Integrated-type comprehensive coal bunker

An integrated, coal storage technology, applied in the field of coal storage, can solve the problems of difficult environmental pollution control, complex operation and management, and large space occupation, so as to save coal transportation energy, optimize personnel allocation, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

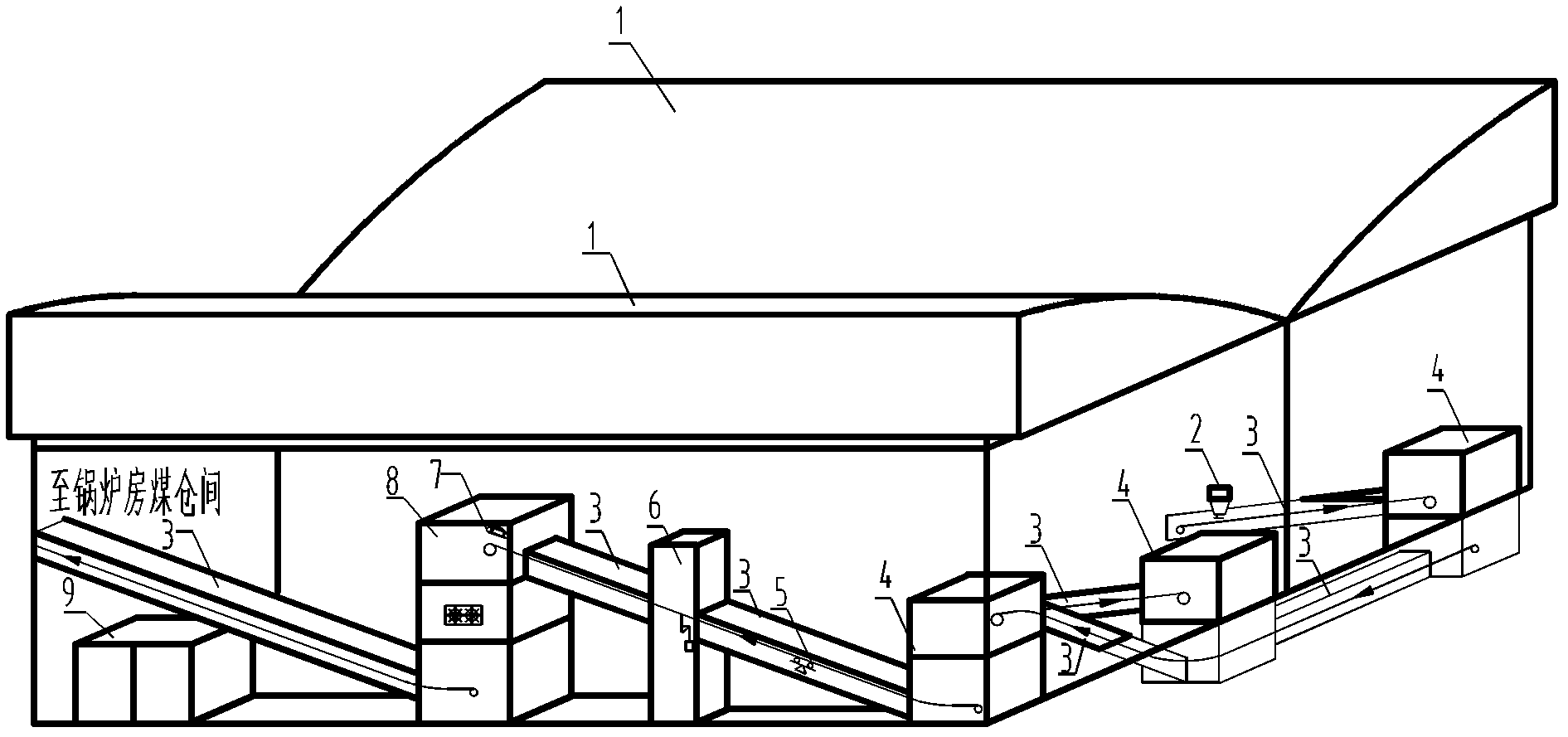

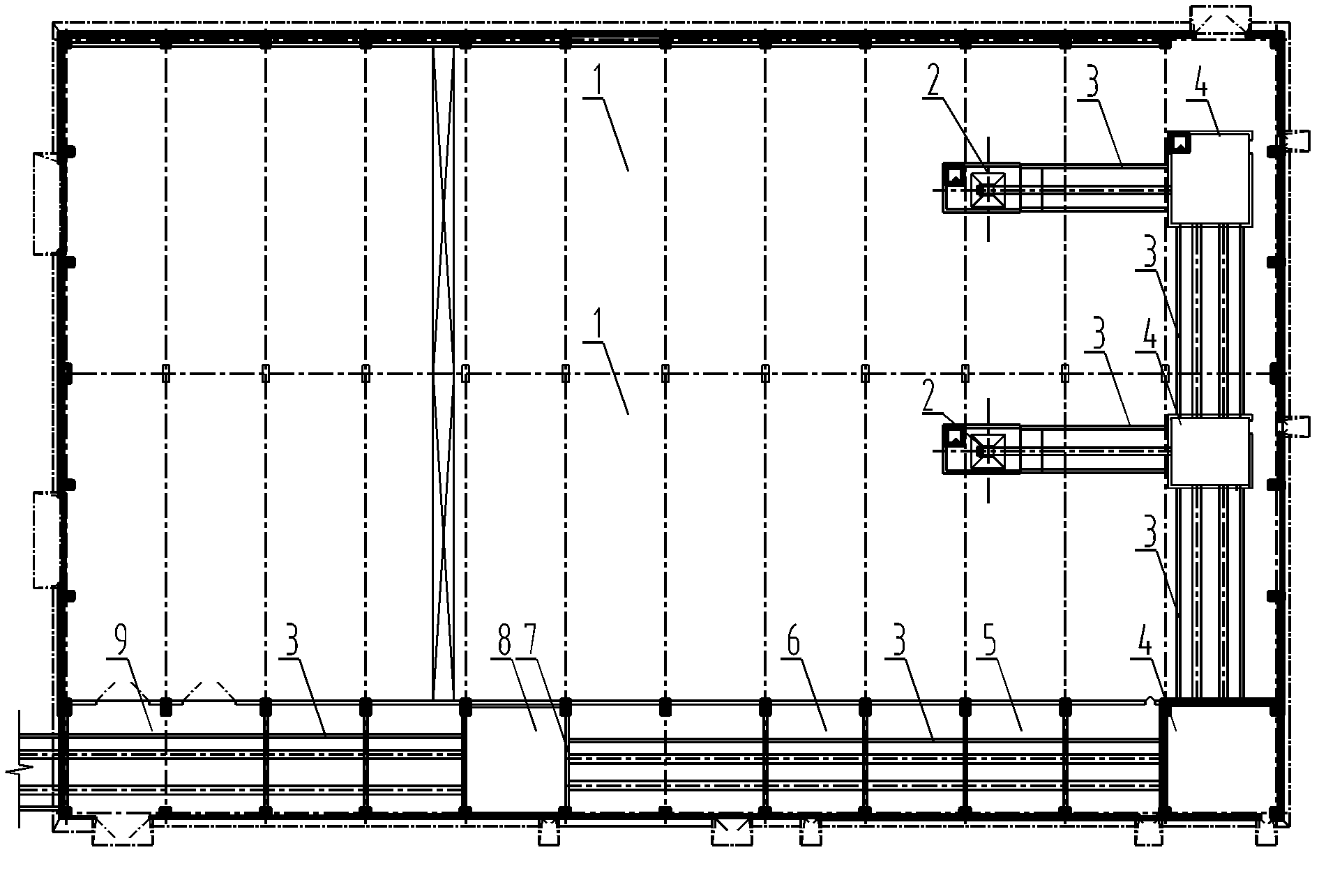

