Paint for preparing aluminum phosphate coating on surface of aluminum alloy and use method of paint

A technology of aluminum alloy surface and aluminum phosphate, which is applied in the coating process of metal materials, etc., can solve problems such as corrosion and holes, and achieve the effects of improving corrosion resistance and wear resistance, short manufacturing cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

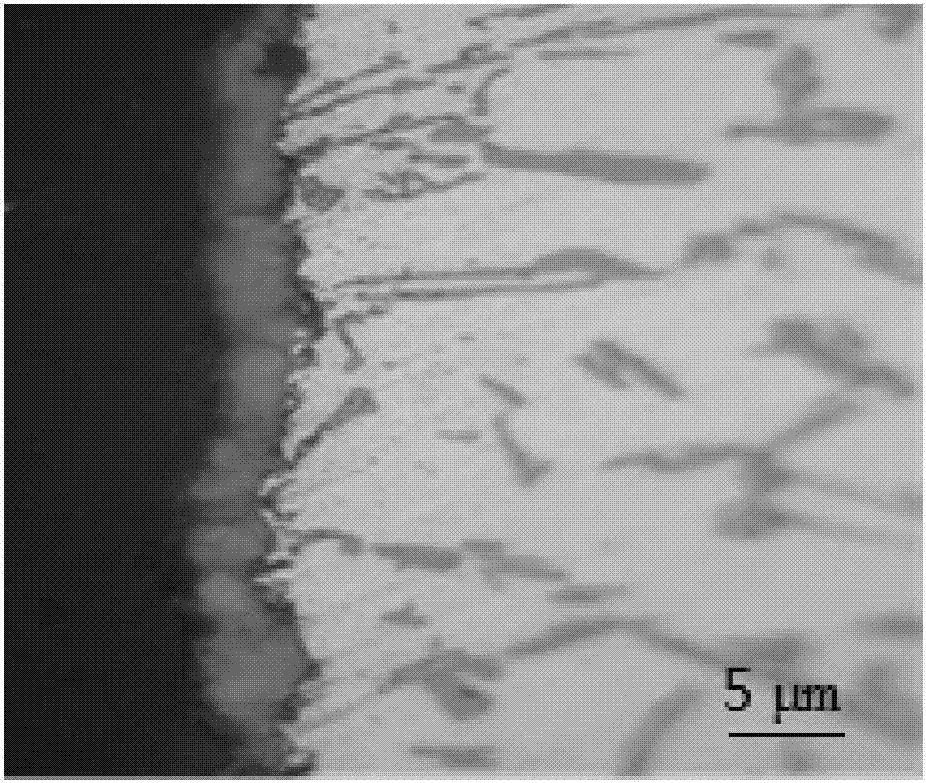

Image

Examples

Embodiment 1

[0030] (1) Configure coating: take 10 parts of Al(H 2 PO 4 ) 3 , 80 parts of pure water, according to Al(H 2 PO 4 ) 3 1.1 times the amount of Al required for all chemical reactions to occur 2 o 3 Powder, mix and stir evenly to make paint;

[0031] (2) Pretreatment of cast aluminum alloy samples: place the cast aluminum alloy samples in 10wt% NaOH solution for alkali washing for 5 minutes, then wash with pure water for 1 minute, and dry naturally for later use;

[0032] (3) Coating preparation: put the dried cast aluminum alloy in the coating and immerse it for 2 minutes and then take it out. After the surface of the coating does not produce obvious flow, the sample is treated in a water vapor environment at 120°C for 90 minutes to obtain the surface with aluminum phosphoric acid. Salt-coated aluminum alloy samples.

Embodiment 2

[0034] (1) Configure coating: take 70 parts of Al(H 2 PO 4 ) 3 , 40 parts of pure water, according to Al(H 2 PO 4 ) 3 1.3 times the amount of Al required for all chemical reactions to occur 2 o 3 Powder, mix and stir evenly to make paint;

[0035] (2) Pretreatment of cast aluminum alloy samples: place the cast aluminum alloy samples in NaOH and NaCO 3 Wash with alkali in the mixed solution for 6 minutes, then wash with pure water for 2 minutes, and dry it naturally for later use. The concentration of NaOH in the mixed solution is 6wt%, and NaCO 3 The concentration is 6wt%;

[0036] (3) Coating preparation: put the dried cast aluminum alloy in the coating and immerse it for 3 minutes and take it out. After the surface of the coating does not produce obvious flow, the sample is treated in a water vapor environment at 160°C for 60 minutes to obtain aluminophosphate Surface-coated cast aluminum alloy samples.

Embodiment 3

[0038] (1) Configure coating: take 40 parts of Al(H 2 PO 4 ) 3 , 60 parts of pure water, according to Al(H 2 PO 4 ) 3 1.2 times the amount of Al required for all chemical reactions to occur 2 o 3 Powder, mix and stir evenly to make paint;

[0039] (2) Pretreatment of cast aluminum alloy samples: place the cast aluminum alloy samples in 10wt% NaOH solution for alkali washing for 6 minutes, then wash with pure water for 2 minutes, and apply the above coating after natural drying;

[0040] (3) Coating preparation: put the dried cast aluminum alloy in the coating and immerse it for 2.5 minutes and take it out. After the surface of the coating does not produce obvious flow, the sample is treated in a water vapor environment at 170°C for 50 minutes to obtain aluminum phosphoric acid. Salt surface-coated cast aluminum alloy samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com