Patents

Literature

73results about How to "Achieving complete environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing waste acid generated in process of preparing acid from metal smelting fume

InactiveCN102115270AIncrease consumptionIncrease processing costWater contaminantsMultistage water/sewage treatmentLiquid wasteSmelting process

The invention relates to a method for processing waste acid generated during preparing acid from fume generated in the smelting process of metal sulphide ore. In the method, the waste acid generated in process of preparing the acid from the metal smelting fume is processed by adopting a ferrous sulfate-lime neutralization method. The method comprises a sulfuration step and a neutralization step and is characterized in that a neutralizer used in the neutralization step is calcium carbide neutralizer slurry prepared from calcium carbide. In the invention, improvement is carried out aiming at the problems that in industrial application, the ferrous sulfate-lime neutralization method is large in the consumption of the calcium material lime of the neutralizer and high in processing cost; through fully utilizing the characteristic that the content of effective CaO in carbide slag is high, the carbide slag is used as a calcium material to replace the lime, thereby greatly reducing the cost, achieving the environment-friendly effect of treating the waste liquid by utilizing the waste slag, creating a novel way for use of calcium carbide and achieving the purpose of using wastes to treat wastes.

Owner:ZHUZHOU SMELTER GRP

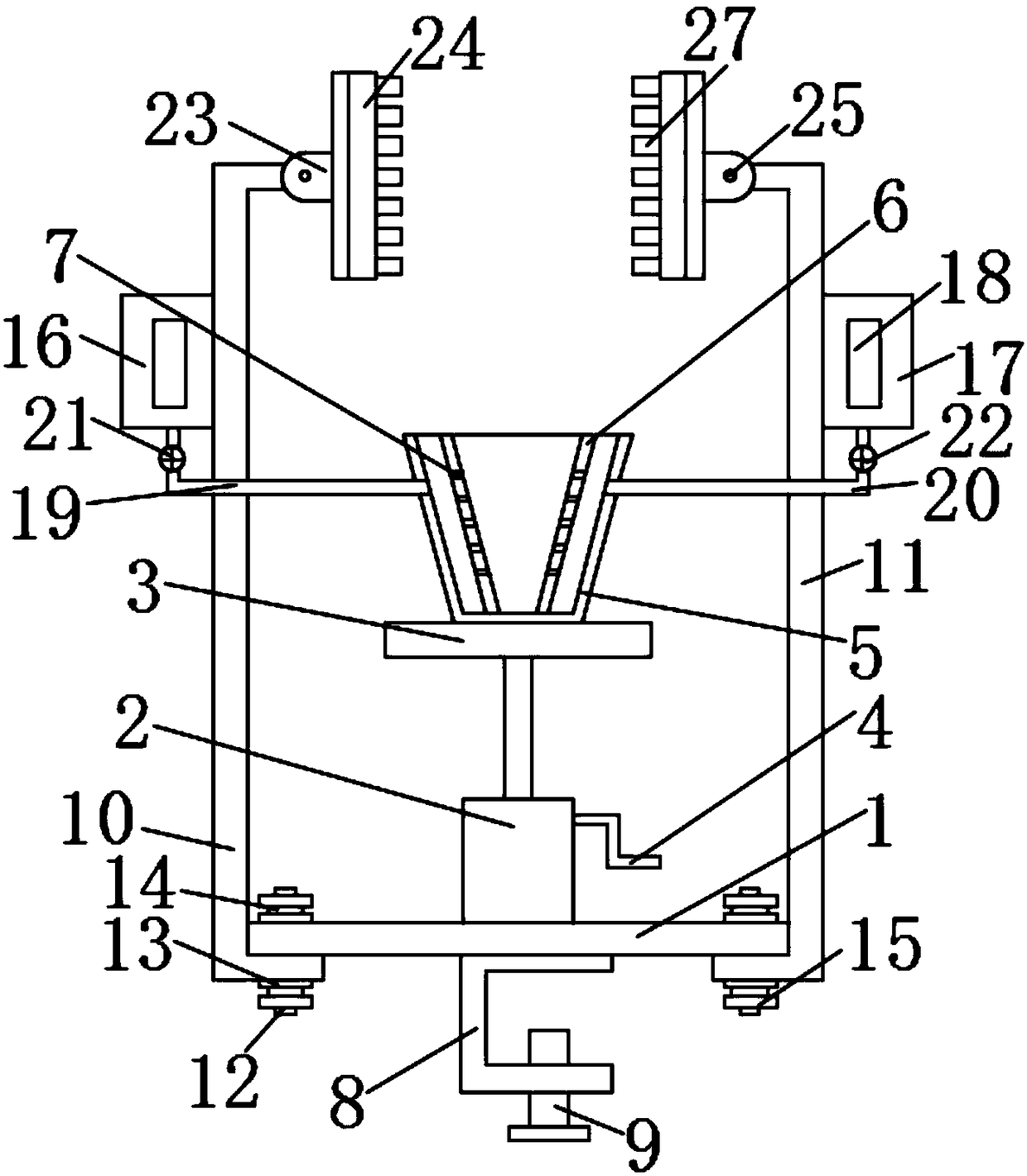

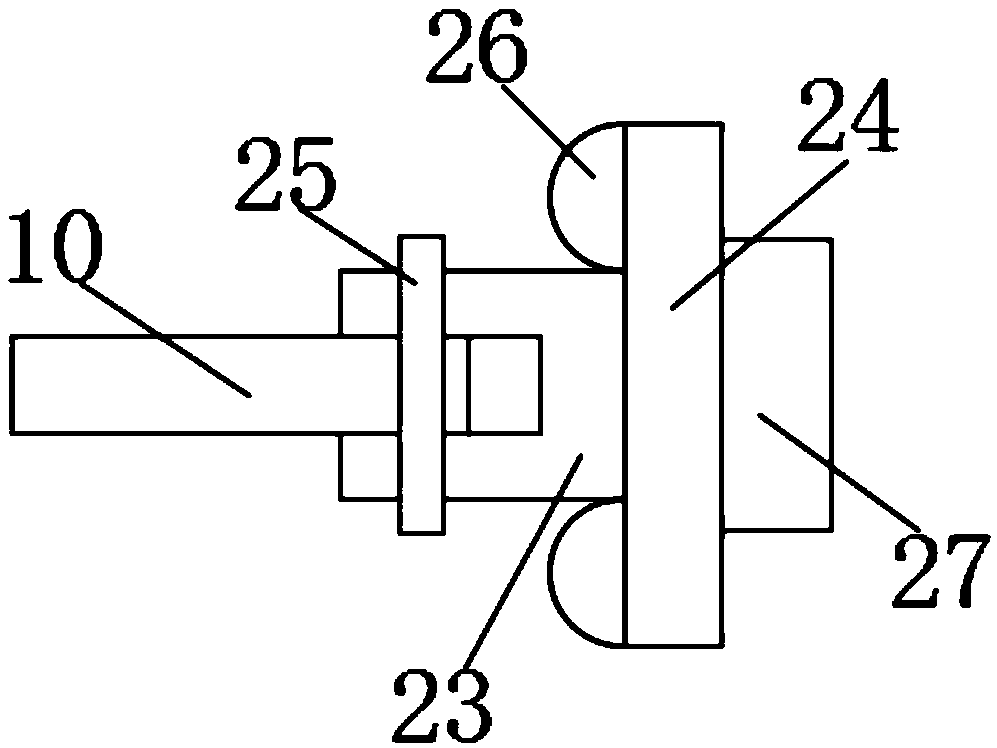

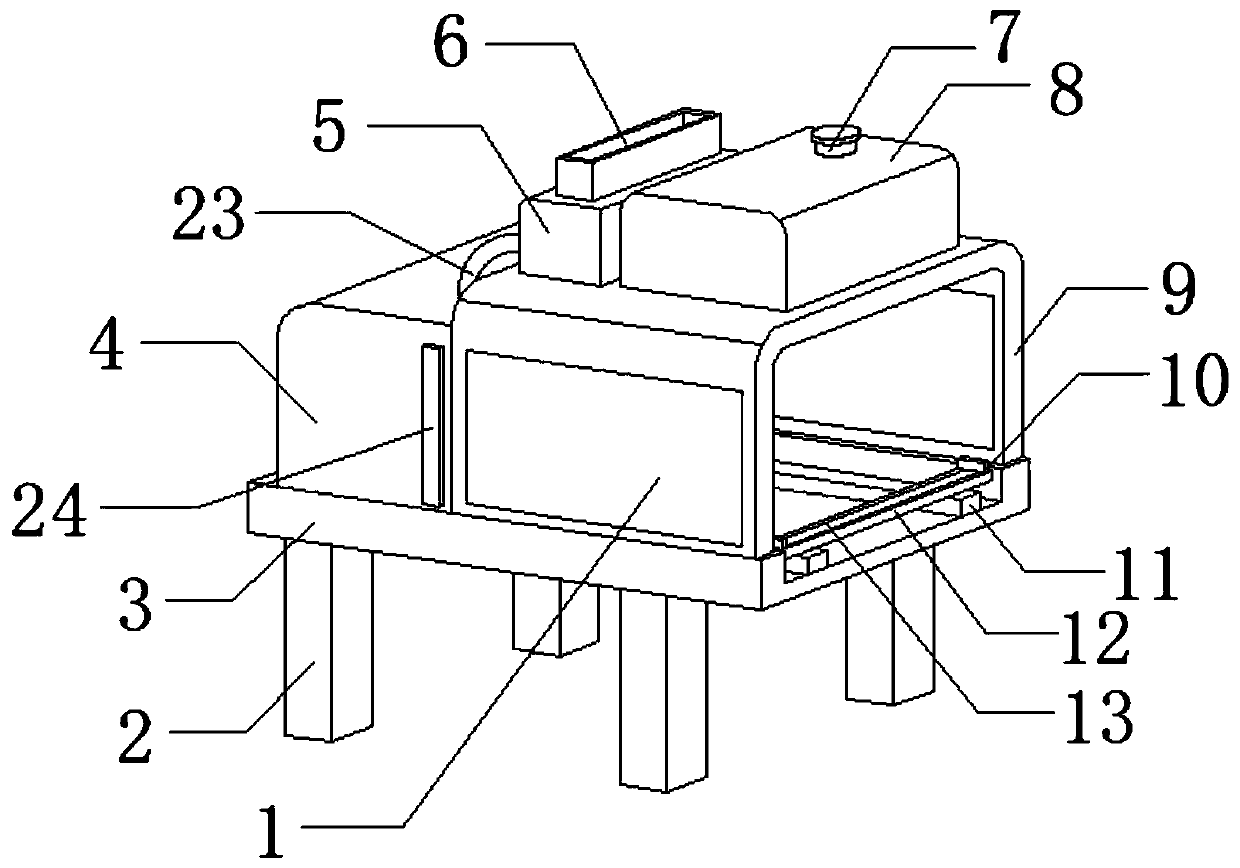

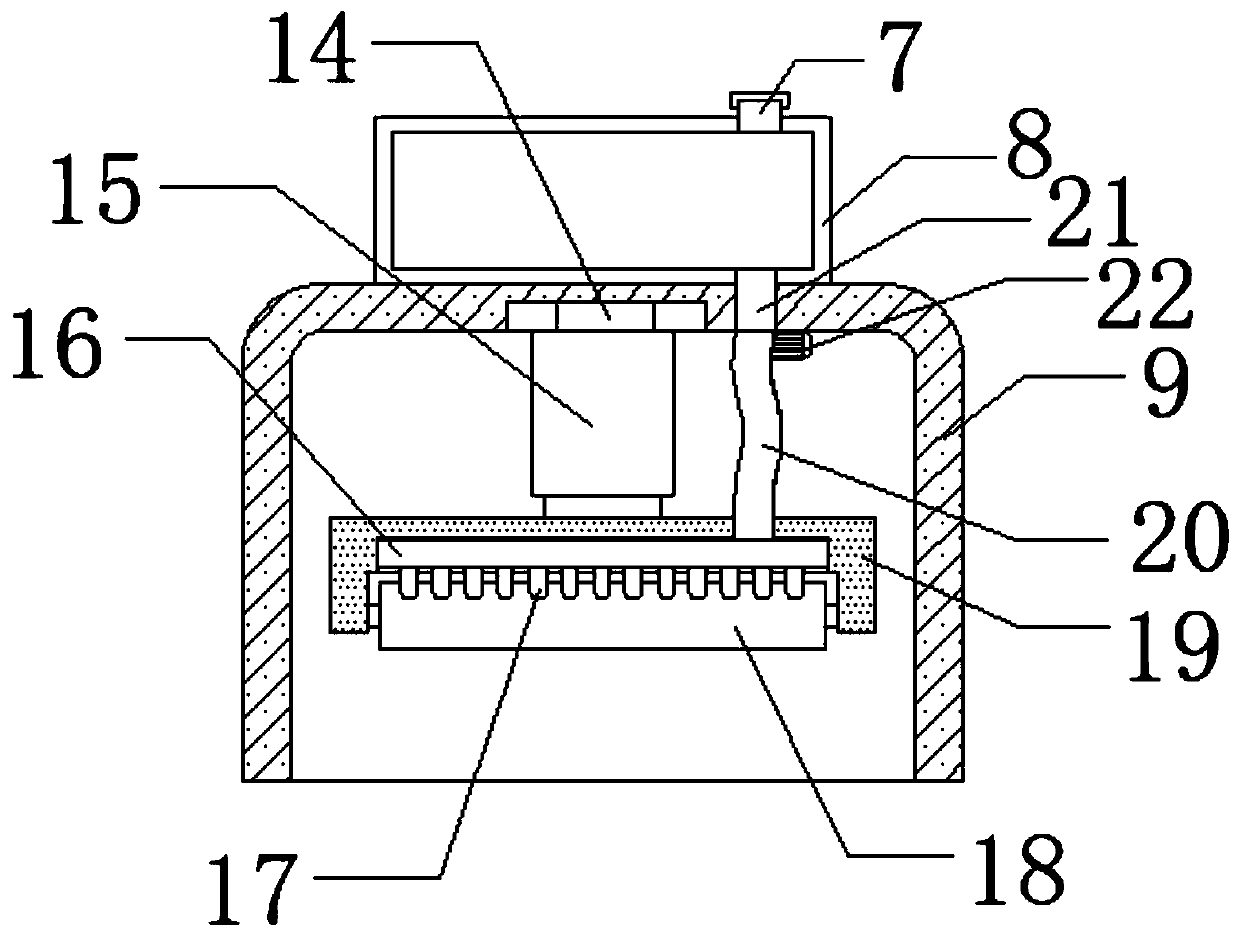

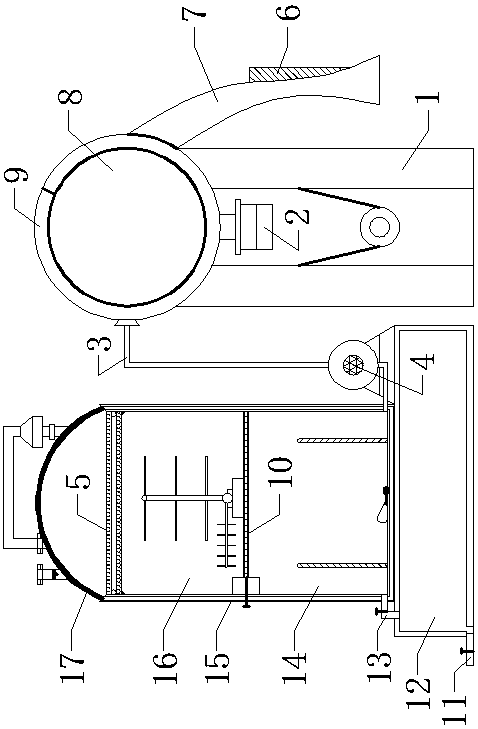

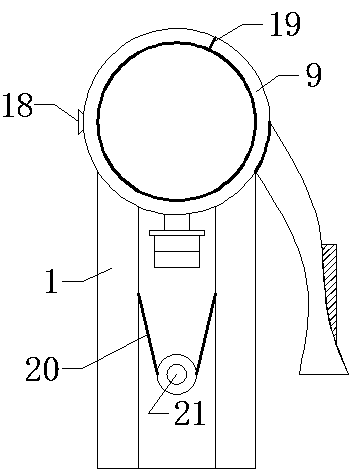

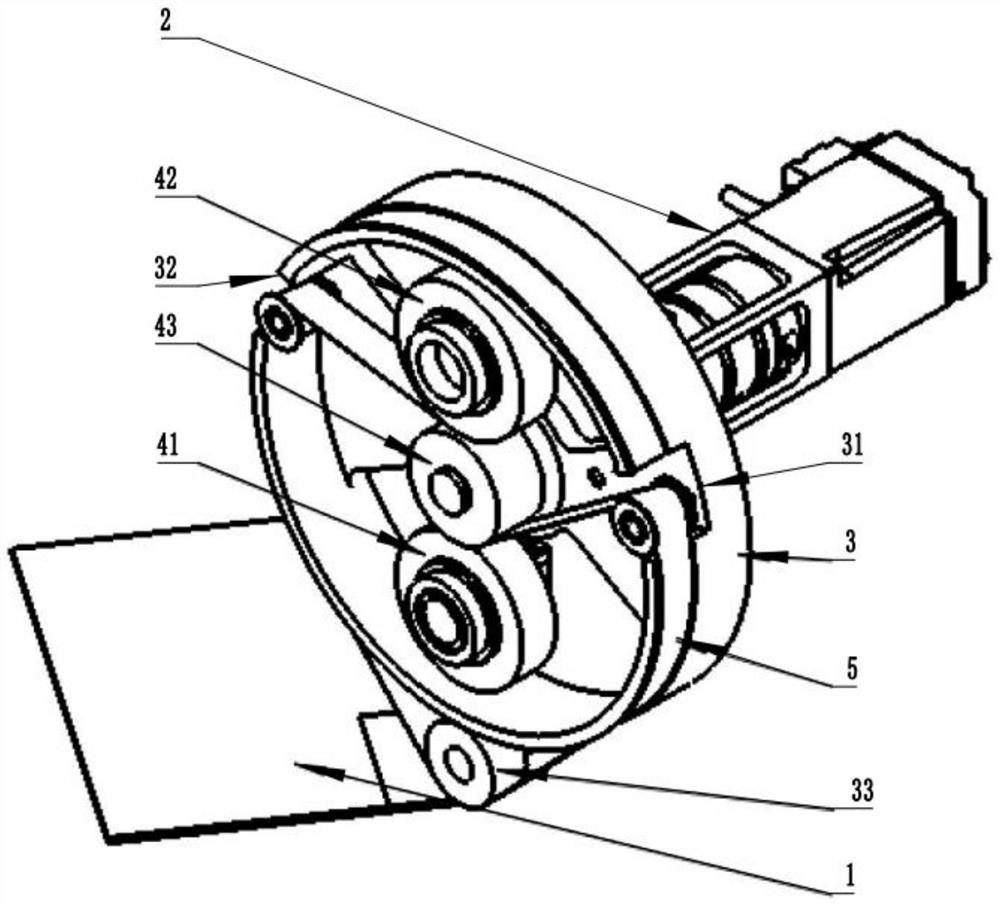

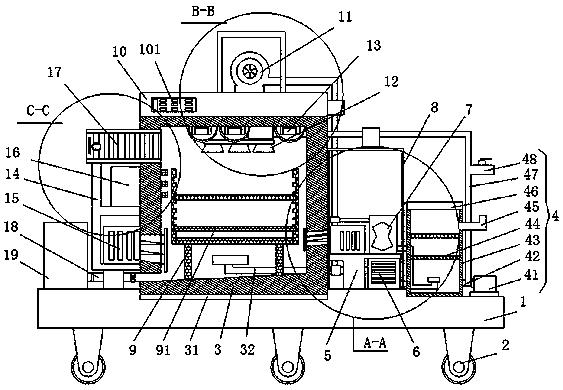

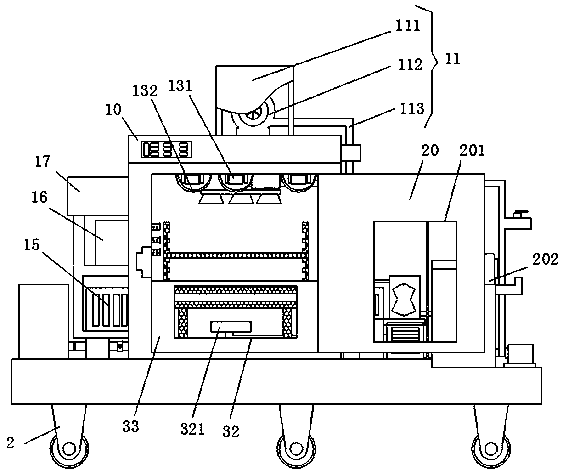

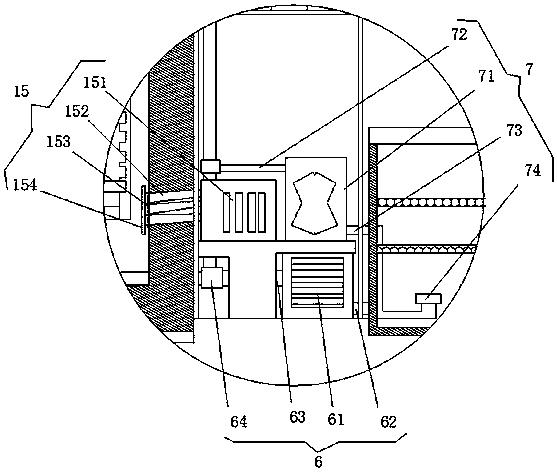

Environment-friendly household garbage crushing device

ActiveCN107469955AImprove crushing efficiencyAchieving complete environmental protectionDispersed particle filtrationDirt cleaningAir filterEngineering

The invention discloses an environment-friendly household garbage crushing device. The device comprises a garbage crushing cylinder and a crushing motor; and the crushing motor is fixedly mounted at the top of the garbage crushing cylinder. The device further comprises a crushing shaft, crushing blades, a winding prevention device, a fixed base, an air sucking port, an exhaust fan, an exhaust pipe and an air filter; and the crushing motor is in transmission connection with the crushing shaft mounted in the garbage crushing cylinder through a connecting shaft. The winding prevention device mounted between the crushing blades can remove household garbage wound on the crushing shaft and the crushing blades, so that obstruction of normal work of the crushing device, or even mechanical faults caused by winding of plastic bags and the like in the household garbage on the crushing shaft and the crushing blades is prevented, and the crushing efficiency of the crushing device is improved; and malodorous gas dissipated by rotting of the garbage in the garbage crushing cylinder is collected in a centralized manner through the exhaust fan, and is filtered through air for cleaning and exhausting to realize environmental protection performance of the crushing device.

Owner:临沂港控能源有限公司

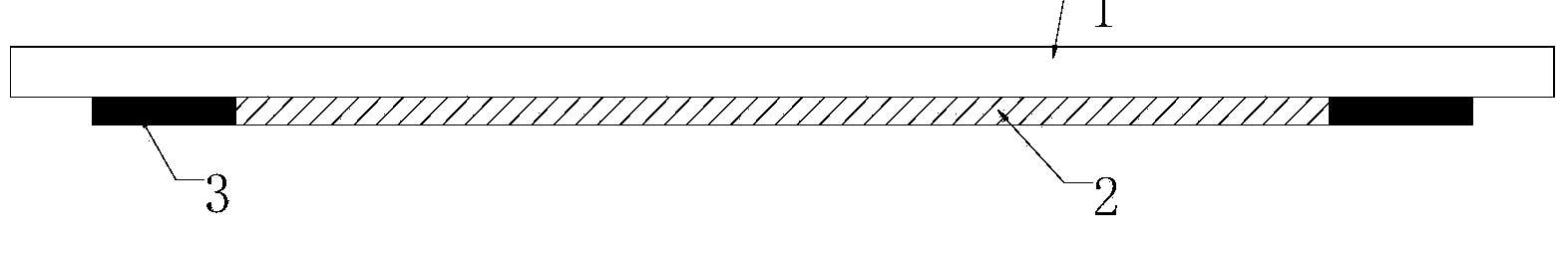

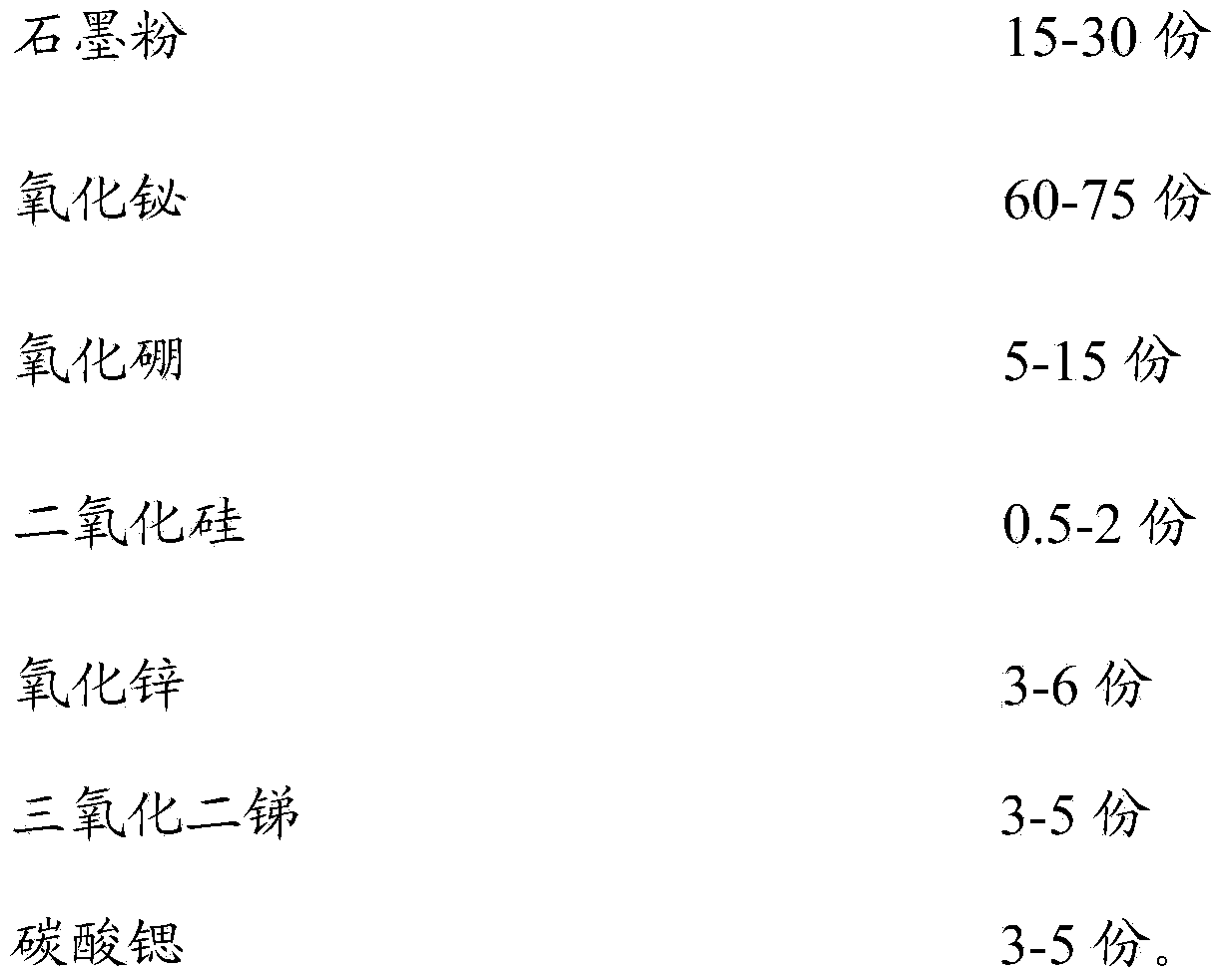

Inorganic resistor thick film and preparing method and application of inorganic resistor thick film

ActiveCN103489550AAchieve performanceIncrease temperatureNon-adjustable resistorsStrontium carbonateLead oxide

