Self-leveling clean plastic and preparation method thereof

A crystal glue, self-leveling technology, applied in the field of polymer materials, can solve the problems of crystal glue pollution, product surface gloss and hardness cannot be further improved, affecting the health of users, etc., to achieve the effect of low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0030] A self-leveling crystal glue, which includes A glue and B glue, and the mixing ratio of A glue and B glue is 3:1.

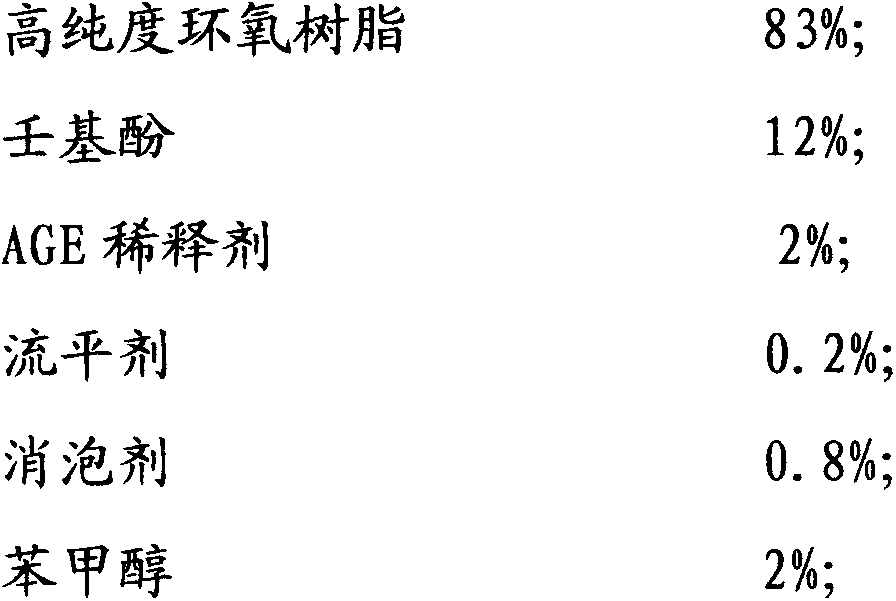

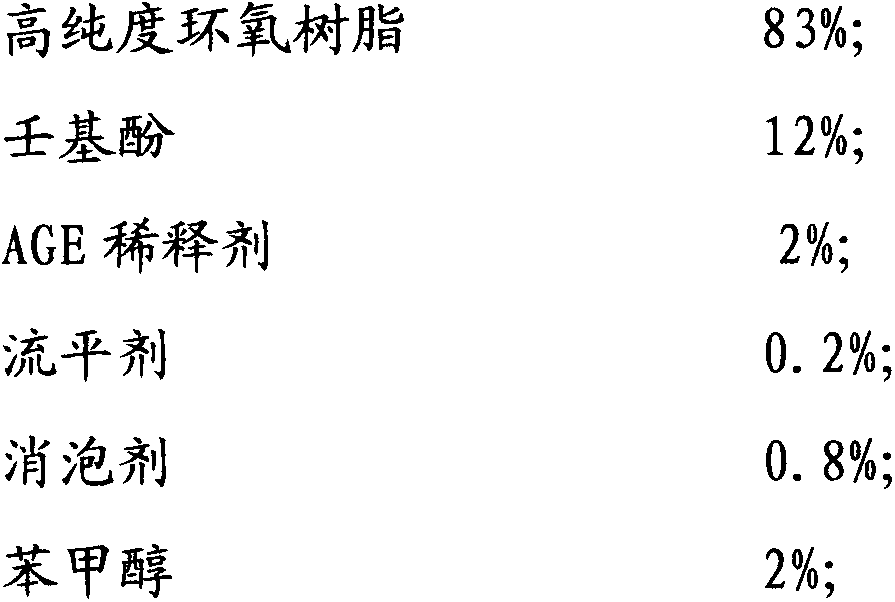

[0031] Among them, glue A is composed of the following components by weight percentage: 83% high-purity epoxy resin; 12% nonylphenol; 2% AGE diluent; 0.2% leveling agent; 0.8% defoamer; 2% benzyl alcohol.

[0032] B glue is composed of the following components by weight percentage: polyetheramine 75%; T403 12.5%; modified IPDA 12.5%.

[0033] The preparation method of self-leveling crystal glue has the following steps. A glue and B glue have different production processes. Specifically, the production process of A glue is as follows:

[0034] 1.1 Put the high-purity epoxy resin into the oven, set the temperature at 40°C-50°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com