Aluminum-zinc phosphate coating and use method thereof

A technology of aluminum zinc phosphate and zinc phosphate, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of irregular shape of aluminum alloy castings, reduce the durability of the overall coating, corrosion of corrosive media, etc., to enhance the physical shielding effect , good durability and corrosion resistance, the effect of improving crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

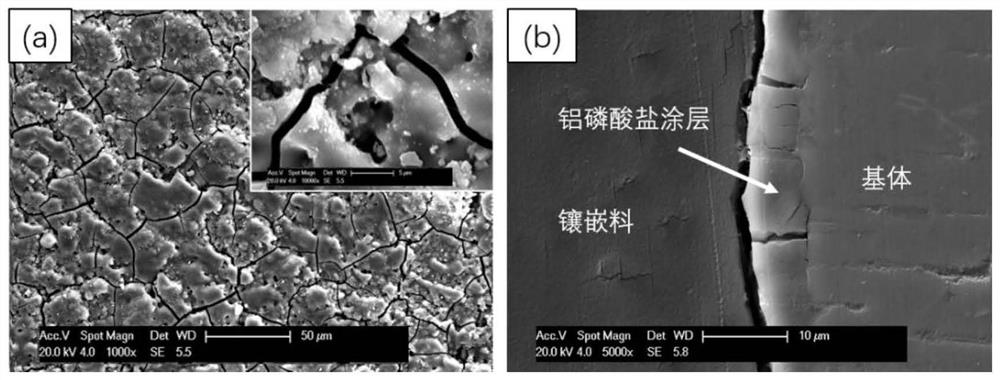

Embodiment 1

[0033] (1) 20 parts by weight of Al(H 2 PO 4 ) 3 , 8 parts of Zn(H 2 PO 4 ) 3 , 2 parts of TEOS and 70 parts of H 2 O carries out weighing of raw material, Al(H 2 PO 4 ) 3 and Zn(H 2 PO 4 ) 3 Join H 2 Stir in O, then follow with Al(H 2 PO 4 ) 3 1.2 times the number of parts required for all chemical reactions and Zn(H 2 PO 4 ) 3 Calculated at 0.7 times the number of parts required for all chemical reactions, add 29.6 parts of Al 2 o 3 Powder, Al 2 o 3 The particle size of the powder is 1000 mesh, and it is stirred at a speed of 1500r / min for 3 hours to obtain a coating;

[0034] (2) Place the cast aluminum alloy sample in NaOH and NaOH 2 CO 3 Wash with alkali in the mixed solution for 2 minutes, then wash with pure water for 1 minute, and dry it naturally for later use. Among them, NaOH and NaOH in the mixed solution 2 CO 3 The mass ratio is 5:4;

[0035] (3) Place the dried cast aluminum alloy sample in the coating for 3 minutes and take it out. Afte...