The invention belongs to the field of new materials, and provides an inorganic resistor thick film and a preparing method and application of the inorganic resistor thick film. The inorganic resistor thick film comprises graphite powder, bismuth oxide, boric oxide, silica, antimonous oxide, zinc oxide, strontium carbonate and the like. According to the inorganic resistor thick film, the bismuth oxide serves as the framework material, the boric oxide, silica, the zinc oxide, the strontium carbonate and the like are used in cooperation with the bismuth oxide, the performance of the inorganic resistor thick film is achieved, and meanwhile compared with existing lead oxide, the inorganic resistor thick film has the advantages that the lead content is zero, and people are prevented from getting lead poisoning in the process of producing and using the inorganic resistor thick film and the environment is prevented from being polluted. The using temperature of the inorganic resistor thick film is greatly increased due to the bismuth oxide, and the application range of the inorganic resistor thick film is enlarged. The preparing method of the inorganic resistor thick film is easy to operate, low in cost and very suitable for industrial production.

Owner:李琴 +1

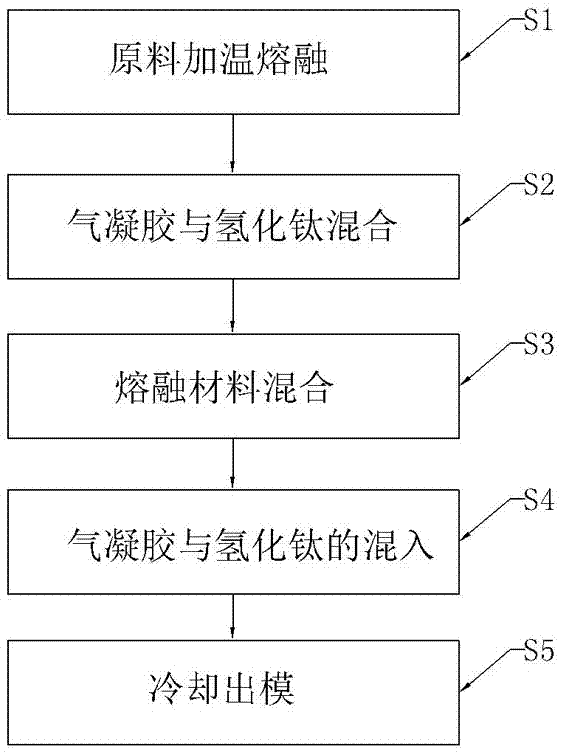

Foaming sound-proof acrylic resin vehicle bottom protective plastisol and preparation method thereof

The invention relates to foaming sound-proof type acrylic resin car-bottom protection plastisol and the preparation process thereof. The foaming sound-proof type acrylic resin car-bottom protection plastisol comprises components with following percentage by weight, 4-8% volatile solvent, 20-40% plasticizing agent, 20-35% acrylic polymer, 5-20% polyurethane resin, 0.2-1.5% foaming agent, 0.2-1.5% thixotropic agent and 15-45% filling. The preparation process comprises mixing raw materials under controlled temperature, stirring, grinding with a three roll mill, stirring under -0.05-0.1MPa, screening and obtaining finished products. The plastisol of the invention has excellent sound-proof effect, less construction usage, safe construction condition and low cost.

Owner:长春依多科化工有限公司

Environmentally-friendly dry powder emulsion paint for inner wall and preparation method thereof

The invention relates to an environmentally-friendly dry powder emulsion paint for an inner wall and a preparation method thereof. The environmentally-friendly dry powder emulsion paint for the inner wall is prepared through the following raw materials in parts by weight: 20-35 parts of white cement, 20-35 parts of calcium carbonate powder, 8-18 parts of ash calcium powder, 30-40 parts of modified degreased soybean powder pulp, 5-10 parts of titanium dioxide, 10-20 parts of propolis powder, 6-8 parts of water soluble glucan, 4-6 parts of flatting agent, 2-3 parts of organobentonite, 1-3 parts of nanometer magnetic ordered mesoporous medium, 2-3 parts of antioxidant, and 1-3 parts of additive, wherein the additive is at least one of flame-retardant powder, nanometer negative ion powder and an antistatic agent; the flatting agent is a liquid acrylic flatting agent. The environmentally-friendly dry powder emulsion paint for the inner wall is reasonable in raw material selection, and proper in matching; compared with an existing emulsion paint, the prepared dry powder emulsion paint has the advantages of being outstanding in water resistance, outstanding in bonding performance, high in consistency in the drying process, and high in flatness; in addition, the emulsion paint is high in stability during the drying process, is influenced slightly by the outside condition, and is hard to discolor; in addition, the emulsion paint is outstanding in antibacterial capacity, high in static resistance and high in fire retardance.

