A high-voltage line deicer

A high-voltage line and deicer technology, which is applied in the installation of cables, overhead installation, electrical components, etc., can solve the problems of lack of automatic machinery, difficulty in de-icing cables, and difficulty in de-icing, and achieves high-altitude operations. Compact, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions and beneficial effects of the present invention will be further explained below in conjunction with the drawings and embodiments, but are not limited to these embodiments.

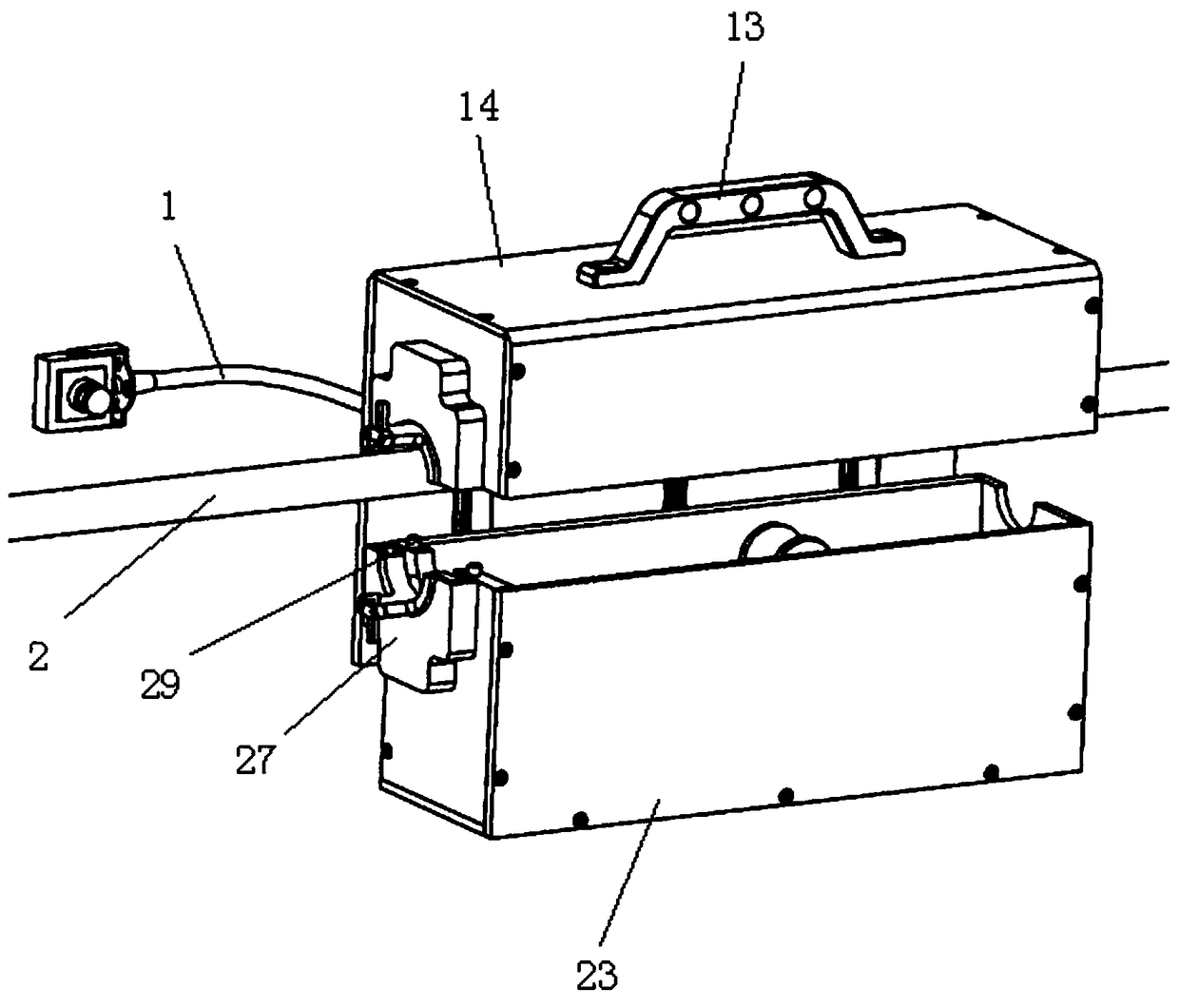

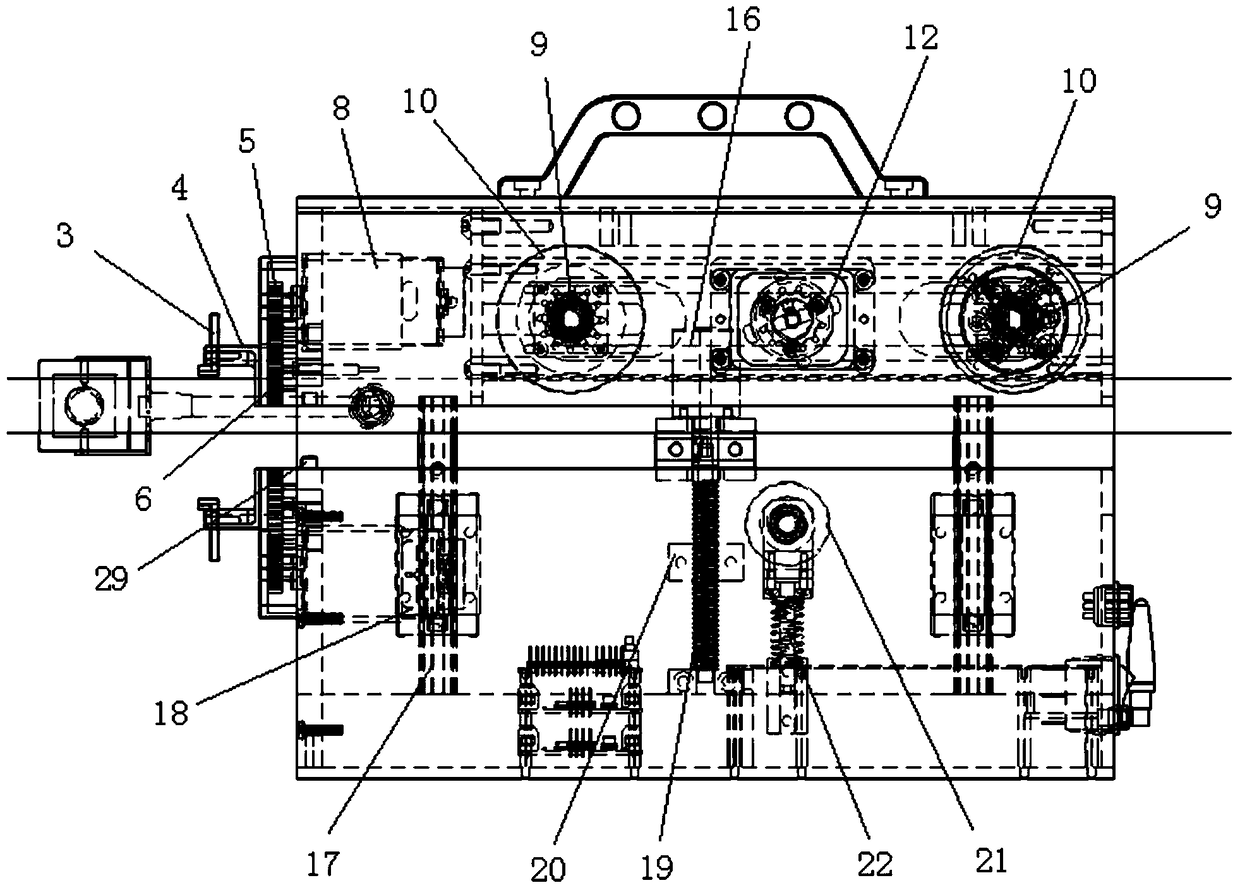

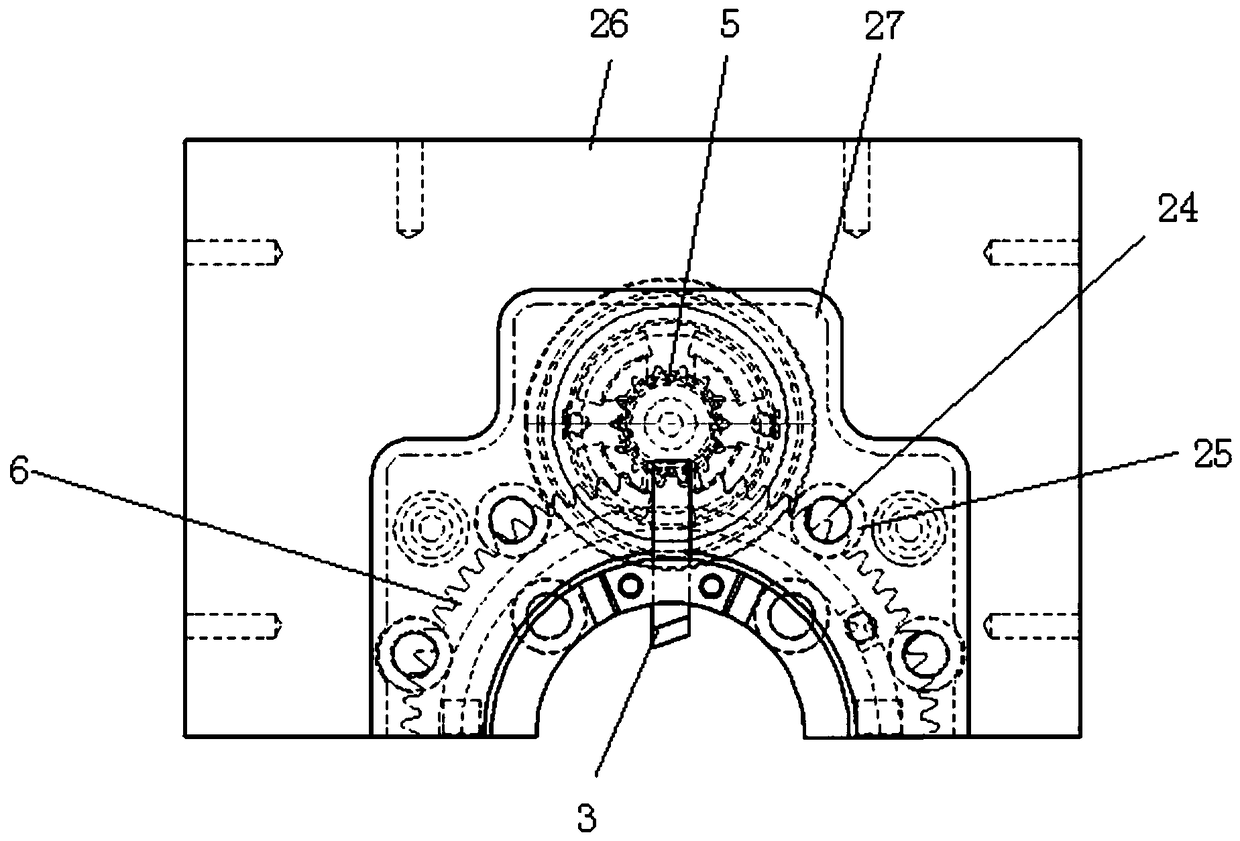

[0022] figure 1 is the exterior view of the deicer; figure 2 It is an internal sectional view showing the internal structure of the machine. The machine lifts an insulating support rod through the handle on the box body, and then the insulating support rod is hung on another cable (not belonging to the deicing machine structure). The whole machine includes a cabinet, a remote video acquisition device, a split deicing mechanism, a walking drive mechanism, a lifting mechanism, and a booster mechanism. All equipment except the cabinet is supported by the cabinet and installed on the cabinet. Going forward on the cables, the pre-deiced cables pass through the middle of the box. The remote video acquisition device 1 is installed on the box body and is used for real-time monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com