Beryllium-copper conductor

a copper conductor and copper-copper technology, applied in the direction of conductive materials, conductive materials, conductors, etc., can solve the problems of conductor rejection, yellow discoloration, conductor reduction, etc., and achieve the effect of improving the electrical conductivity of c17510 and improving the surface brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0024]A sample of alloy C17510 was obtained with the Ni / Be weight ratio of 6.0. Chemistry of this alloy is listed in Table 2.

TABLE 2Chemical composition for Improved C17510Be, %Ni, %Cu0.321.93Balance

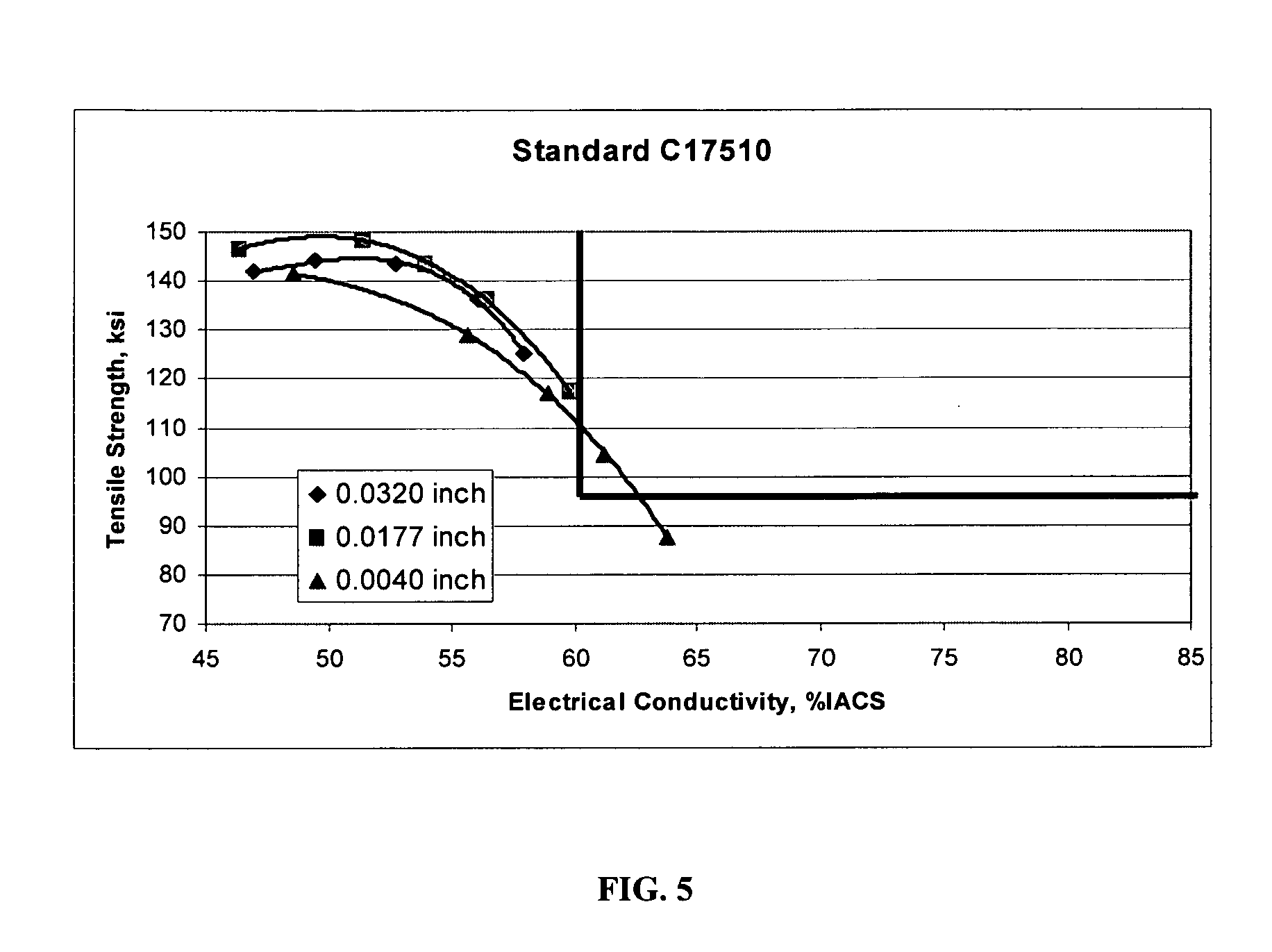

[0025]Performance of this alloy was compared with C17510 having “standard” or typical chemistry for this alloy. Chemical composition of material used for comparison is listed in Table 3. Ni / Be ratio for the standard chemistry sample is 4.4.

