Air pressure shaping technology of carbon fiber product and glass fiber product and used die

A glass fiber and molding process technology, which is applied in the field of wind pressure molding process and the mold structure used in the process, can solve the problems of long and complicated processing methods of glass fiber products, save subsequent processes and man-hours, reduce difficulty, The effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

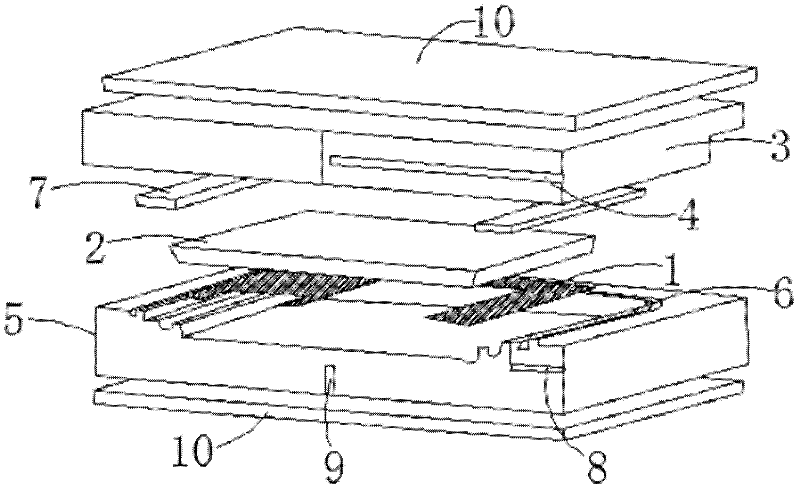

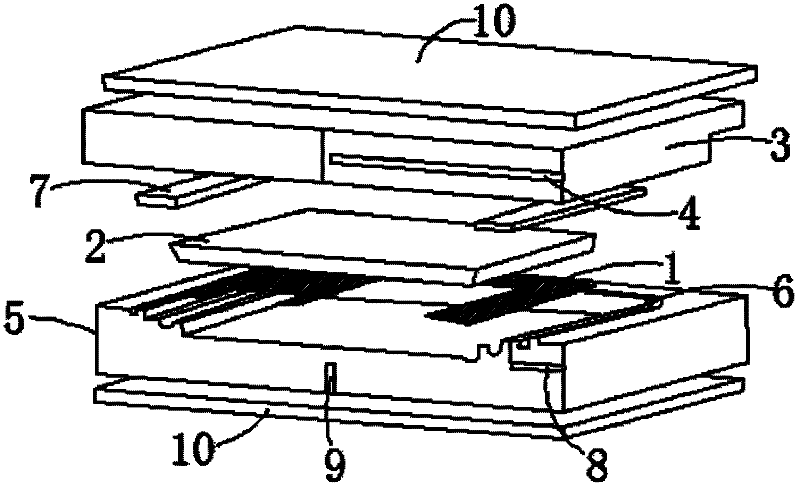

[0019] Embodiment: a kind of air pressure forming process of carbon fiber product and glass fiber product, carry out according to the following steps:

[0020] ①. Pretreatment: Cut the fiber prepreg into the required size and shape, the fiber prepreg is one of carbon fiber prepreg and glass fiber prepreg, and then cut the prepreg according to the thickness requirements Several layers of fiber prepregs are stacked, and a release film is pasted on the surface of the stacked fiber prepregs. Pasting the release film can make the resin on the carbon fiber prepreg or glass fiber prepreg under high temperature and high pressure. It can be evenly leveled in the horizontal direction, which is beneficial to obtain smooth carbon fiber semi-finished products or glass fiber semi-finished products without pits and pinholes on the surface;

[0021] ②, air pressure molding: put the fiber prepreg stacked in step ① and coated with release film into the mold, and put the pressure block 2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com