A Dyneema rope non-destructive fast anchor and its operation method

A technology of Dyneema rope and operation method, applied in the field of Dyneema rope non-destructive quick anchor, can solve the problems of shortening the service cycle, Dyneema rope damage, affecting strength, etc., so as to reduce the possibility of damage, Improved operating efficiency and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

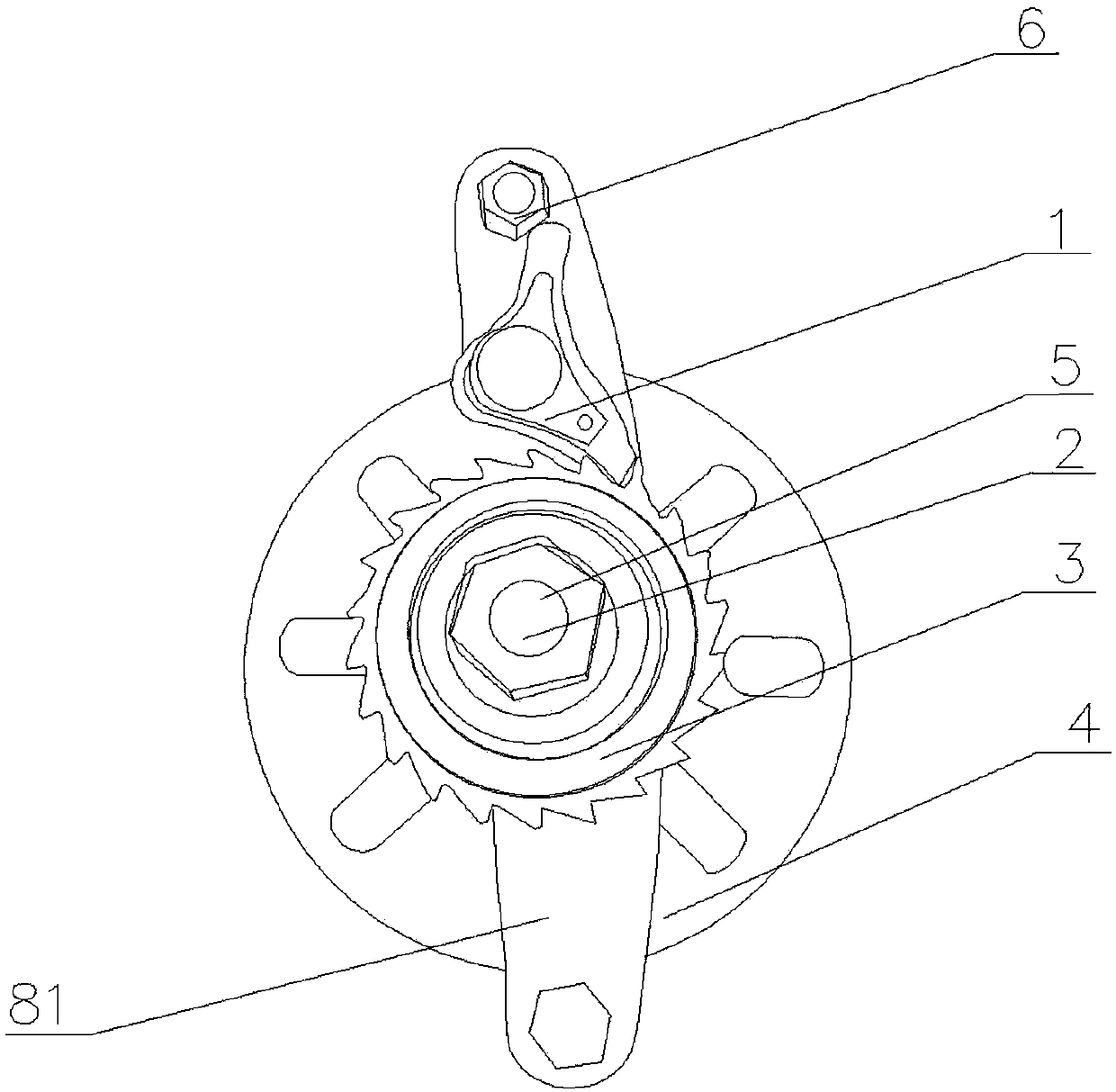

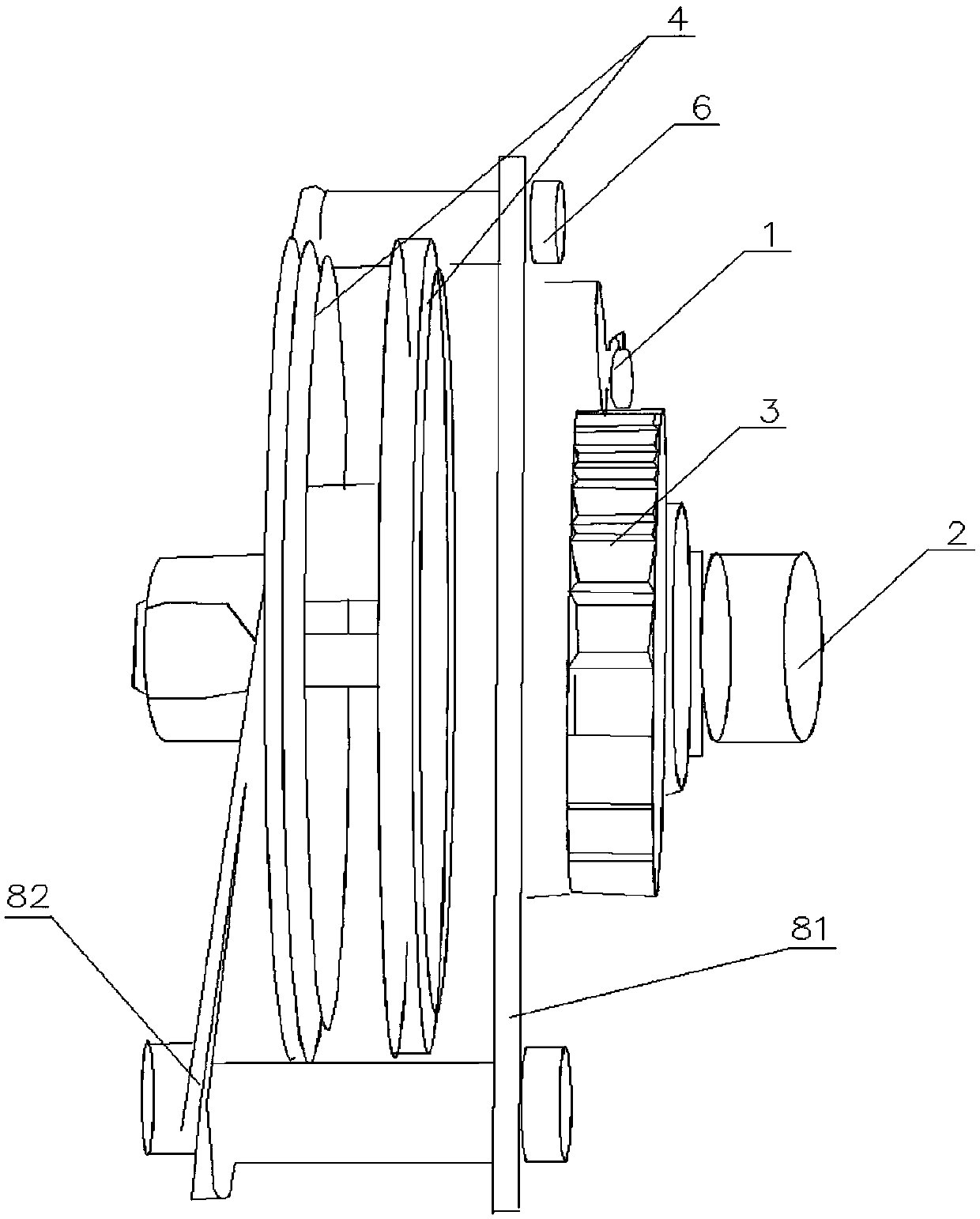

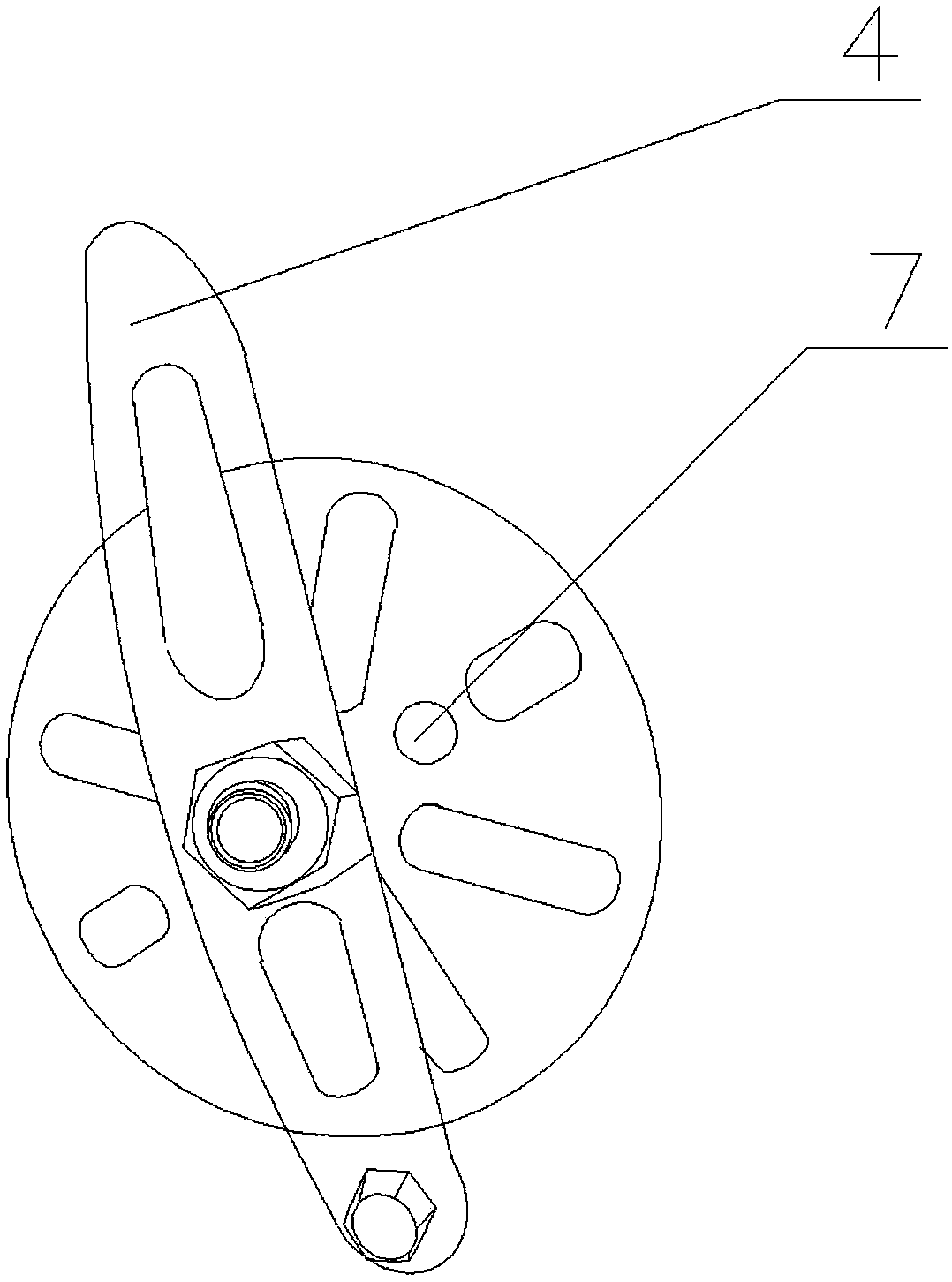

[0042] Such as figure 1 , figure 2 , image 3 As shown, a Dyneema rope non-destructive quick anchor of the present invention includes a winding reel 4 and a fixed shaft 2, the fixed shaft 2 passes through the center of the reel 4, and the connection between the fixed shaft 2 and a plurality of reels 4 The distance