TABLE 3Chemical composition for standard C17510Be, %Ni, %Cu0.361.57Balance

[0026]Both the standard and improved wires were obtained in the solutionized condition at 0.0508″ diameter following identical processing. Mechanical properties and electrical conductivity of the as received wires are listed in Table 4. Both versions of the alloy have the same tensile strength and elongation while improved C17510 shows higher electrical conductivity.

TABLE 4Mechanical properties and electrical conductivityof the solution annealed 0.0508″ wireTensileElongation,Cond...

example 2

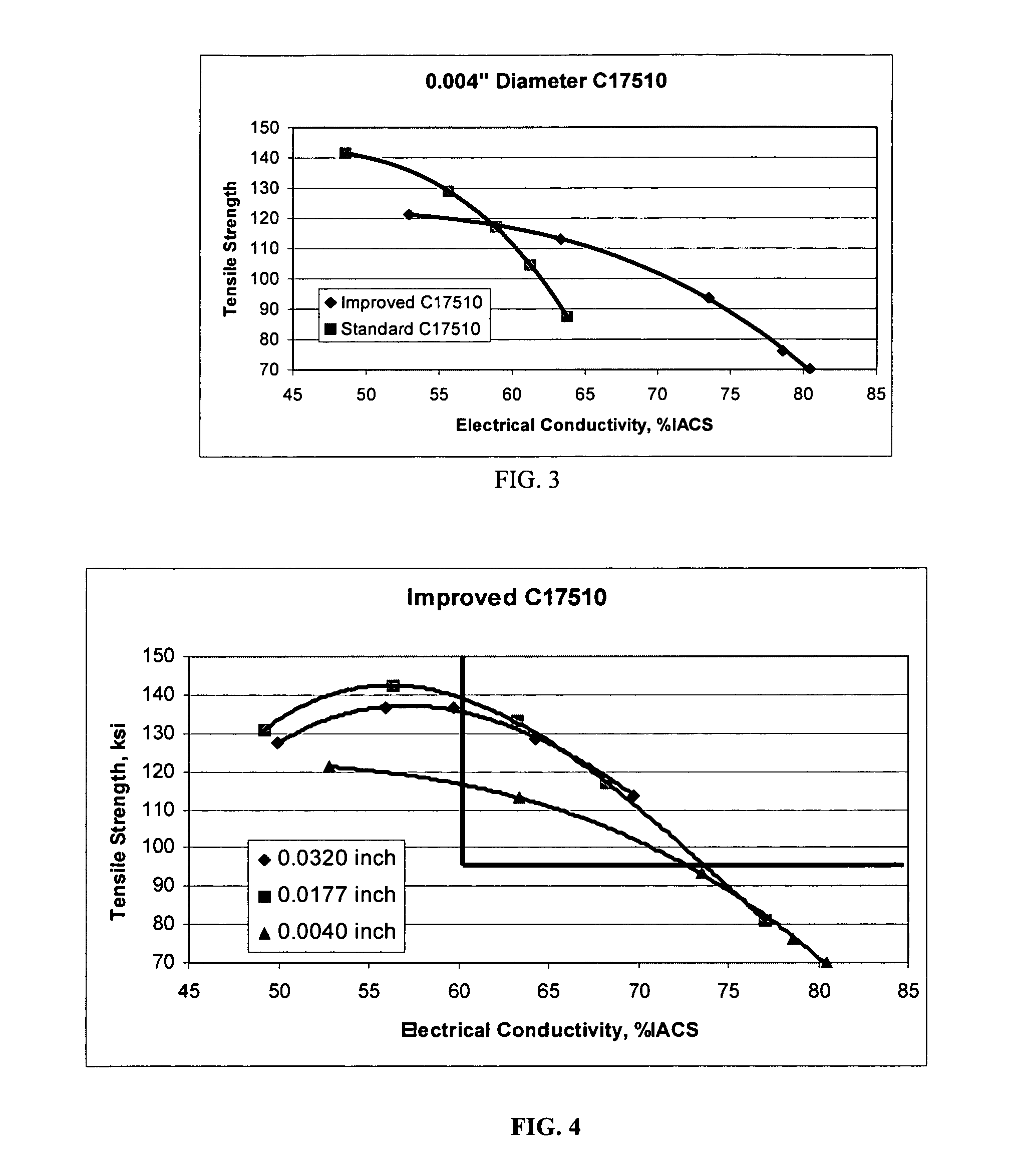

[0029]The wires of example 1 having the chemistries shown in Tables 2 and 3 were drawn in three steps to 38 AWG (0.004″ in diameter), a typical conductor diameter. As expected, both alloys showed good drawability and could be easily drawn to greater than 99% reduction in area. Properties of the as-drawn wires as a function of cold reduction are listed in Table 6.

