured, and the H-type steel beam installation gap adjusting device can be used repeatedly.

Owner:CHINA THIRD METALLURGICAL GRP

C-shaped cable clamp

PendingCN109449621AAchieve one-way rotationSimple structureCoupling contact membersMultiple conductors connectorEngineeringConductive materials

The invention provides a C-shaped cable clamp. The C-shaped cable clamp comprises a C-shaped clamping base, a movable block assembly, a check limiting part and an elastic part; the C-shaped clamping base is a column structure which is made of a conductive material and has a C-shaped cross section; the movable block assembly comprises an inner movable block and an outer movable block which are hinged with each other, the inner movable block is provided with a hinged end, the outer movable block is provided with a hinged groove corresponding to the hinged end of the inner movable block, a non-hinged end of the inner movable block and a non-hinged end of the outer movable block can cooperate with the two ends of the C-shaped clamping base to clamp a cable, and the outer movable block is further provided with a reserved space communicated with the hinge groove; the check limiting part is arranged in the reserved space, the surface of the check limiting part and the surface of the inner movable block are provided with check structures cooperating with each other, and the check structures are used for enabling the inner movable block and the outer movable block to be only capable of moving in the direction capable of enabling an included angle formed by the inner movable block and the outer movable block to be enlarged; and the elastic part is arranged between the outer movable blockand the check limiting part to apply support force towards the surface of the inner movable block to the check limiting part.

Owner:YONGGU GRP

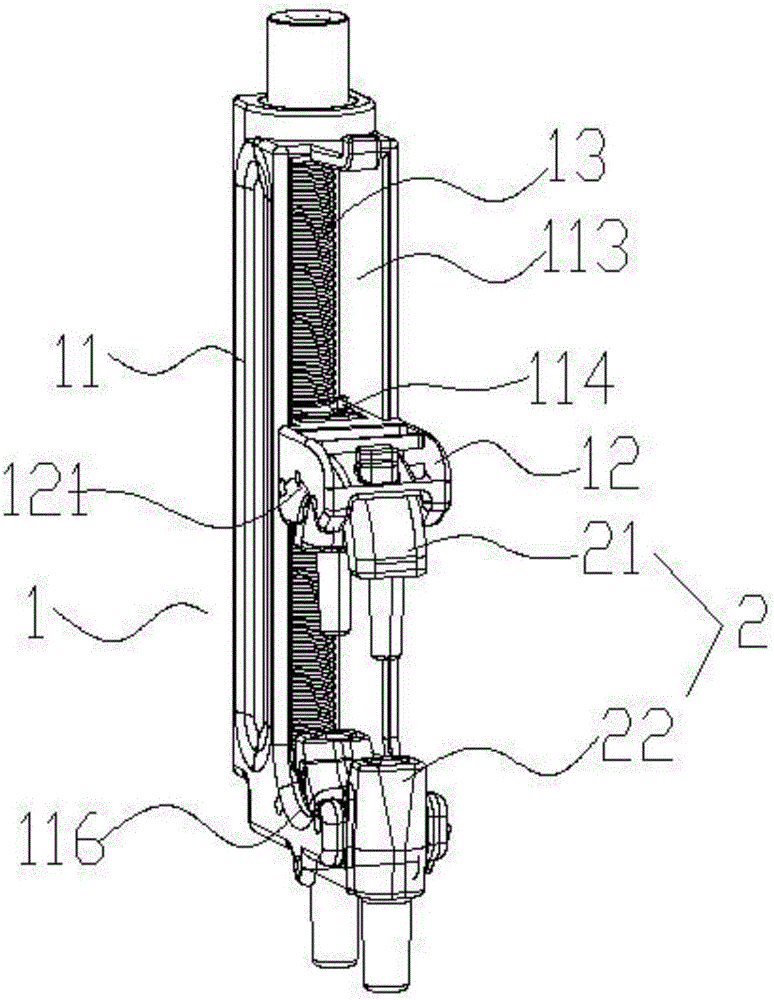

Crimping device for improving pre-binding force of joint between carbon fiber composite core wire and fitting

PendingCN111029990AReduce weightEasy to carryApparatus for joining/termination cablesMechanical engineeringCarbon fiber composite

The invention relates to the technical field of conducting wire fitting fastening, particularly to a crimping device for improving the pre-binding force of a joint between a carbon fiber composite core wire and a fitting, wherein the crimping device comprises an operating platform, an ultrahigh-pressure hydraulic system, a stress stop block, a pressure transmitter and the like. According to the invention, the crimping device is high in interchangeability, can achieve the crimping and pre-tightening of aluminum stranded wire carbon fiber composite core conducting wire and fitting joints of different specifications by adjusting the stress stop block and the pressure transmitter, and can well solve problems that the core rod and the cone fitting are not firmly combined, slippage is extremelylikely to happen, and even wire falling is caused in the existing crimping technology can be well solved.