Owner:陈浩谦

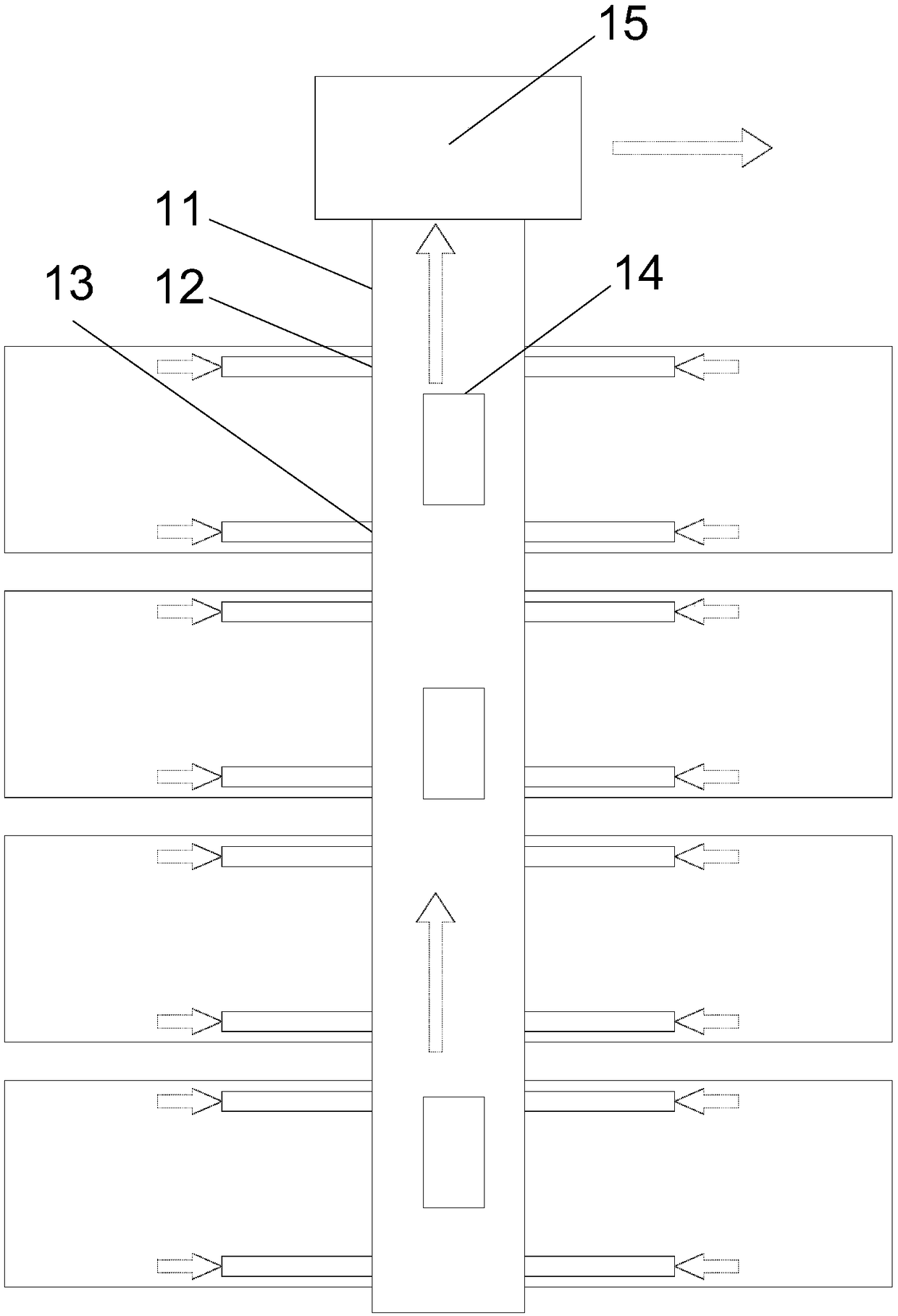

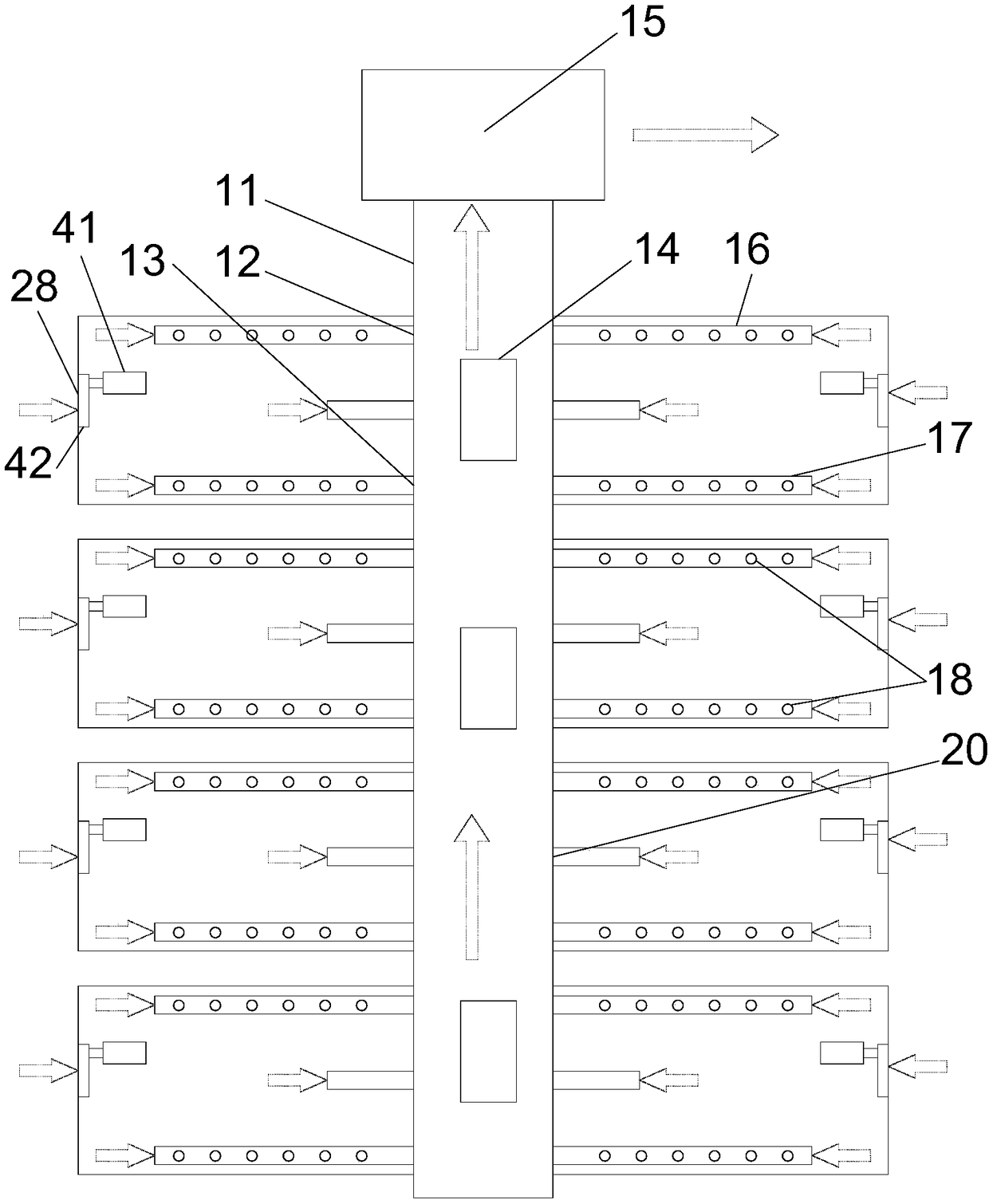

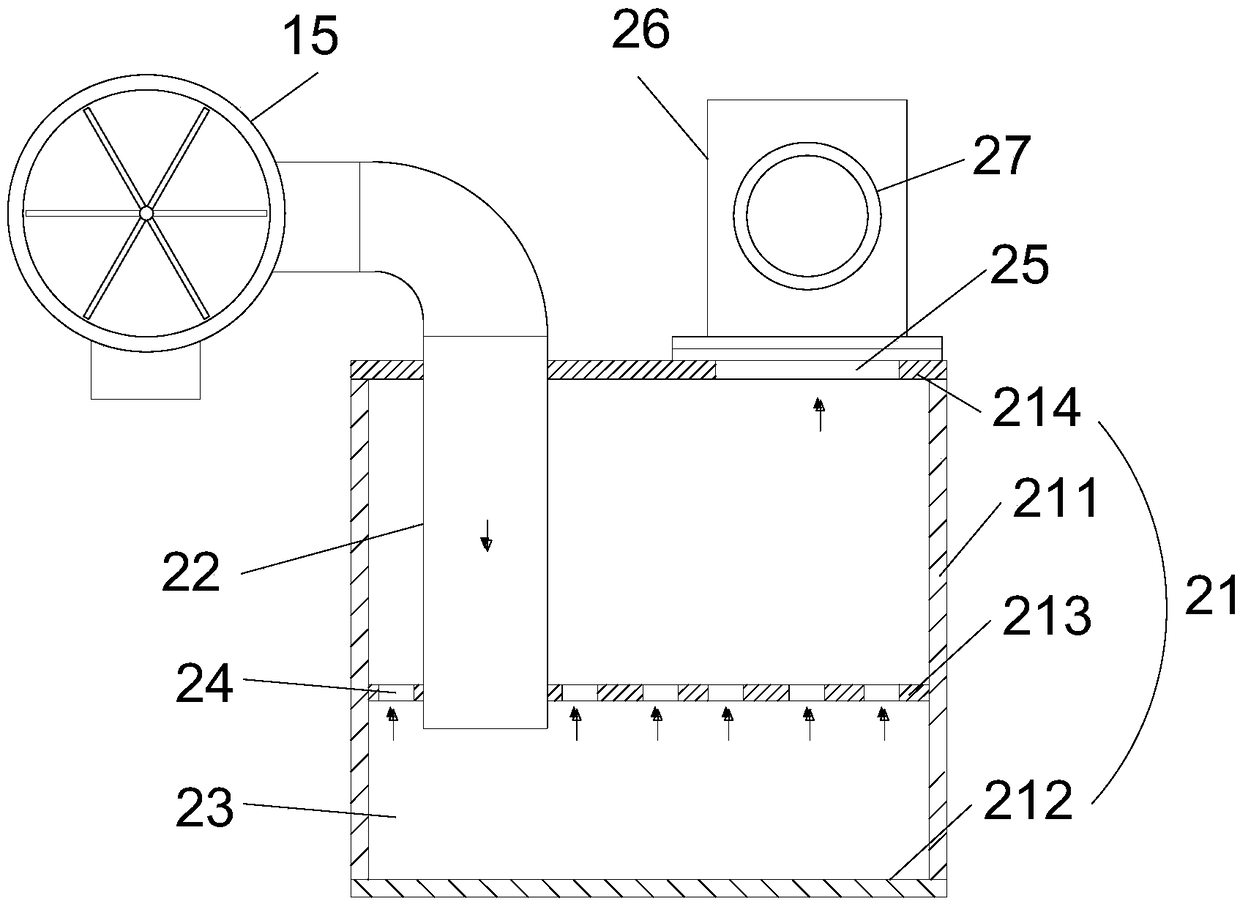

Air purification system for building

InactiveCN109163409AReduce health hazardsAchieve environmental protection effectMechanical apparatusLighting and heating apparatusPulp and paper industryAir purification

The invention relates to an air purification system for a building. The air purification system for the building comprises a longitudinal exhaust pipeline, the longitudinal exhaust pipeline passes through each floor, a first exhaust port and a second exhaust port are formed in a room of each resident, the first exhaust ports are formed at a first height, and the second exhaust ports are formed ata second height; the first exhaust ports and the second exhaust ports communicate with the longitudinal exhaust pipeline, first fans are arranged in the longitudinal exhaust pipeline, a second fan isarranged at the top end of the longitudinal exhaust pipeline, an inlet of the second fan communicates with the longitudinal air exhaust pipeline, and an outlet of the second fan communicates with theoutside air; and the first height is higher than the second height. According to the air purification system for the building, the first exhaust ports and the second exhaust ports are arranged at different heights, so that indoor air flow is easily formed, then indoor polluted air can be uniformly extracted through the fans and discharged to the outside air, the comfort of the life of people is guaranteed, and the harm to the body health of people living in the room for a long time is reduced.

Owner:孔维连 +2

Fireproof polyurethane floor coating

InactiveCN106189775AAvoid human health hazardsAchieving complete environmental protectionFireproof paintsWax coatingsSolventParaffin wax

The invention discloses fireproof polyurethane floor coating. The floor coating comprises the following components in parts by weight: 78 to 86 parts of waterborne polyurethane resin, 20 to 24 parts of melamine formaldehyde resin, 15 to 25 parts of polyvinyl acetate emulsion, 16 to 18 parts of paraffin emulsion, 3 to 7 parts of alkylbenzene sulfonate, 6 to 8 parts of vinyl trimethoxysilane, 11 to 14 parts of hydroxyethyl cellulose, 3 to 7 parts of dinonylnaphthalene sulfonic acid, 1 to 4 parts of butyl titanate, 4 to 7 parts of citric acid, 3 to 7 parts of zinc naphthenate, 2 to 4 parts of sodium borate, 5 to 12 parts of a polyurethane curing agent and 10 to 15 parts of a polyurethane dispersant. The fireproof polyurethane floor coating disclosed by the invention is free of solvents, non-toxic and harmless, and environment-friendly to avoid harm of the organic solvents on health of a human body, and can realize completely environment-friendly construction and application. Furthermore, the fireproof polyurethane floor coating has the characteristics of better water resistance and fire resistance, high tinting strength and yellowing resistance, and further is higher in layer surface brightness, brighter in color and luster and more excellent in physical properties.

Owner:张海棠

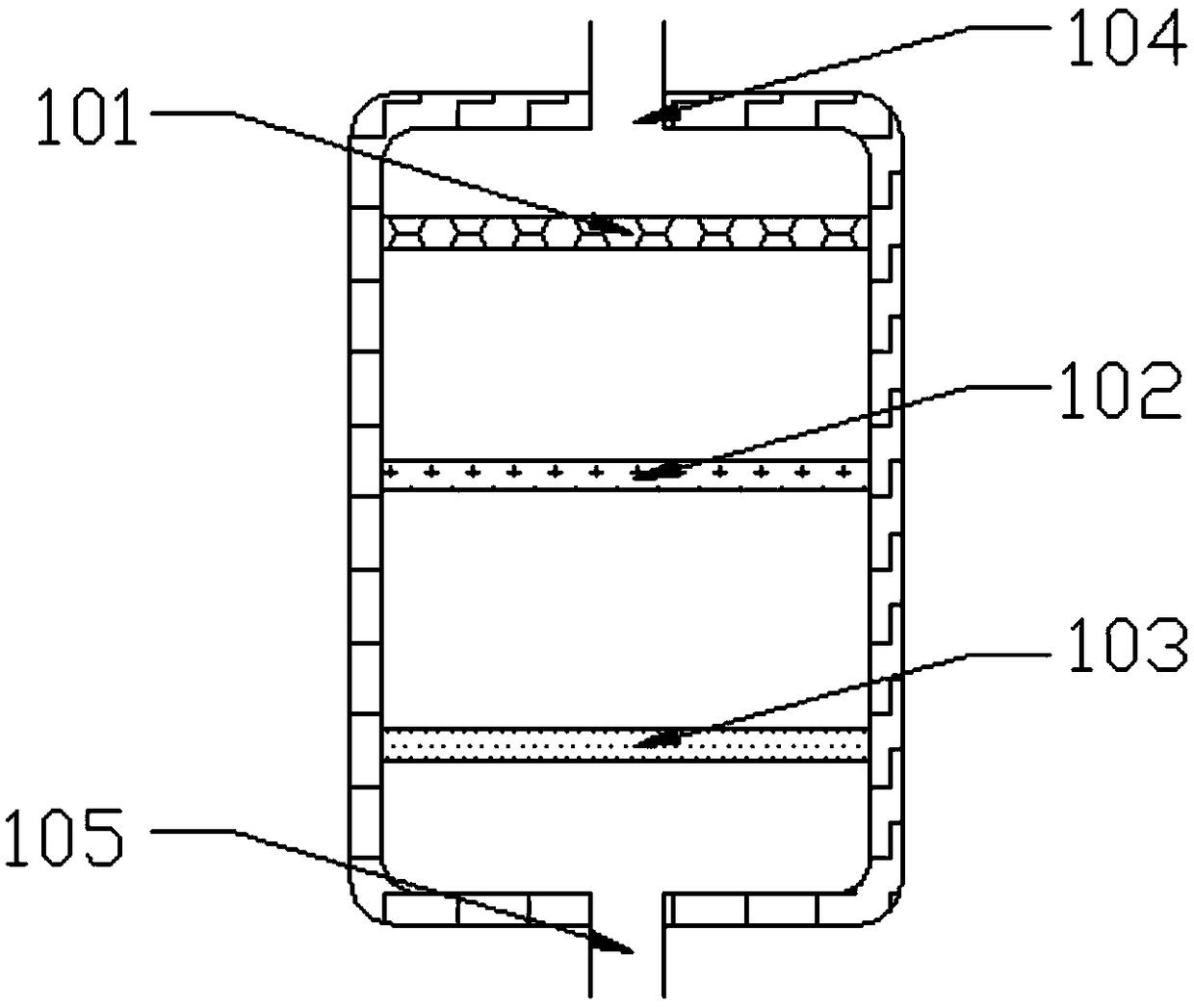

Flowerpot conductive to flowering plant growth and used for planting flowering plant

InactiveCN108849061AEasy to adjustIncrease productivitySelf-acting watering devicesSaving energy measuresEngineeringIrradiation

The invention discloses a flowerpot conductive to flowering plant growth and used for planting a flowering plant, and relates to the technical field of plantation of flowering plant. The flowerpot comprises a bottom plate, wherein the middle of the top of the bottom plate is fixedly provided with a pusher, the top end of the pusher is fixedly connected with a supporting plate, the top of the supporting plate is fixedly connected with a flowerpot body, the two sides of the bottom plate are fixedly provided with a first supporting plate and a second supporting plate respectively, and the bottomsof the first supporting plate and second supporting plate are both in inserted connection with threaded columns. The flowerpot conductive to the flowering plant growth and used for planting the flowering plant has the advantages that a worker adjusts the height of the flowerpot conveniently, the operation is simple and fast, thereby well receiving irradiation, greatly improving the production efficiency of the flowering plant, promoting the flowering plant to better absorb nutrients, and improving the high quality of the flowering plant; the specificity and novelty of the design provides convenience for the worker to place the flowerpot, improves the tightness and firmness of the installation, and provides convenience for the worker to control the liquid inlet amount according to the change of the liquid level.

