General connecting cable clamp

A technology for connecting wire clips and wire clips, which is applied in connection, conductive connection, electrical component connection, etc., can solve the problems of difficult installation, achieve good versatility, solve the effects of easy heating, and eliminate thermal faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

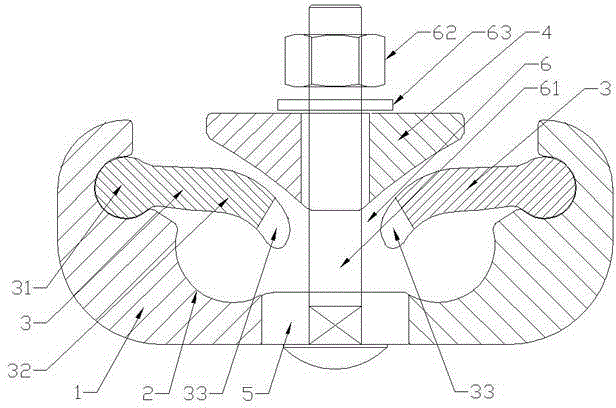

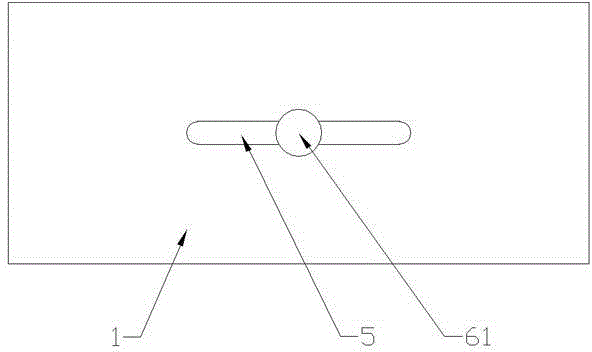

[0017] Such as Figure 1 to Figure 4 As shown, the present invention includes a wire clamp body 1, a wire slot 2 is arranged on the wire clamp body 1, a hinge block 3 is hingedly arranged on one side of the wire slot 2, and the wire clamp also includes a pressing block 4 and the bolt device 6 passing through the elongated through hole 5 on the clamp body 1 and the compression block 4, the compression block 4 compresses the hinge block 3 and drives the hinge Block 3 compresses the wires located in said trunking 2 . The bolt device 6 includes a bolt body 61 , a nut 62 and a washer 63 matched with the bolt body 61 .

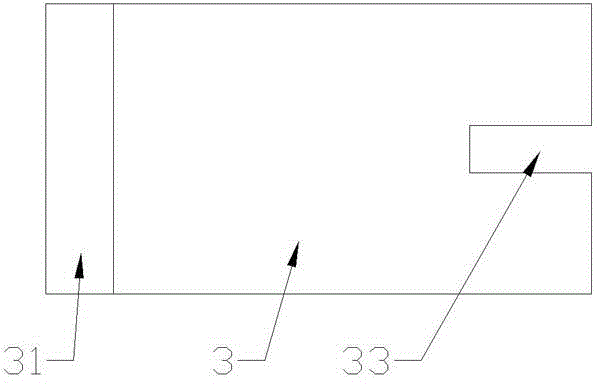

[0018] The hinge block 3 includes a hinge joint 31 and a pressing part 32, the hinge joint 31 is rotatably matched with the hinge groove 11 provided on the clamp body 1, the pressing part 32 is curved, and the pressing part 32 is curved. The degree of curvature of the surface of the portion 32 in contact with the wire disposed in the trunking 2 is consistent with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com