Preparation method of cathode with composite metal layer for rare earth electrolysis

A composite metal layer and cathode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve problems such as service life not exceeding one year, high price, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

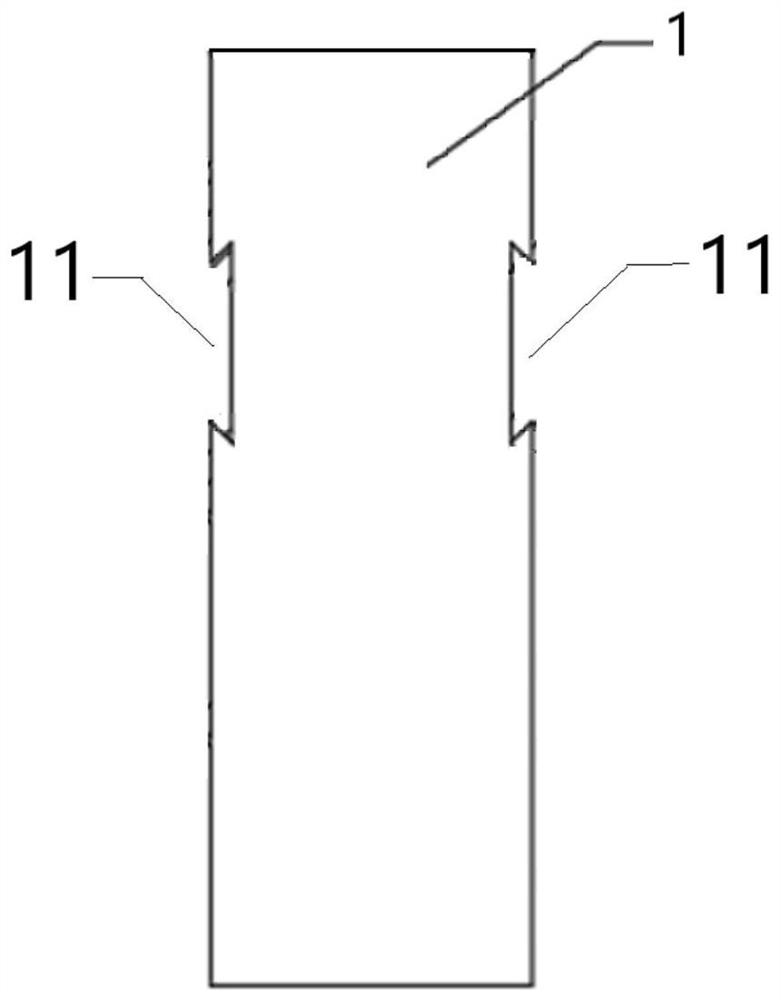

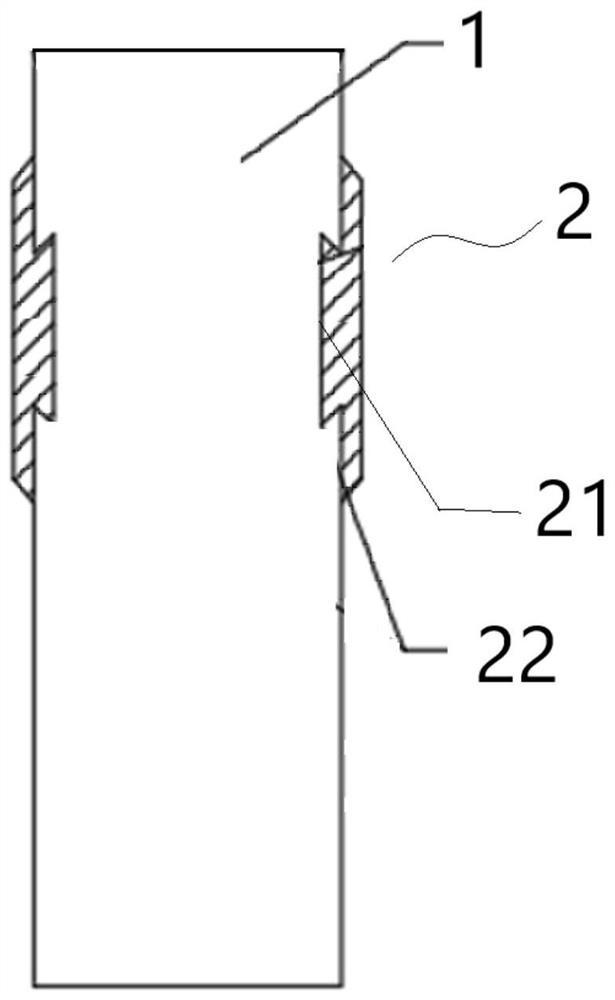

[0054] Such as figure 1 As shown, the corrosion-prone part of the tungsten rod base 1 (that is, the setting area located 120mm below the connection between the upper part of the cathode and the electrolytic equipment to 100mm above the liquid level of the electrolyte) is processed into a groove with an isosceles trapezoidal cross section. Structure 11 (i.e. a dovetail-shaped groove structure), the upper bottom of the isosceles trapezoid is located on the surface of the tungsten rod substrate 1, the lower bottom is parallel to the central axis of the tungsten rod substrate 1, and the length of the upper bottom is less than the length of the lower bottom; The groove structure 11 is arranged along the circumferential direction of the tungsten rod base 1 . The groove structure 11 is located near the end of the tungsten rod base 1 .