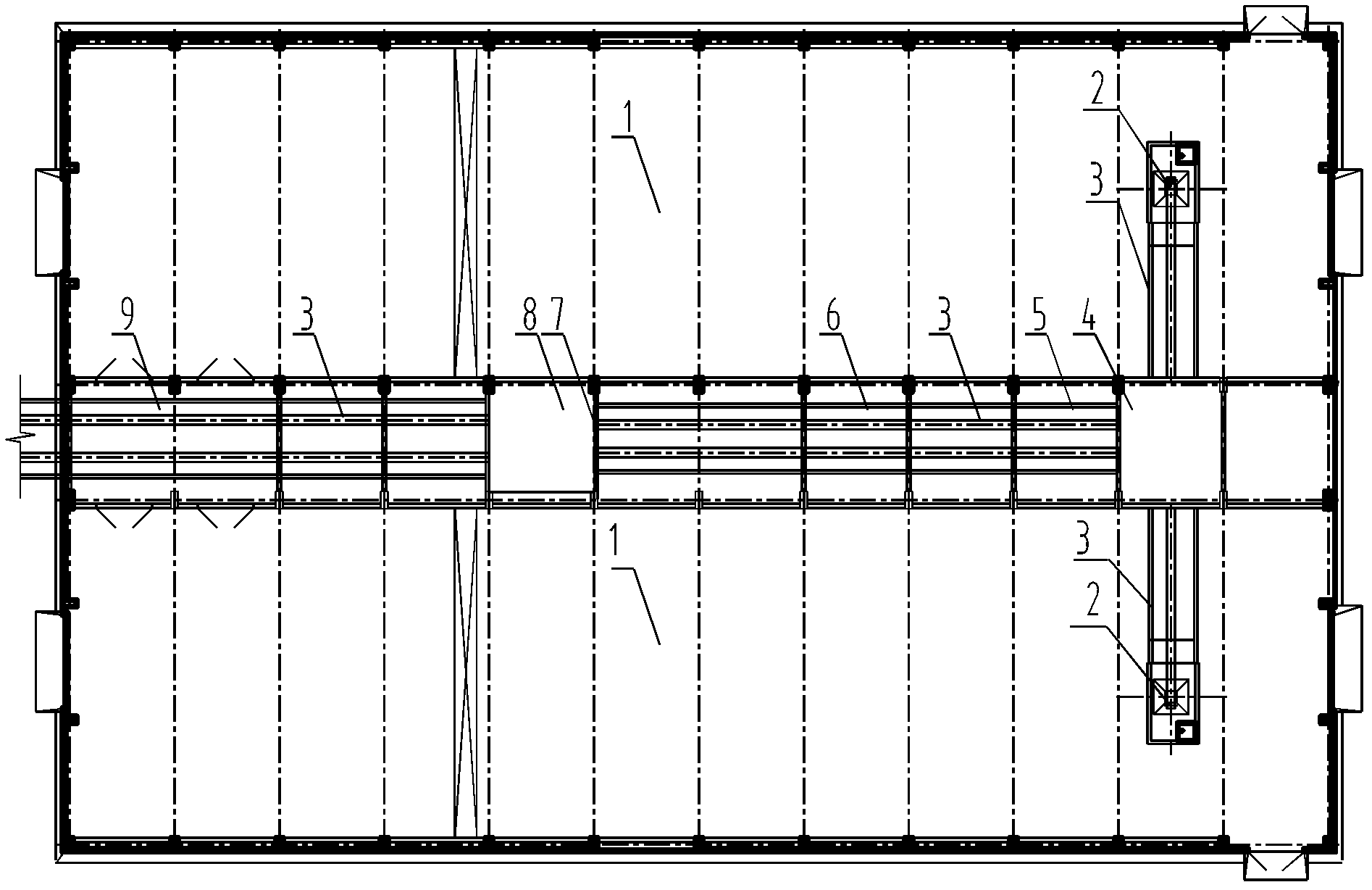

[0036] figure 1 is a system schematic diagram of an embodiment of the present invention, figure 2 It is a schematic plan layout diagram of a comprehensive coal depot in which the multi-functional frame of the present invention is placed outside the double-span coal depot. Such as figure 1 and 2 As shown: the present invention includes a double-span coal storage warehouse 1, two underground coal hoppers 2, 6 coal delivery trestles 3, 3 transfer stations 4, a sampling room 6, a coal crusher room 8, and a coal pushing hangar 9 Other structures and bridge-type coal grabbers, loaders or / and coal pushers, coal feeders, belt conveyors, electronic belt scales 5, furnace coal sampling and sampling devices in the sampling room 6, iron removers 7, Coal transportation facilities such as coal sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com