Owner:安吉美维农业发展有限公司

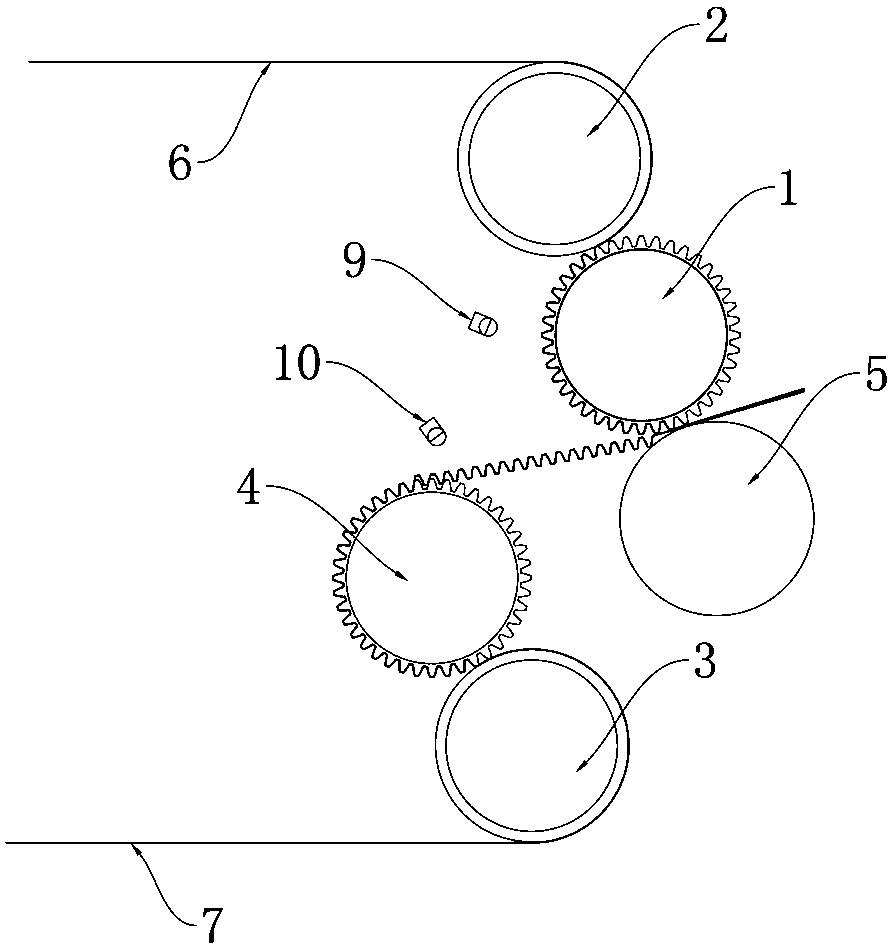

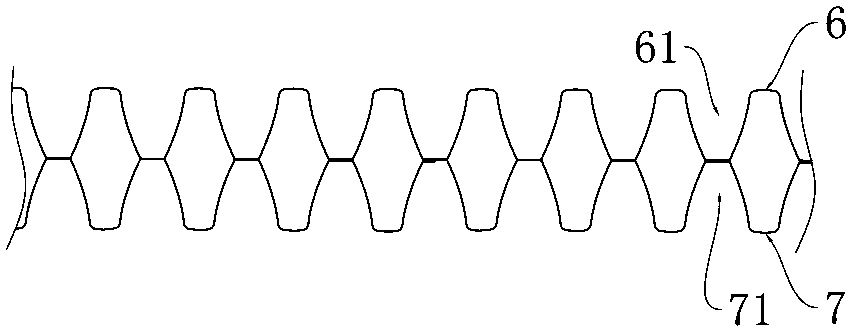

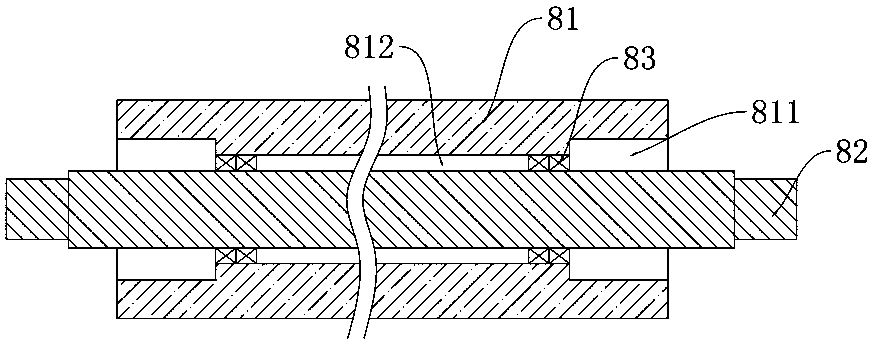

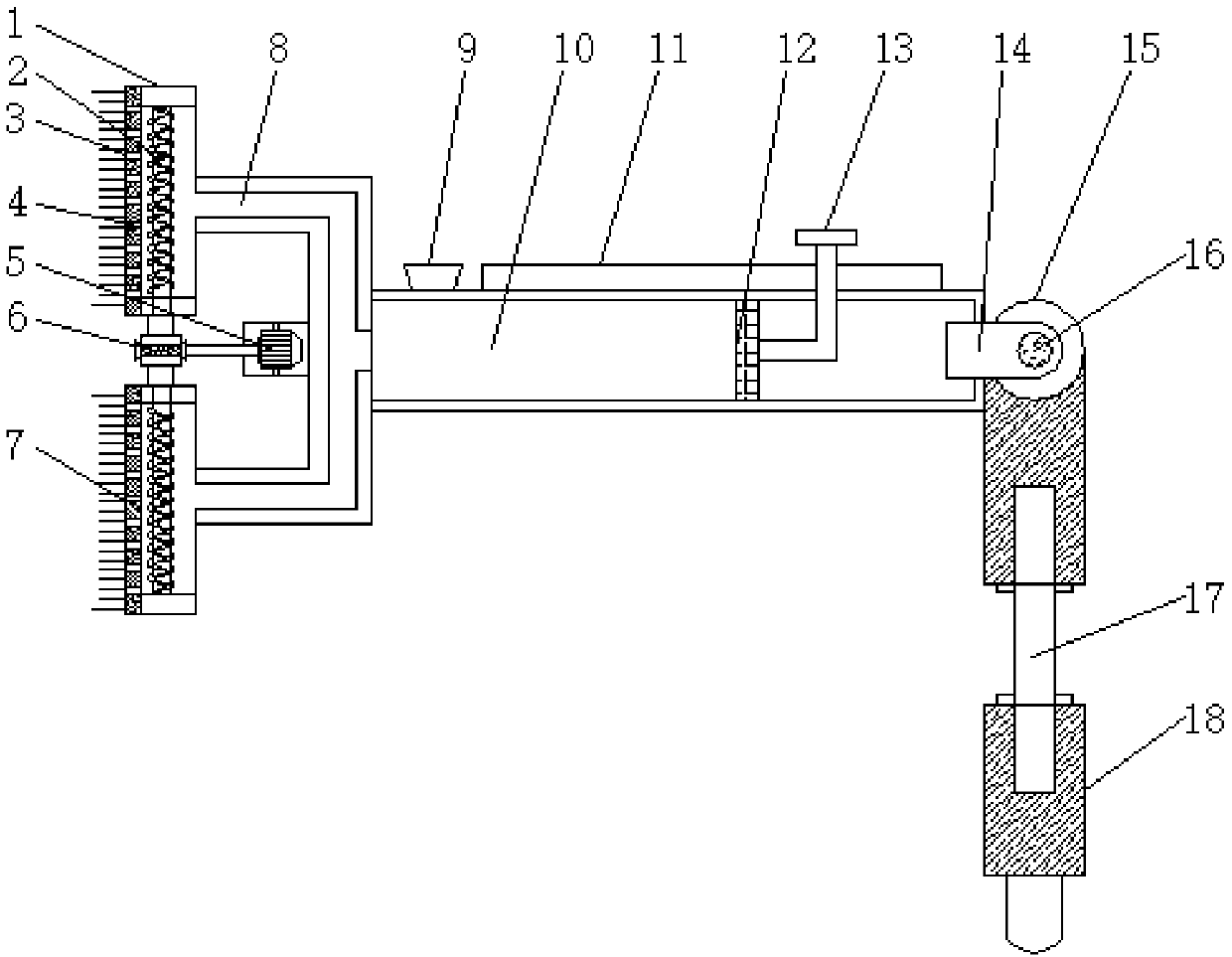

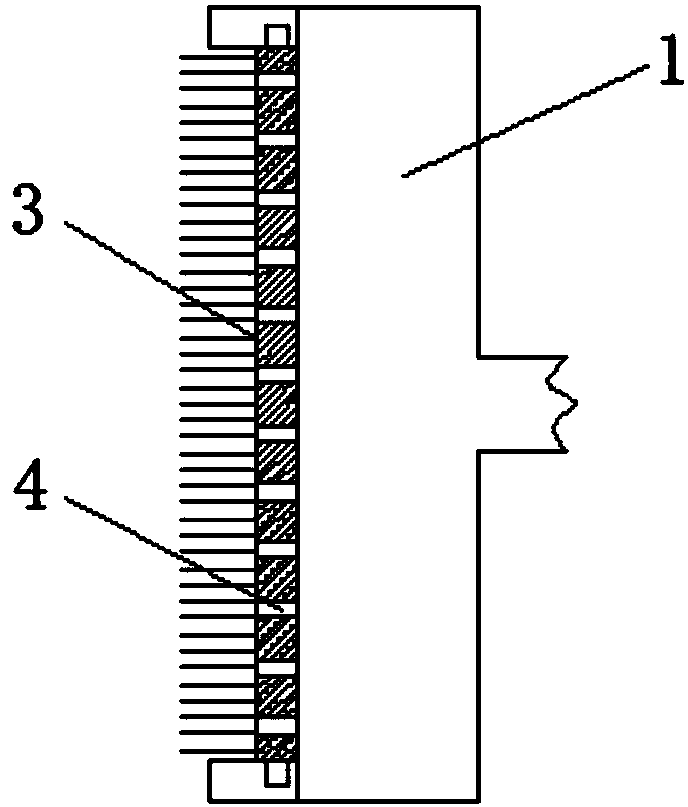

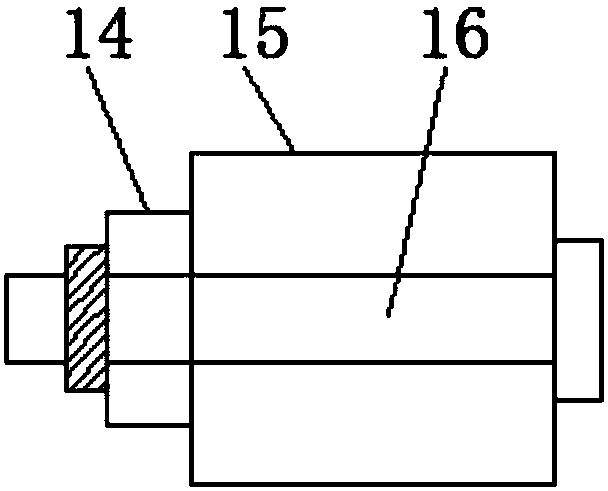

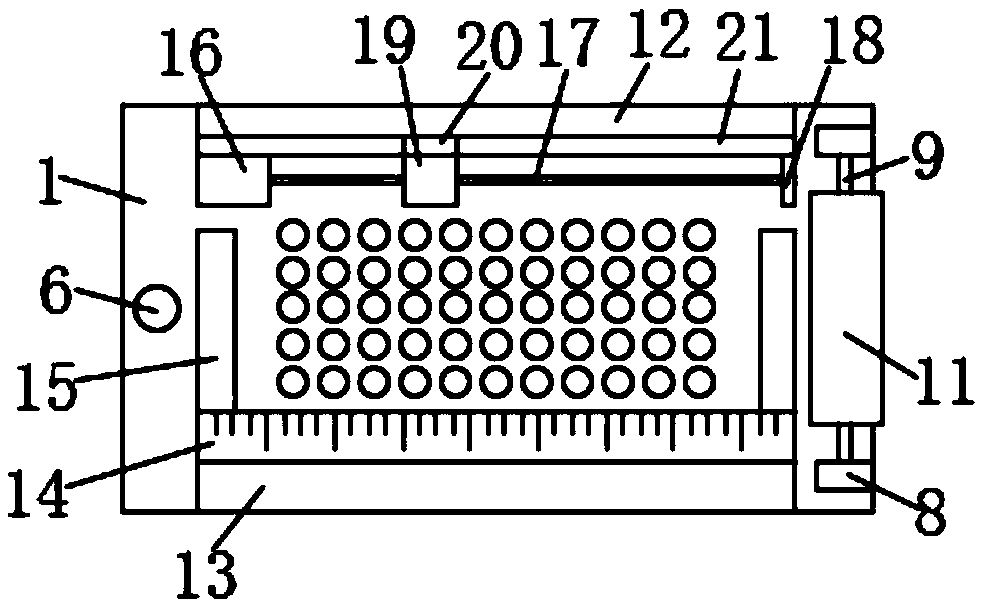

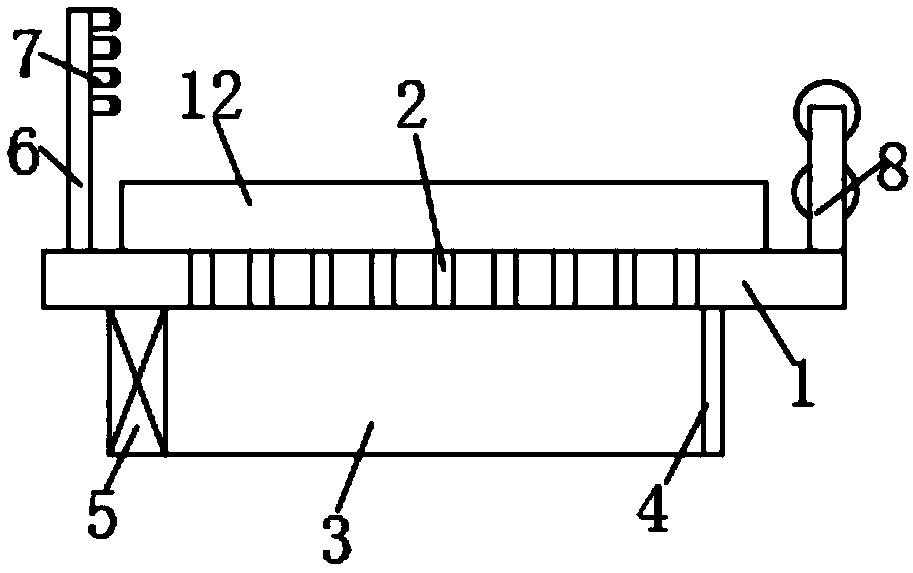

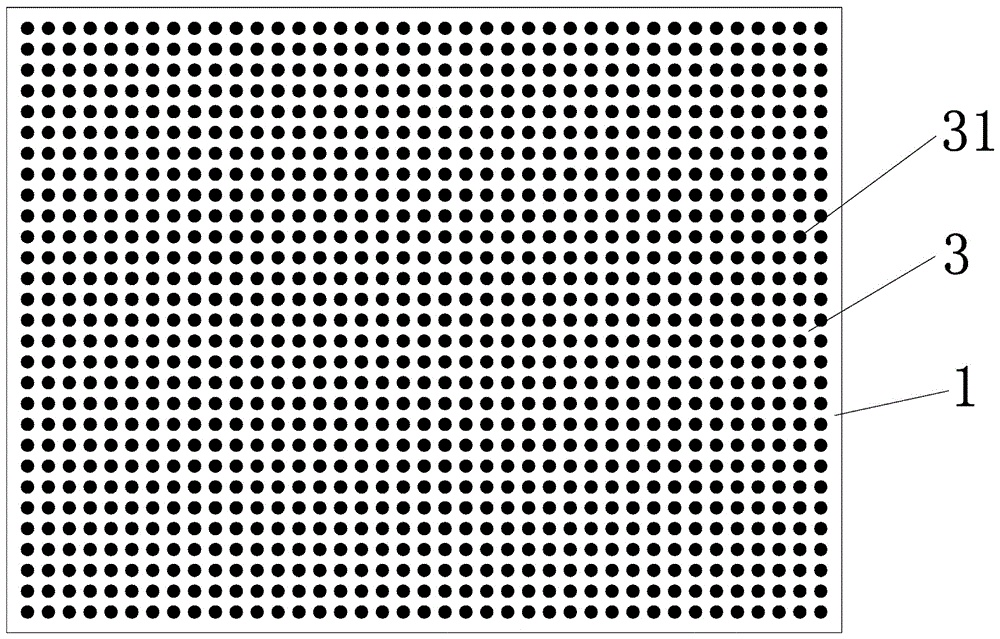

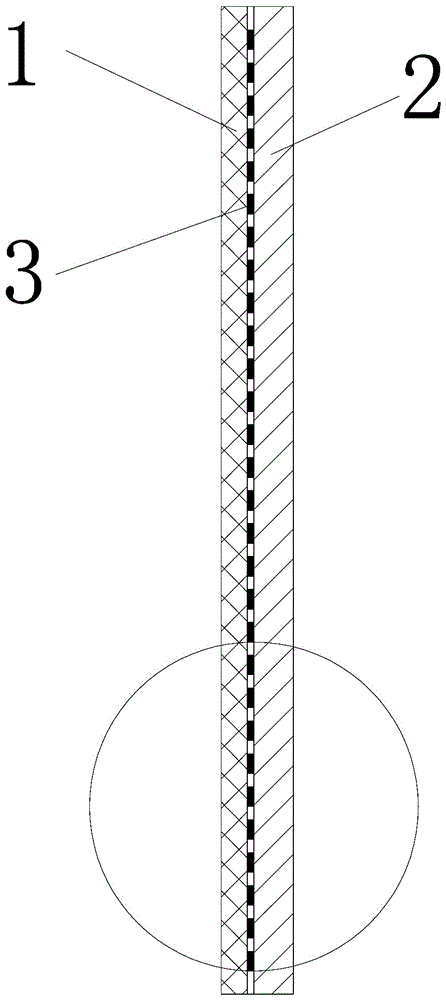

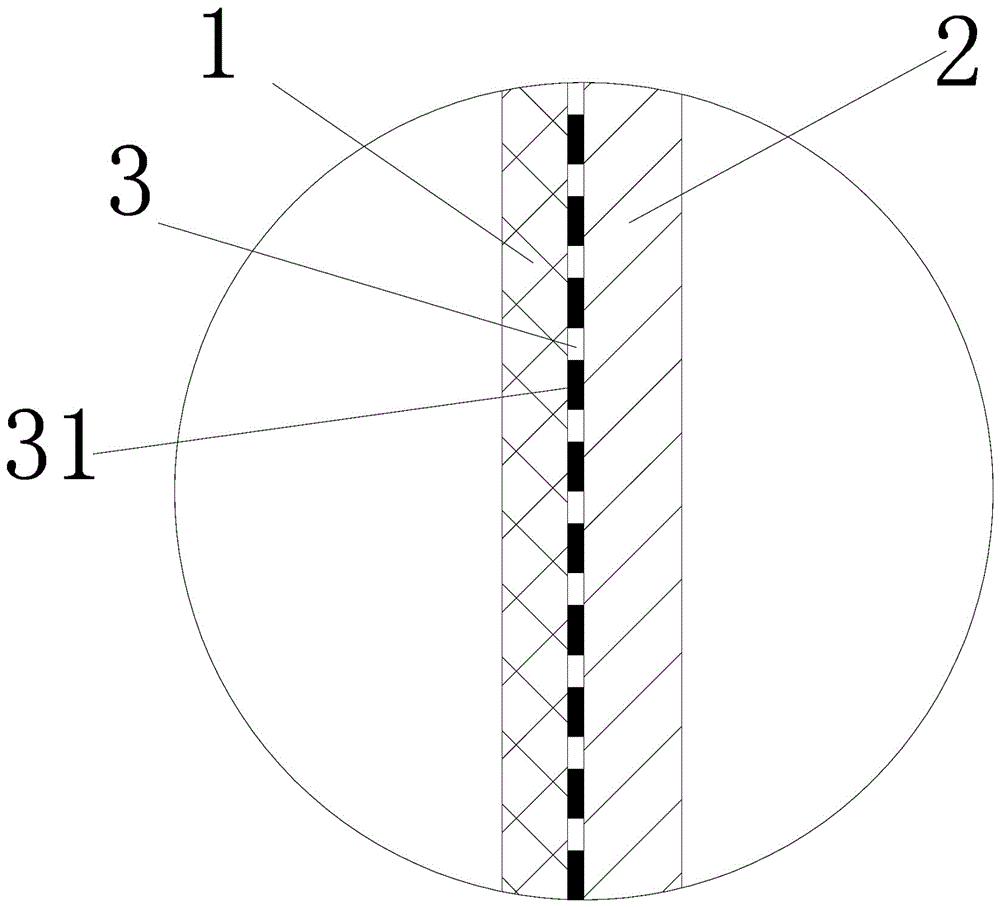

Double-layer point-to-point glue-free composite embossing system and composite embossing paper

PendingCN108481986AGuarantee a tight bondReduce manufacturing costEmbossing decorationsEnvironmental resistanceEngineering

The invention discloses a double-layer point-to-point glue-free composite embossing system. The double-layer point-to-point glue-free composite embossing system comprises an upper glue roller, an upper embossing roller, a lower glue roller, a lower embossing roller and a smooth roller, wherein the upper glue roller and the upper embossing roller are close to each other so as to cooperate with eachother for performing embossing, and therefore pre-arranged first body paper forms a texture pattern which is composed of a plurality of first concave points; the lower glue roller and the lower embossing roller are close to each other so as to cooperate with each other for performing embossing, and therefore pre-arranged second body paper forms a texture pattern which is composed of a plurality of second concave points; and the upper embossing roller and the smooth roller are close to each other, the embossed first body paper and the embossed second body paper converge at the tangent point ofthe upper embossing roller and the smooth roller so as to cooperate with each other for pressed compositing, and therefore the first concave points correspond to the second concave points in a one-to-one mode, and the bottom ends of the corresponding first concave points and second concave points are tightly combined. The composite mode is adopted, so that the two layers of body paper are tightlycombined, the environment-friendly effect is achieved, and the production cost is reduced for enterprises.

Owner:广东志德胜科技有限公司

Chromium-based coke removal and ash removal coal saving agent composition for boiler and preparation method for composition

The invention relates to coal burning additives used in coal burning boilers in the industries of power generation, thermoelectricity, petroleum, chemical engineering, metallurgy and the like, in particular to chromium-based coke removal and ash removal coal saving agent composition for a boiler. The composition is prepared from the following raw materials in parts by weight: 60-75 parts of chromic oxide, 10-16 parts of copper sulfate, 7-12 parts of cerium oxide, 10-15 parts of barium molybdate, 6-12 parts of manganese dioxide, 12-17 parts of potassium permanganate, 5-11 parts of potassium chlorate, 15-22 parts of zinc oxide, 8-13 parts of cobalt sulfate, 22-30 parts of potassium carbonate, 30-40 parts of active attapulgite clay and 0.1-0.3 parts of a penetrating agent JFC. The composition is added into the coal burning boiler, so that the coal saving rate is 8-25%, a furnace coking phenomenon is radically changed, the combustion time of fire coal can be prolonged, the heat efficiency of the boiler is improved, furnace tailings are reduced, the service life and repair cycle of equipment are prolonged, the emission of toxic and harmful gas and substances is reduced, and environmental protection effects of alleviating pollution and reducing emission are fundamentally achieved.

Owner:兰州熙瑞化工科技有限公司

Shell spraying device for computer production

PendingCN110918349AEffective clampingImprove stabilityPretreated surfacesLiquid spraying apparatusEngineeringMechanical engineering

The invention belongs to the technical field of computer production, particularly to a shell spraying device for computer production, and aims to solve the problem of incapability of timely and effectively drying sprayed shells in the use process of a traditional spraying device. The shell spraying device for computer production comprises a support table and fourth support legs; the four support legs are mounted on the outer walls of four corners of the bottom of the support table through bolts; a first support shell is fixedly mounted on the outer wall of one side of the top of the support table; and an intake pipe is fixedly mounted on the outer wall of the top of one side of the first support shell. In the shell spraying device for computer production, through arrangement of a first electric guide rail and a second electric guide rail and arrangement of clamping plates on second electric slide blocks, computer shells needing to be sprayed can be placed among four clamping plates, and the clamping plates are driven to move by the four second electric slide blocks, so that the effective clamping of the computer shells is realized, and the spraying treatment stability is improved.

Owner:曾为濠

