Preparation method for rosinyl composite nano polymer micro-sphere

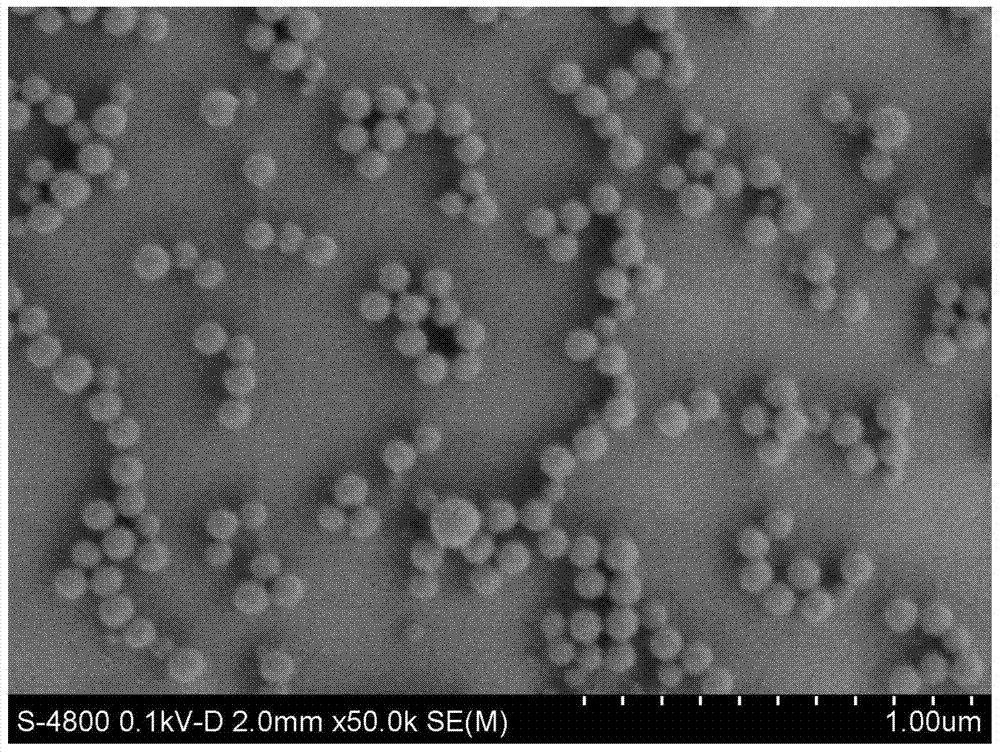

A nano-polymer and nano-microsphere technology, which is applied in the field of preparation of nano-scale rosin-based composite polymer microspheres, can solve the problems of compatibility and migration, performance defects of composite materials, etc., and achieves stability and uniform size. , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of novel rosin-based composite nanometer polymer microspheres, the preparation steps are:

