Easy-to-repair lead plastic hinge

A technology of plastic hinges and lead blocks, which is applied in the direction of building components, building types, earthquake resistance, etc., can solve the problems of leakage and frictional plastic hinges, which are difficult to manufacture, and achieve the effects of easy maintenance, good shock absorption effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

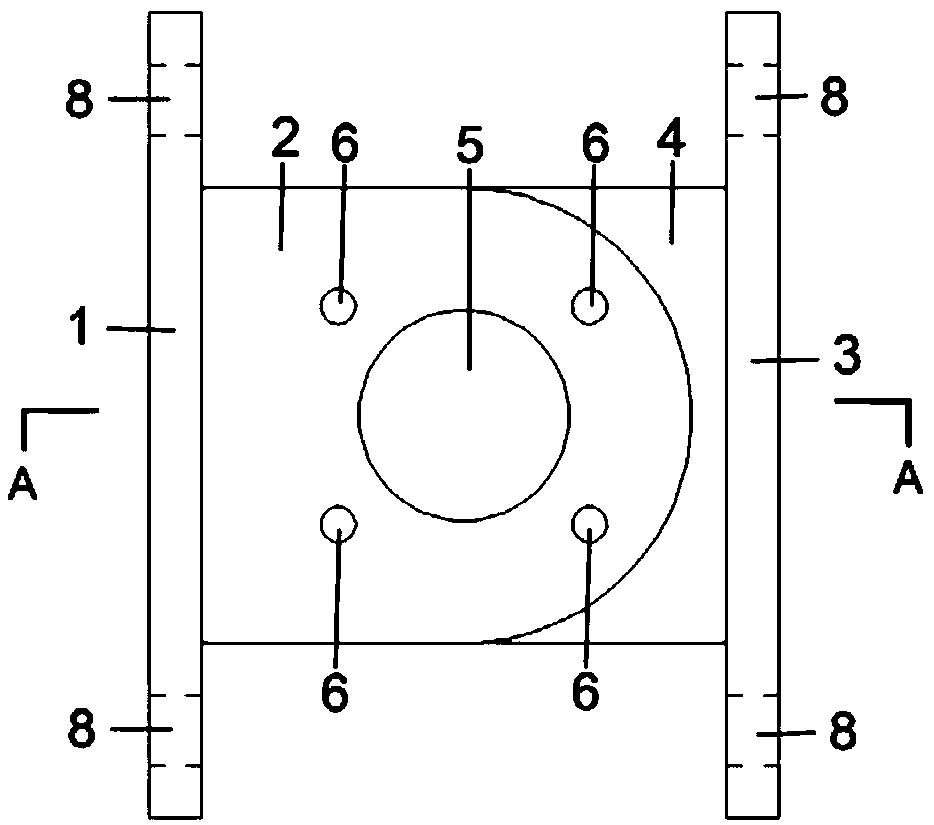

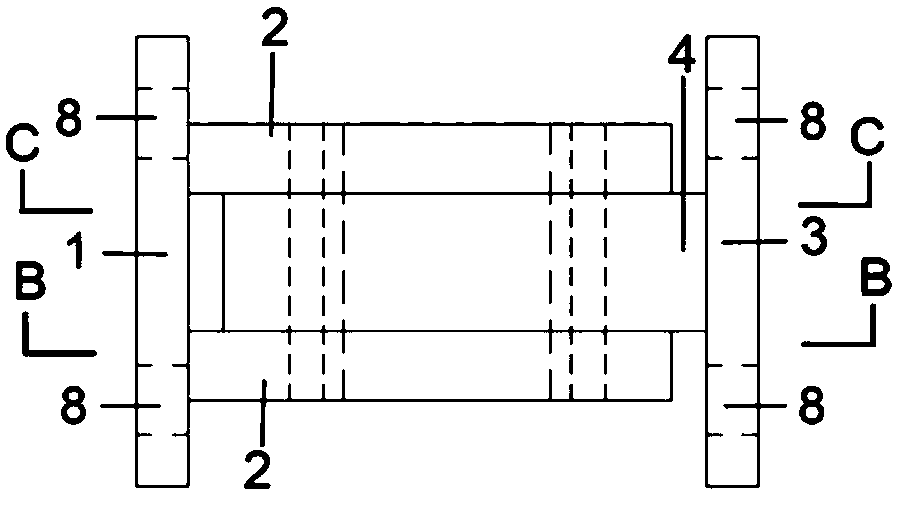

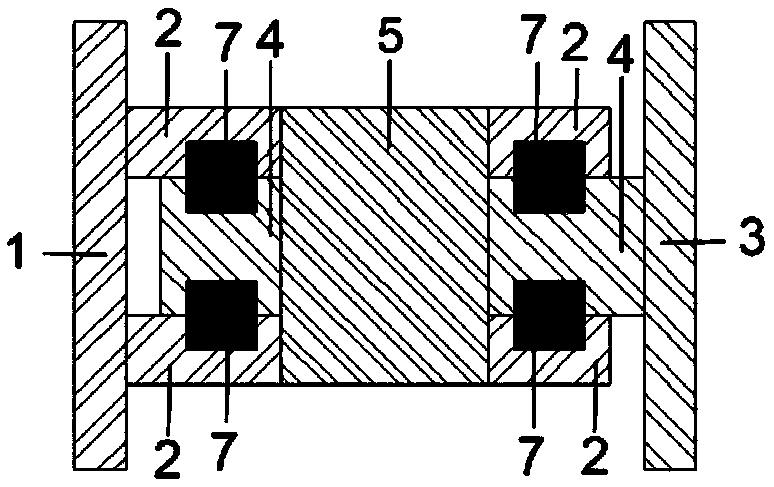

[0026] An easily repairable lead-plastic hinge, refer to Figure 1-5 , including left connecting plate 1, left ear plate 2, right connecting plate 3, right ear plate 4, rotating shaft 5, limit pin 6 and lead block 7, left ear plate 2 is double ear plate, right ear plate 4 is single Ear plate, the right ear plate 4 is arranged between the left ear plate 2, and the left ear plate 2 and the right ear plate 4 are respectively provided with four grooves on their contacting surfaces, the grooves on the left ear plate and the right ear plate Correspondingly arranged, four cavities for placing lead weights are jointly formed, and lead weights 7 having the same size as the cavity are embedded therein. The left connecting plate 1 and the left ear plate 2 are welded together to form the left part of the easily repairable lead-plastic hinge, the right connecting plate 3 and the right ear plate 4 are welded together to form the right part, and the left ear plate 2 and the right ear plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com