Crimping device for improving pre-binding force of joint between carbon fiber composite core wire and fitting

A technology of crimping device and composite core, which is applied to the equipment for connecting/terminating cables, etc., can solve the problem of unreliable combination of mandrel and cone fittings, insufficient bonding force between mandrel and cone fittings, and easy slippage, etc. The problem is to overcome the unreliable combination, compact structure and reduce the overall weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

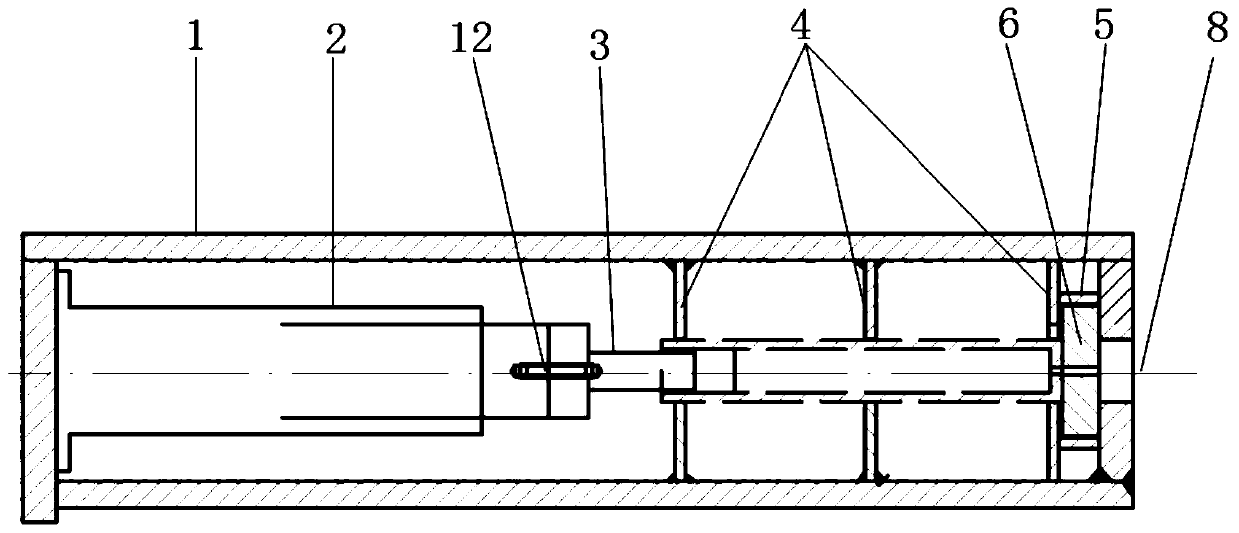

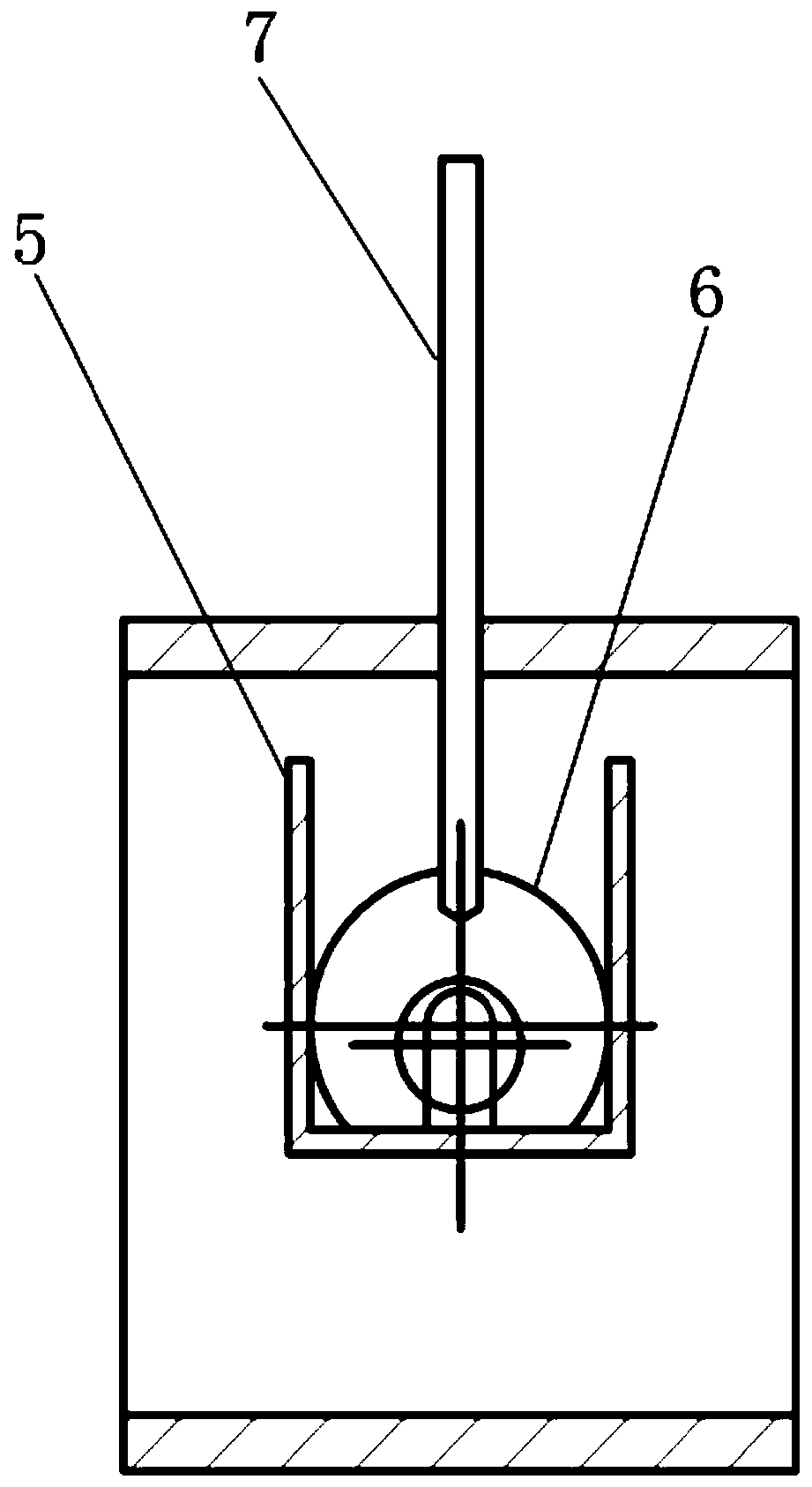

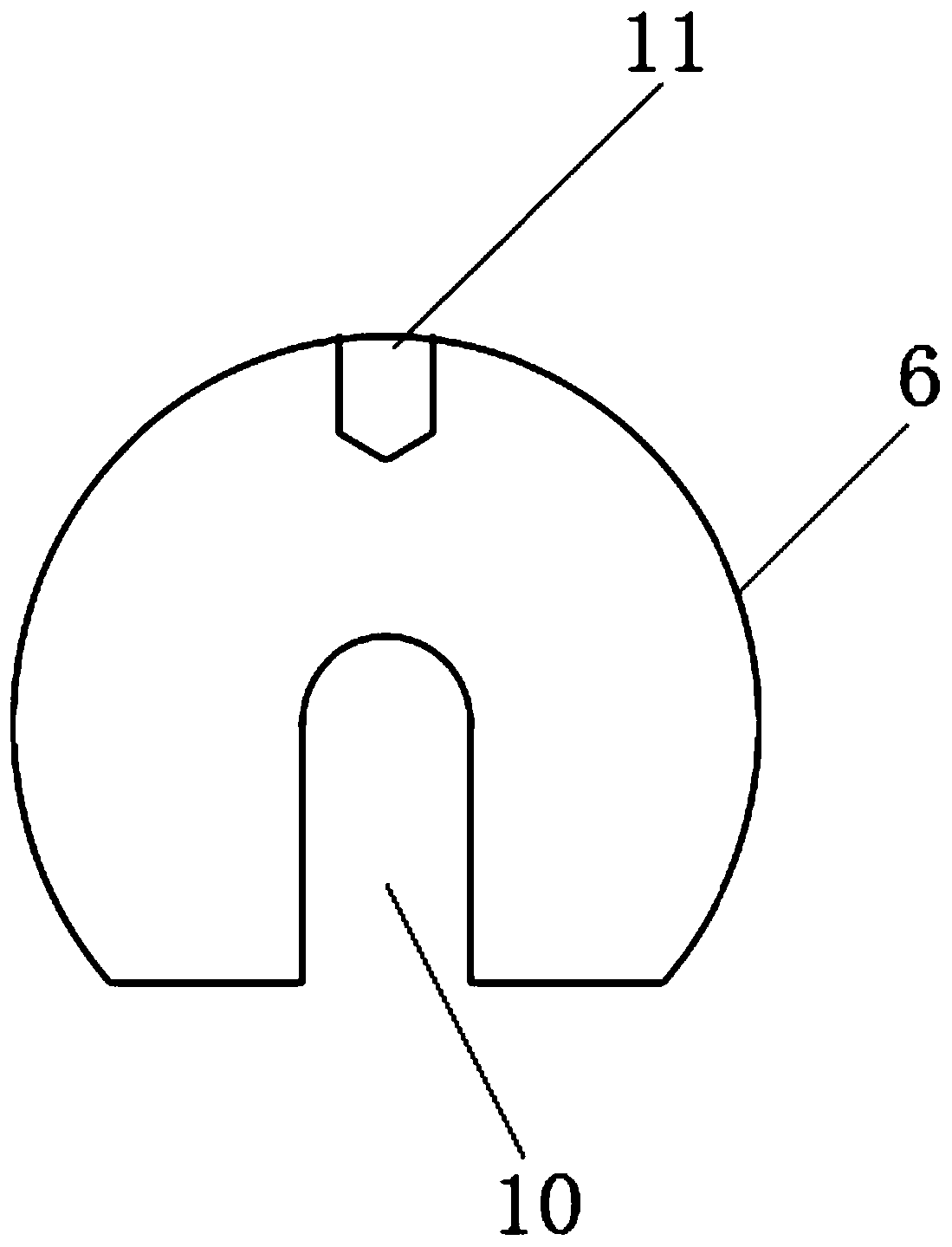