Owner:山东宽原新材料科技有限公司

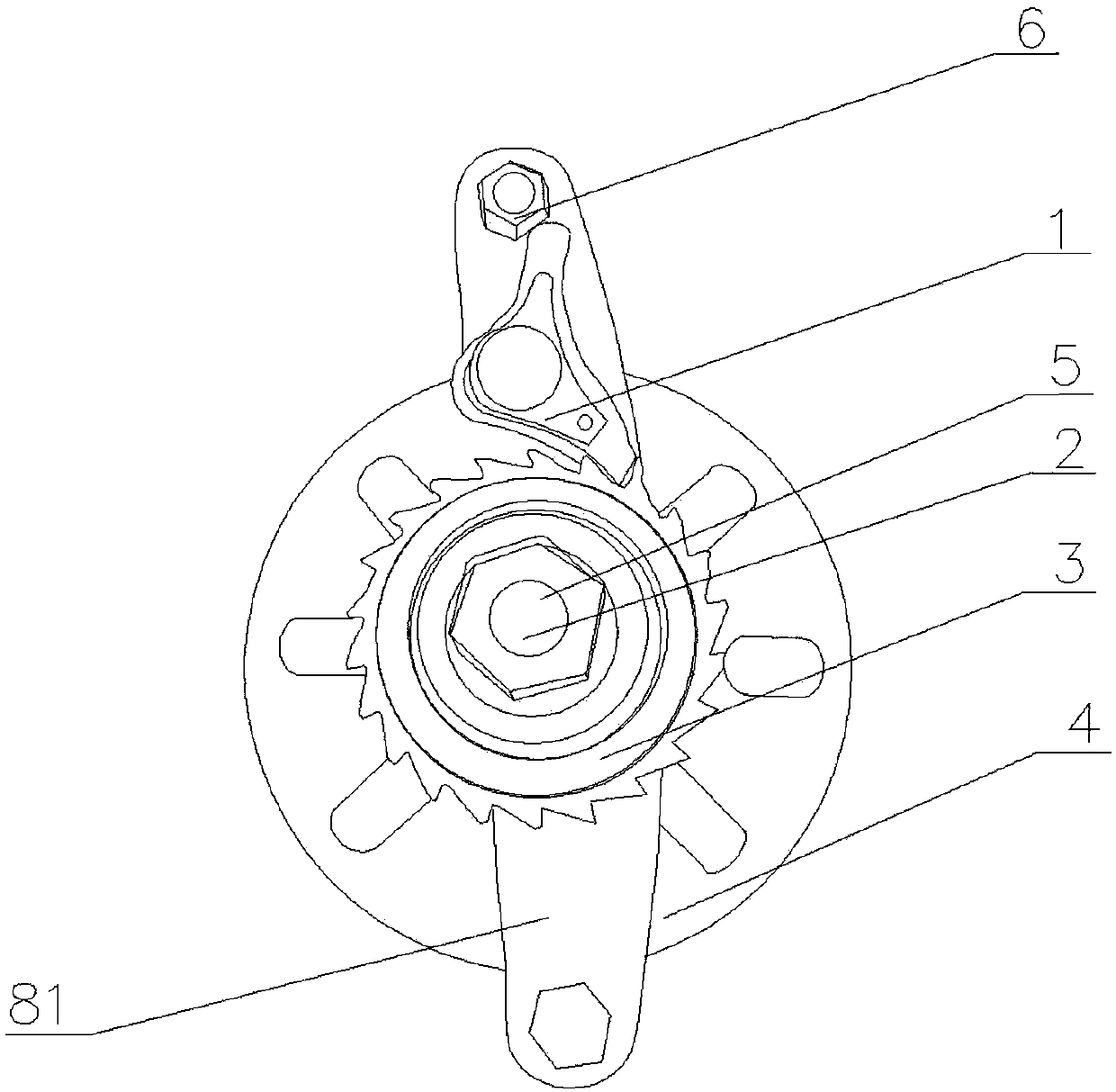

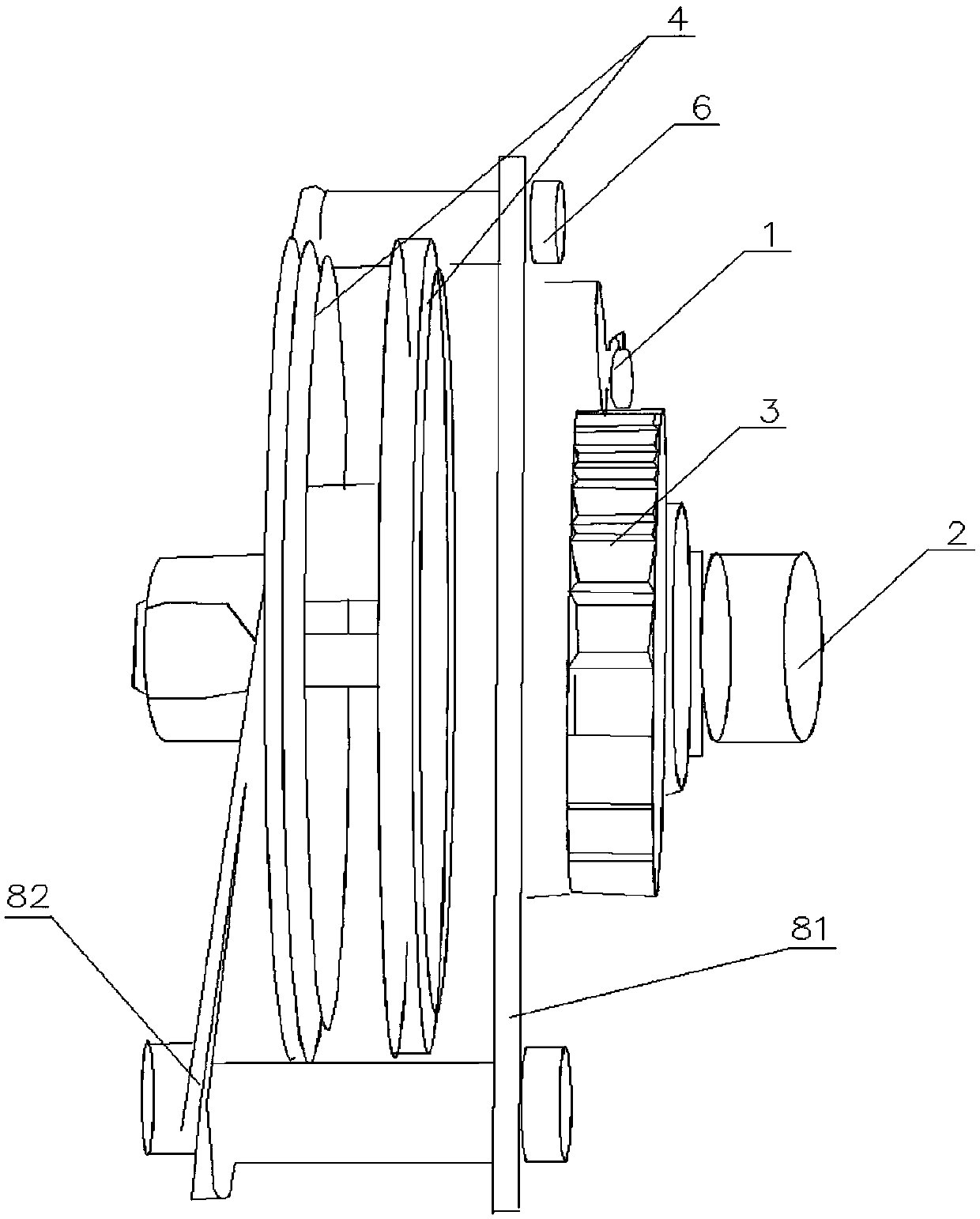

Multifunctional bolt turning tool ratchet handle

The invention relates to a multifunctional bolt turning tool ratchet handle, in particular to a multi-head multifunctional bolt turning tool ratchet handle which can rotate with 360 DEG and can be used as both screwdriver handle and sleeve spanner handle. The multifunctional bolt turning tool ratchet handle comprises a ratchet part, a handle body and a hand holding part, wherein the back end of the handle body is fixed with the hand holding part, the front end of the handle body is provided with the ratchet part capable of rotating with 360 DEG, the rotating central axis of the ratchet part is vertically intersected with the central axis of the handle, the outer edge of the ratchet part is distributed with a plurality of turning tool joints in radial shape, and the central axes of the turning tool joints and the central axis of the handle are in the same plane. The multifunctional bolt turning tool ratchet handle in the invention is combined with the ratchet bolt turning tool and the ratchet sleeve spanner in the existing technology together and is integrated with multiple specifications of bolt turning tool joints integrally to make up the defects in the existing technology, suchas single linking form, single using mode, limited angle adjusting, and inconvenient using and carrying.