Production process of coke by preheating coal and stacking

InactiveCN107400527AIncrease stickinessIncrease dosageSpecial form destructive distillationCoking wastewaterQuenching

The invention relates to a production process of coke by preheating coal and stacking. The production process comprises the following steps of pretreatment: preheating and crushing a coal material according to the property of a coal type, and then weighing and taking the corresponding crushed coal material according to a coal proportion, adding or not adding a binder, and then mixing to obtain raw-material coal; molding: carrying out hot press molding on the raw-material coal to obtain molded coal; stacking: stacking the molded coal to be a coal wall, and laterally loading into a vertical coke oven; coking: carrying out dry distillation in the vertical coke oven; coke quenching: pushing the coke into a coke quenching car, screening and storing after the coke quenching, and carrying out recovery treatment on coal gas generated during the dry distillation. According to the technical scheme of the production process, the viscosity of the coal is effectively improved through preheating the coal; the use level of weak caking coal can be increased by 45 percent or above; the density of the weak caking coal is improved by adopting a hot molding technique; the coking time can be greatly shortened; the initial temperature of the dry distillation can be effectively improved, the generation of coking wastewater is reduced and the quality of the coal gas is improved by preheating the coal entering the oven and the production process is used for realizing energy-saving and environment-friendly effects through recovering the sensible heat of the generated coal gas.

Owner:山西博嘉慧科技有限公司

Safe and environmentally-friendly plastic-blasting method capable of realizing corrosion prevention and weather resistance of sheet material

InactiveCN110370405AWeather resistantNo deformationWood treatment detailsWood impregnation detailsWeather resistanceAging resistance

The invention discloses a safe and environmentally-friendly plastic-blasting method capable of realizing corrosion prevention and weather resistance of a sheet material. The safe and environmentally-friendly plastic-blasting method for corrosion prevention and weather resistance of the sheet material comprises the following steps: processing treatment of the sheet material: subjecting the sheet material to rough processing, and remaining a processing allowance of 3.5 to 5 mm so as to obtain a roughly-processed to-be-blanked material, then polishing the roughly-processed to-be-blanked material,and cutting a polished sheet material into a same shape so as to obtain a roughly-processed sheet material; and degreasing treatment of the roughly-processed sheet material: completely immersing theroughly-processed sheet material into a glycerin solution, carrying out soaking for 6 to 8 h, then stewing the soaked sheet material, carrying out slow heating until the temperature of glycerin is 50to 65 DEG C, carrying out heat-preserving and stewing for 4 to 6 h, taking the stewed sheet material out of the glycerin solution, and carrying out standing for 2 to 3 h so as to obtain a degreased sheet material. The safe and environmentally-friendly plastic-blasting method capable of realizing corrosion prevention and weather resistance of the sheet material provided by the invention has the following advantages: through the steps of degreasing treatment, treatment with flowing water, cyclic drying treatment, corrosion prevention treatment and the like, the sheet material is insusceptible togenerating the phenomenons of surface cracking and fracturing of the interior of the sheet material when in use, has the effects of corrosion prevention and aging resistance in long-term use at the same time, and has good application prospect.

Owner:江苏优氟防腐科技有限公司

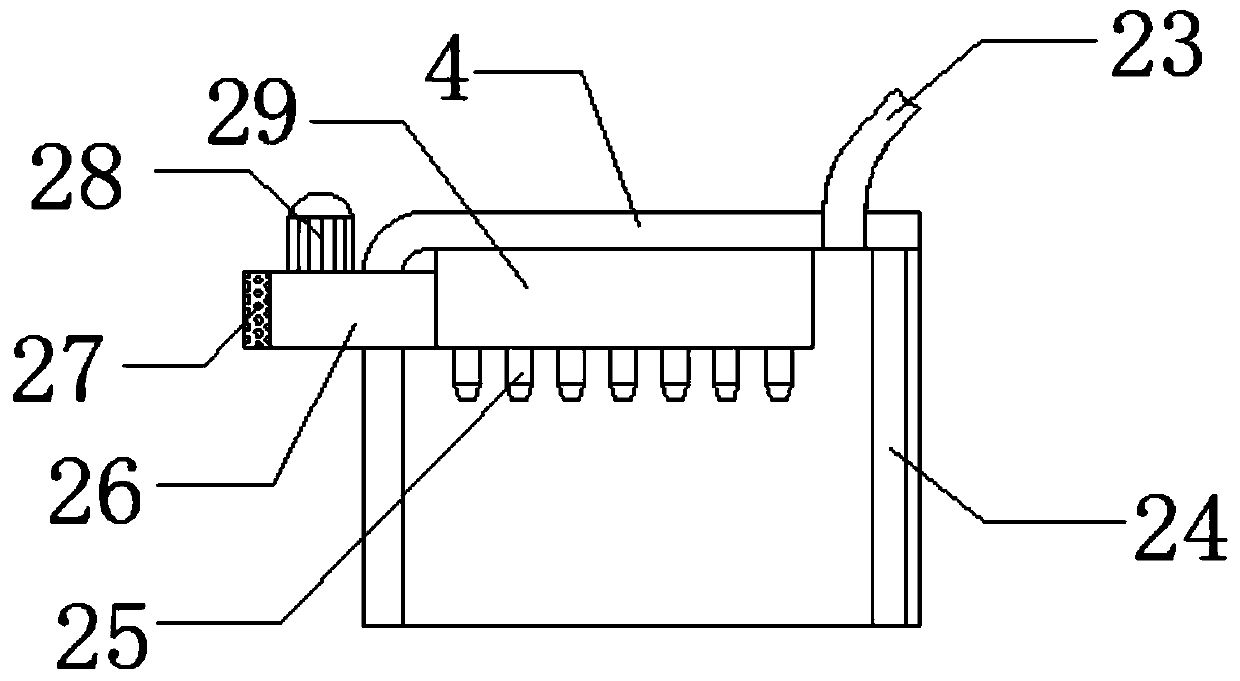

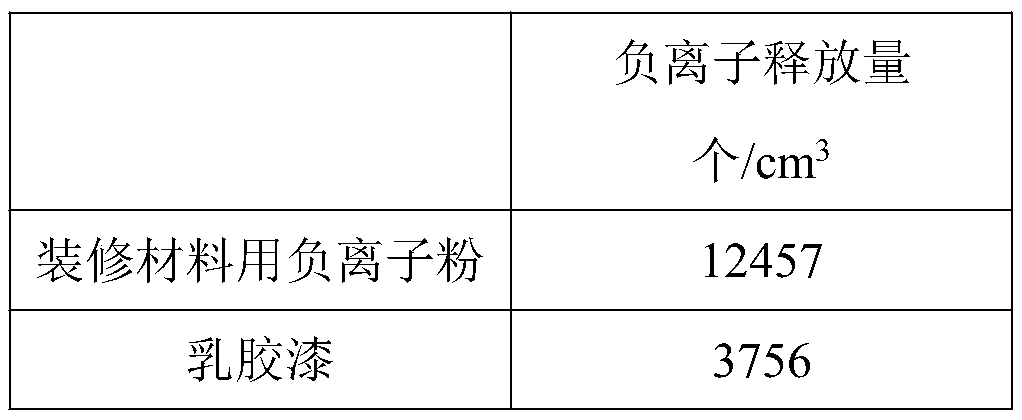

Negative ion powder for decoration material and preparation method and application thereof

InactiveCN111303678AGood dispersionImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesPhysical chemistryAnti bacteria

The invention discloses negative ion powder for a decoration material and a preparation method and application thereof, relates to negative ion powder and a preparation method and application thereof,and aims to solve the problems of limited negative ion generation capacity and no antibacterial property of negative ion powder in the existing application process. The negative ion powder for the decoration material is formed by mixing tourmaline powder, opal powder and neodymium oxide, wherein the tourmaline powder is coated with a porous chitosan film and nano-silver grows on the tourmaline powder. The method comprises the following steps: 1, coating tourmaline powder with chitosan; 2, growth of nano-silver; 3, mixing. The application is as follows: the negative ion powder for the decoration material is used for preparing the environment-friendly latex paint.

