Mounting method and fast connection locking mechanism for vertical rods of steel pipe scaffolds

A technology of locking mechanism and quick connection, which is applied in the connection of scaffolding, building structure, building structure support, etc. It can solve the problems of time-consuming, laborious, unsafe and troublesome work at heights, reduce the installation process and avoid unsafe factors in operation , the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The steel pipe scaffold pole quick connection locking mechanism and method of the present invention include the following steps:

[0025] Steel pipe scaffold pole quick connection locking mechanism of the present invention

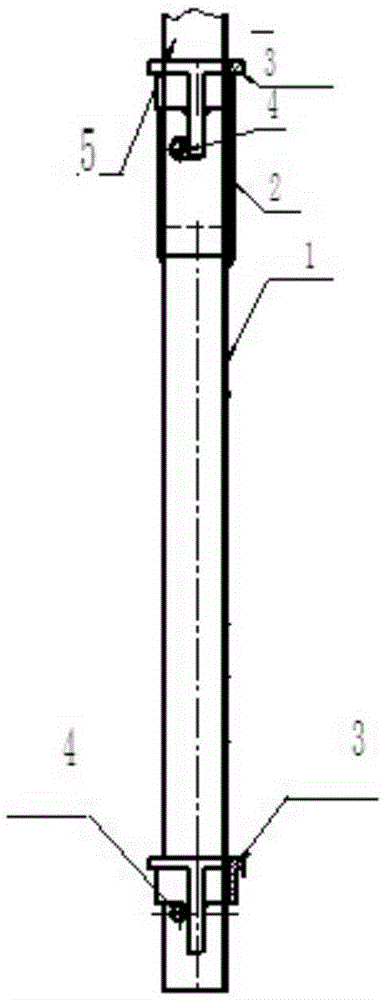

[0026] The steel pipe scaffold pole quick connection locking mechanism includes: a lower pole 1, a locking sleeve 2, a sleeve locking card 3, a locking nail 4 and an upper pole 5.

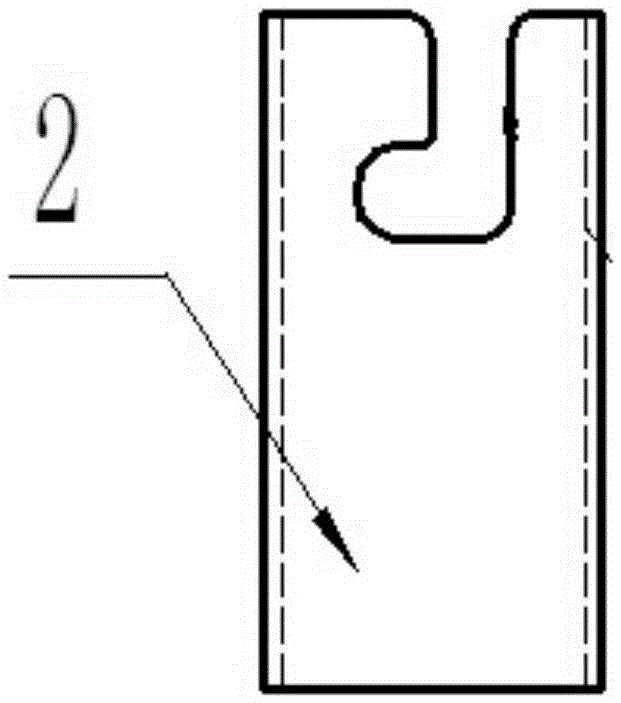

[0027] The lock sleeve 2 is exactly processed with a pair of symmetrical notches of fixed length and fixed width at one end of the lock sleeve, and the bottom of the groove turns 90° to have two semi-arc locks, such as figure 2 As shown, the upper end of the lower vertical rod 1 is inserted, and the lock is welded firmly with the vertical rod after the upward positioning of the lock to form a fixed lock sleeve.

[0028] The sleeve locking card 3 is exactly processed with a pair of symmetrical locking cards of fixed length and fixed width at one end of the sleeve lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com