Owner:南通海迈五金有限公司

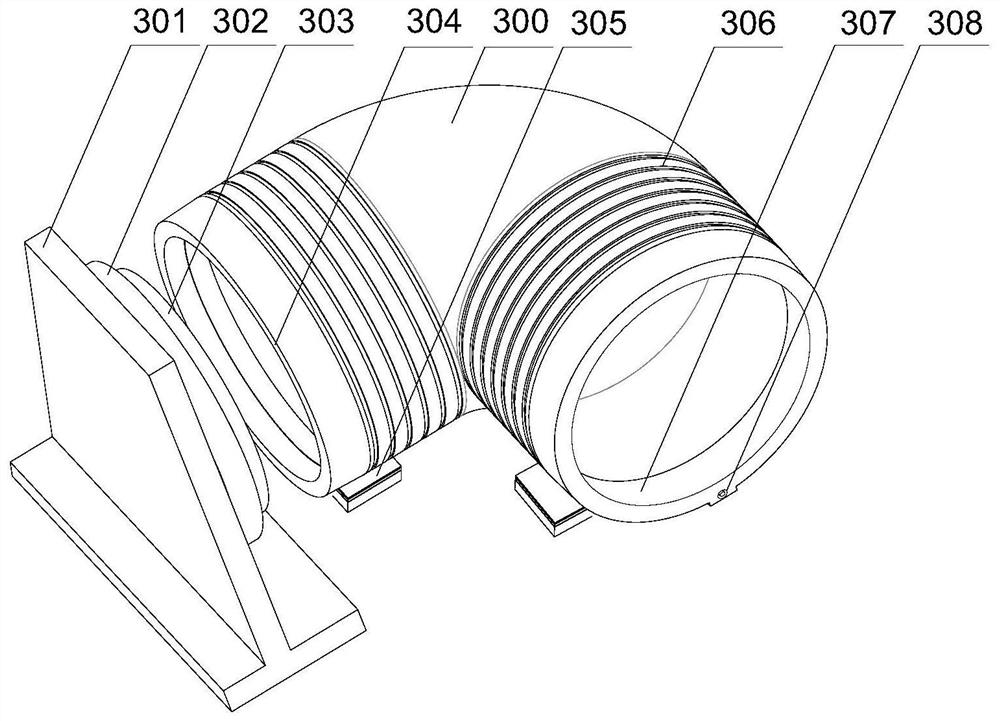

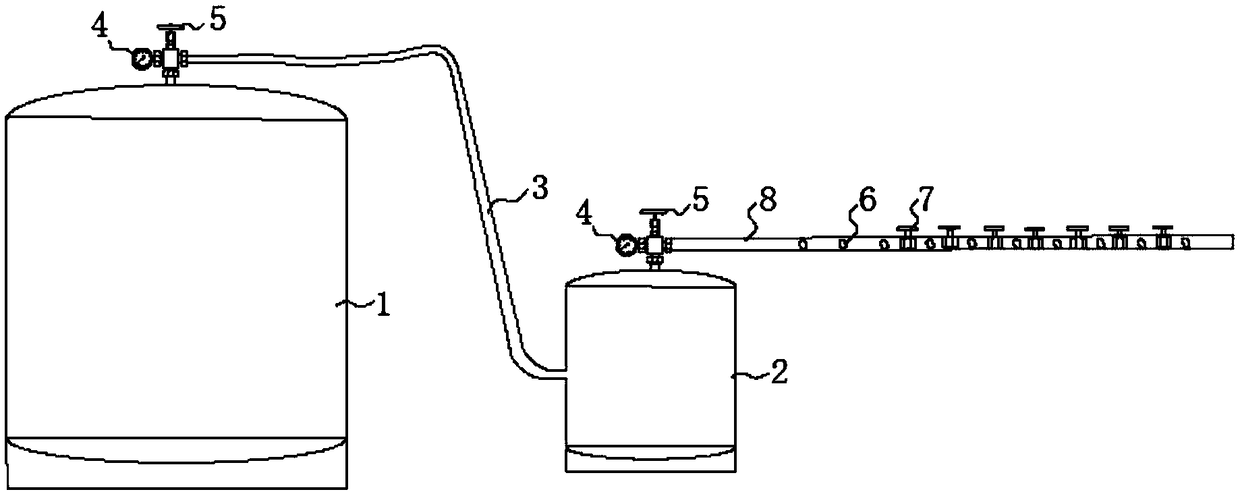

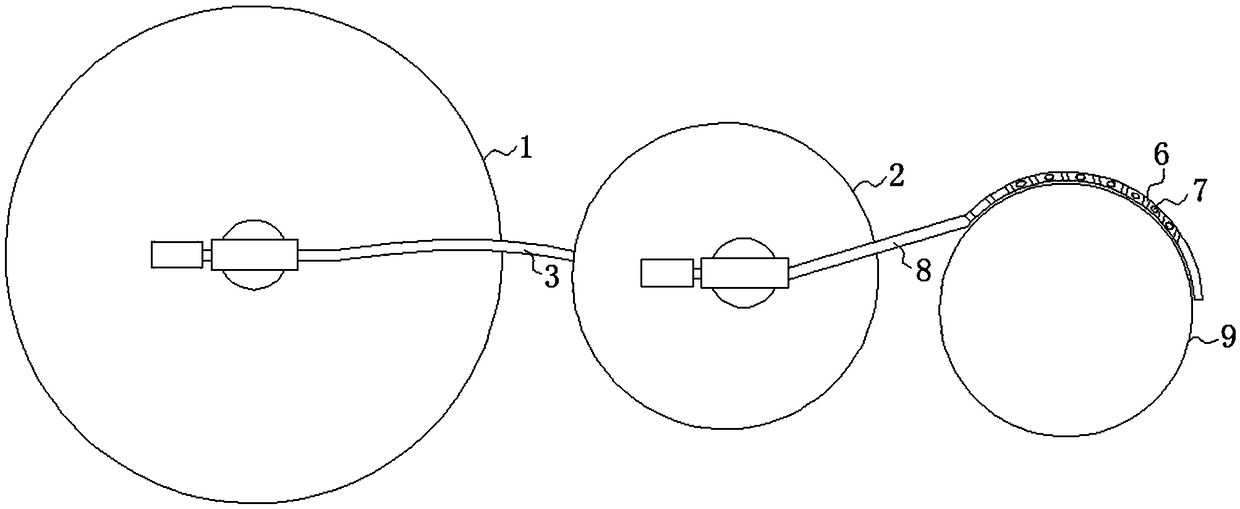

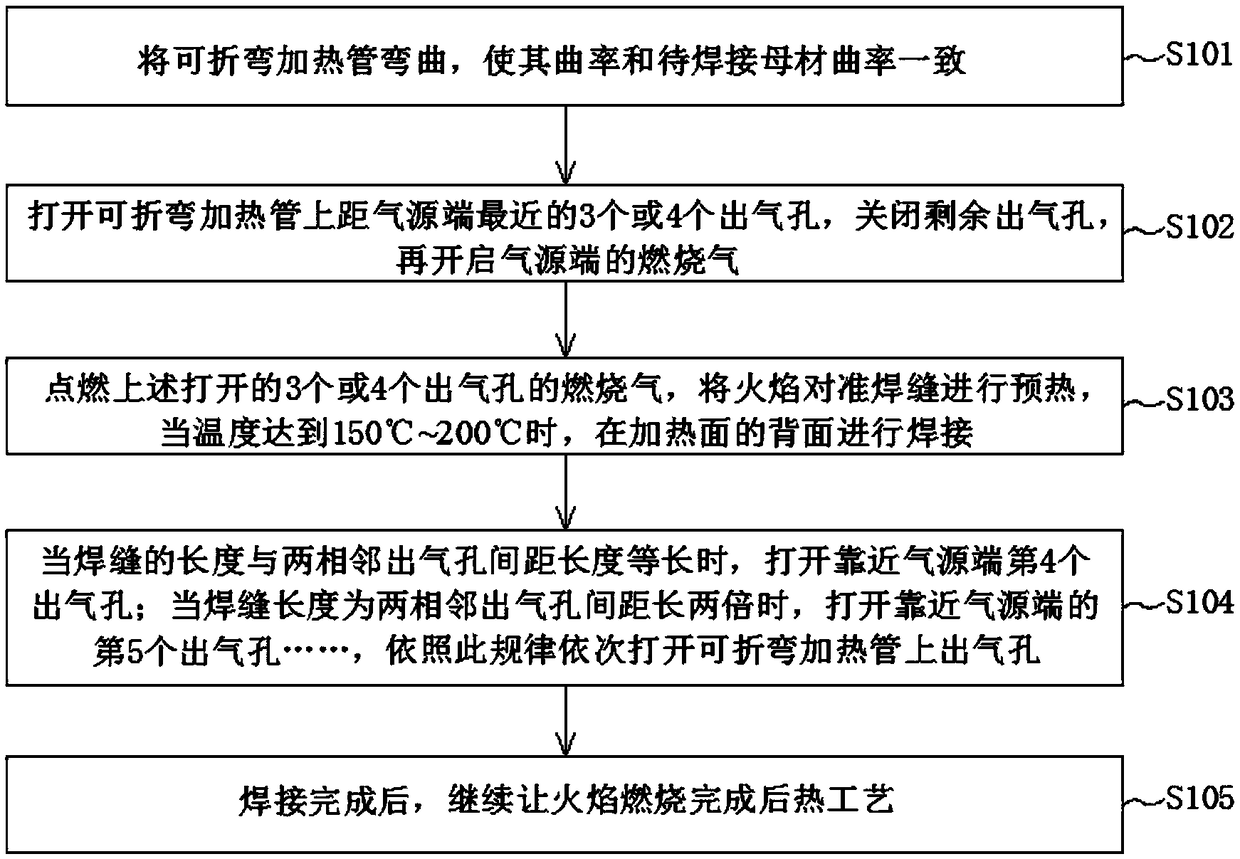

Preheating and after-heating device for welding

InactiveCN109332955AImprove versatilityEasy to control heating lengthWelding/cutting auxillary devicesAuxillary welding devicesBuffer tankProcess engineering

The invention discloses a preheating and after-heating device for welding, and belongs to the field of welding equipment. The preheating and after-heating device for welding comprises a gas source tank, a bendable heating pipe is connected to the gas source tank, a plurality of gas outlet holes which are transversely and evenly distributed are formed in the bendable heating pipe, a control valve is arranged on each gas outlet hole, and the end, far away from the gas source tank, of the bendable heating pipe is closed. According to the preheating and after-heating device for welding, the bending curvature of the bendable heating pipe can be adjusted according to the curvature of to-be-welded base metal, and the universality is higher; the control valves are arranged at the gas outlet holes,therefore, opening and closing of the gas outlet holes can be controlled by the control valves, the control valves are sequentially opened along with increasing of the welding seam length, the heating length can be conveniently controlled, and meanwhile energy sources can be better saved; and in addition, a buffer tank is connected between the gas source tank and the bendable heating pipe, gas inthe buffer tank can be used for achieving supplementing when burning gas in the gas source tank is about to be used up, gas sources can be supplemented to the gas source tank in time, the working efficiency is significantly improved, and a flame is more stable and more uniform, so that the preheating effect is better.

Owner:ANHUI SPECIAL EQUIP INSPECTION INST

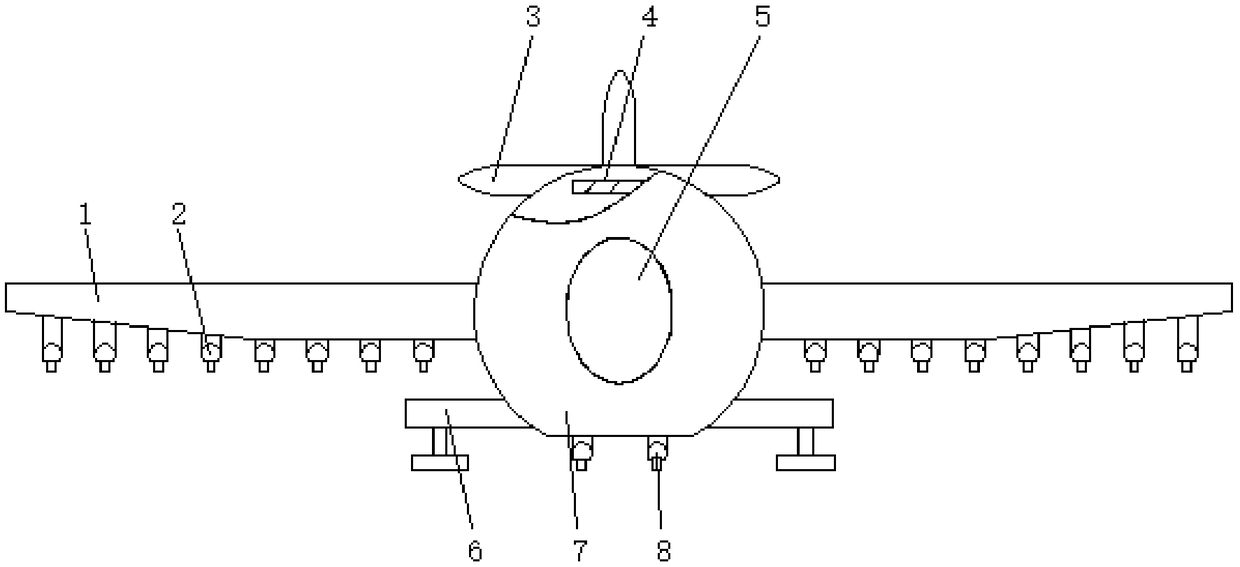

Energy-saving agricultural machinery spraying system

PendingCN108782530ASuitable for working at heightsStir wellAircraft componentsInsect catchers and killersAgricultural engineeringFarm machine

The invention discloses an energy-saving agricultural machinery spraying system. The energy-saving agricultural machinery spraying system includes a machine body and wings, wherein the wings are arranged on the two sides of the machine body; the upper surface of the machine body is covered with a solar film, a machine head and a tail wing are arranged on the front and rear ends of the machine body, a control panel is in embedded connection with the inner wall of the machine body, and a distance sensor and a camera are in embedded connection with the interior of the machine body. The energy-saving agricultural machinery spraying system is reasonable in structure, convenient to use and suitable for working at height and can not only achieve pesticide spraying and fertilizer applying in theair but also work in cooperation with multiple unit groups, the working efficiency of spraying and fertilization is greatly improved, the situations cannot occur that multiple units collide in the airand repeatedly work in the same area, and therefore the energy-saving agricultural machinery spraying system is suitable for large-scale application and popularization in farms and forests.