between the winding reels 4 is used for winding the Dyneema rope, and the two ends of the fixed shaft 2 are provided with fixing bolts 5. A thread locking pin 7 is installed on the position close to the fixed shaft 2 on the winding reel 4 , the thread locking pin 7 is detachably connected with the winding reel 4 , and the thread locking pin 7 runs through the winding reel 4 . A first bracket 81 and a second bracket 82 are respectively arranged between the said winding reel 4 and the end close to the fixed shaft 2, and the two ends of the first bracket 81 and the two ends of the second bracket 82 are provided with a penetrating first bracket. 81 . The anchor ring ...

Embodiment 2

[0049] An operation method of a Dyneema rope non-destructive quick anchor, comprising the following steps:

[0050]Step 1: Remove the locking pin 7, ride the anchor on the Dyneema rope to be anchored, and re-screw the locking pin 7 and install it on the winding reel 4;

[0051] Step 2: Connect one of the anchor rings 6 with the U-shaped ring of the ground anchor rope;

[0052] Step 3: Use an M16 torx wrench to rotate the fixing bolt 5 to drive the fixed shaft 2 and the winding reel 4 to rotate. Under the guidance of the locking pin 7, the Dyneema rope is wound on the fixed shaft 2, so that the Dyneema rope The lamination method is stored in the winding reel 4. After winding at least 2 layers on the fixed shaft 2, stop turning the fixing bolt 5 to achieve the effect of anchoring the Dyneema rope;

[0053] Step 4: When removing the anchor, manually open the ratchet 3, use the M16 torx wrench to reversely rotate the fixing bolt 5, gradually loosen the Dyneema rope, re-lock the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com