Pull explosion screw nail

A screw and nut technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of rust on the surface of stainless steel, affecting the aesthetics, and increasing the amount of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

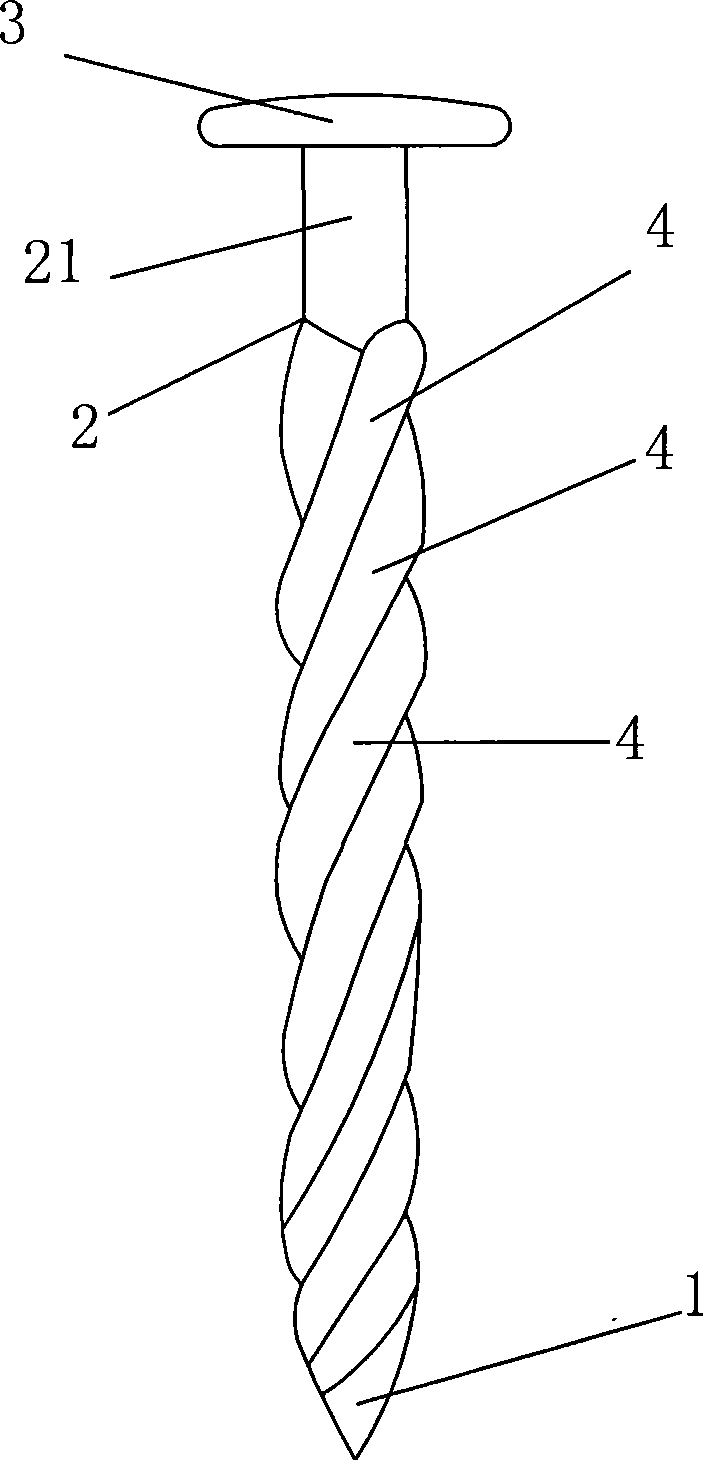

[0007] see Figure 1 to Figure 2 , a pop-up screw, which includes a conical head 1, a main body 2, a nut 3, a plurality of head thread 4.

[0008] The nut 3 is installed on the head of the main body 2 , and the nut 3 has a smooth and smooth appearance and a model decoration letter 31 in the middle part.

[0009] The conical head 1 is mounted on the tail of the main body 2 .

[0010] On the main body 2, a toothless area 21 of 5 mm is provided downward from its head, and the toothless area 21 is for the convenience of being equipped with pad buttons and accessories for movable use.

[0011] The lower end of the toothless area 21 on the main body 2 is provided with several head threads 4, the several head threads 4 are mainly to facilitate the self-rotation of the bursting screw during the beating process, so that labor-saving, time-saving and convenient in the process of nailing. More suitable for working at heights.

[0012] The present invention is simple in structure and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com