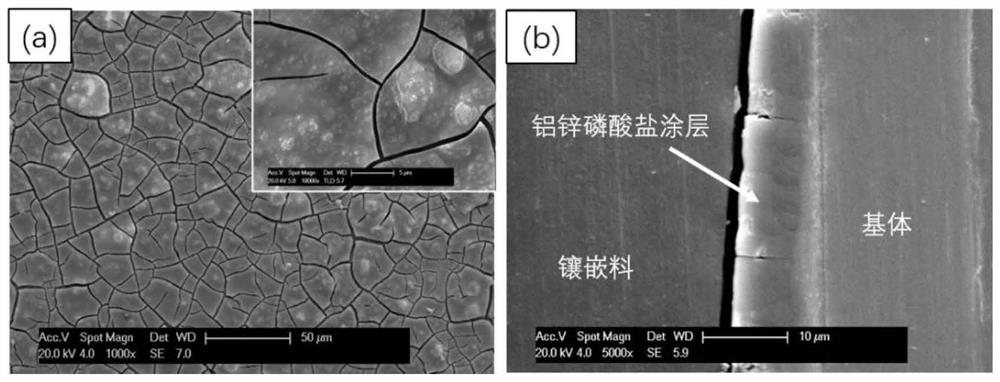

Embodiment 2

[0037] (1) 15 parts by weight of Al(H 2 PO 4 ) 3 , 10 parts of Zn(H 2 PO 4 ) 3 , 5 parts of TEOS and 70 parts of H 2 O carries out weighing of raw material, Al(H 2 PO 4 ) 3 and Zn(H 2 PO 4 ) 3 Join H 2 Stir in O, then follow with Al(H 2 PO 4 ) 3 1.0 times the number of parts required for all chemical reactions and Zn(H 2 PO 4 ) 3 Calculated at 0.6 times the number of parts required for all chemical reactions, add 16 parts of Al 2 o 3 Powder, Al 2 o 3 The particle size of the powder is 700 mesh, and it is stirred at a speed of 1000r / min for 5h to obtain a coating;

[0038] (2) Place the cast aluminum alloy sample in NaOH and NaOH 2 CO 3 Wash with alkali in the mixed solution for 3 minutes, then wash with pure water for 2 minutes, and dry it naturally for later use. Among them, NaOH and NaOH in the mixed solution 2 CO 3 The mass ratio is 5:3;

[0039] (3) Place the dried cast aluminum alloy sample in the coating for 2 minutes and take it out. After the ...

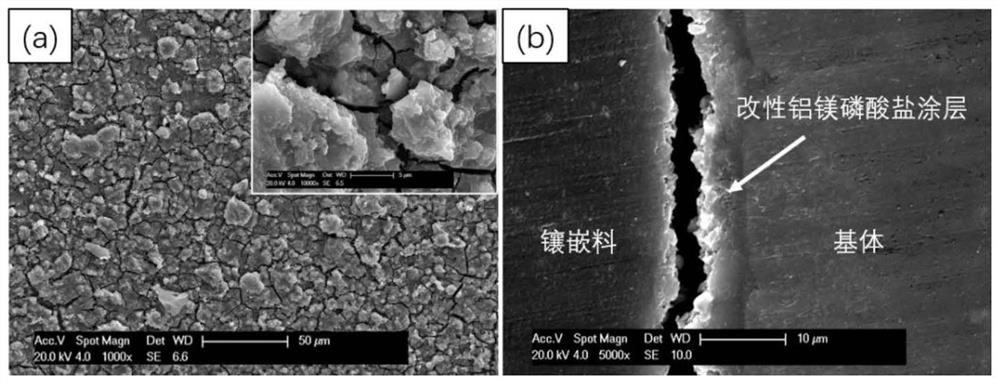

Embodiment 3

[0041] (1) 21 parts by weight of Al(H 2 PO 4 ) 3 , 7 parts of Zn(H 2 PO 4 ) 3 , 5 parts of TEOS and 70 parts of H 2 O carries out weighing of raw material, Al(H 2 PO 4 ) 3 and Zn(H 2 PO 4 ) 3 Join H 2 Stir in O, then follow with Al(H 2 PO 4 ) 3 1.3 times the number of parts required for all chemical reactions and Zn(H 2 PO 4 ) 3 Calculated at 0.8 times the number of parts required for all chemical reactions, add 32.9 parts of Al 2 o 3 Powder, Al 2 o 3 The particle size of the powder is 900 mesh, and the coating is obtained by stirring at a speed of 1200r / min for 3h;

[0042] (2) Place the cast aluminum alloy sample in NaOH and NaOH 2 CO 3 Wash with alkali in the mixed solution for 2 minutes, then wash with pure water for 2 minutes, and dry it naturally for later use. Among them, NaOH and NaOH in the mixed solution 2 CO 3 The mass ratio is 5:4;

[0043] (3) Place the dried cast aluminum alloy sample in the coating for 3 minutes and take it out. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com