Preheating and after-heating device for welding

A heating device and heating tube technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as inconvenient operation, and achieve the effects of convenient heating length, energy saving, and uniform flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

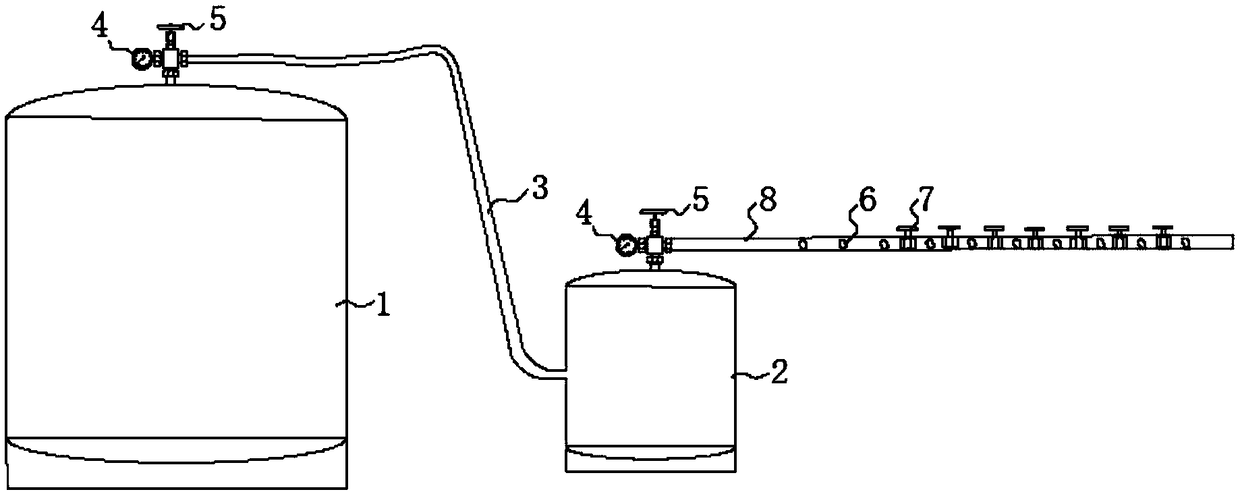

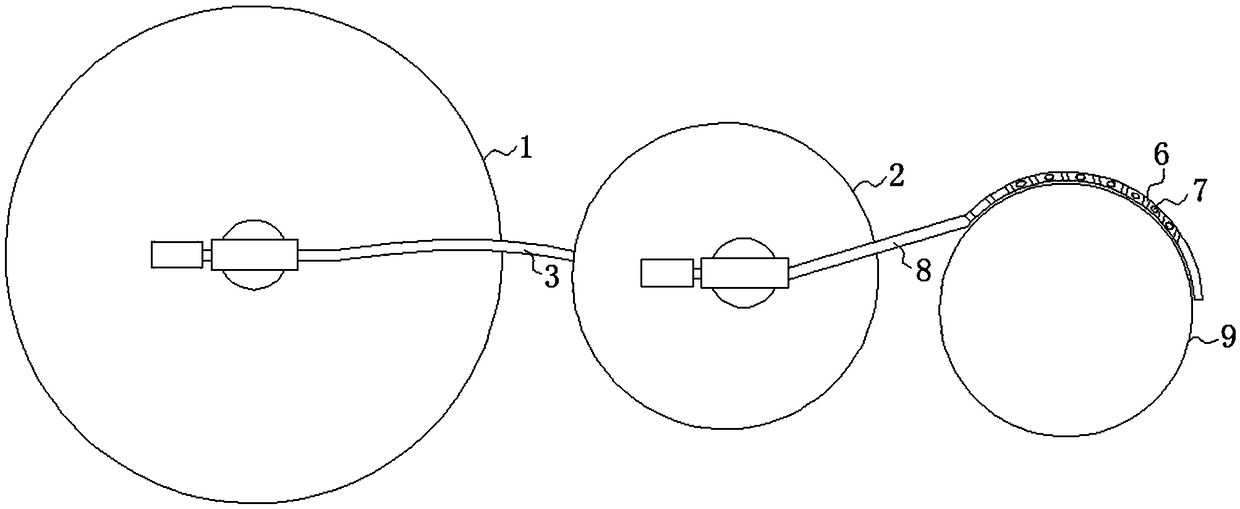

[0033] Such as figure 1 As shown, a heating device after welding preheating includes a gas source tank 1, the combustion gas in the gas source tank 1 can be combustible gases such as liquefied petroleum gas, propane or ethane, and the output end of the gas source tank 1 is connected with a foldable Bend the heating tube 8, the material of the bendable heating tube 8 can be iron, steel, etc., in order to facilitate the operator to bend the bendable heating tube 8, the bendable heating tube 8 of this embodiment adopts a stainless steel hose, On the one hand, the stainless steel hose is easier to deform, and is more resistant to bending and high temperature; through the bendable heating tube 8, the operator can adjust the bending rate of the heating tube according to the curvature of the base material 9 to be welded, which has higher versatility.

[0034] The bendable heating tube 8 of this embodiment is provided with a number of air outlet holes 6 uniformly distributed in the ho...