[0055] The mold filling part formed by polystyrene foam that matches the groove structure 1 is packed into the groove structure 11 on the tungsten r...

Embodiment 2

[0061] Except the following difference, all the other are the same as embodiment 1:

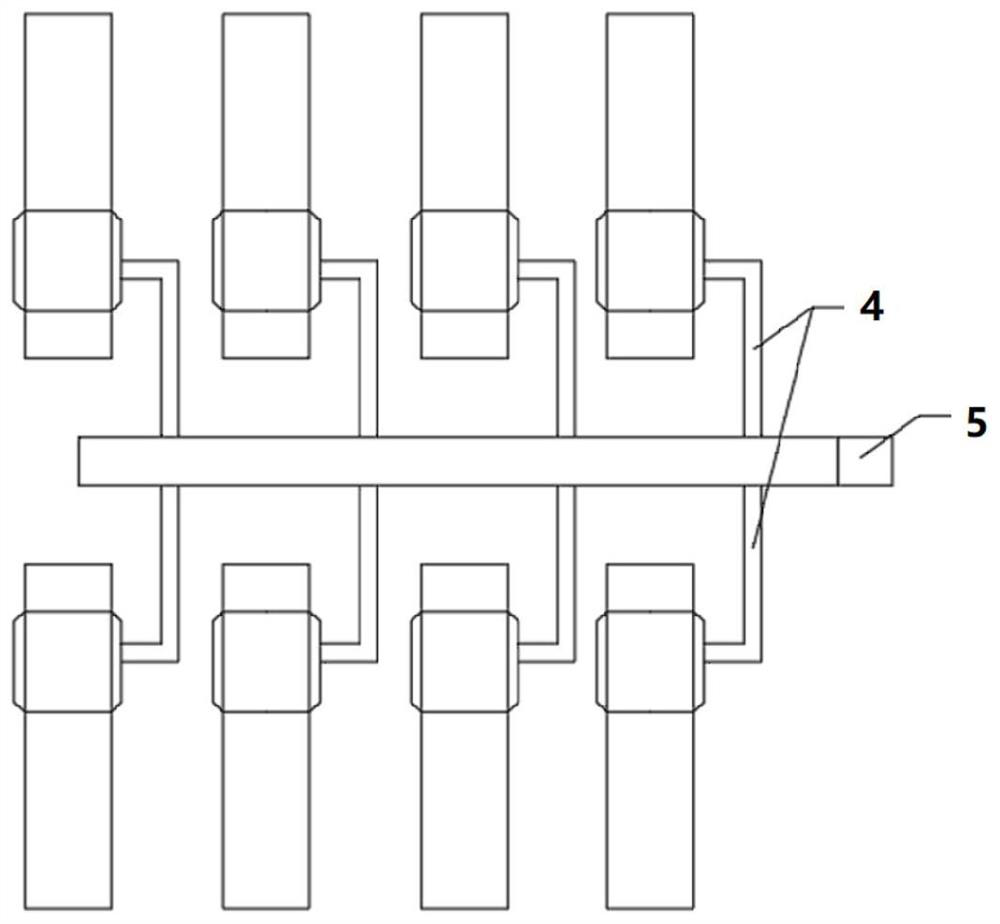

[0062] Place 8 coated tungsten rod substrates containing the model layer in each layer, symmetrically placed on both sides of the runner, the melting temperature is 1630°C, the pouring speed is 17kg / s, and the thickness of the extension of the composite metal layer is 25mm.

[0063] Under the same conditions as in Example 1, the service life of the cathode obtained in this example is 270 days.

Embodiment 3

[0065] Except the following difference, all the other are the same as embodiment 2:

[0066] The total coating thickness of the paint is 2.0mm; the negative pressure of the sand box is -0.02MPa; the melting temperature is 1620°C, the pouring speed is 20kg / s, and the thickness of the extension part of the composite metal layer is 30mm.

[0067] Under the same conditions as in Example 1, the service life of the cathode obtained in this example is 300 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com