Owner:HUNAN AGRICULTURAL UNIV

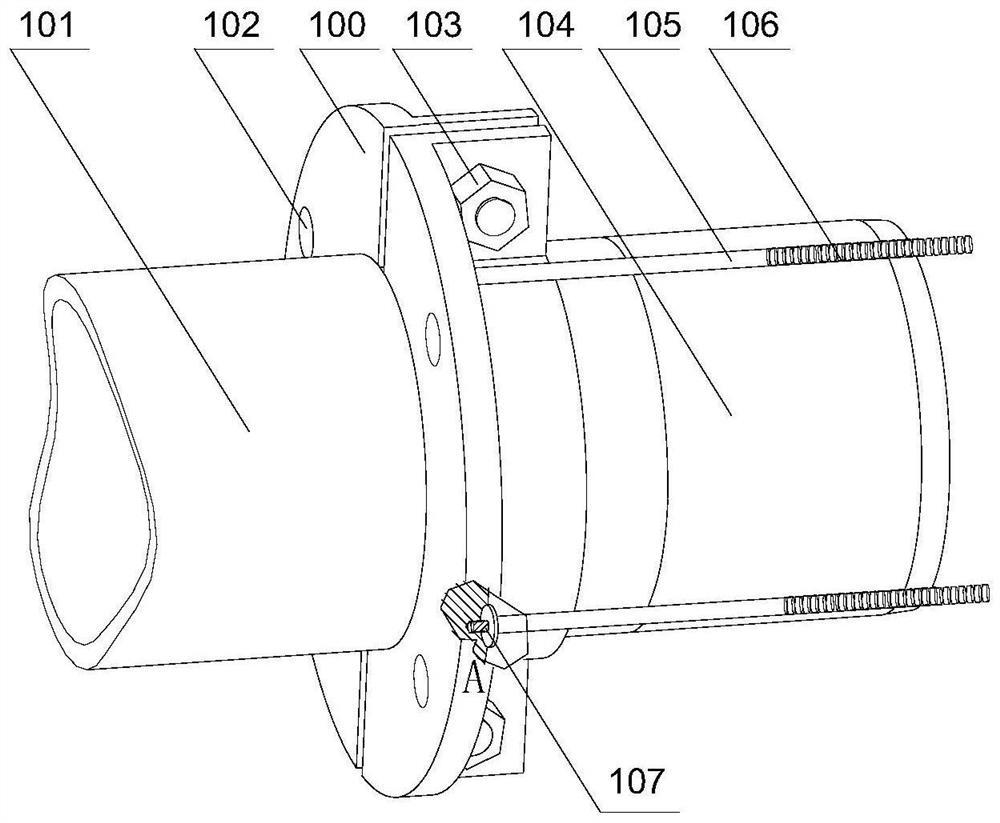

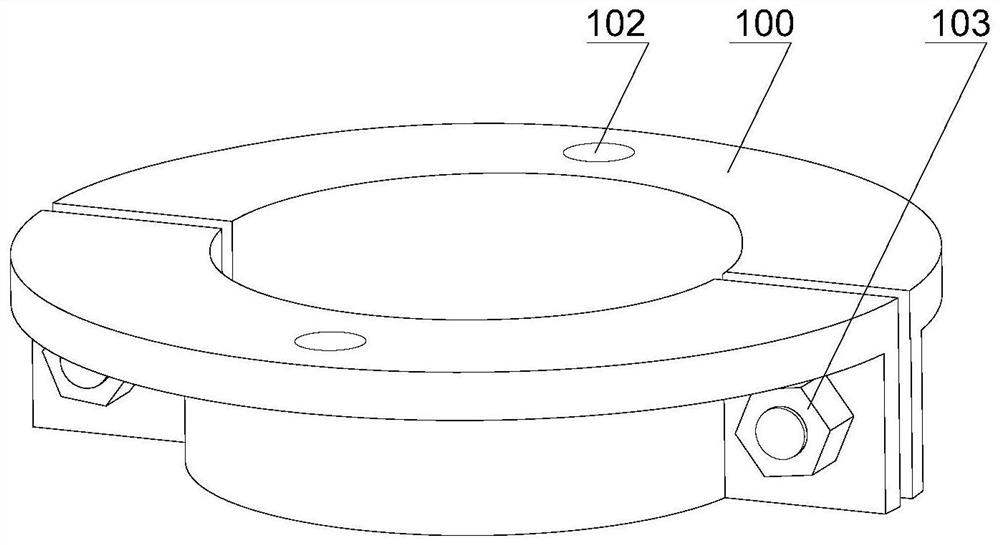

Fixing device and fixing method for hot-line installation auxiliary equipment

InactiveCN103872620AGuaranteed reliabilityEasy to operateApparatus for overhead lines/cablesEngineeringElectrification

The invention provides a fixing device and a fixing method for hot-line installation auxiliary equipment. The fixing device is used for fixing and connecting auxiliary equipment and a component with electrification danger. The fixing device comprises a fixing clamp and a fastening mechanism, wherein the fixing clamp comprises a first support foot, a second support foot and a connecting beam, the first support foot and the second support foot are in opposite arrangement, the connecting beam is connected with the first support foot and the second support foot, the first support foot is provided with a threaded connecting hole, a gap formed between the first support foot and the second support foot is used for accommodating a first connecting part of the component and a second connecting part of the auxiliary equipment, the fastening mechanism comprises a propping part and a locking part, the propping part comprises a threaded section matched with the threaded connecting hole, the propping part tightly props the first connecting part, the second connecting part and the second support foot, and the locking part is matched with the propping part and is used for locking the propping part onto the first support foot. When the fixing device provided by the invention is adopted, the component and the auxiliary equipment can be fixed on the premise of not damaging the structures of the auxiliary equipment and the component with the electrification danger.

