Light aluminium alloy chain block

A lever hoist, aluminum alloy technology, which is applied to portable lifting devices, hoisting devices, etc., can solve the problems of inability to work at high altitudes and heavy use, and achieve the effects of light weight, flexible and lightweight use, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

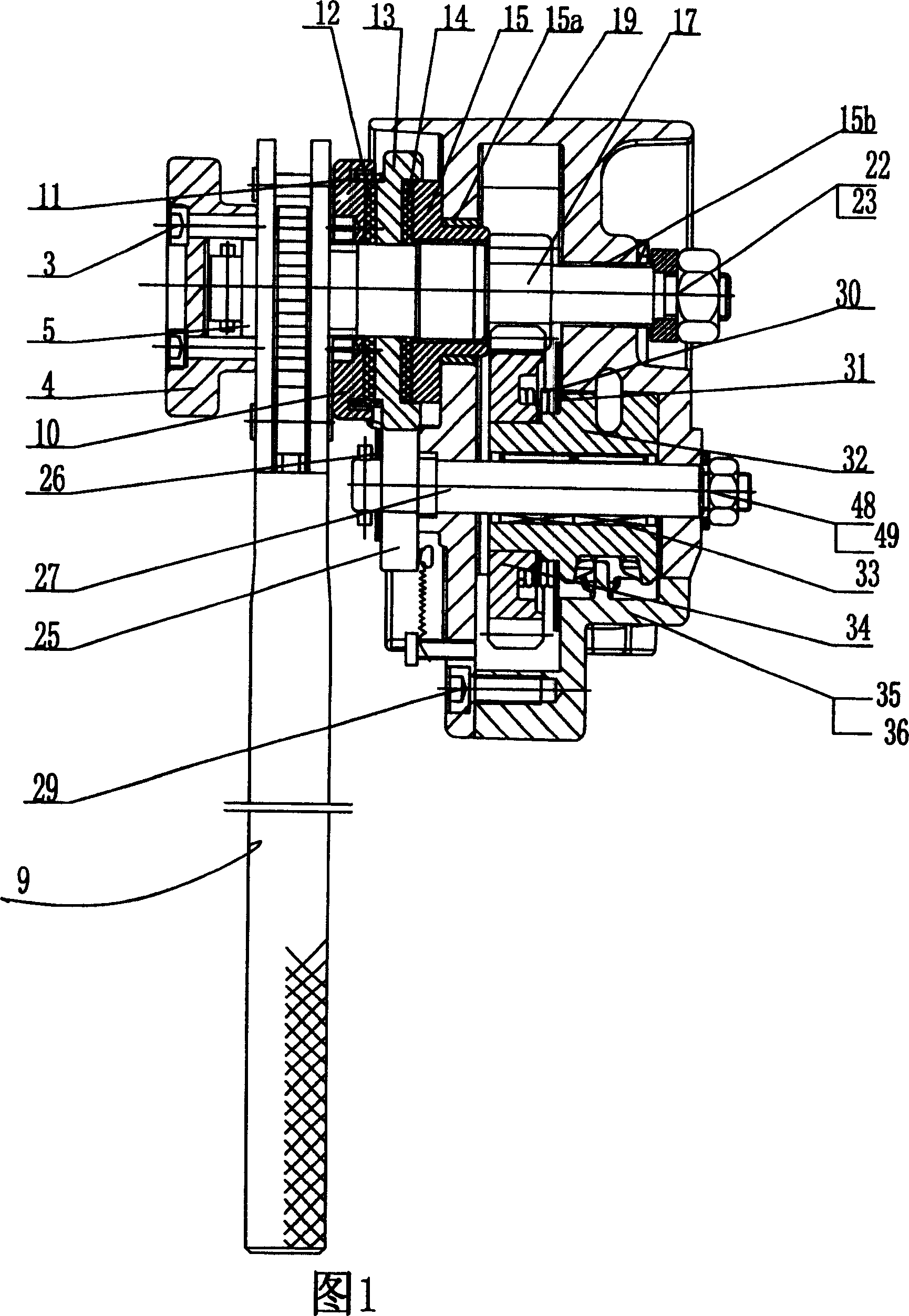

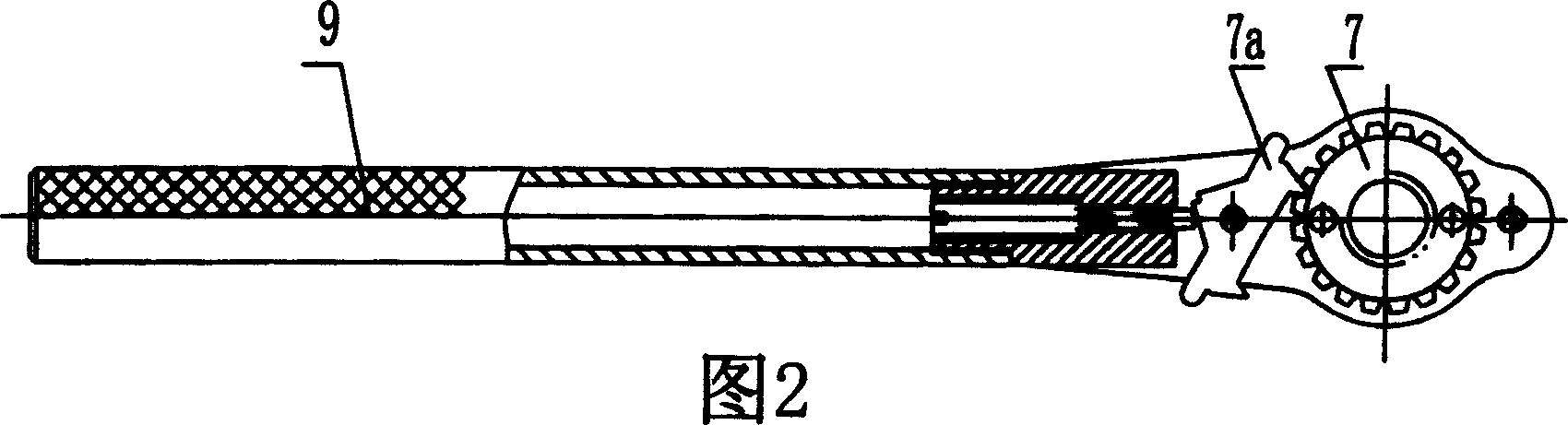

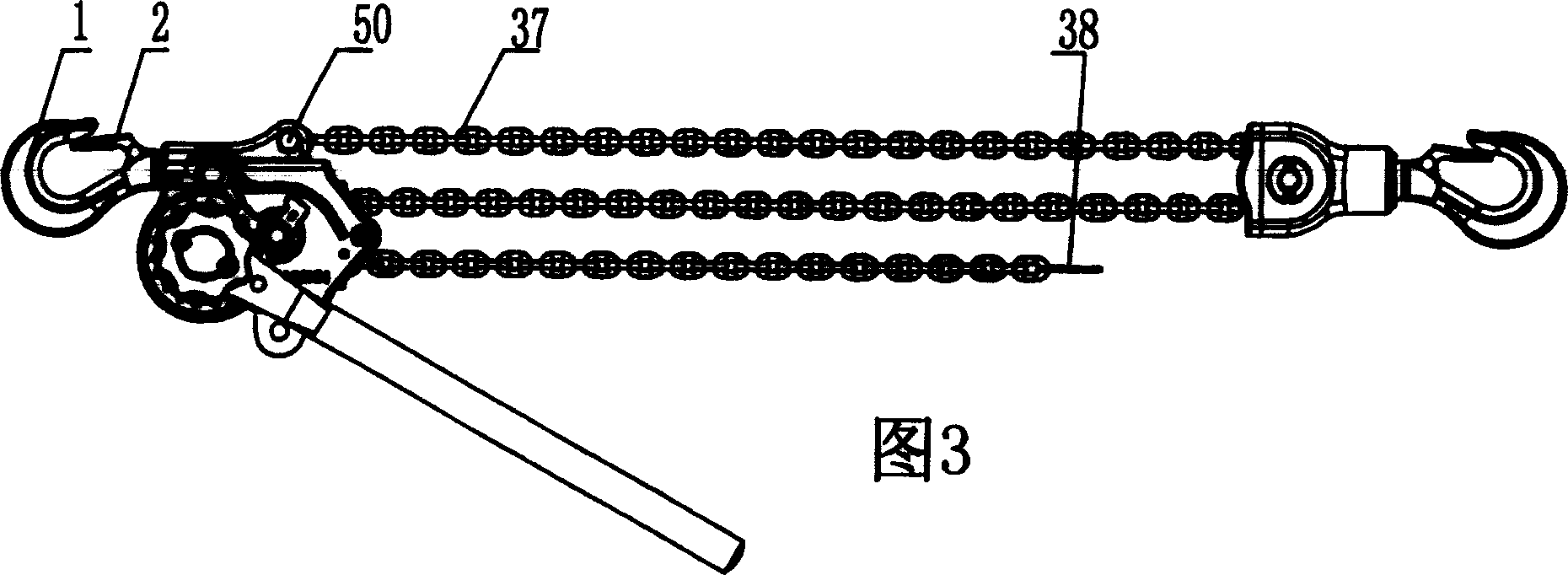

[0021] The structure of the present invention is shown in Fig. 1 to Fig. 5 . Portable aluminum alloy lever hoist, including matching main body mechanism, ratchet wrench mechanism and driven sprocket mechanism; the main body mechanism includes a main body shell 19 and a main body cover plate 35 screwed to the lower part of the main body shell 19 via socket head cap screws 29 and 36 , the upper hook 1 is connected to the upper part of the main body shell 19 through the outer hex nut 21 and the copper sleeve 20; the main body shell 19 has a built-in anti-reversal gear transmission device and a sprocket drive device, and the openings of the two hooks are equipped with a lock to prevent the chain from falling out. The cable plate assembly; the ratchet handle assembly 9 in the ratchet wrench mechanism is matched with the gear shaft 17 .

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com