Owner:关圣睿

An environment-friendly household garbage crushing device

ActiveCN107469955BImprove crushing efficiencyAchieving complete environmental protectionDispersed particle filtrationDirt cleaningAir filterEngineering

Owner:临沂港控能源有限公司

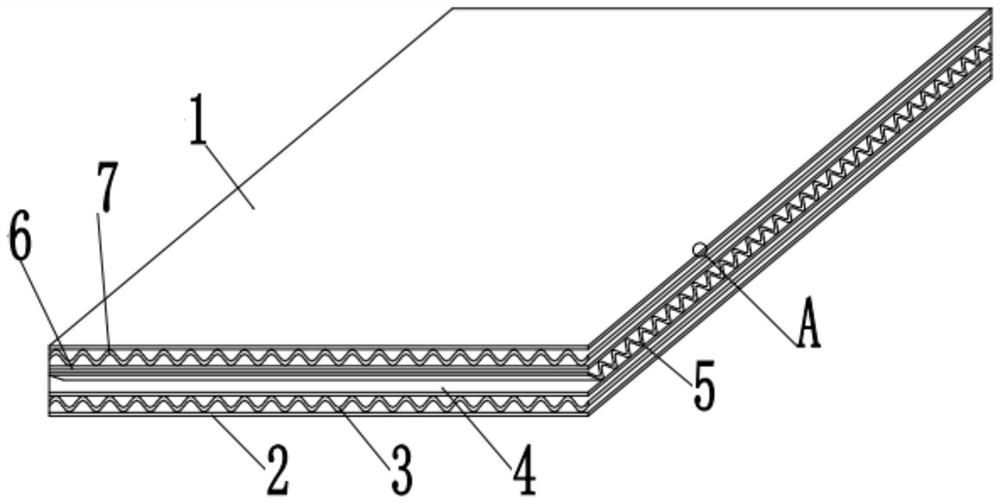

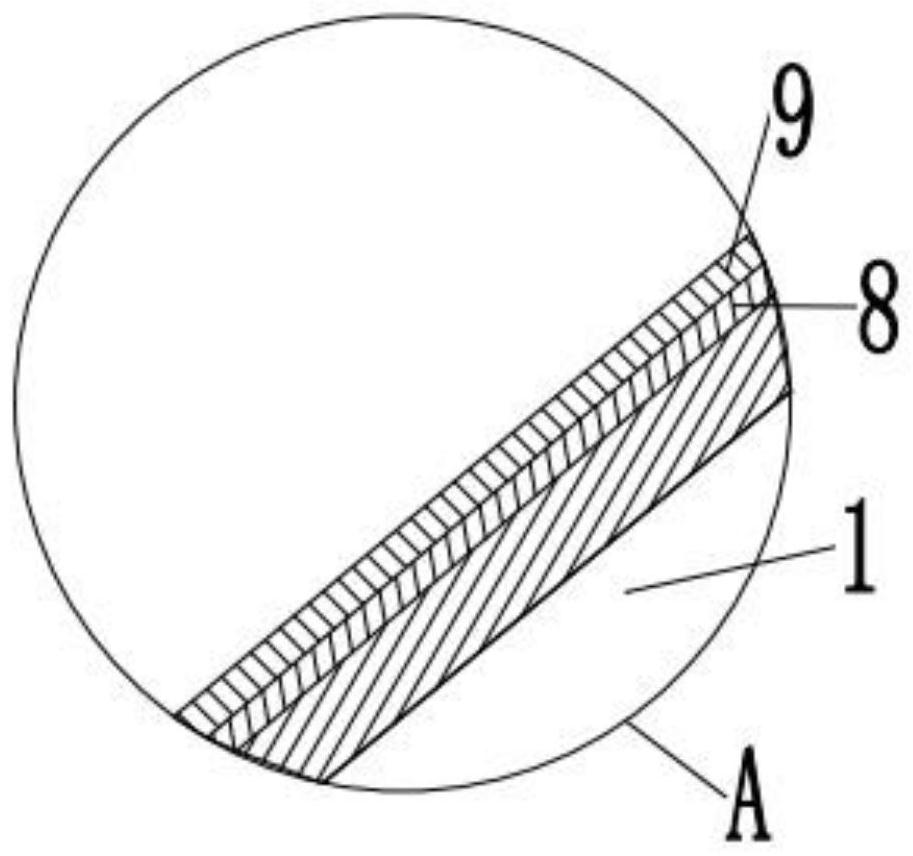

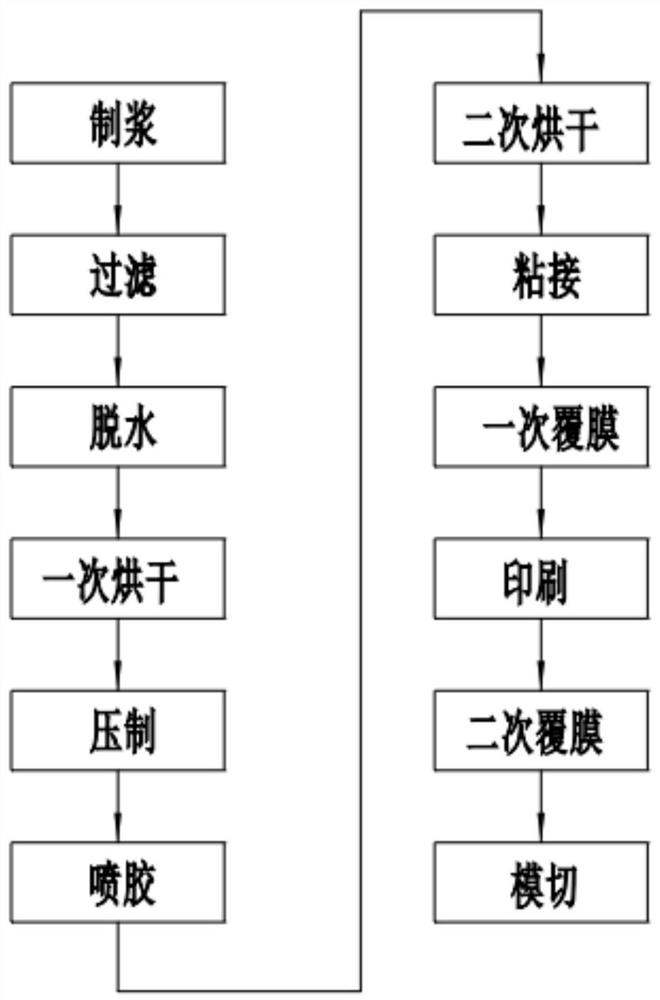

Environment-friendly high-strength printing packaging paper and production technology thereof

The invention relates to the technical field of packaging paper, in particular to environment-friendly high-strength printing packaging paper and a production technology thereof. The production technology comprises the following steps of S1, pulping, specifically, smashing recycled waste cartons through a smashing machine and then putting into a stirring machine, adding warm water into the stirring machine for stirring, and preparing paper pulp uniform in texture, S2, filtering, specifically, filtering the paper pulp in the S1 by using a 200-300-mesh filter screen to remove impurities with larger particles, and then filtering the paper pulp by using a 500-600-mesh filter screen to obtain paper pulp A with thicker fibers and paper pulp B with thinner fibers, and S3, dehydrating, specifically, dehydrating the paper pulp A and the paper pulp B in the S2 by adopting a dehydrator respectively, and distributing the dehydrated paper pulp by adopting a pulp distributor respectively. The lower corrugated layer, the upper corrugated layer and the middle corrugated layer are distributed in a staggered mode, so that the strength of the prepared packaging paper is higher, the gravity borne by the packaging paper during product packaging is larger, the high-strength effect of the packaging paper is achieved, and the service life of the packaging paper is prolonged.

Owner:滁州远达彩印包装有限公司

Epoxy fireproof terrace paint

InactiveCN105907145ARealize environmental protectionGood water resistanceFireproof paintsFungicideOrganosolv

The invention discloses epoxy fireproof terrace paint. The terrace paint is prepared from, by weight, 80-120 parts of waterborne epoxy resin, 21-25 parts of amino resin, 4-8 parts of divinyl dimethoxy silane, 12-16 parts of calcite, 3-7 parts of dinonyl naphthalene sulfonic acid, 4.5-6.5 parts of epoxy curing agent, 4-6 parts of 2,2,4-Trimethyl-1,3-pentanediolmono(2-methylpropanoate), 4-6 parts of salicylic acid, 20-30 parts of vinyl acetate-acrylic emulsion, 5-9 parts of oxidized polyethlene wax, 5-9 parts of epoxy dispersion agent, 5-9 parts of anion fungicide, 5-11 parts of vinyl triethoxysilane, 8-15 parts of acetylene black and 3-6 parts of alkyl phosphonate. The terrace paint does not contain solvents, is free of harm and toxin, is environmentally friendly, prevents harm of organic solvents to health of people, and is completely environmentally friendly during construction and application. The terrace paint has the advantages of being good in water resistance and fireproof performance, high in tinting strength and resistant to yellowing, brightness of the surface layer is higher, the color is brighter, and physical properties are better.

Owner:SUZHOU KEMIAO NEW MATERIAL

Environment-friendly paint brush

The invention discloses an environmentally friendly paint brush, which comprises a first working chamber, a screw rod and a second working chamber. A brush is arranged on one side of the first working chamber, and a material outlet is opened inside the brush. The inside of the first working chamber is provided with a screw rod, and the bottom of the screw rod is provided with a rotating disk, one side of the rotating disk is connected to the screw rod inside the second working chamber, and the other side of the rotating disk is connected to the motor through the conveyor belt. Transmission connection, one side of the first working bin and the second working bin are both connected to the storage bin through the delivery pipe. In the present invention, a storage bin is provided inside the paint brush body, and a push plate is arranged inside the storage bin, and a push rod is arranged on one side of the push plate, so that the storage bin can be used to store paint, and it can be directly pushed when it is to be used. Only the support rod is enough, so such setting can store the paint, and the paint will not be wasted during use, and the effect of environmental protection is realized.

Owner:CHENGDU XINXIN HIGH STRENGTH FASTENER MFRCO

Positioning worktable for clothes tailoring

The invention discloses a positioning worktable for clothes tailoring, and relates to the technical field of clothes tailoring. The positioning worktable for clothes tailoring comprises a working panel, wherein chipping suction holes which are arranged uniformly are formed in the front surface of the working panel; a chipping collecting box is fixedly mounted on the bottom of the working panel; adust collector is fixedly mounted on the left side of the chipping collecting box; and the right side of the working panel is fixedly connected with supports arranged symmetrically. By the positioningworktable for clothes tailoring, waste chippings remaining after clothes tailoring can be cleaned effectively, environmental pollution caused by splashing of the waste chippings is avoided, health ofworkers is protected favorably, clothes can be adsorbed and positioned, hollowing is prevented, the tailoring efficiency is improved, the collected waste chippings are cleaned periodically by workersconveniently, cleanliness of the worktable is ensured, illumination can be provided, the tailoring quality is improved favorably, tailoring errors are avoided, clothes can be positioned and limited,and upwarp of edges and corners is prevented.

Owner:湖州南童魔服饰有限公司

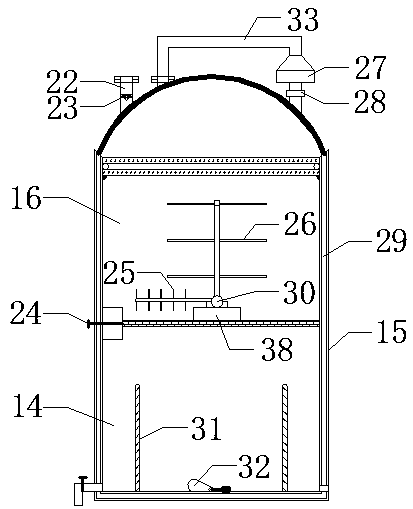

Separation and purification apparatus for processing 4-hydroxybiphenyl

PendingCN109651091AAchieving complete environmental protectionQuality improvementGas treatmentOrganic chemistryBiochemical engineeringCooling chamber

The invention discloses a separation and purification apparatus for processing 4-hydroxybiphenyl. The apparatus comprises a reaction device and a crystallization device, the reaction device comprisesan upper reaction chamber and a lower layering chamber, horizontal stirring shafts and vertical stirring shafts are mounted in the upper reaction chamber, vibrating rods are mounted in the lower layering chamber, a floater is arranged in lower layering chamber, the lower end of the reaction device is communicated with a purifying tank, a water pump is mounted on the upper surface of one end of thepurifying tank, the crystallization device is fixedly connected to the right side of the reaction device, the crystallization device includes a cooling chamber and a cooling drum, the lower end of the right side of the crystallization device is communicated with a discharging pipeline, and the surface of one side of the discharging pipeline is provided with a PLC. The separation and purificationapparatus for processing 4-hydroxybiphenyl realizes separation and purification of 4-hydroxybiphenyl through the reaction device and the crystallization device, and has high use values.

Owner:SINOCHEM HEBEI FUHENG CO LTD

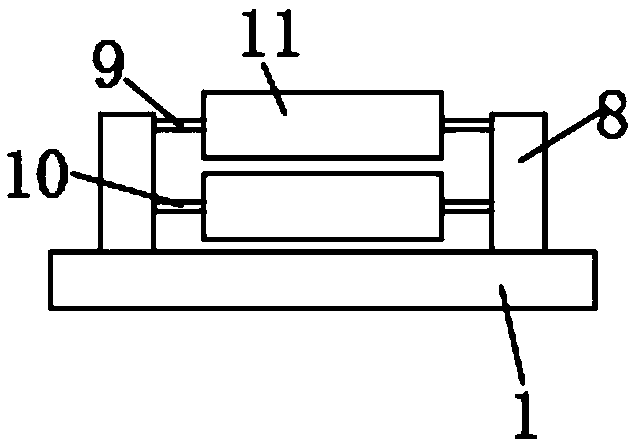

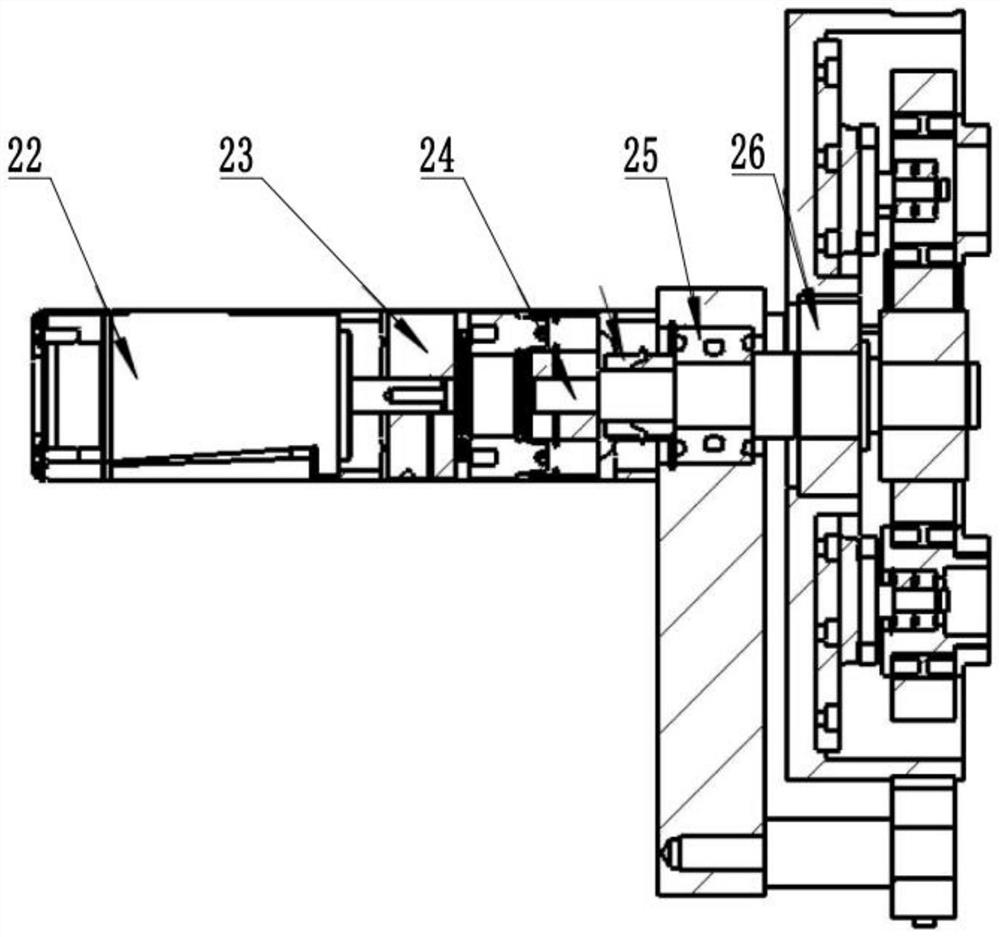

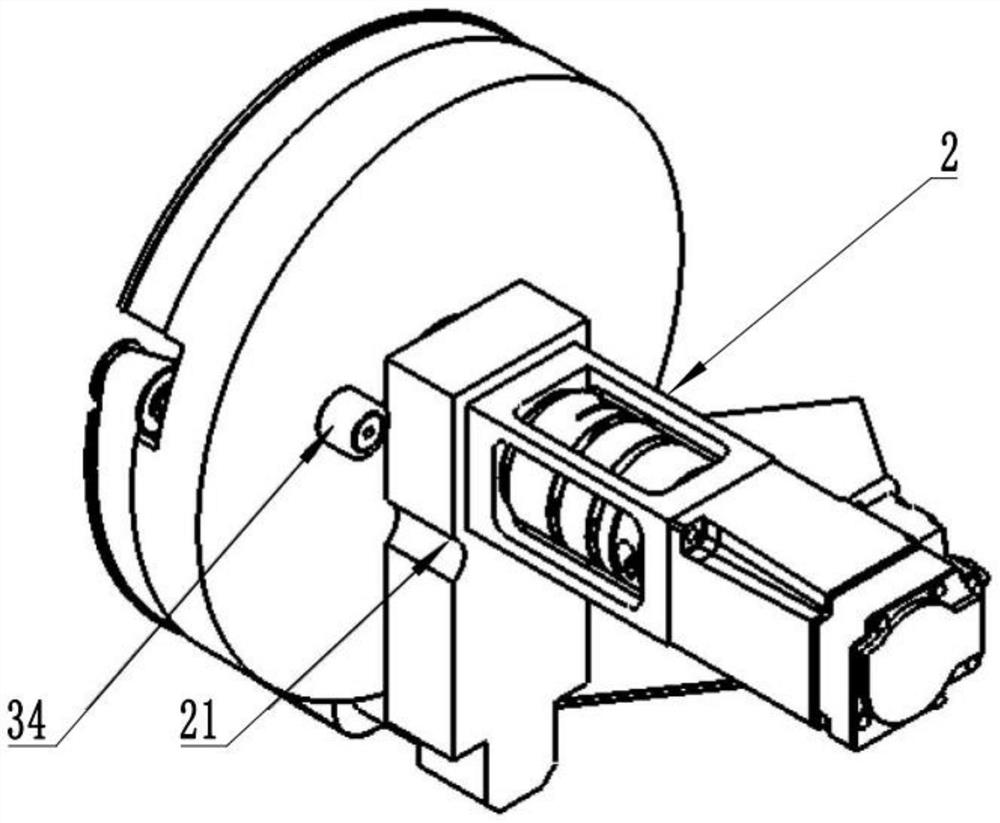

Film tearing mechanism, film tearing equipment and film tearing method

PendingCN112849615AStrong stickinessGuarantee the efficiency of the filmArticle unpackingThin membraneEngineering

The invention discloses a film tearing mechanism, film tearing equipment and a film tearing method, and relates to the technical field of battery production. When film tearing is carried out on a plate, a rotating device is firstly made to drive a film tearing disc to rotate by a preset first angle in the first rotating direction, the first rotating direction refers to the direction opposite to the extending direction of an adhesive tape, the first angle comprises two stages, the first stage is a film lifting angle, and the second stage is a film tearing angle; when the rotating device rotates by the film lifting angle, an adhesive tape tensioned on a first extrusion roller is a new adhesive tape, the viscosity is high, and the film lifting efficiency can be guaranteed; and then, the rotating device drives the film tearing disc to continuously rotate the film tearing angle in the first rotating direction, and due to the fact that the first rotating direction is equal to the extending direction of the adhesive tape, the old adhesive tape is pulled to the first extrusion roller, that is, the old adhesive tape is used for separating the remaining film from the plate, the film tearing process is completed, the old adhesive tape is fully utilized, the environment-friendly effect is achieved, and the production cost is reduced.

