Hinge type middle jointing clamp

A hinged, indirect technology, applied in the direction of multi-conductor connectors, clamping/spring connections, etc., can solve the problems of troublesome operation of T-shaped clamps, falling of hexagonal nuts and U-shaped rings, and inconvenience, etc., to achieve Simple and convenient installation and disassembly, cost saving, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

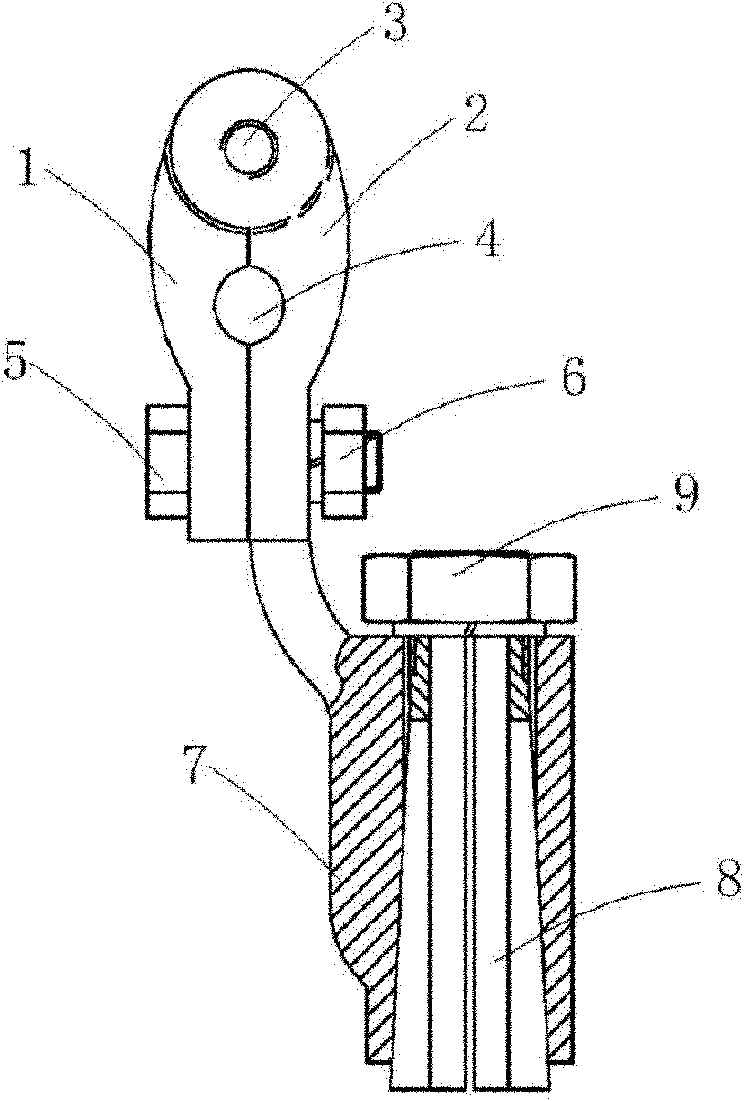

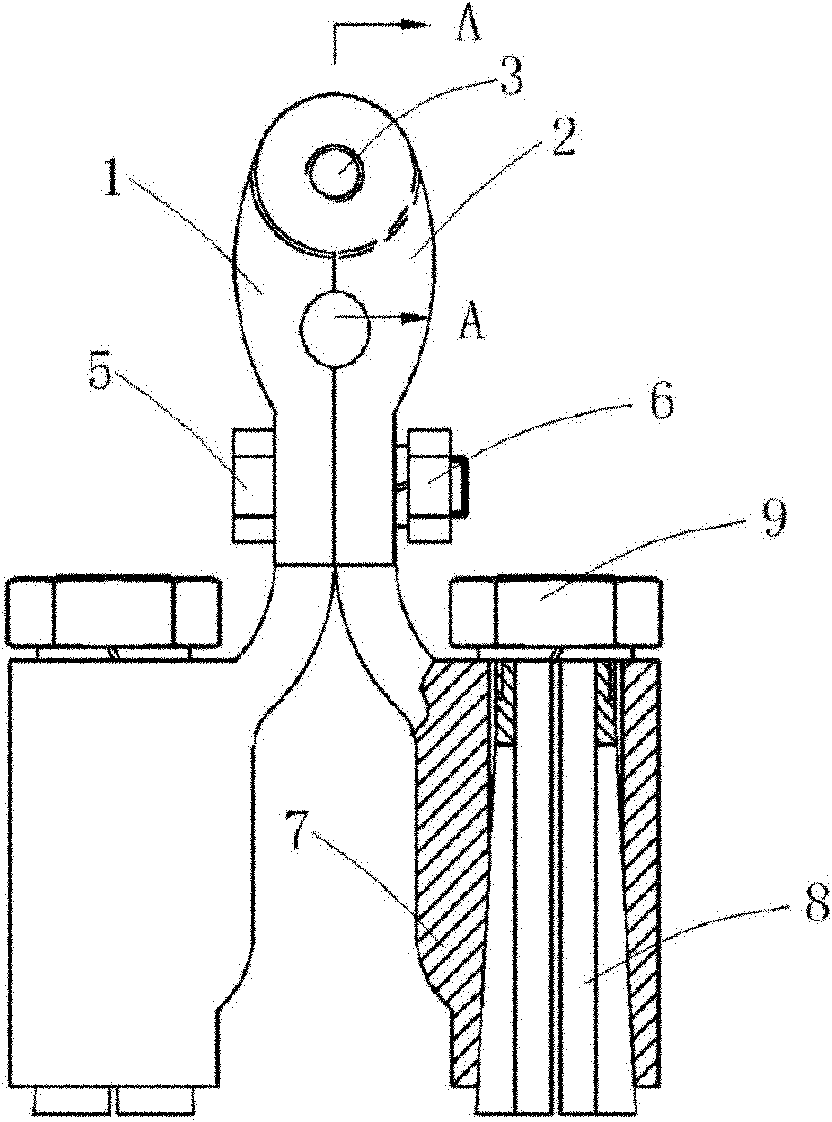

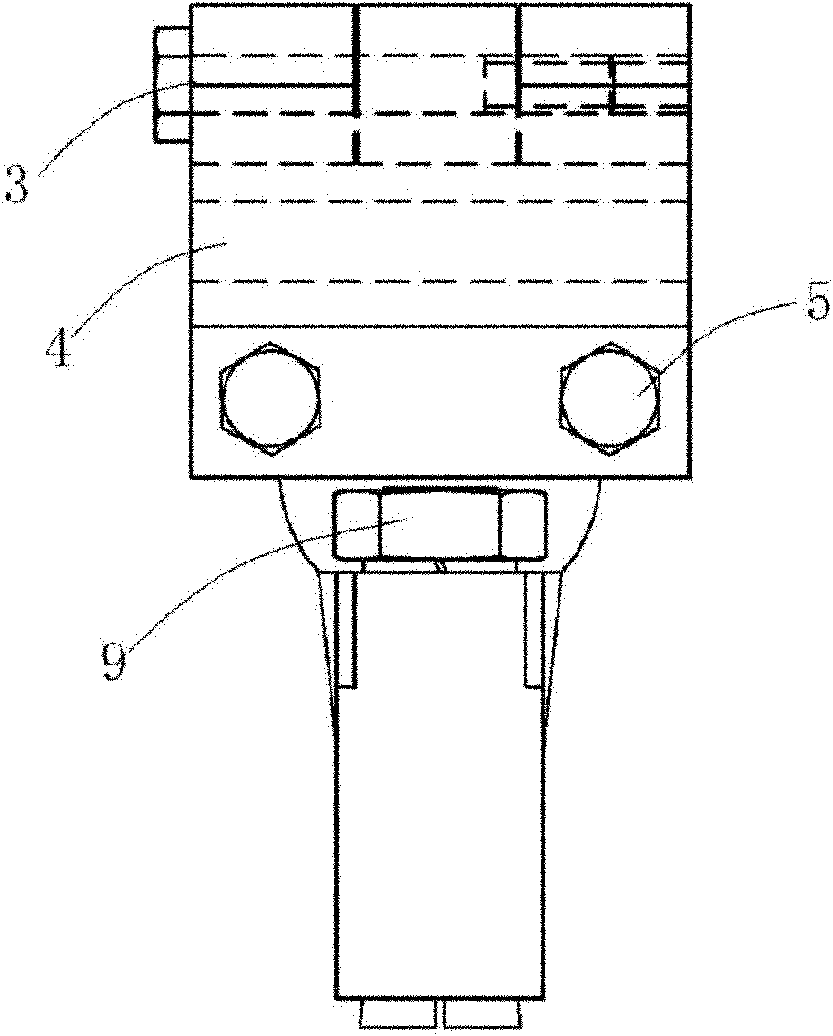

[0013] Example: see figure 1 , figure 1 Shown is the structure of the single-ended terminal clamp, including:

[0014] A connection card, the connection card is composed of a first terminal block 1 and a second terminal block 2, the bolts 3 above the upper end of the two terminal blocks are the common rotating shaft, and the bolts and nuts 5 and 6 below the lower end of the two terminal blocks are connected and clamped, And the opposite surfaces of the two wire sockets are provided with grooves to form clamping holes 4 for clamping cables; a sleeve 7 is fixedly connected to the lower end of the second wire socket 2, and a sleeve 7 is coaxially arranged in the sleeve There is a hollow frustum-shaped elastic taper sleeve 8 with a small upper end and a large lower end. The upper threaded section of the elastic taper sleeve stretches out from the sleeve and is connected with a tightening nut 9 on the threaded section. The elastic taper sleeve 8 The lower part is provided with fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com