Aluminum product chemical polishing solution and polishing method thereof

A technology of chemical polishing and aluminum products, which is applied in the field of chemical polishing liquid and its polishing of aluminum products, can solve problems such as the inability to fundamentally eliminate the hazard of NO, the inability to meet the brightness requirements of the "three-acid" polishing process, and unstable polishing effects. Achieve the effects of inhibiting transfer corrosion, reducing over-corrosion points, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Polishing liquid formula: sulfuric acid 77g, phosphoric acid 23g, aluminum sulfate 1.8g, potassium permanganate 0.11g, sodium nitrate 0.22g, sodium diphenylamine sulfonate 0.11g, tartaric acid 0.11g, zinc sulfate 0.22g.

[0017] A chemical polishing method for aluminum products, comprising the steps of:

[0018] (1) mix and make polishing liquid by above-mentioned component distribution ratio;

[0019] (2) Heating the polishing solution to 120°C;

[0020] (3) Immerse the dry and clean aluminum product to be polished in the polishing solution, and take it out after polishing for 60 seconds;

[0021] (4) Immediately wash the aluminum products taken out with tap water, then rinse with pure water, and dry.

[0022] Chemical polishing quality evaluation: (1) reflectivity: 134.46%; (2) weight loss rate: 2.0753g / dm 3 ;

Embodiment 2-6

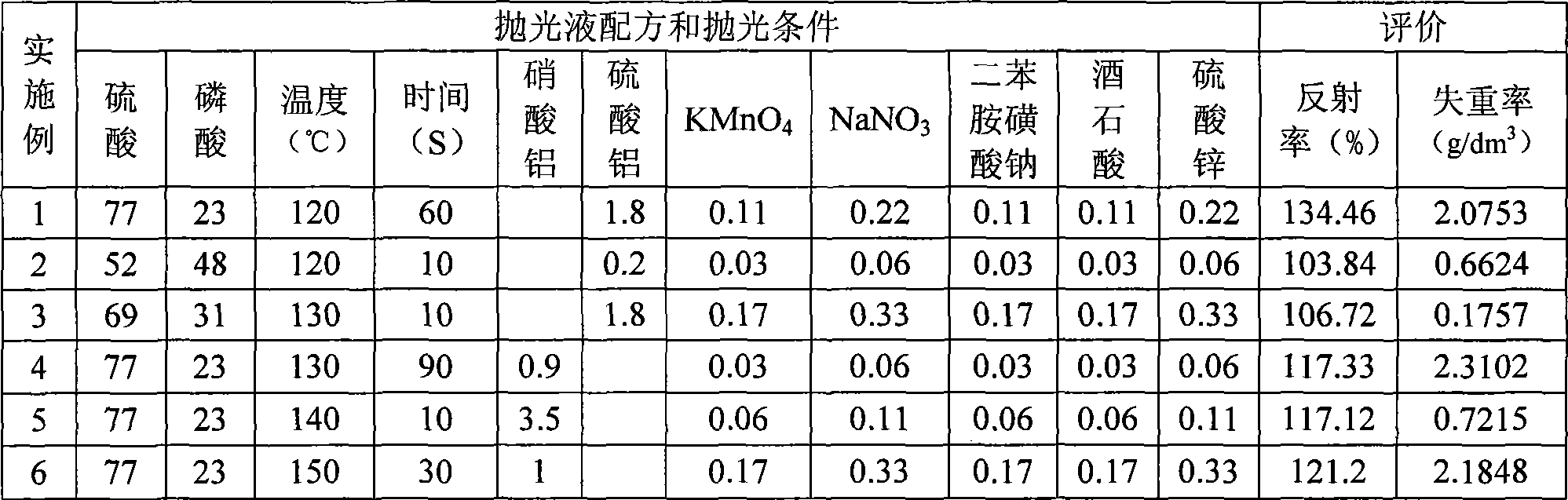

[0024] The polishing liquid formula, polishing conditions, and polishing quality evaluation are shown in Table 1.

[0025] Table 1 Polishing liquid formula, polishing conditions, polishing quality evaluation

[0026]

[0027] The present invention compares with tri-acid polishing:

[0028] Tri-acid polishing has a reflectivity of 100% and a weight loss rate of 2.38g / dm 3 . The reflectance of each embodiment exceeds the tri-acid polishing process, and the weight loss rate is smaller than the tri-acid polishing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com