Pavement reinforcement system

A control system and hydraulic cylinder technology, applied in roads, roads, road repairs, etc., can solve problems such as incompetence, poor pressure adjustment performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In conjunction with the accompanying drawings, the present invention is explained in detail.

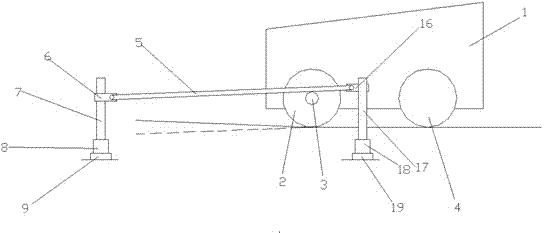

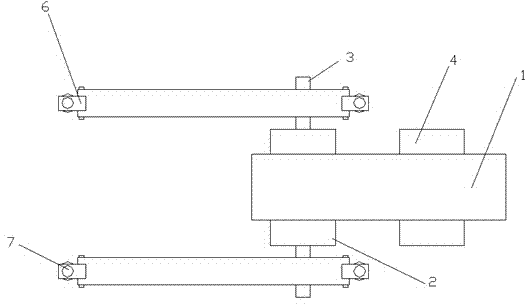

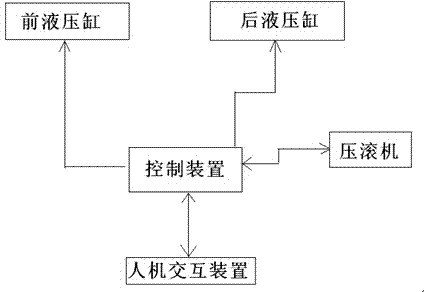

[0017] The road surface reinforcement system includes: a rolling machine, two sets of rail pressing devices and a control system; the rolling machine includes a fuselage 1, a compacting roller 2 and a driving roller 4, and the compacting roller 2 and the driving roller 4 are respectively Installed at the front end and the rear end of the fuselage 1, the center of the two ends of the compacting roller 2 is provided with a cylindrical rail pressing shaft 3 extending axially outward.

[0018] Each set of said rail pressure device includes a front telescopic system, a rear telescopic system and a rail pressure rod 5, said front telescopic system includes a front hydraulic cylinder 8, a front fixing device 9, a front piston rod 7 and a front connecting piece 6, said front The fixing device 9 is used to fixedly connect the front hydraulic cylinder 8 to the ground, the front piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com