Rapid-hardening and early-strength structural reinforcement materials based on aluminate cement and steel slag

A technology of aluminate cement and reinforcement materials, which is applied in the field of building materials, can solve the problems of low comprehensive utilization rate of steel slag, land occupation, waste of resources, etc., achieve low comprehensive reinforcement cost, improve production and construction efficiency, and have high fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

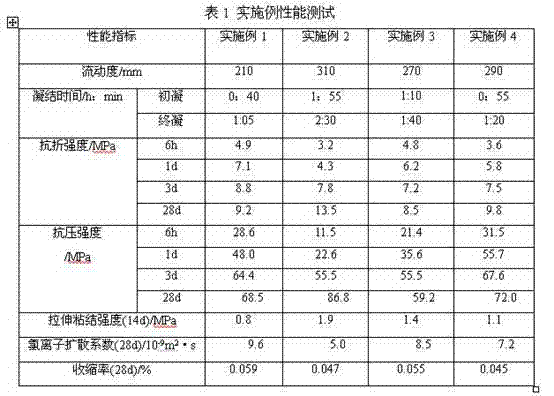

[0051] Example 1, a fast-hardening and early-strength structural reinforcement material based on aluminate cement and steel slag, according to CA-50 aluminate cement 100, steel slag 100, S75 slag powder 10, fly ash 5, silica fume 5, retarder 0.002, polycarboxylic acid water reducing agent 0.05, latex powder 1, cellulose ether 0.01, defoamer 0.02, polyvinyl alcohol fiber 0.05 in weight ratio. Add water according to 10% of the total weight of the reinforcement material and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 2

[0052] Example 2, a fast-hardening and early-strength structural reinforcement material based on aluminate cement and steel slag, according to CA-60 aluminate cement 100, steel slag 400, S95 slag powder 45, fly ash 35, silica fume 15, and retarder 0.010, naphthalene water reducer 3.00, latex powder 4, cellulose ether 0.15, defoamer 0.15, polyvinyl alcohol fiber 0.80 in weight ratio. Add water at 15% of the total weight of the reinforcing material and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 3

[0053] Example 3, fast-hardening and early-strength structural reinforcement material based on aluminate cement and steel slag, according to CA-70 aluminate cement 100, steel slag 350, S95 slag powder 25, fly ash 15, silica fume 8, retarder It is formulated in a weight ratio of 0.008, naphthalene water reducing agent 1.80, latex powder 3, cellulose ether 0.10, defoaming agent 0.06, and polyvinyl alcohol fiber 0.09. Add water at 12% of the total weight of the reinforcing material and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com