Owner:STATE GRID CORP OF CHINA +1

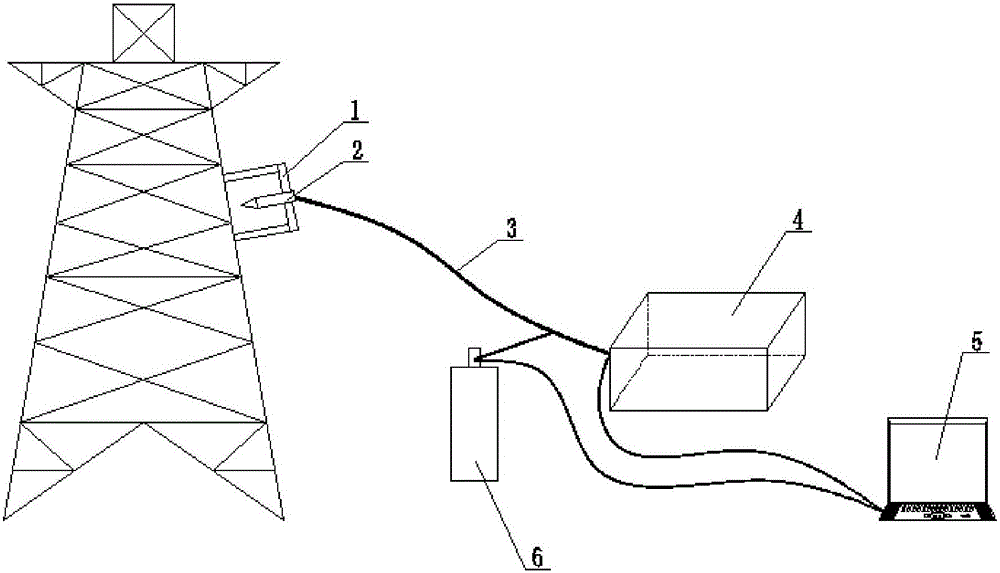

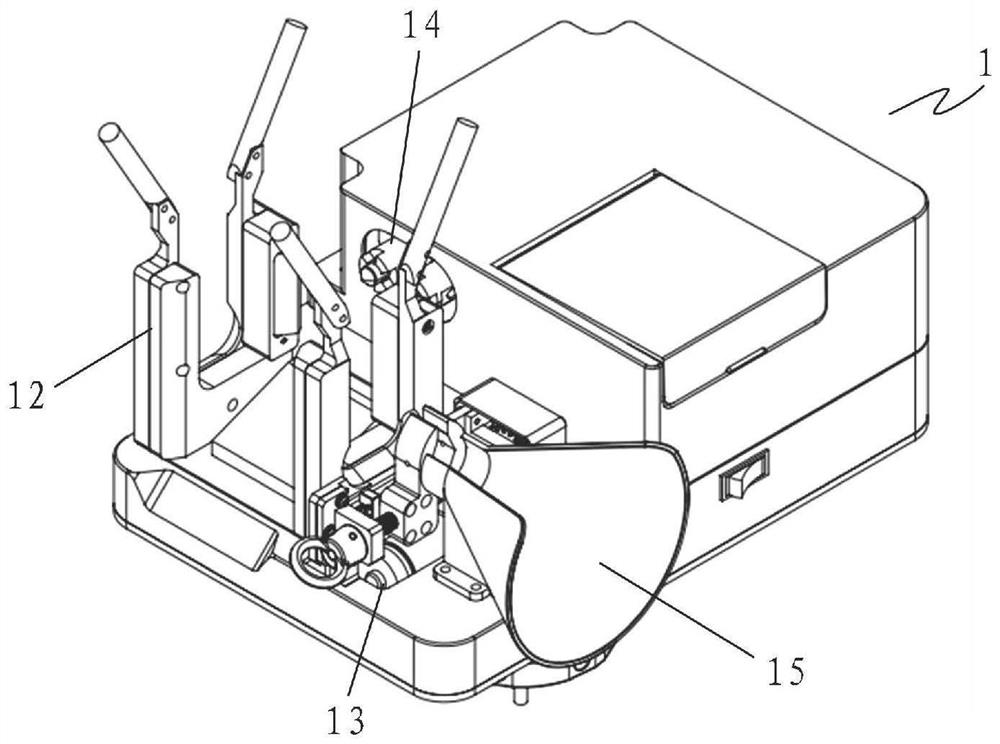

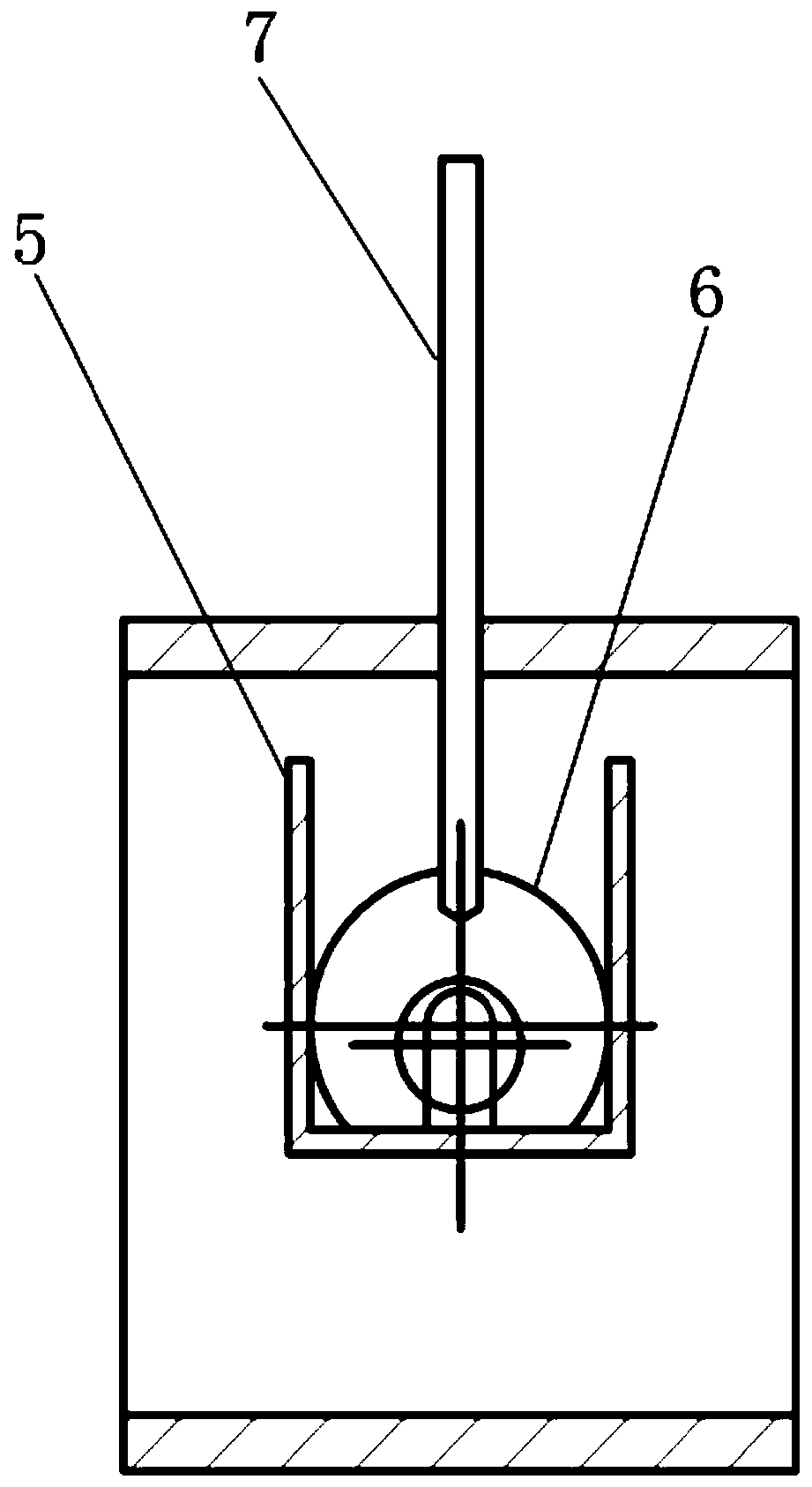

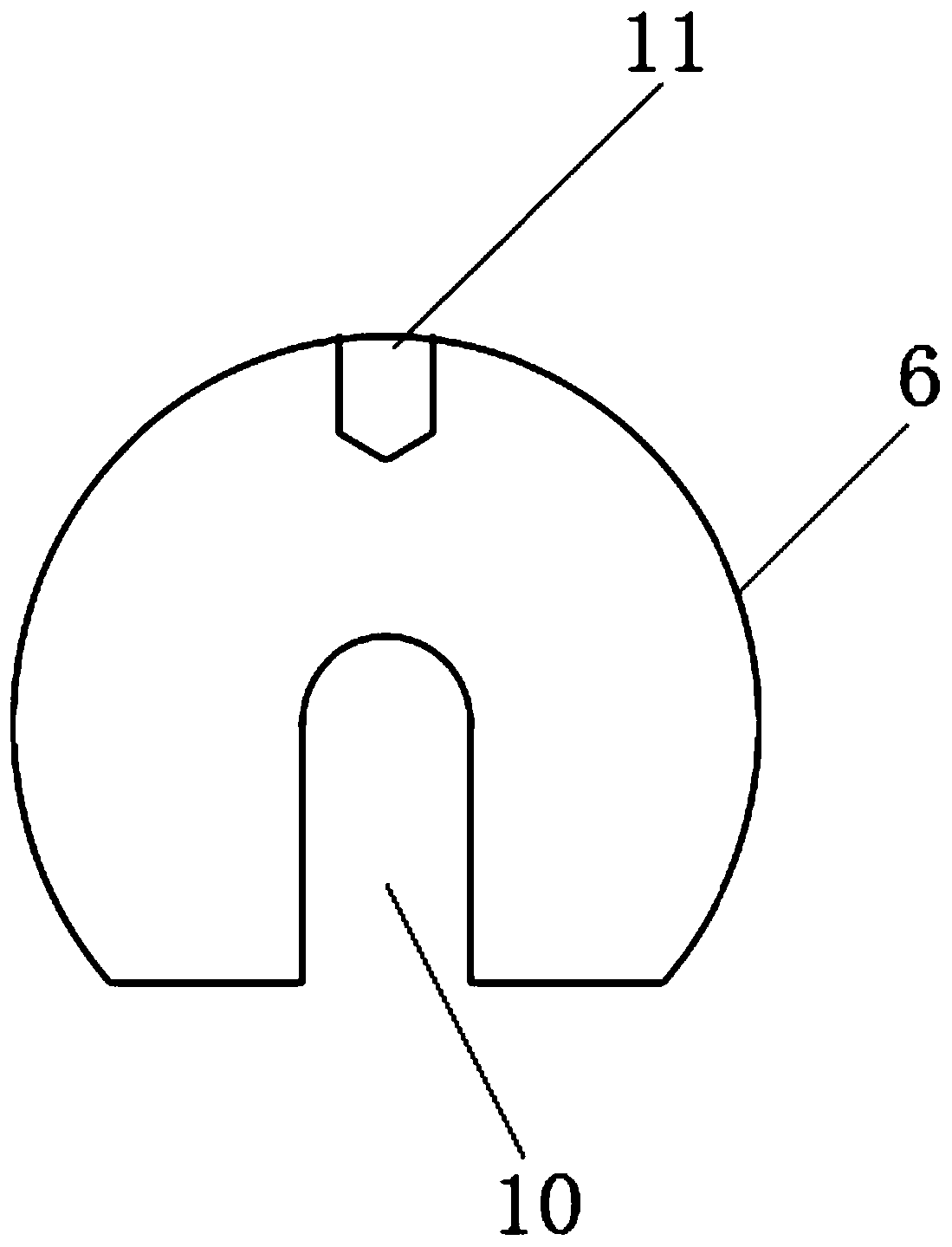

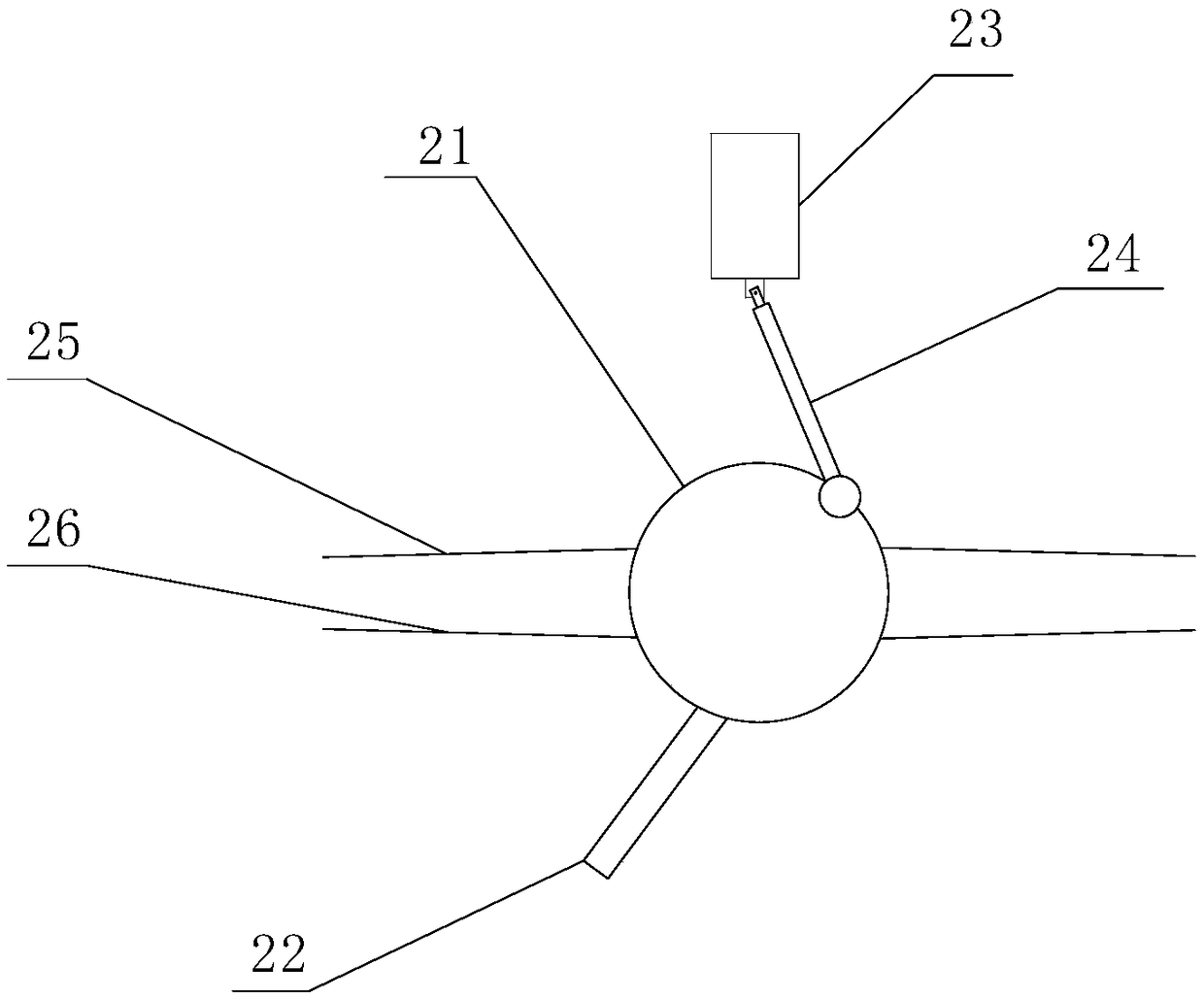

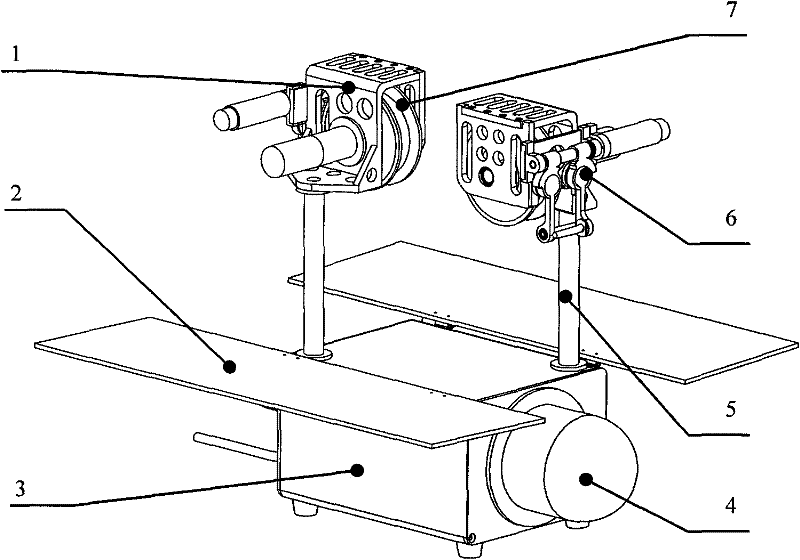

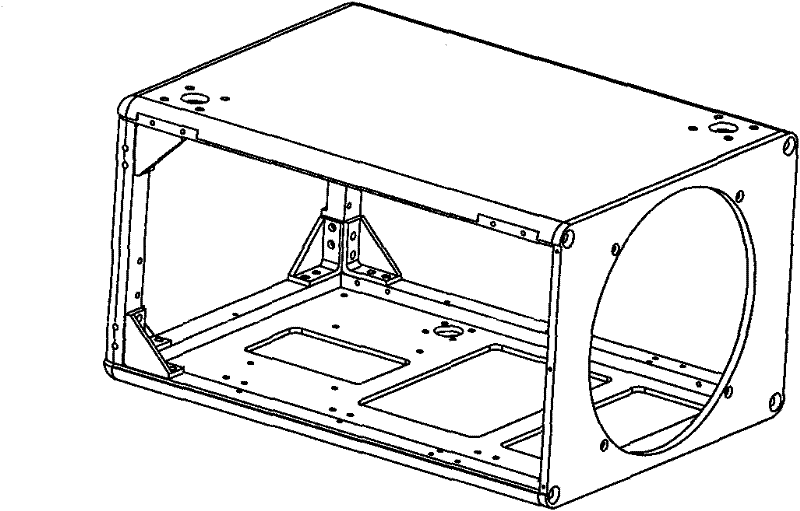

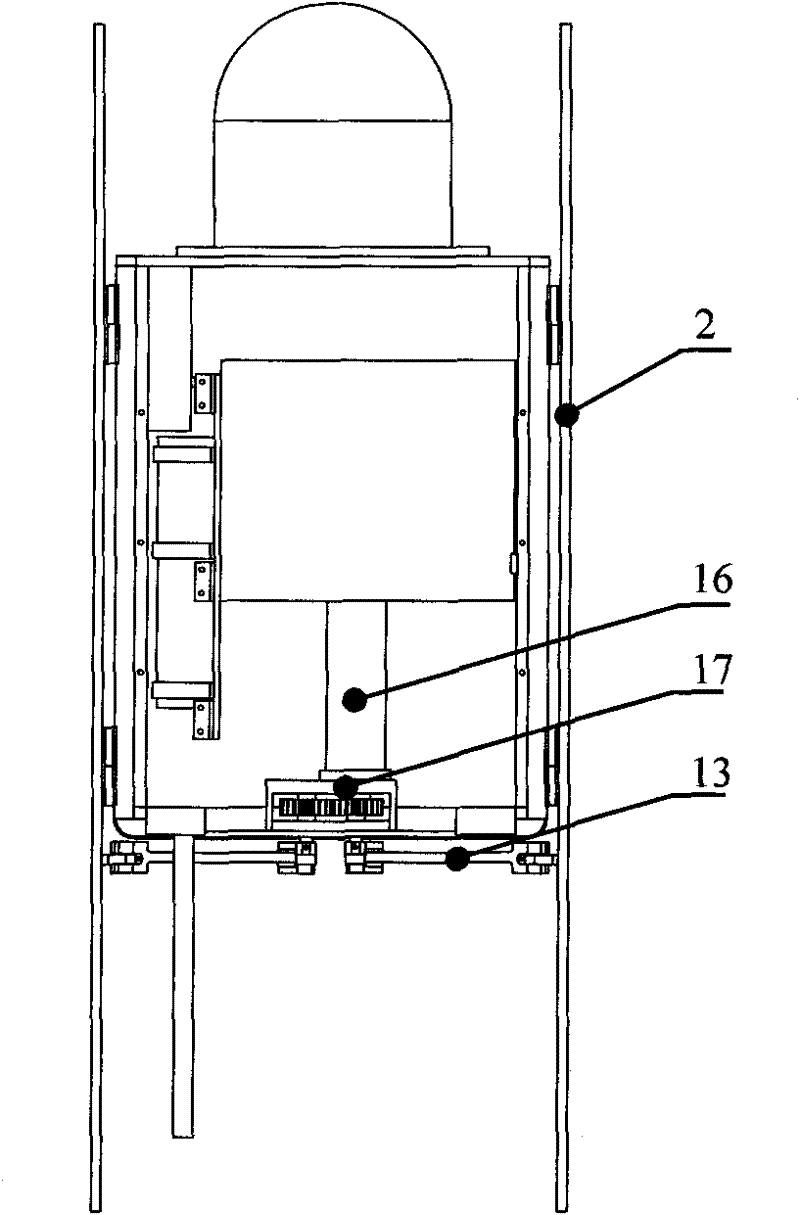

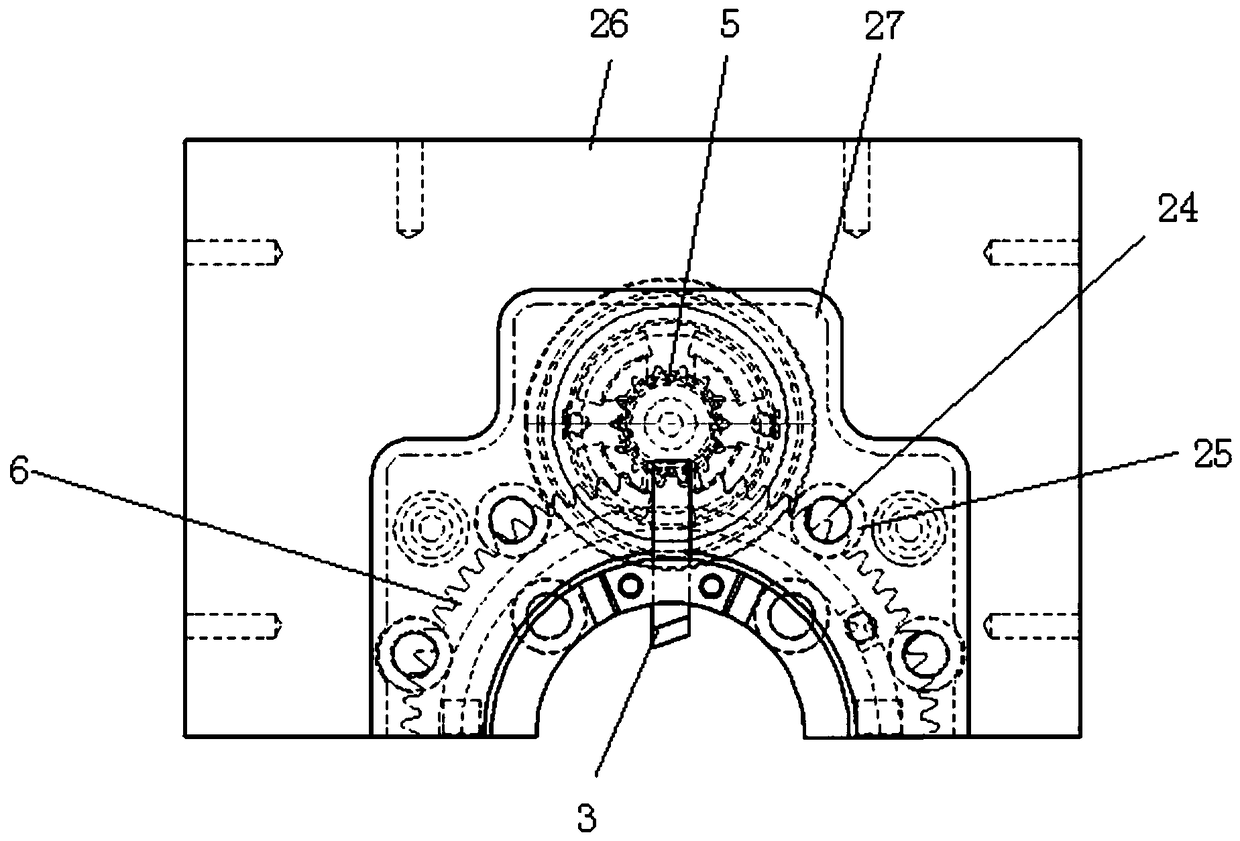

Inspection robot for ultra-high voltage power transmission lines

InactiveCN101800403BSave inspection timeGuaranteed uptimeManipulatorApparatus for overhead lines/cablesUltra high voltageWireless image transmission

The invention discloses an inspection robot for ultra-high voltage power transmission lines, which is characterized by comprising a robot main body (3), walking and clamping mechanisms and a charging device, wherein