Owner:东莞工至科技有限公司

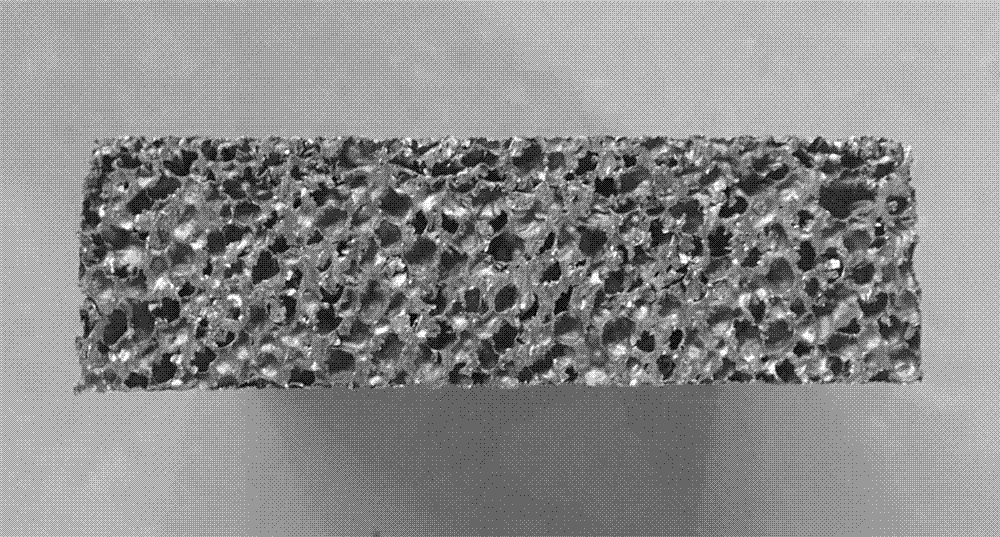

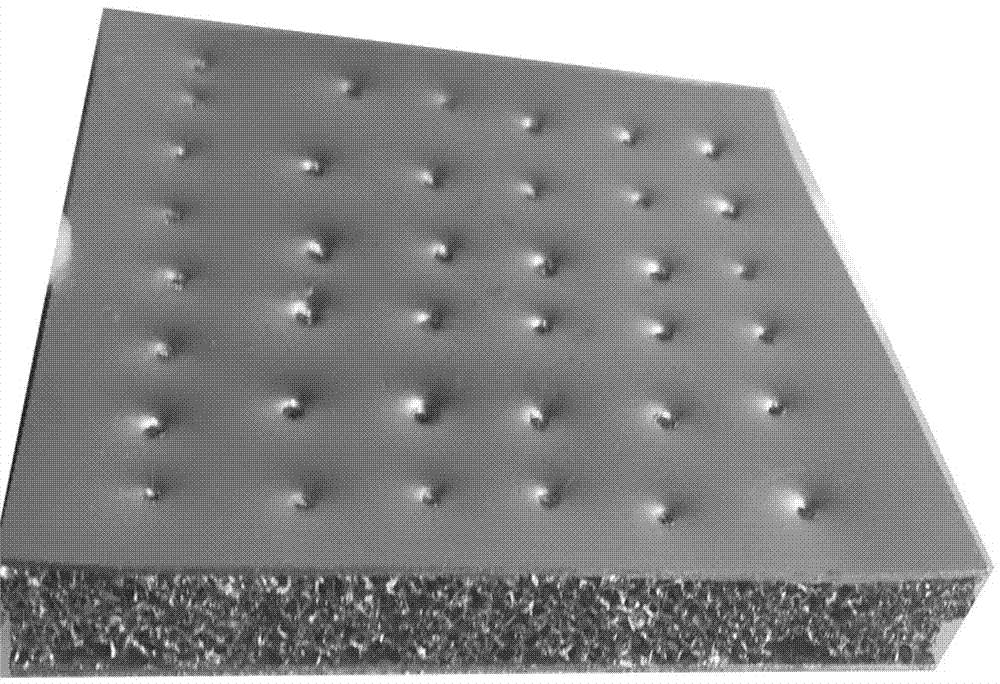

Light and high-strength metal bridge plate and manufacturing method thereof

The invention discloses a light and high-strength metal bridge plate and a manufacturing method thereof. The metal bridge plate comprises the following components in parts by mass: 50 to 70 parts of an aluminium material, 10 to 20 parts of an iron material, 3 to 8 parts of a magnesium material, 3 to 8 parts of a nickel material, 0.1 to 0.3 part of a graphene material, 3 to 8 parts of feldspar powder, 1 to 2 parts of fumed silica and 0.2 to 0.4 part of aerogel. The modified composite metal bridge plate manufactured through the aluminium material, the iron material, the magnesium material, the nickel material, the graphene material, feldspar powder, fumed silica and aerogel is light in mass, high in strength and good in toughness, and has good pressure resistant, stretching resistant, antiseismic and anticollision functions; and the metal bridge plate is a porous plate, moisture can directly penetrate through the plate, the metal bridge plate has good rustproof and water-permeable functions, a lot of steel can be saved, service life is long, and economic benefits are greatly increased.

Owner:IDEAL NEW MATERIAL TECH HONGKONG LTD

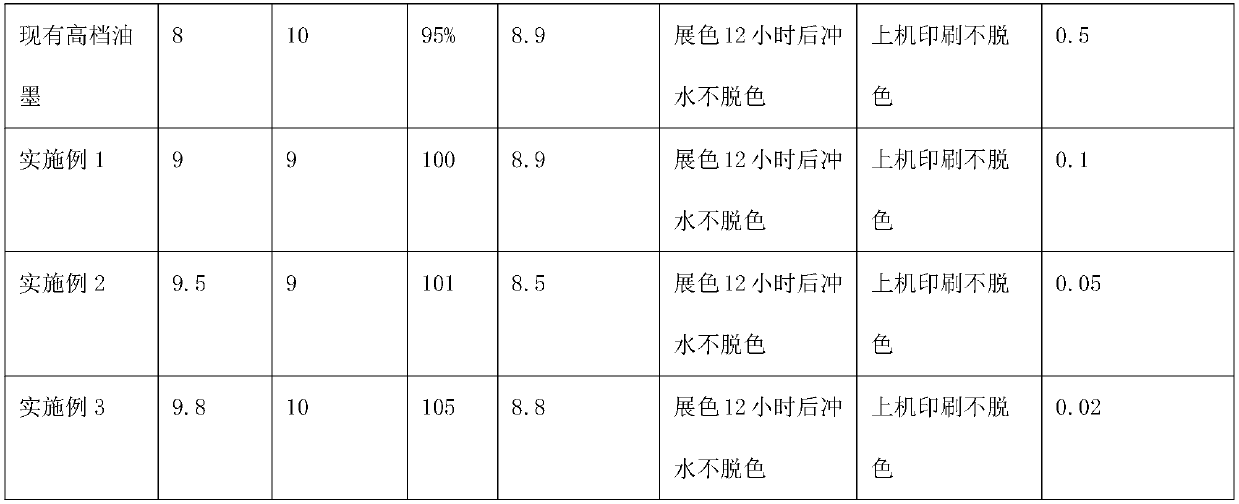

Green ink printing substrate special for medical packing bag

InactiveCN107556813AAchieving complete environmental protectionRealization of processing environmental protection performanceInksChemistryEnvironmental resistance

The invention provides a green ink printing substrate special for a medical packing bag and relates to the technical field of the medical packing bag processing. The green ink printing substrate is prepared from the following raw materials: 3-5 parts of titanium dioxide, 5-7 parts of allyl alcohol, 6-8 parts of ethyl acetate, 2-4 parts of polyurethane resin, 1-3 parts of carbon powder, 5-7 parts of curing agent, 3-5 parts of acetic ether, 6-8 parts of antistatic agent, 6-8 parts of pigment powder, 6-8 parts of lavender flowers, 5-7 parts of orange flowers, 5-7 parts of soybean oil, 3-5 parts of castor oil, 5-7 parts of epoxy resin, 2-4 parts of sodium methyl naphthalene sulfonate and 60-80 parts of deionized water. The invention has the beneficial effects that the operation is simple and feasible, the processing is convenient, the ink formula is scientific and reasonable, the processed medical packing bag is environment-friendly, healthy, nontoxic and harmless, the green and environment-friendly efficient performance is realized and the medical packing bag is clean and pollution-free and is high in quality.

Owner:安徽省嘉瑞医药科技股份有限公司

Environment-friendly building active glue

InactiveCN103571398AImprove the bactericidal effectAvoid cancer riskNon-macromolecular adhesive additivesUnsaturated alcohol polymer adhesivesPolyvinyl alcoholHazardous substance

The invention discloses environment-friendly building active glue which is prepared from polyvinyl alcohol powder and ozone water. The environment-friendly building active glue has the beneficial effects that the environment-friendly building active glue is safe and environment-friendly, free of substances, such as formaldehyde and acrylamide harmful to a human body, strong in bactericidal ability and fewer in bacteria; a carcinogenic risk caused by manpower can be avoided; human health of a worker can be protected; the building glue is fabricated in a manner of mixing the polyvinyl alcohol powder and the ozone water instead of the traditional heat boiling mode. The production technology is simplified; the target of producing the environment-friendly building active glue can be achieved by using simple equipment; the production is not limited by the conditions of time and place; the production efficiency is high; the used environment-friendly building glue is free of volatilizable harmful substances, has a good using effect, and plays a protection role in people living in the building; the environment-friendly effect can be completely achieved; popularization is facilitated.

Owner:麻卢红

Energy-saving dual-purpose furnace end using alcohol-based fuel

InactiveCN103471102AImprove combustion efficiencyFully heatedIndirect carbon-dioxide mitigationGaseous fuel burnerAlcoholInlet channel

The invention provides an energy-saving dual-purpose furnace end using alcohol-based fuel. The energy-saving dual-purpose furnace end comprises a furnace end and a furnace bottom, wherein the furnace end is provided with an inner surface and an outer surface; the inner surface annularly forms a combustion chamber; a closed preheating chamber for preheating the fuel is arranged on the outer surface; an air inlet channel for allowing the fuel to enter the preheating chamber is arranged in the preheating chamber; a plurality of conveying channels for feeding gas into the bottom of the combustion chamber are also arranged in the preheating chamber; after the fuel is combusted in the combustion chamber, heat energy generated by the combustion of the chamber wall of the combustion chamber and the surface of the furnace end is transferred to the inside of the preheating chamber for heating the fuel in the preheating chamber; the fuel heated in the heating chamber is conveyed to the combustion chamber for combustion. Due to the adoption of the unique structural design, the fuel being about to enter the furnace end for combustion is preheated by the heat generated by combustion; the effects of sufficient combustion and higher combustion efficiency of the fuel are realized by preheating the fuel.

Owner:刁辉

Vacuum infusion double-layer fiberglass reinforced plastic with hollow monitoring structure and production process for vacuum infusion double-layer fiberglass reinforced plastic

The invention relates to vacuum infusion double-layer fiberglass reinforced plastic with a hollow monitoring structure and a production process for the vacuum infusion double-layer fiberglass reinforced plastic. The vacuum infusion double-layer fiberglass reinforced plastic comprises a sealed cavity formed by upper and lower fiberglass reinforced plastic layers, wherein the hollow monitoring structure is formed in the sealed cavity formed between the upper and lower fiberglass reinforced plastic layers and is an interconnected mesh layer. The vacuum infusion double-layer fiberglass reinforced plastic with the hollow monitoring structure simultaneously has the advantages of high strength, good uniformity, smoothness and density and does not have the defects of bubbles, pin holes and the like. Meanwhile, according to the vacuum infusion double-layer fiberglass reinforced plastic, the environmental protection action and vacuum system curing are realized, and the quantity of volatile matters flowing out in the chemical reaction process is reduced; and as a soluble or fusible middle layer is adopted, and meshes are formed in the middle layer, after being dissolved or fused, the middle layer is formed into a stereo reticular structure, a penetration middle layer is also formed, and meanwhile, the reticular stereo structure has good enhancement action.

Owner:XIAMEN HANSHENG YACHT BUILDING

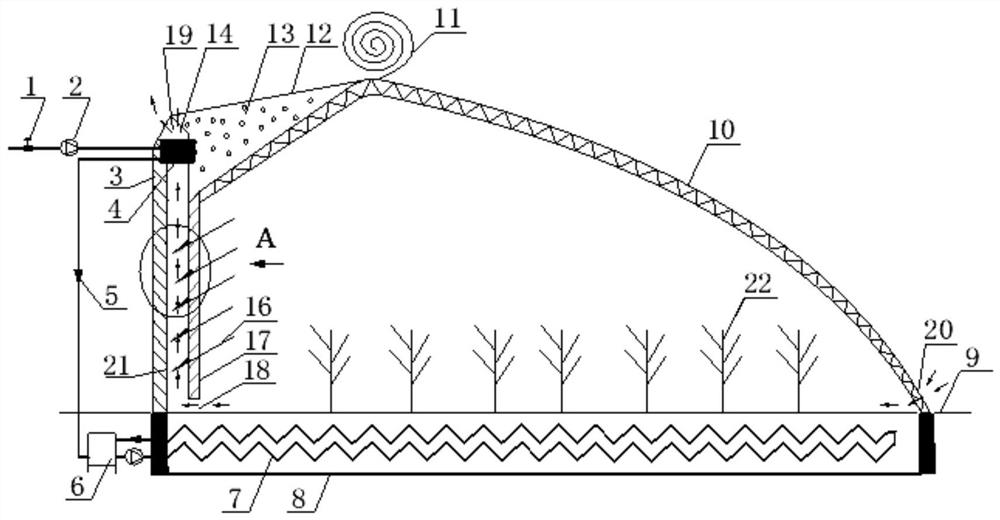

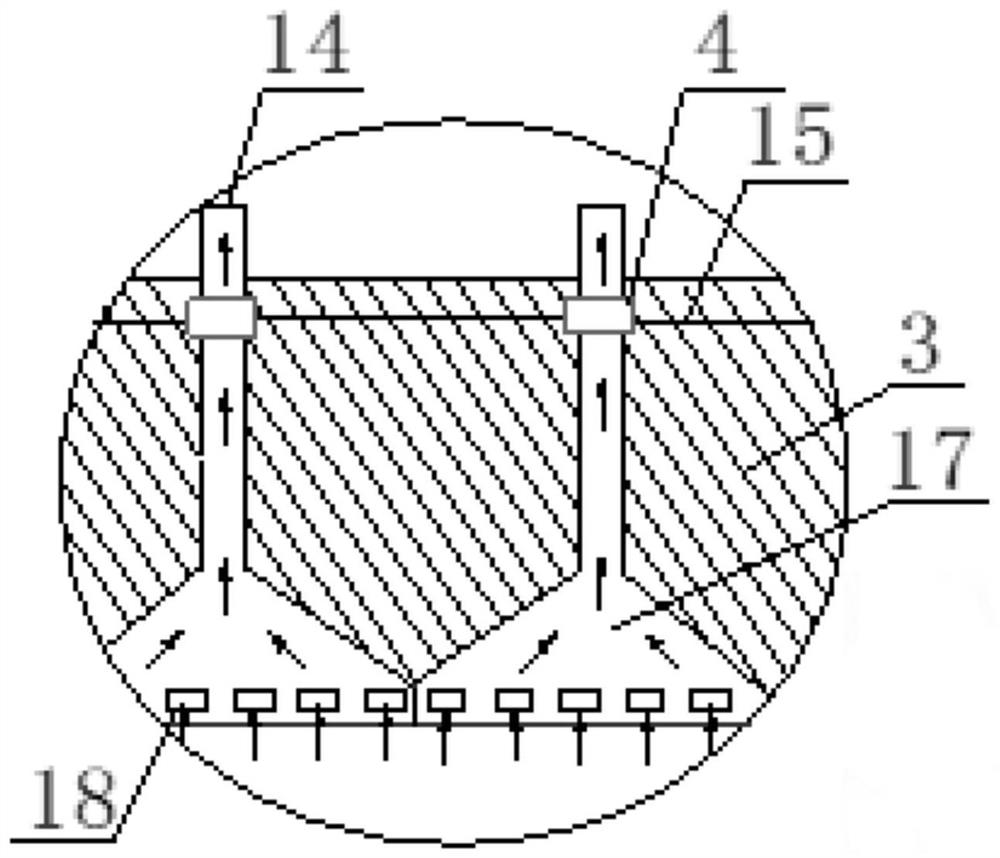

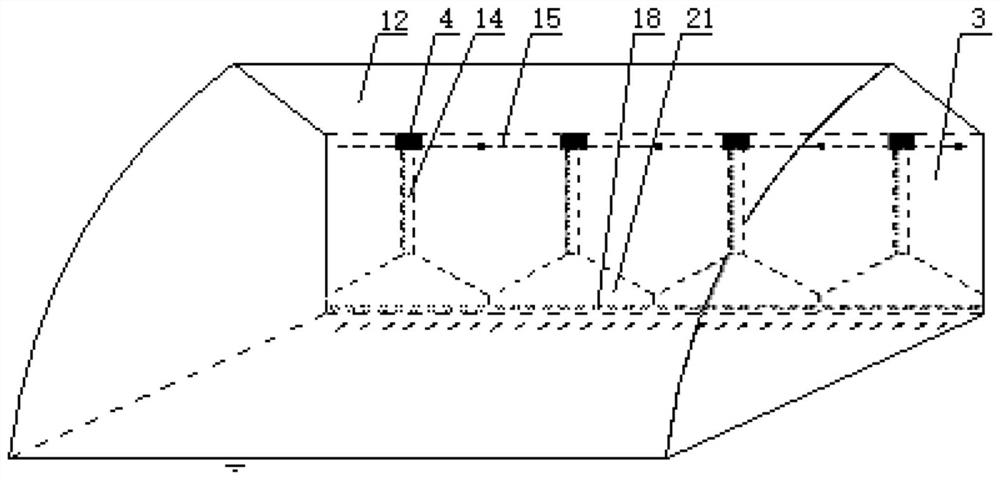

A solar greenhouse ventilation heat recovery system and a solar greenhouse equipped with the system

