Multilayer optical thin film and manufacturing method thereof

A technology of optical film and manufacturing method, applied in optics, optical components, instruments, etc., to achieve the effect of improving optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

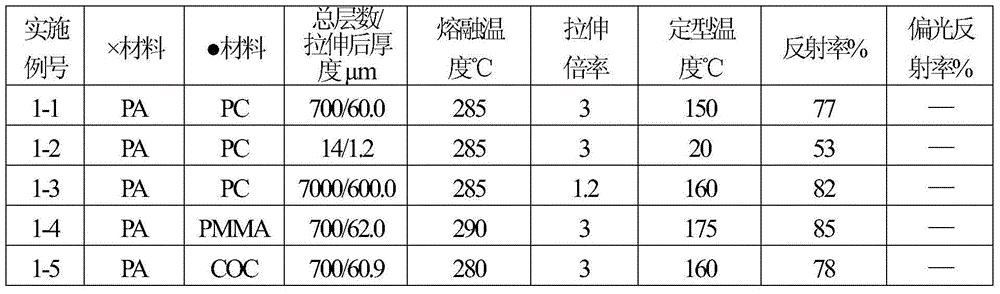

Embodiment 1

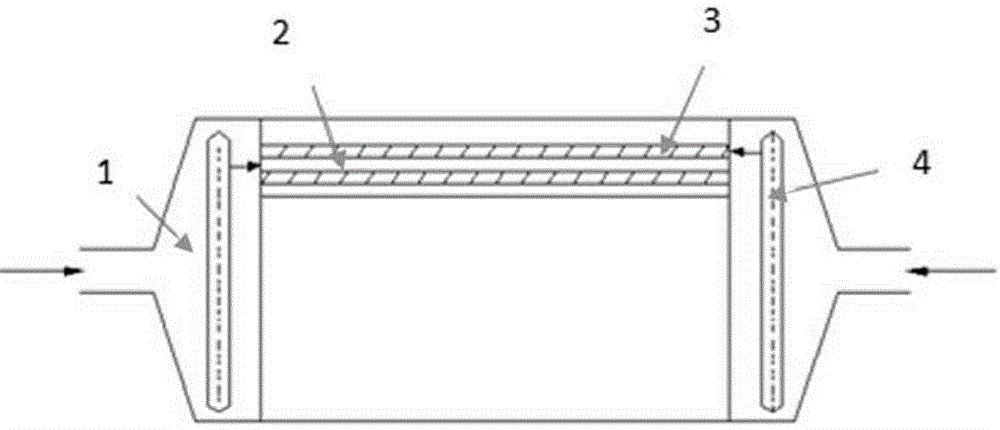

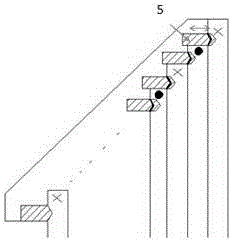

[0042] The basic process of preparing multilayer optical film (visible light total reflection function):

[0043] According to the total thickness and functional requirements of the multilayer optical film, adjust and determine the × material layer of the splitter die C, the number of layers of the extrusion notch of the material layer and the opening of the extrusion notch, and the weighed × material, ●Materials are fed into 1# extruder and 2# extruder respectively, and after melting at 150~300℃, they are extruded through the extrusion port A or the extrusion port B of the 1# extruder and 2# extruder respectively and enter the splitter The pipeline of × material or ● material in the flow divider die head C respectively passes through the extrusion notch of × material layer and ● material layer, and co-extrudes to form a thick sheet composed of multiple layers. The thick sheet is stretched longitudinally , the stretch ratio is 1 to 100 times, and the stretched sheet is cooled ...

Embodiment 2

[0050] The basic process of preparing multilayer optical film (ultraviolet light total reflection function):

[0051] According to the total thickness and functional requirements of the multilayer optical film, adjust and determine the × material layer of the splitter die C, the number of layers of the extrusion notch of the material layer and the opening of the extrusion notch, and the weighed × material, ●Materials are fed into 1# extruder and 2# extruder respectively, and after melting at 150~300℃, they are extruded through the extrusion port A or the extrusion port B of the 1# extruder and 2# extruder respectively and enter the splitter The pipeline of × material or ● material in the flow divider die head C respectively passes through the extrusion notch of × material layer and ● material layer, and co-extrudes to form a thick sheet composed of multiple layers. The thick sheet is stretched longitudinally , the stretch ratio is 1 to 100 times, and the stretched sheet is coo...

Embodiment 3

[0056] Basic preparation process of 550nm green light multilayer optical film (function of filtering 550nm green light):

[0057] According to the total thickness and functional requirements of the multilayer optical film, adjust and determine the × material layer of the splitter die C, the number of layers of the extrusion notch of the material layer and the opening of the extrusion notch, and the weighed × material, ●Materials are put into 1# extruder and 2# extruder respectively, and after melting at 200~300℃, they are extruded through the extrusion port A or the extrusion port B of the 1# extruder and 2# extruder respectively and enter the splitter The pipes of × material or ● material in the flow divider die head C respectively pass through the extrusion slots of × material layer and ● material layer, and co-extrude to form a thick sheet composed of multiple layers. The rollers are cooled to 25-60°C, stretched longitudinally after a preheating section at 80°C-160°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness specification | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com