Fountain solution application method and system based on ultrasonic atomization as well as application

A technology of ultrasonic atomization and ultrasonic atomizer, applied in lithographic rotary printing machines, printing, rotary printing machines, etc., can solve the problems of dampening water that have not been reported yet, and achieve reduced dosage, lower surface tension, and lower organic content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

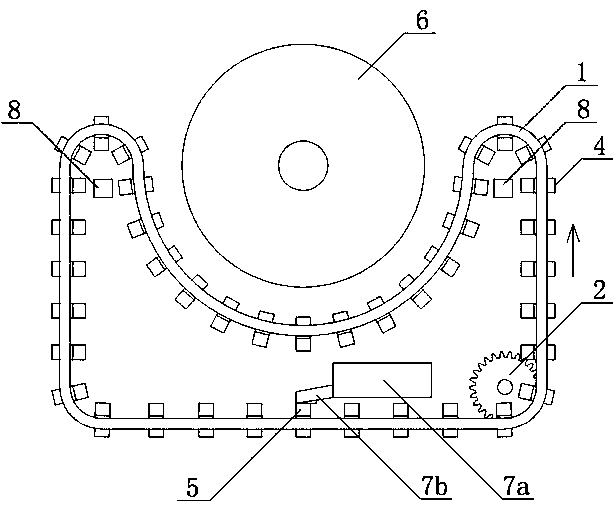

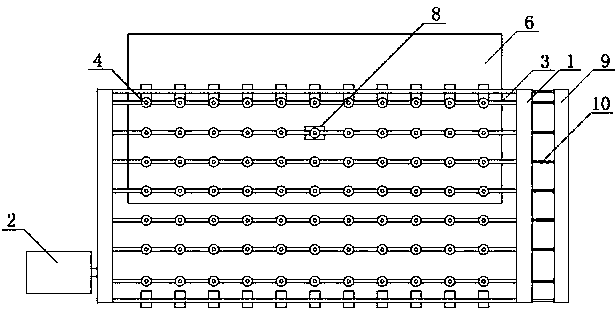

[0056] A method for applying dampening water based on ultrasonic atomization, comprising the following steps:

[0057] 1) Install an ultrasonic atomization device under the water roller, and add dampening water into the ultrasonic atomization device; the ultrasonic atomization device is set at 0.1 cm below the water roller;

[0058] 2) Turn on the ultrasonic atomization device at the same time, and ultrasonically atomize the dampening water onto the water roller under 0.1MHz ultrasound, so that a layer of water film is formed on the water roller; the thickness of the water film on the water roller is 0.1μm , the contact angle is about 60°;

[0059] 3) Start the water roller so that the dampening water is transferred from the water roller to the printing plate in the form of a continuous and uniform water film.

[0060] An application of a dampening water application method based on ultrasonic atomization in lithographic printing, specifically comprising the following steps: ...

Embodiment 2

[0066] A method for applying dampening water based on ultrasonic atomization, comprising the following steps:

[0067] 1) Install an ultrasonic atomization device under the water roller, and add dampening water into the ultrasonic atomization device; the ultrasonic atomization device is set at 1 cm below the water roller;

[0068] 2) Turn on the ultrasonic atomization device at the same time, and ultrasonically atomize the dampening water onto the water roller under 1MHz ultrasound, so that a layer of water film is formed on the water roller; the thickness of the water film on the water roller is 1 μm, contact The angle is about 10°;

[0069] 3) Start the water roller so that the dampening water is transferred from the water roller to the printing plate in the form of a continuous and uniform water film.

[0070] An application of a dampening water application method based on ultrasonic atomization in lithographic printing, specifically comprising the following steps:

[007...

Embodiment 3

[0076] A method for applying dampening water based on ultrasonic atomization, comprising the following steps:

[0077] 1) An ultrasonic atomization device is installed under the water roller, and dampening water is added to the ultrasonic atomization device; the ultrasonic atomization device is set at 3 cm below the water roller; the dampening water is tap water;

[0078] 2) Turn on the ultrasonic atomization device at the same time, and ultrasonically atomize the dampening water onto the water roller under 100MHz ultrasound, so that a layer of water film is formed on the water roller; the thickness of the water film on the water roller is 5 μm, contact The angle is about 50°;

[0079] 3) Start the water roller so that the dampening water is transferred from the water roller to the printing plate in the form of a continuous and uniform water film.

[0080] An application of a dampening water application method based on ultrasonic atomization in lithographic printing, specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com