the robot main body (3) has a framed box structure and comprises a control device, a detection device and a wireless image transmission device; each walking and clamping mechanism comprises a walking mechanism (1) and a clamping mechanism (6); two sets of the walking and clamping mechanisms are provided and are connected with the robot main body (3) by arms (5) having a structure of a hollow tube; and the charging device is positioned on the two sides of the robot main body (3) and connected with the robot main body (3) by a hinge (15). The inspection robot has the advantages of greatly improving the working efficiency and meeting requirements of specific robots for overhead operation, along with simple structure, easy implementation, light weight, safety, and environmental protection.

Owner:昆山市工业技术研究院有限责任公司

An H-shaped steel beam installation gap adjustment device and its use method

ActiveCN103835516BSimple structureEasy to operateBuilding material handlingStructural engineeringOperation safety

Owner:CHINA THIRD METALLURGICAL GRP

Overhead operation platform

PendingCN108063391AExpand the scope of workImprove stabilityLifting devicesApparatus for overhead lines/cablesEngineeringAerial work platform

Owner:STATE GRID XINJIANG ELECTRIC POWER +1

A Dyneema rope non-destructive fast anchor and its operation method

ActiveCN106451198BReduce the likelihood of damageChange pinch modeFilament handlingCable installation apparatusConductor CoilMechanical engineering

Owner:SICHUAN POWER TRANSMISSION & TRANSFORMATION CONSTR +1

Belt type fastening device

ActiveCN105465115ASuitable for working at heightsEasy to installFriction grip releasable fasteningsScrew thread

