Weather-resistance ASA-based composite material, co-extruded plastic product and plastic product

A technology for composite materials and plastic products, applied in the field of polymer composite materials, can solve the problems of ABS plastics such as poor weather resistance, limitations, and unsuitability for outdoor products, and achieve excellent hardness, improve surface hardness and brightness, excellent gloss and chemical resistance. medium effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0030] Embodiment 1~8, blank example and comparative example

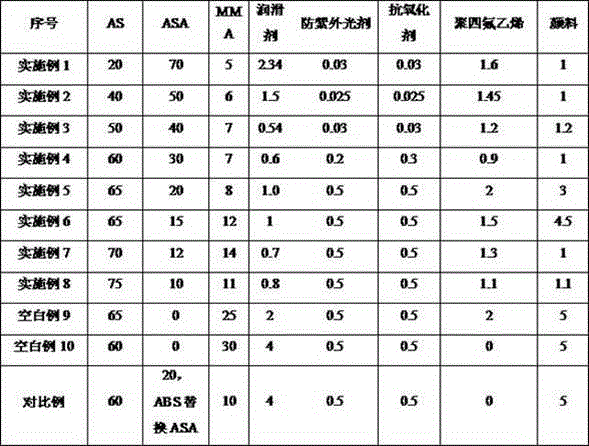

[0031] After blending the ingredients according to the formula shown in Table 1 below, stir and mix them evenly in a high-speed mixer, then add them to the granulator together, and keep the temperature at 180°C-200°C for granulation to obtain weather resistance ASA-based composites. The obtained weather-resistant ASA-based composite material and PVC are co-extruded in a screw extruder, and the processing temperature ranges from 160 to 220 ° C to form co-extruded plastic products, such as doors and windows.

[0032]Table 1 Components and their mass percentages in each case

[0033]

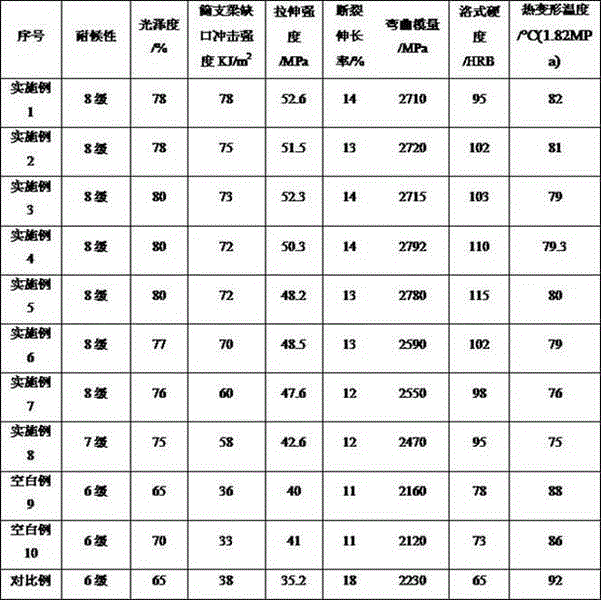

[0034] Table 2 embodiment 1-8 and blank example and each performance contrast of comparative example (following test according to ASTM standard)

[0035]

[0036] Table 2 shows the various performances of Examples 1-8, blank examples and comparative examples. As can be seen from Table 2, the ASA-based composite material of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com