Live-line work robot lead lap joint device and lap joint method

A technology of lead wire lapping and live work, which is applied to the installation of cables, busbars, manipulators, etc., can solve the problems of high labor intensity, high processing difficulty, personal danger of live work personnel, etc., and achieve design and component simplification, Reduced power and weight, increased ease of disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

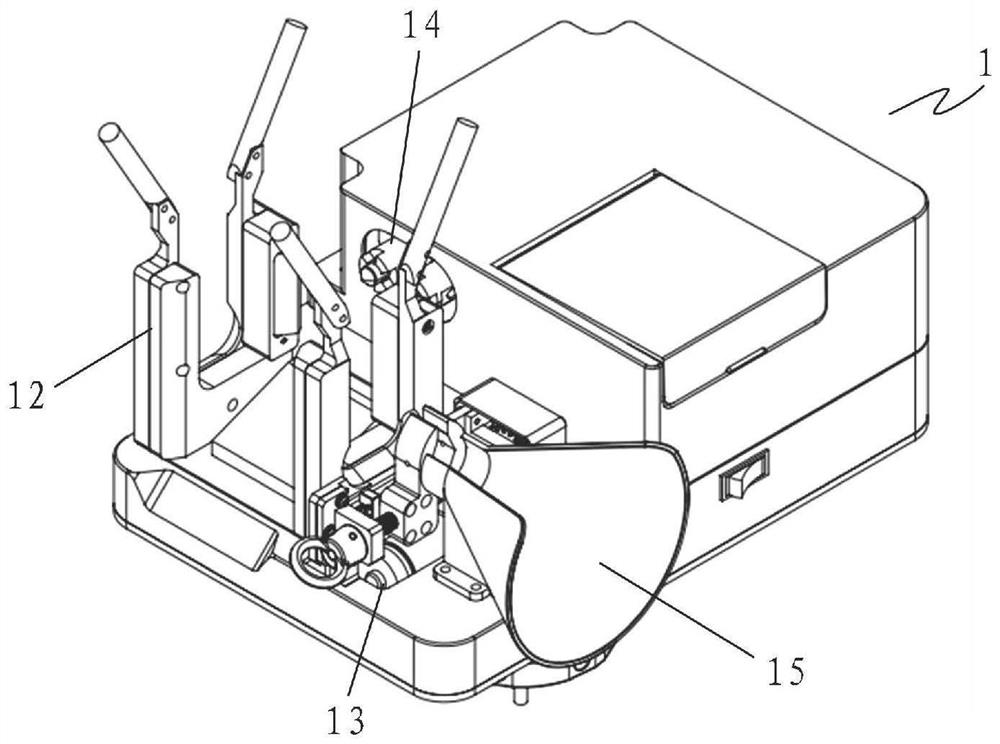

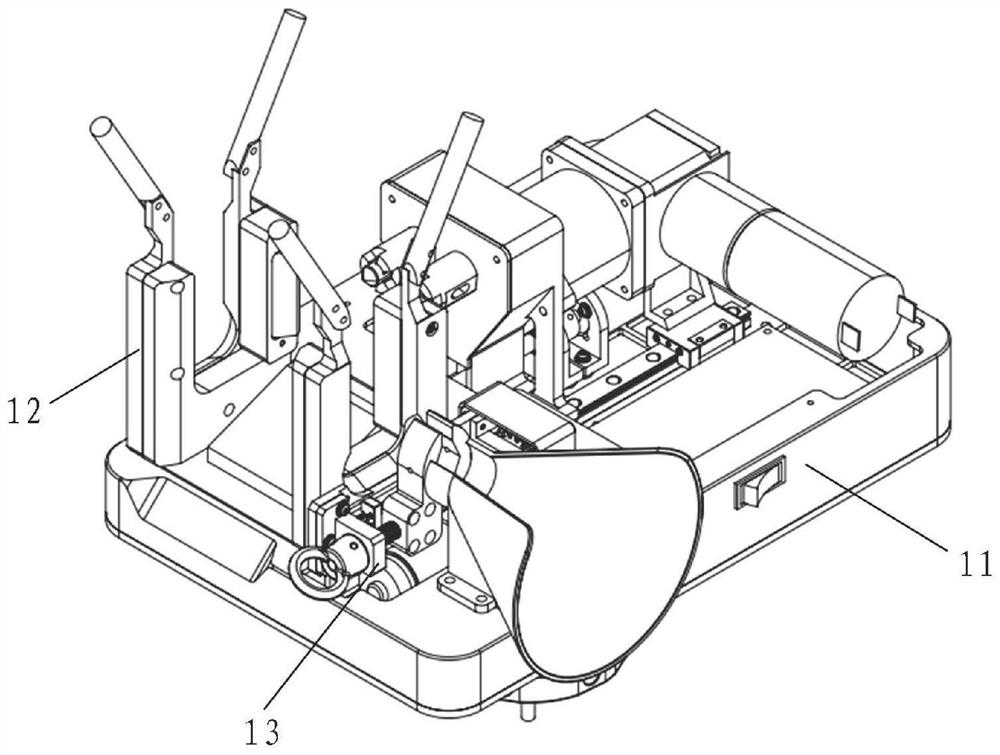

[0067] see Figure 1 to Figure 10 As shown, a lead wire bonding device of a live working robot includes: a wiring tool 1 and a wire clip 2;

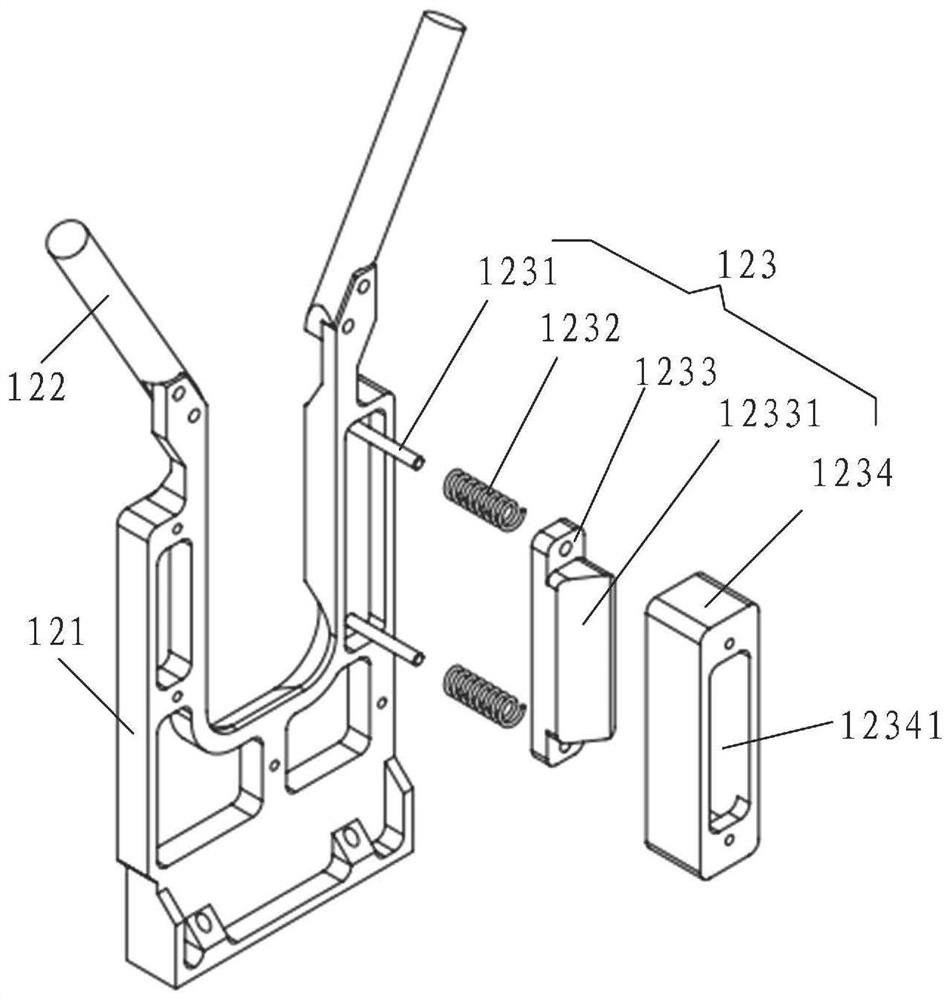

[0068] The wiring tool 1 includes: a frame 11 , a wire clamp mounting mechanism 12 , a lead wire clamping mechanism 13 and a wire clamp tightening mechanism 14 ; the wire clamp installation mechanism 12 and the wire clamp mechanism 12 are arranged side by side at the front end above the frame 11 , the wire clamp tightening mechanism 14 is arranged at the rear end above the frame 11;

[0069] like Figure 4 As shown, the wire clip 2 includes: a front side part 21 and a rear side part 22. The front side part 21 and the rear side part 22 are connected by at least a pair of bolts, and the front side part 21 and the rear side part 22 are connected by at least one pair of bolts. A busbar slot 23 and a lead slot 24 are formed between the busbars and the lead wires; a wire clip fixing box, the wire clip is installed in the wire clip fixing box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com