Owner:IDEX TECH (SUZHOU) CO LTD

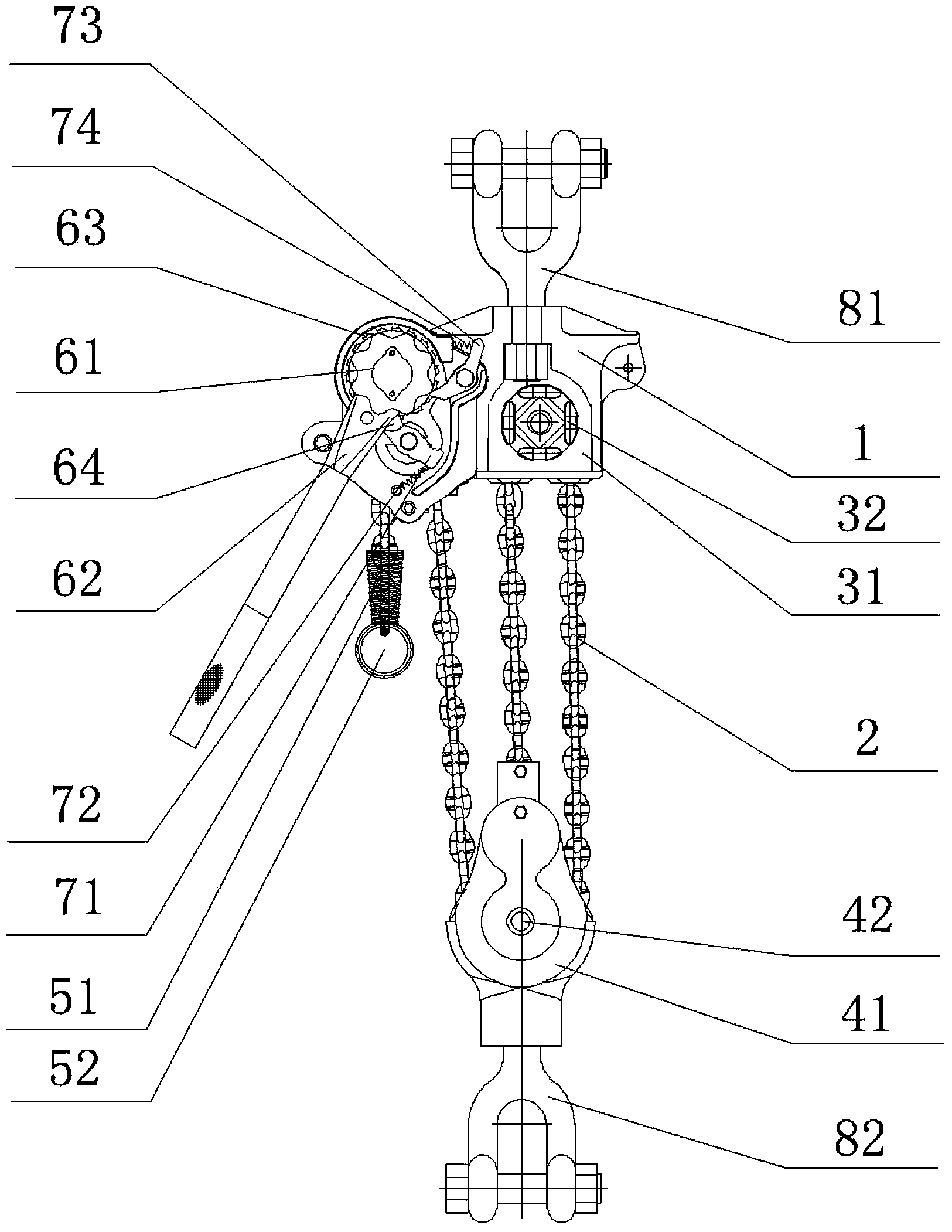

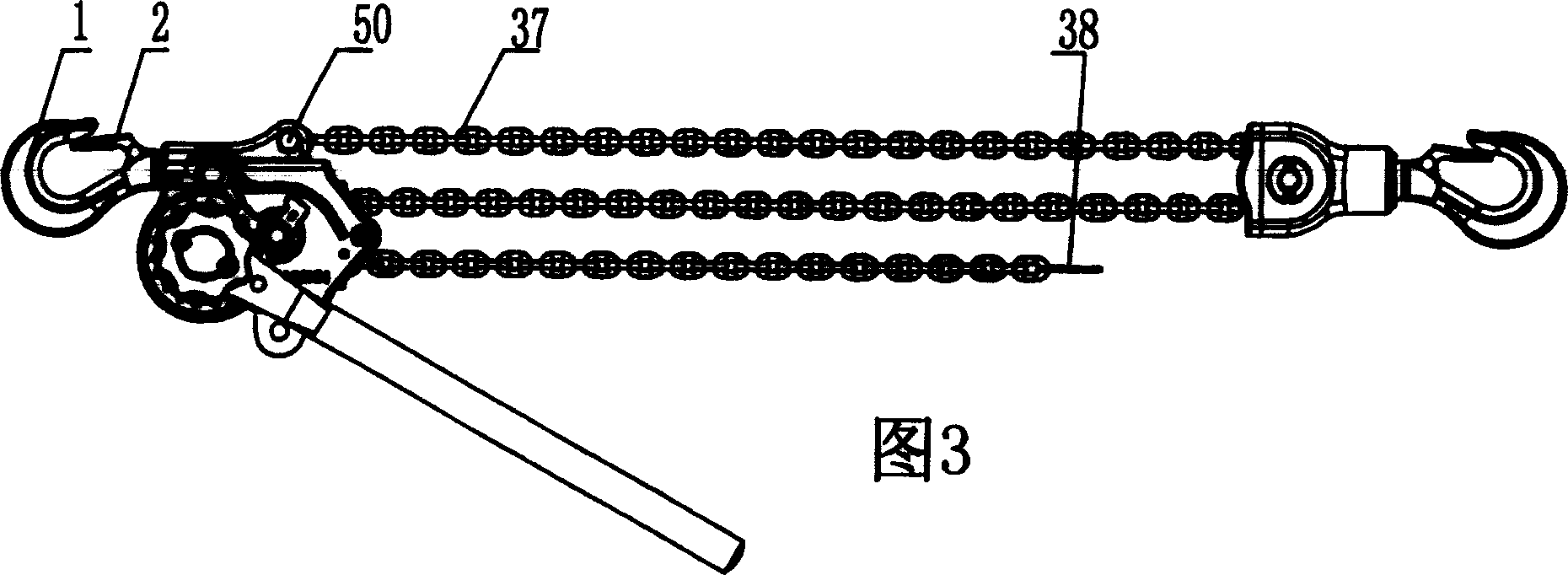

Light aluminium alloy chain block

The light aluminum alloy chain block includes main body mechanism, ratchet spanner mechanism and driven chain wheel mechanism. The main body mechanism includes casing, screwed cover plate, upper lifting hook, non-return gear set and chain wheel set inside the casing, and cable clamping board assembly to avoid outer separation of the chain. The ratchet spanner mechanism has ratchet handle assembly fitted to the gear shaft. The present invention has simple and compact structure, light weight, no reverse turning, and flexible and light operation, and is suitable for overhead operation.

Owner:邱以刚

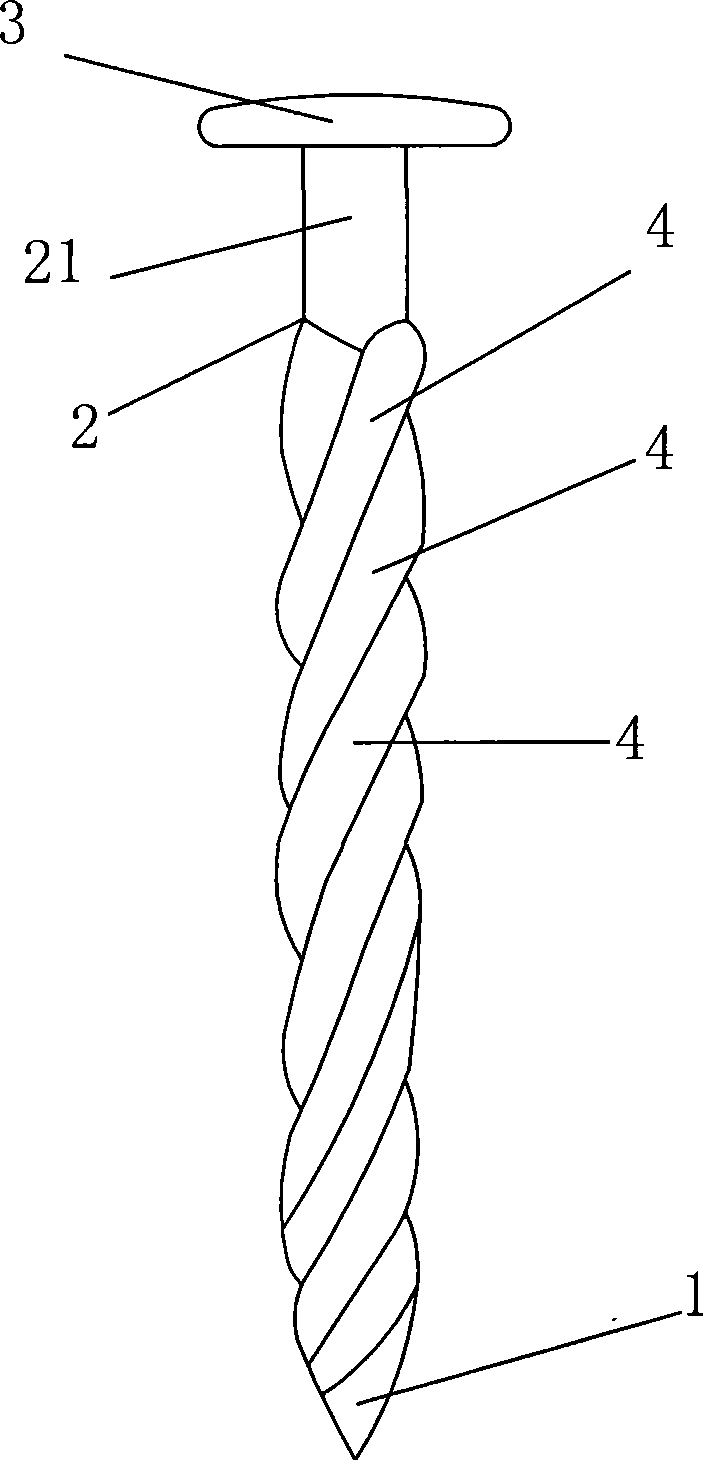

Pull explosion screw nail

An expansion screw comprises a conical head, a main body, a screw cap and a plurality of screw threads. The screw cap is arranged on head part of the main body, has a round and smooth external surface and is provided with a model decoration letter at the central part. The conical head is arranged at the tail part of the main body. A toothless area with the width of 5 mm is arranged at the main body from the head downwards, and is provided for facilitating movable use for providing a cushion buckle and accessories; the screw threads are arranged at the lower end of the toothless area on the main body, and are mainly used for facilitating the expansion screw to automatically rotate during knocking, which saves labor and time saving during driving, and is more suitable for overhead work.

Owner:SHENZHEN YONGLI HARDWARE SPRINGS IND

A high-voltage line deicer

The invention discloses a high-tension cable de-icing machine which comprises a split type box. A de-icing high-tension cable penetrates through the box along a semicircular hole, a de-icing mechanism is arranged at one end of the box, and the de-icing mechanism comprises a geared motor, a driving gear and a driven gear, wherein the driving gear and the driven gear are meshed with each other. The driven gear is formed by combining two semicircular gears, and tools are arranged on the end face of the driven gear. A walking driving mechanism and a gear motor are arranged in the box, and an output shaft of the gear motor is connected with driving chain wheels and driven chain wheels through chains. Each driven chain path shaft is sleeved with a polyurethane wheel, and the polyurethane wheels are pressed on the high-tension cable to be de-iced to move forward in a rolling mode along the cable. The high-tension cable de-icing machine further comprises remote video collecting equipment, a lifting mechanism and a pressurizing mechanism. After the de-icing machine is hung on the cable through an insulating rod, a lower box body is driven by the lifting mechanism to be combined together with an upper box body, and the box can achieve the function of fixing other parts and the function of supporting. The de-icing machine is compact in structure, small in size, low in weight and suitable for working high above the ground.

Owner:NANJING HYDRAULIC RES INST

Universal connection clip

ActiveCN104701648BSolve easy feverSimple structureElectric connection structural associationsClamped/spring connectionsEngineeringGuide wires

The invention aims to provide a general connecting cable clamp which is simple in structure, safe and reliable and capable of being suitable for connecting guide wires with different diameters. The general connecting cable clamp comprises a cable clamp body (1), wherein a cable slot (2) is formed in the cable clamp body (1); a hinged block (3) is hinged at one side of the cable slot (2); the cable clamp further comprises a pressing block (4), a long-strip-shaped through hole (5) penetrating through the cable clamp body (1) and a bolt device (6) of the pressing block (4), the pressing block (4) presses the hinged block (3) and drives the hinged block (3) to press a guide wire in the cable slot (2). The general connecting cable clamp can be applied to the electric equipment field.

Owner:ZHUHAI ZHONGLI ELECTRICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com