A kind of reinforcement method of engineering hollow member

A hollow component and engineering technology, used in bridge reinforcement, building construction, building maintenance, etc., can solve the problems of difficult construction conditions, poor structural durability, and difficult to guarantee construction quality, and achieve good reinforcement effect, convenient construction, and economical reinforcement. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

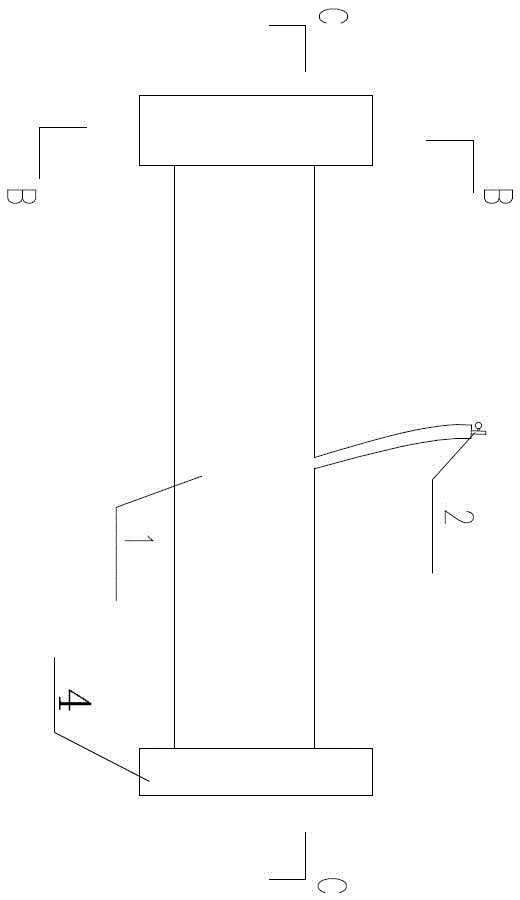

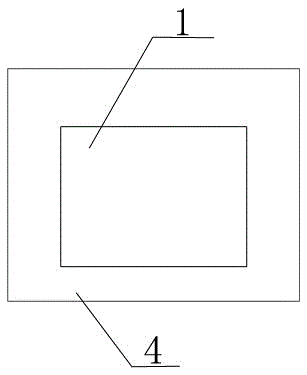

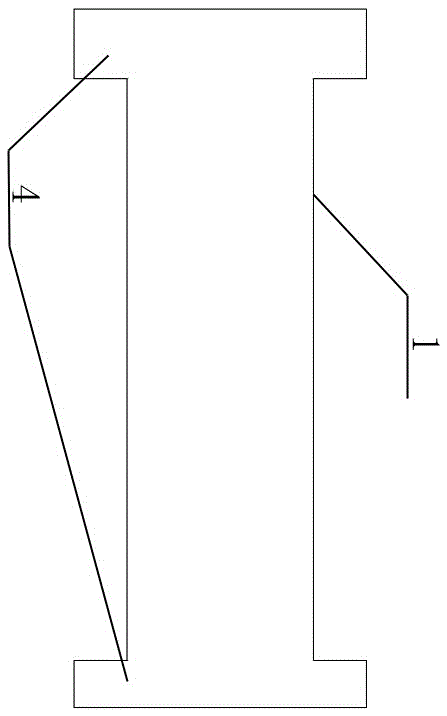

[0019] Reinforce the prestressed concrete hollow slab to increase the shear bearing capacity. The specific implementation steps are as follows: ① Make the inner mold of the airbag for reinforcement. The inner mold of the airbag is as follows: Figure 1-3 As shown, including inner mold 1, the two ends of inner mold 1 are provided with end mold 4 respectively, and the external shape of inner mold 1 is cuboid, and end mold 4 is cuboid, and inner mold 1 communicates with end mold 4; The mold 4 together forms a dumbbell-shaped hollow structure, and the inner membrane 1 is provided with a valve 2; the length of the airbag inner mold is 3.0m, the cross-sectional dimensions at both ends are 1.25m wide x 0.997m high, and the middle cross-sectional dimension is 0.8m wide x 0.6m high; ② Open a hole on the top of the prestressed concrete hollow slab 2 to form a hole 3 with a size of 20cm×50cm, and place the airbag inner mold inside the prestressed concrete hollow slab 2; ③ Inflate the airb...

Embodiment 2

[0022] The difference between embodiment 2 and embodiment 1 is that step 3. inflates the inner mold of the airbag until the pressure of the inner mold of the airbag is 6MPa; The thickness of the second layer of pouring is 35cm, and the third layer is poured to the bottom of the hole 3 .

Embodiment 3

[0024] The difference between embodiment 3 and embodiment 1 is that step 3. inflates the inner mold of the airbag until the air pressure of the inner mold of the airbag is 5MPa; The thickness of the second layer of pouring is 25cm, and the third layer is poured to the bottom of the hole 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com