[0035] first embodiment ,refer to Figure 1-6, an example of a crimping device designed in the present invention to improve the pre-bonding force between the carbon fiber composite core wire and the joint between the fittings, including: including: an operating platform 1, a hydraulic device 2, a pressure transmitter 3, a fitting centering template 4, a positioning Block 5, force block 6, handle 7, inlet 8 and hydraulic device power source.

[0036] The operating platform 1 is a tubular structure with a chamber, one end of which is fixed with a hydraulic device 2, and the hydraulic device is a butterfly hydraulic device with a built-in thread 11 in the center of its plunger, which is connected with a pressure transmitter 3 through a screw rod. The type hydraulic device has small size, light weight, compact structure, high jacking force and high efficiency, and it has the same effect when placed at any angle. After the hydraulic pressure transmitter is connected with the pre...

no. 2 example

[0042] second embodiment , the operation platform 1 is welded by high-strength steel plate Q235, and the steel plate at the welding seam is beveled to increase the welding area and thus improve the strength of the welded steel plate.

no. 3 example

[0043] third embodiment , according to the stress mode and stress point of the load on the operating platform, a number of small holes are opened on the wall of the operating platform 1, which can reduce the overall weight and facilitate carrying during field construction. It should be noted that the setting of the small holes cannot affect the operation. Structural stability of the platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com