Wide intelligent carpet circular screen printer

A smart carpet and printing machine technology, applied to screen printing machines, printing machines, screen printing, etc., can solve the problems of poor printing and dyeing effects, inconvenient production, low efficiency, etc., and achieve convenient cleaning and maintenance and good printing effect Good, the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

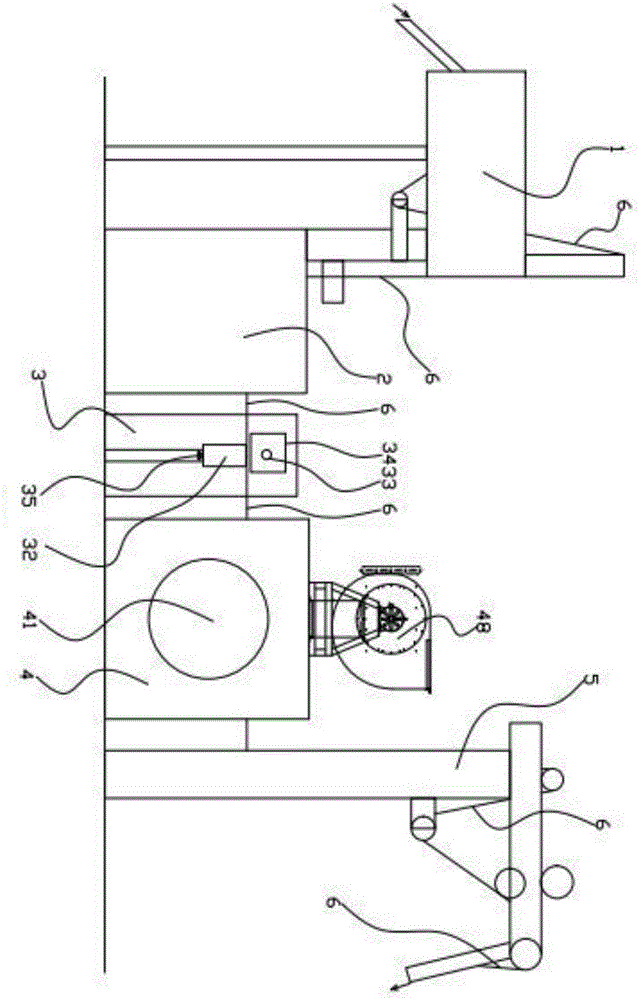

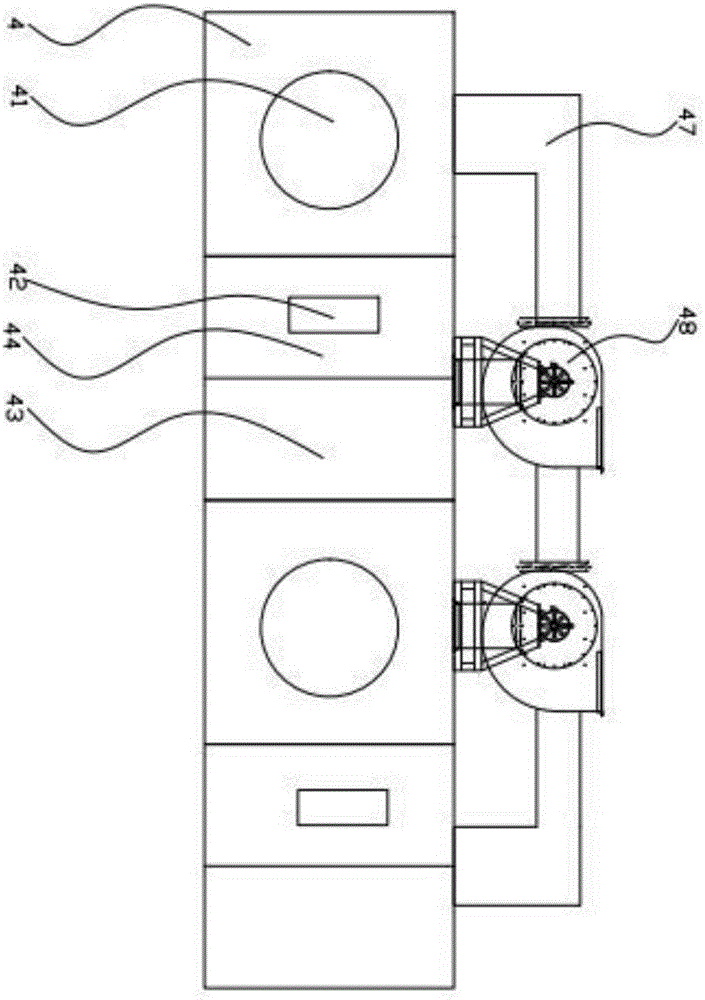

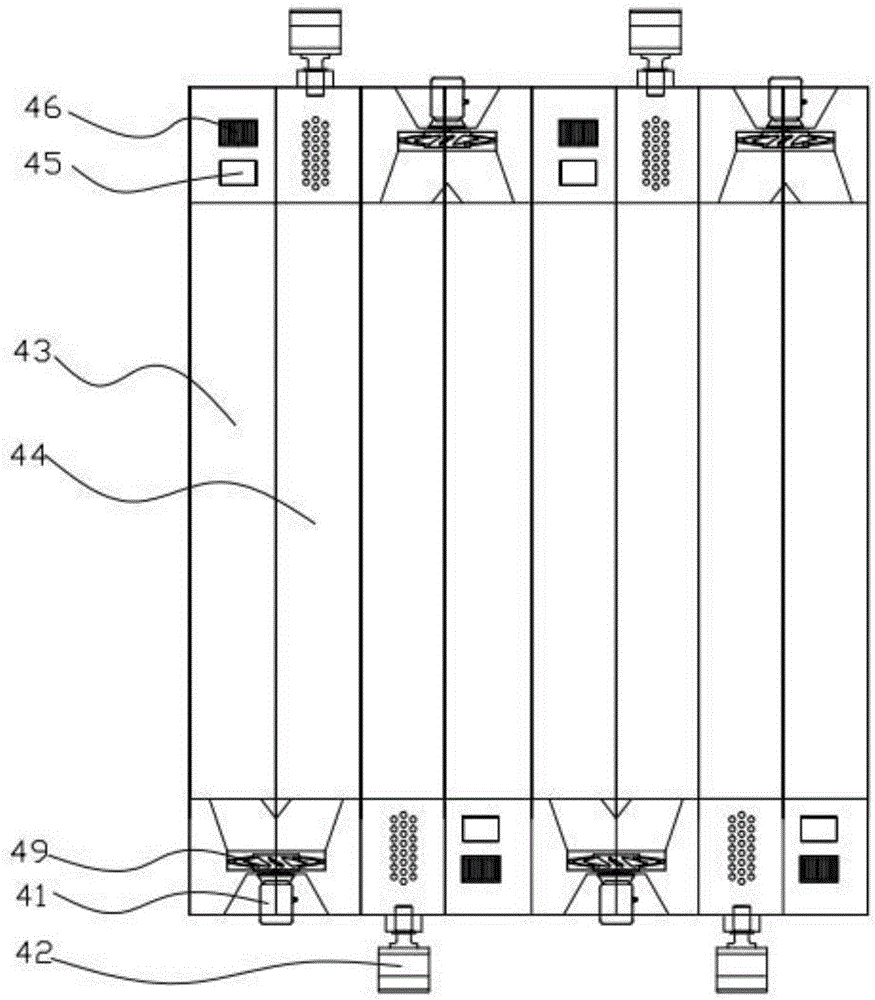

[0025] Such as figure 1 As shown, the wide-width intelligent carpet rotary screen printing machine includes a carpet feeding mechanism 1, a carpet passing mechanism 2, a printing mechanism 3, a drying mechanism 4, and a blanket receiving mechanism 5 connected in sequence; figure 1 , Figure 4 as well as Figure 5 As shown, the printing mechanism 3 includes a rotary screen 31, a magnetic table 32 and a dye tube 33; the rotary screen 31 is placed horizontally above the magnetic table 32, and there is a gap between the rotary screen 31 and the magnetic table 32 to facilitate the passage of the carpet 6. The dye tube 33 is connected to the side end of the rotary screen 31; there are multiple printing mechanisms 3 and they are connected sequentially along the horizontal direction.

[0026] Such as figure 1 , Figure 4 as well as Figure 5 as shown in figure 1 , Figure 4 as well as Figure 5 As shown, the printing mechanism 3 also includes a driver 34 for driving the rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com