TABLE 6Mechanical properties and electrical conductivity ofas-drawn C17510Improved AlloyStandard Alloy% ColdTensileConductivity,TensileConductivity,WorkStrength, ksi% IACSStrength, ksi% IACS0.055.240.555.835.920.874.340.574.036.335.577.639.579.034.949.578.840.782.935.360.880.540.885.536.087.894.638.399.835.599.3117.239.4126.933.6

[0030]The standard chemistry shows a higher work hardening rate but at a lower electrical conductivity. At the highest cold reduction of 99.3% (38 AWG) tensile strength for the standard chemistry is about 10 ksi higher than that of improved C17510.

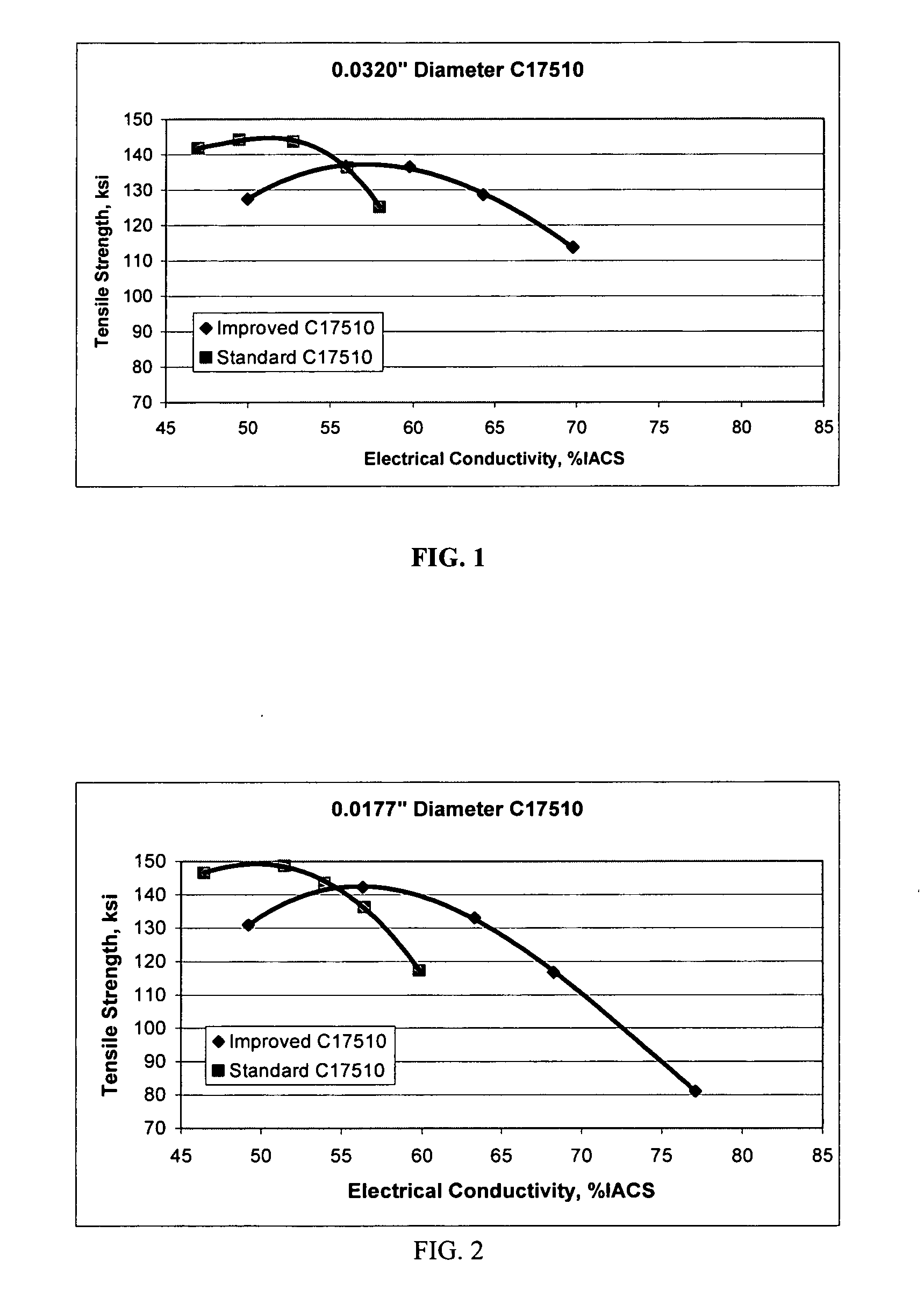

[0031]The wires drawn to 0.0320″, 0.0179″ and 0.004″ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com