Embodiment 2

[0036] Such as figure 1 As shown, a welding preheating and afterheating device of this embodiment includes a gas source tank 1 and a buffer tank 2 connected by a pressure tube 3, and a bendable heating tube 8 is connected to the output end of the buffer tank 2, which can be A number of air outlet holes 6 uniformly distributed in the transverse direction are opened on the bent heating tube 8 , and a control valve 7 is arranged on the air outlet holes 6 , and the end of the bendable heating tube 8 away from the gas source tank 1 is closed.

[0037] It should be noted that, in other embodiments, multiple gas source tanks 1 can be provided, and multiple gas source tanks 1 are connected to one buffer tank 2, and can be opened together to supply gas to the buffer tank 2 and the bendable heating tube 8 , it should be noted that it is sufficient to adjust the air pressure of each air source tank 1 to ensure that it is within the pressure range of the buffer tank 2 . It is also possib...

Embodiment 3

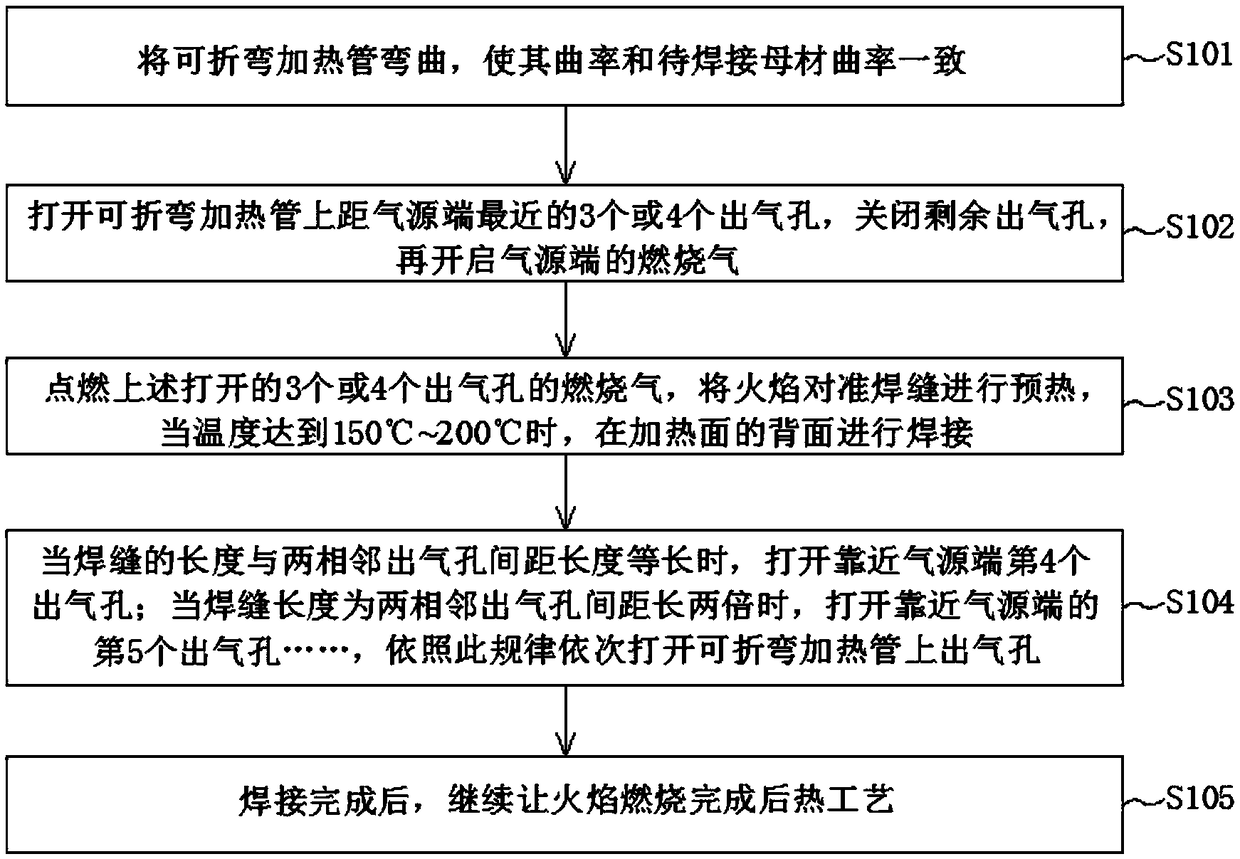

[0042] A kind of welding preheating post-heating device of this embodiment, in order to facilitate the portability of the whole device and facilitate operators to carry out high-altitude operations, the welding pre-heating post-heating device includes a 35.5L liquefied petroleum gas tank connected by a pressure-bearing pipe 3 and 4.7L buffer tank 2, if it is the welding of large-scale equipment on the ground, a larger size gas source tank 1 and buffer tank 2 can be used. The output end of the buffer tank 2 is connected to the bendable heating tube 8, and the bendable heating tube 8 There are 7 to 10 air outlets 6 on the top, except for the first 3 or 4 air outlets 6 close to the air source tank 1, the other air outlets 6 are connected to the control valve 7, and the bendable heating tube 8 is far away from the air source. Tank 1 is closed at one end. Not all of the air outlets 6 in this embodiment are provided with control valves 7, because preheating starts before welding, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com