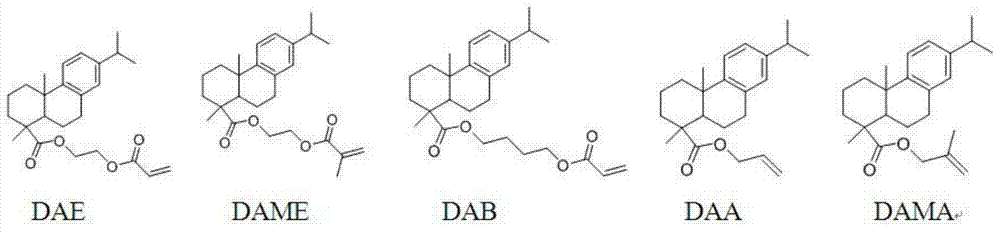

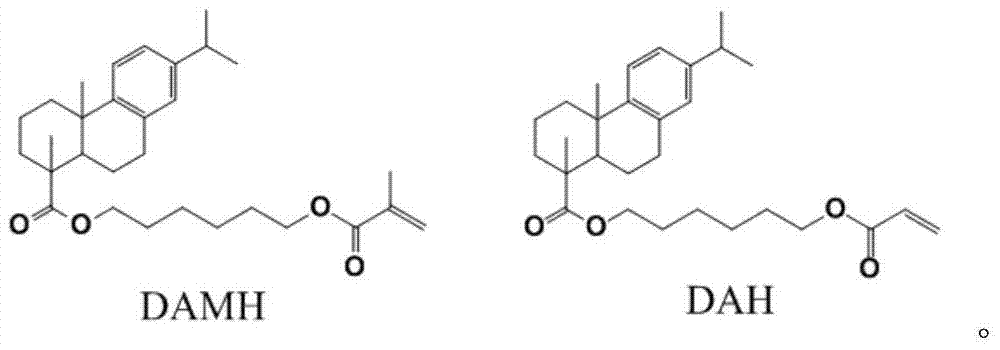

[0031] In the first step, the polymerizable rosin-based monomer is dissolved in the vinyl monomer as a solvent to prepare a composite solution of the polymerizable rosin-based monomer. The ethylenic monomer used contains acrylate (such as methyl methacrylate, butyl acrylate, etc.), vinyl ester (such as vinyl acetate, etc.), styrene, etc. The mass ratio of polymerizable rosin-based monomers to vinyl monomers is: (1.5-0.01): 1; the synthesis method of free radical polymerizable rosin-based monomers refers to the following published patents (CN101215445, CN101492591, CN101265392, CN101066918, CN103232349A) The record in embodiment 1. The structural formula is as follows:

[0032]

[0033] In the second step, the polymerizable rosin-based monomer composite solution is added to an aqueous solution containing an emulsifier, stirred and dispersed to generate a ...

Embodiment 2

[0037] Synthetic steps:

[0038] In the first step, 13.3 g of polymerizable rosin-based monomer (DAE) was dissolved in 26.7 g of methyl methacrylate monomer to prepare a DAE-methyl methacrylate composite solution. The mass ratio of DAE to methyl methacrylate is: 0.5:1;

[0039] In the second step, a total of 40.0 g of the DAE-methyl methacrylate composite solution is added to the water (195 g) solution containing the emulsifier sodium dodecylbenzenesulfonate (0.4 g), stirred and dispersed to generate DAE-methacrylic acid Methyl ester monomer pre-emulsion, the amount of emulsifier used is 1% relative to the mass ratio of DAE-methyl methacrylate;

[0040] The third step is to prepare the DAE-methyl methacrylate monomer monomer nano-particles by homogeneously dispersing the polymerizable rosin-based monomer pre-emulsion. ball;

[0041] The fourth step is to add water-soluble hydrogen peroxide (1.5g)-ascorbic acid (0.4g) redox initiator, raise the temperature to 85°C, and carr...

Embodiment 3

[0043] Synthetic steps:

[0044]In the first step, 16.0 g of methyl methacrylate monomer was used as a solvent, and 24.0 g of polymerizable rosin-based monomer (DAE) was dissolved in it to prepare a DAE-methyl methacrylate composite solution. The mass ratio of DAE to methyl methacrylate is: 1.5:1;

[0045] In the second step, a total of 40.0 g of the DAE-methyl methacrylate composite solution is added to the water (195 g) solution containing the emulsifier sodium dodecylbenzenesulfonate (0.4 g), stirred and dispersed to generate DAE-methacrylic acid Methyl ester monomer pre-emulsion, the amount of emulsifier used is 1% relative to the mass ratio of DAE-methyl methacrylate;

[0046] The third step is to prepare DAE-methyl methacrylate monomer nano-microspheres by homogeneously dispersing the polymerizable rosin-based monomer pre-emulsion with a treatment time of 20 seconds, an interval of 30 seconds, and a total treatment time of 3 minutes;

[0047] The fourth step is to add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com