Inspection robot for ultra-high voltage power transmission lines

A technology for inspection robots and transmission lines, applied in the field of robots, can solve problems affecting the reliability of power systems, long inspection cycles, and economic losses, and achieve the effects of ensuring safe and reliable operation, saving inspection time, and solving slippage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

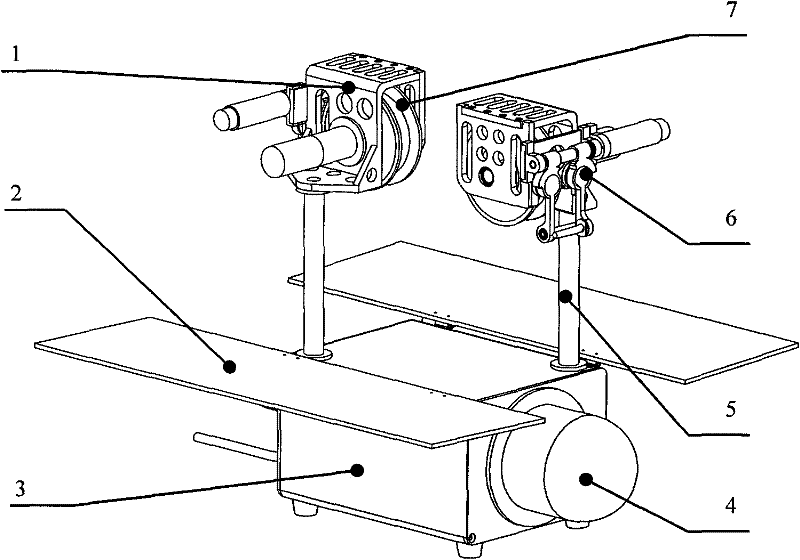

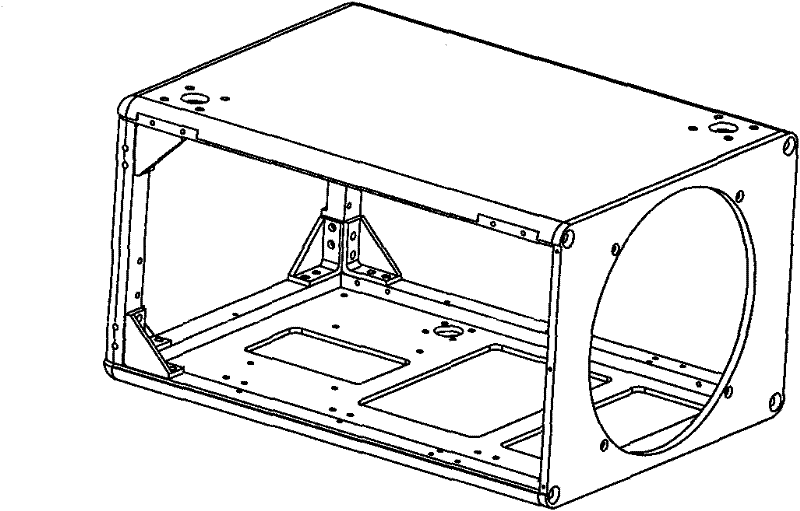

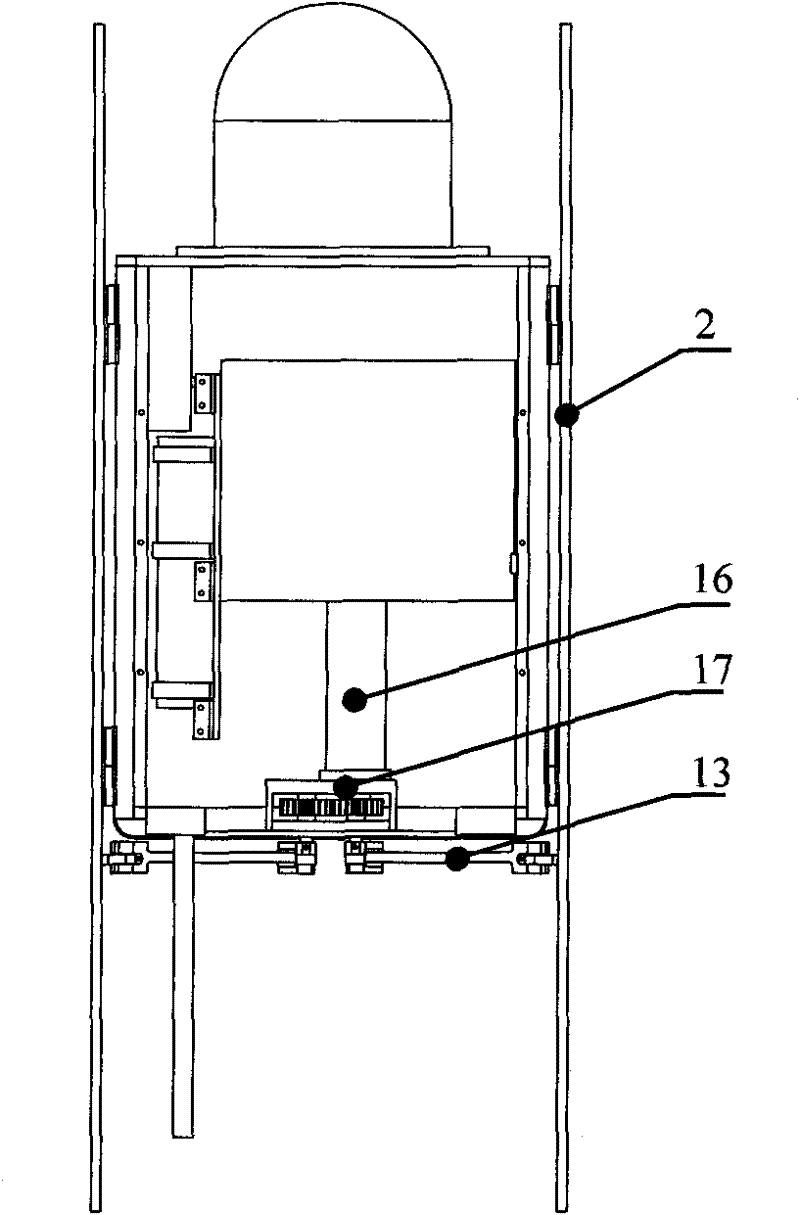

[0031] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention; figure 2 It is a schematic structural view of the frame structure of the robot body described in the present invention.

[0032] Such as figure 1 and figure 2 As shown: the ultra-high voltage transmission line inspection robot includes a robot body 3, a walking clamping mechanism and a charging device, wherein the robot body 3 is a frame-type box structure, and its exterior is covered with an aluminum skin. The robot body 3 includes a control Device, detection device and wireless image transmission device, described detection device is camera 4, and it is arranged on the front end of robot body 3, carries out real-time photograph to power line surface, and the image of taking is sent to ground image by wireless image transmission device The receiving part; the walking clamping mechanism includes a walking mechanism 1 and a clamping mechanism 6, and the walking cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com