An H-shaped steel beam installation gap adjustment device and its use method

An adjustment device, H-shaped steel technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems affecting structural safety, safety accidents, waste of manpower, etc., to ensure safe operation, convenient operation, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

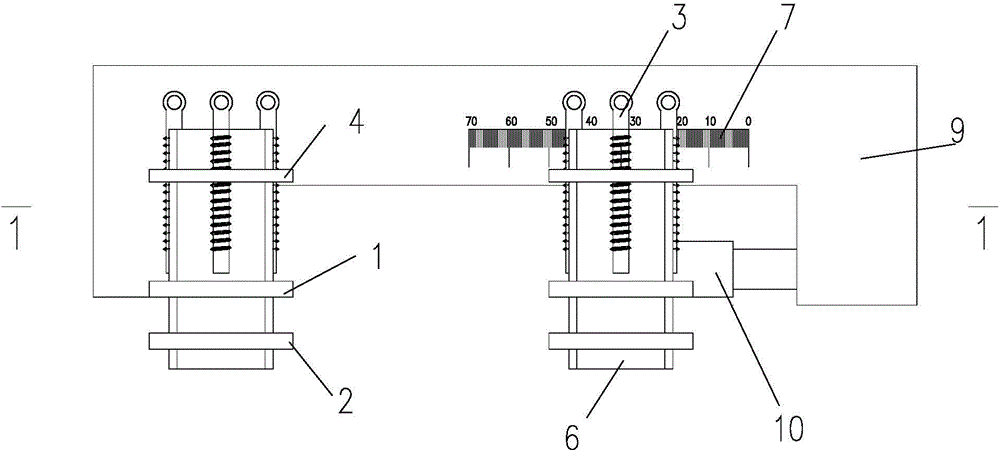

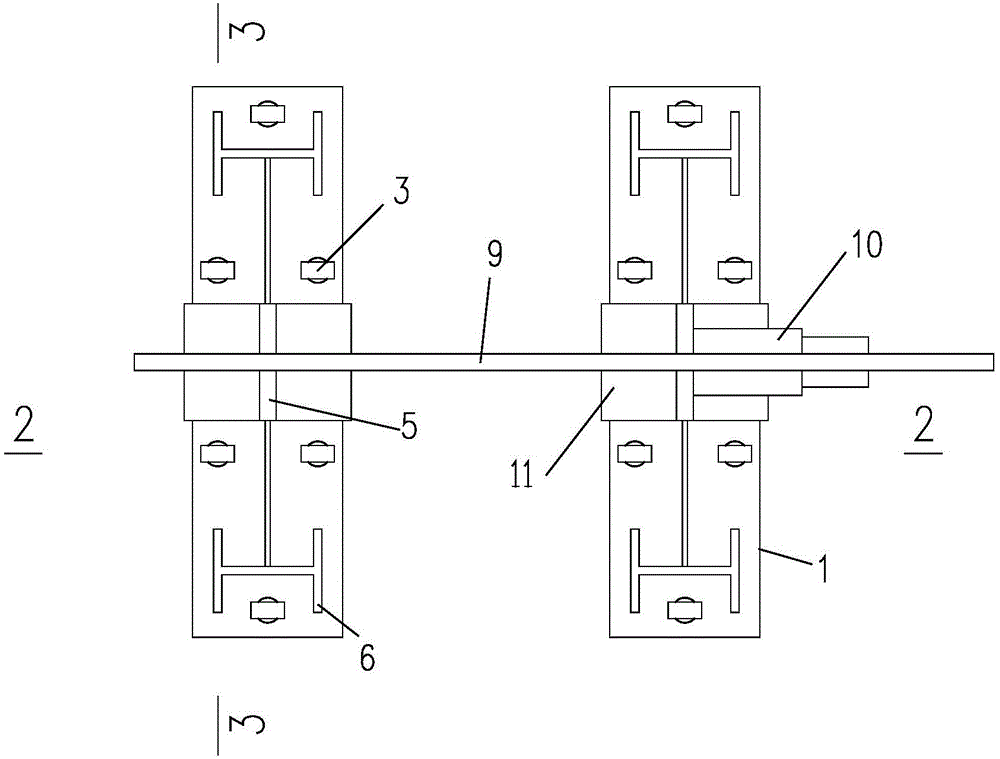

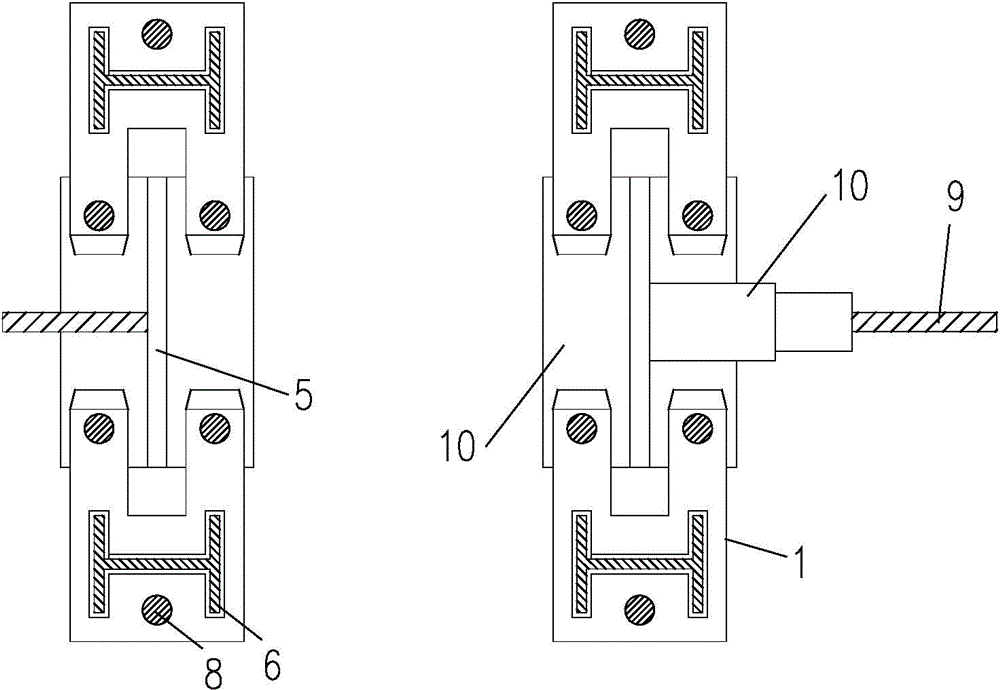

[0037] [Example 1] see Figure 1-Figure 3 , is a specific structure of the H-shaped steel beam installation gap adjustment device according to the present invention. The overall height of the device is 380mm and the length is 1030mm. The sliding splint 1 is stamped from a 20mm thick steel plate and can slide up and down along the H-shaped slideway 6 The fixed splint 2 is stamped from a 20mm thick steel plate and welded below the H-shaped slideway 6; the jacking bolt 3 is an M20 head with a ring adjusting bolt. In this embodiment, each set of clamping mechanisms is provided with 3 jacking bolts Tighten the bolts 3, wherein two H-shaped slideways are arranged on the inner side and one on the outer side, and are arranged symmetrically along the center line of the clamping mechanism. The tightening bolt 3 can pass through the fixed adjustment plate 4 and be pushed into the anti-skid groove 8 of the sliding splint 1; the fixed adjustment plate 4 is a 16mm steel plate, welded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com