Stainless steel composite corrosion-resisting reinforcement bar and preparation method thereof

A stainless steel, corrosion-resistant technology, applied in building components, structural elements, buildings, etc., can solve the problems of low cost, poor corrosion resistance, and high cost of carbon steel reinforcement, and achieve improved corrosion resistance, less investment in equipment, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

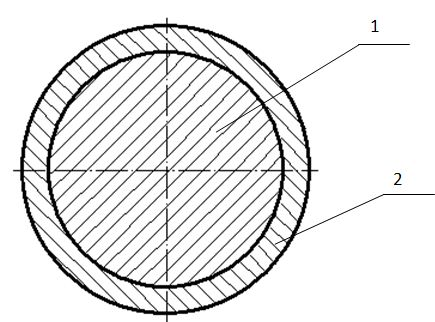

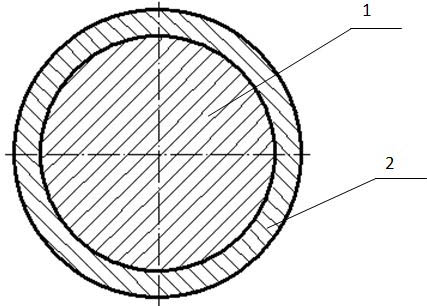

[0035] figure 1 Among them, the stainless steel composite corrosion-resistant steel bar has a specification (that is, a diameter) of 6 mm to 40 mm. It is mainly composed of a core 1 metal and a stainless steel alloy layer 2 around it along the length of the core 1 metal. The metallurgical combination between the two , the thickness of the stainless steel alloy layer 2 is 1mm~10mm.

[0036] The metal of the core part 1 is any one of low carbon steel and low alloy steel.

[0037] The stainless steel alloy layer 2 is one of the existing austenitic stainless steel, martensitic stainless steel, ferritic stainless steel or duplex stainless steel. Austenitic stainless steel is preferred.

[0038] Prepare stainless steel composite corrosion-resistant smooth steel bars, the core 1 is carbon steel Q235, the geometric shape of the cross-section is a circle with a diameter of 10mm, the thickness of the corrosion-resistant stainless steel alloy layer 2 is 2mm, and the selection of the st...

Embodiment 2

[0048] Prepare stainless steel composite anti-corrosion smooth steel bar, the core 1 is carbon steel, the chemical composition is the same as that of commercially available HRB335 secondary steel bar, the geometric shape of the cross section is a circle with a diameter of 19mm, and the thickness of the corrosion-resistant stainless steel alloy layer 2 is 3mm , the stainless steel alloy layer 2 is selected from 06Cr17Ni12Mo2 austenitic stainless steel that conforms to the national standard GB / T 20878-2007.

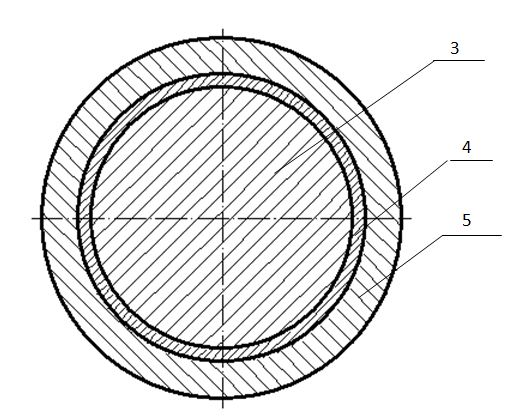

[0049] (1) The carbon steel billet 3 of HRB335 secondary steel bar is produced by using the existing casting method. The length of the carbon steel billet 3 is 3m, the geometry of the cross section is circular, and the diameter is 100mm.

[0050] (2) Remove the oil stain on the surface of the carbon steel slab 3 prepared in step (1) with a 10% NaOH aqueous solution at a temperature of 80°C for 8 minutes. Then use H with a mass fraction of 10% 2 SO 4 Aqueous solution, at a...

Embodiment 3

[0058] Prepare stainless steel composite anti-corrosion smooth steel bar, the core 1 is carbon steel, the chemical composition is the same as that of commercially available HRB400 tertiary steel bar, the geometric shape of the cross section is a circle with a diameter of 24mm, and the thickness of the corrosion-resistant stainless steel alloy layer 2 is 3mm , the stainless steel alloy layer 2 is selected from 06Cr17Ni12Mo2 austenitic stainless steel that conforms to the national standard GB / T 20878-2007.

[0059] (1) Select the existing casting method to produce the carbon steel billet 3 of the HRB400 secondary steel bar, the length of the carbon steel billet 3 is 1m, the geometric shape of the cross section is square, and the side length is 120mm.

[0060] (2) Remove the oil stain on the surface of the carbon steel billet 3 prepared in step (1) with a 10% NaOH aqueous solution at a temperature of 90°C for 10 minutes. Then, it was etched with 10% HCl aqueous solution at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com