ActiveCN108834685BImprove heat exchange and heat storage efficiencyIncrease heat releaseClimate change adaptationGreenhouse cultivationEngineeringAtmospheric sciences

The invention relates to the technical field of agricultural sunlight greenhouse systems, in particular to a sunlight greenhouse ventilation and heat recycling system and a sunlight greenhouse with the same. According to the sunlight greenhouse ventilation and heat recycling system and the sunlight greenhouse disclosed by the invention, one or more groups of Trumbo chimneys are mounted in the greenhouse; the chimneys are fixed to the sunny side of a heat collecting wall; an air current channel is arranged in each group of the Trumbo chimneys, and is used for heating air in the corresponding air current channel through sunlight to drive the air in the air current channel to be heated and flow; a heat exchanger is mounted in a drainage cavity in the air current channels, and is used for absorbing heat quantity of the heated air; and a heat storing and heat emission assembly is connected with the heat exchanger, and is used for storing heat quantity and emitting the heat quantity to the greenhouse. According to the sunlight greenhouse ventilation and heat recycling system disclosed by the invention, a natural ventilation manner is adopted, and the thermal air in the greenhouse is introduced into each Trumbo chimney with a hollow structure; excessive heat energy of the air is stored in a heat storage water tank in a fluid medium manner through heat exchanging, so that the temperature of the greenhouse is adjusted through buried pipes.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

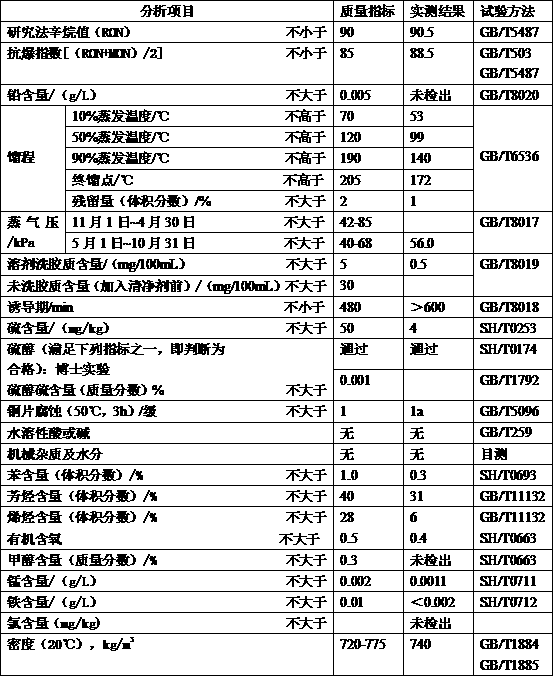

Production method of composite refined ethanol gasoline and blending ingredient oil used for high purity gasoline

InactiveCN107586573AImprove combustion effectReduce production processLiquid carbonaceous fuelsNaphthaGasoline

The invention relates to a production method of a composite refined gasoline blending ingredient oil, and is mainly used for solving problems in the prior art that production technology of gasoline blending ingredient oil is complex, octane value is relatively low, and anti-seismic properties are poor. The composite refined gasoline blending ingredient oil is prepared from, by weight, 10% of trimethylbenzene, 10% of xylene, 10% of toluene, 22% of isopentane, 24% of naphtha, and 24% of an alkylated compound. The production method comprises following steps: the ingredients are delivered into a stirring kettle at the above weight ratio, pipelines and a circulating pump are used for circulation sealed stirring, and a finished product is obtained via uniform mixing of the ingredients. The advantages are that: the production method is high, the octane value is relatively low, and the anti-seismic properties are excellent.

Owner:张宝月

A kind of preparation method of water-based floor paint and construction technology of water-based floor

A method for preparing a water-based floor paint and a construction process thereof, belonging to the field of floor materials, the preparation method comprising the following steps: mixing 10-30 parts of deionized water, 15-40 parts of titanium dioxide, 0.4-0.8 parts of a dispersant, 0.2-0.5 parts of defoamer, high-speed dispersion for 30-50 minutes; add 30-60 parts of water-based acrylic resin, 1-3 parts of color paste, 0.3-0.6 parts of defoamer, 0.5-1 part of leveling agent, 0.5-1 1 part wetting agent, 2‑5 parts thickener, disperse at medium speed for 10‑30 minutes; stop dispersing to get this material. Compared with the prior art, the present invention mixes the hydroxyacrylic acid emulsion and the hydroxyacrylic acid dispersion in any proportion, which can obtain better brightness, abrasion resistance, flexibility and color retention rate, and provide longer-lasting color retention rate and Weather resistance; water-based floor is non-toxic and harmless, green and environmentally friendly, avoiding the harm of organic solvents to human health, and can achieve complete environmental protection in construction and application.

Owner:山东世纪联合新材料科技有限公司

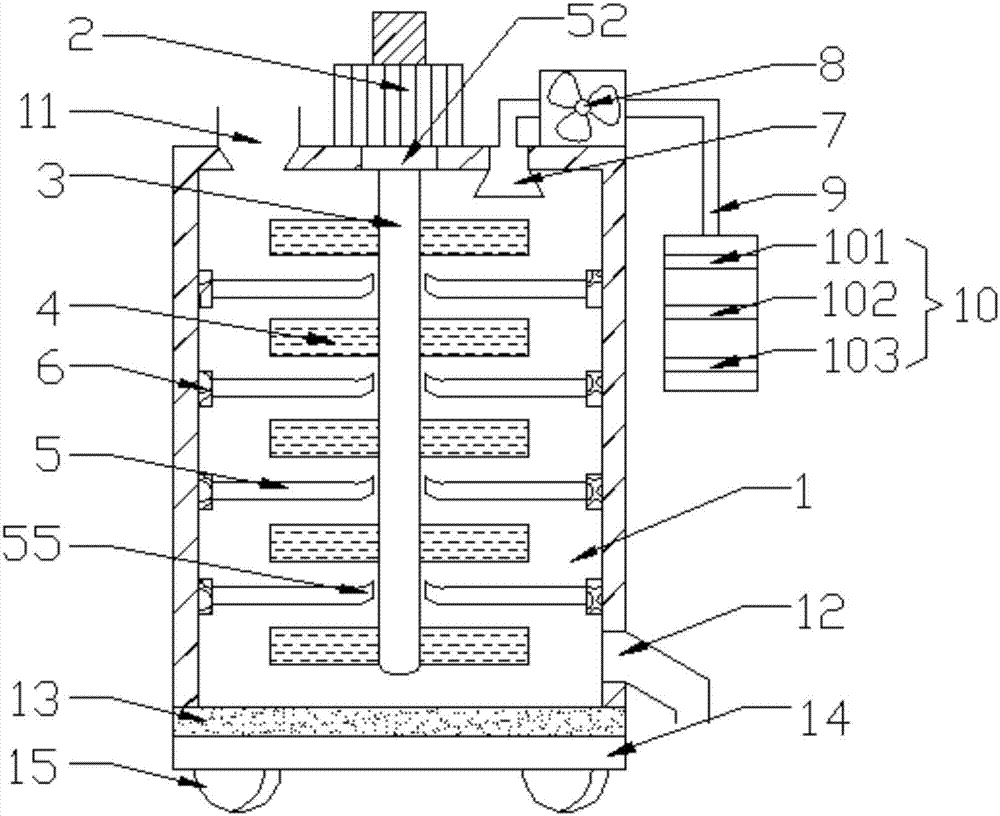

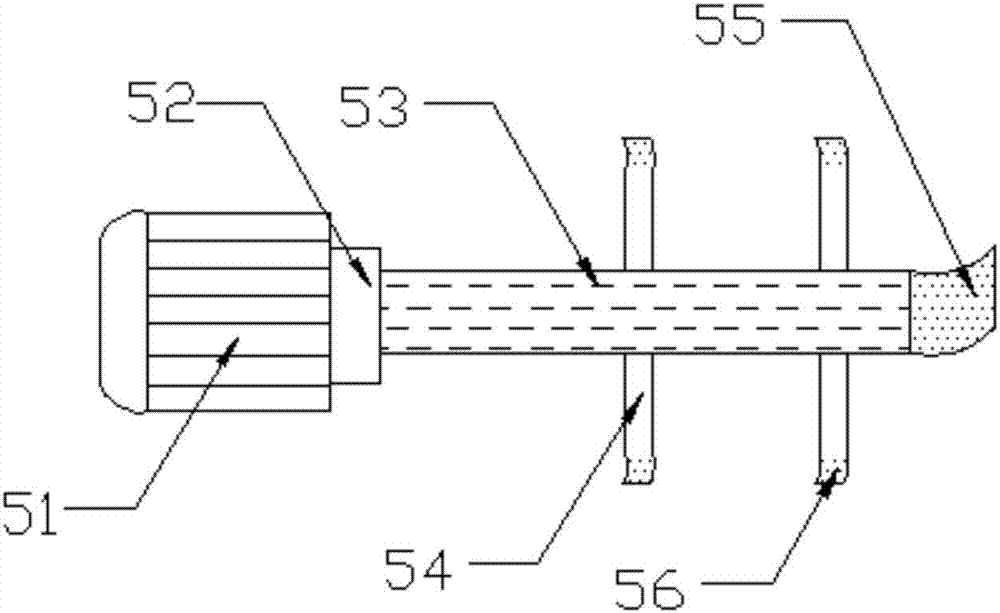

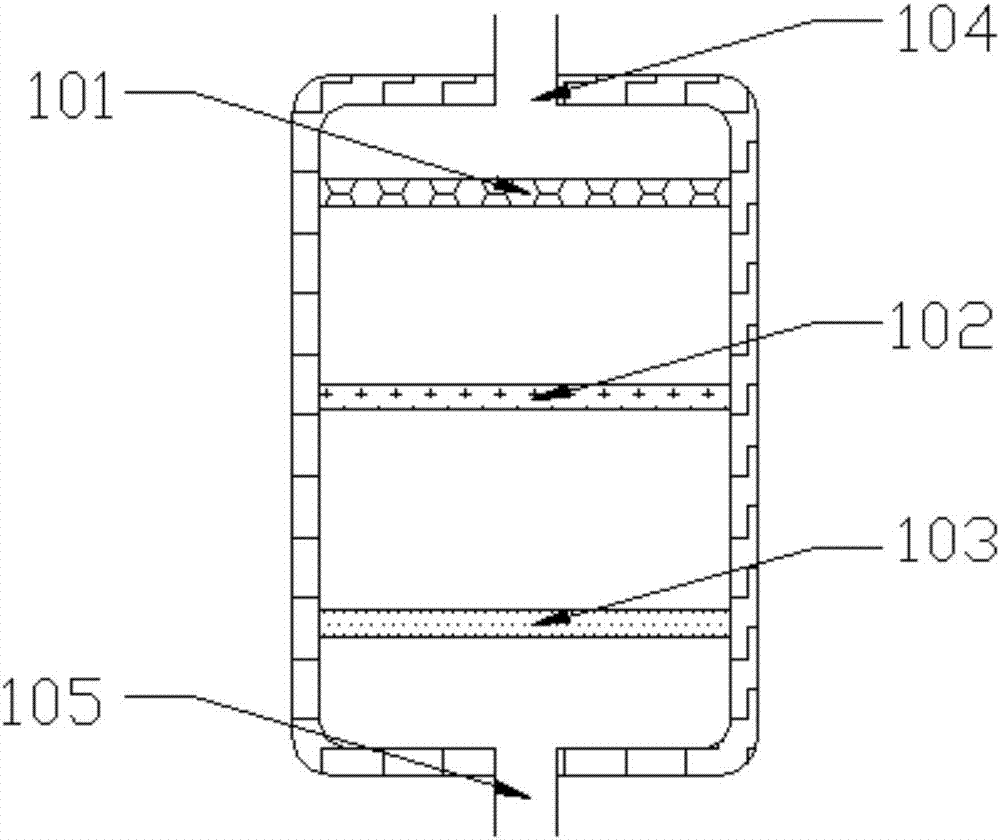

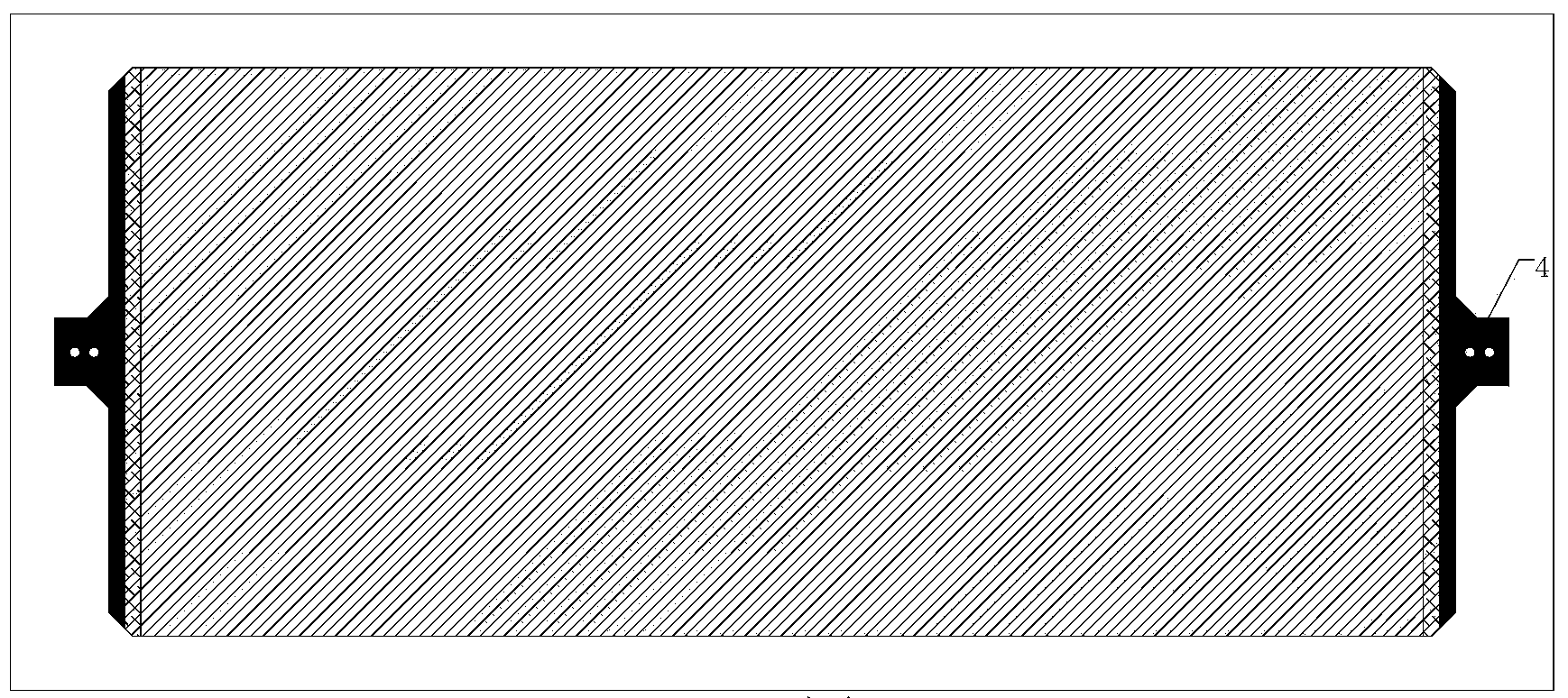

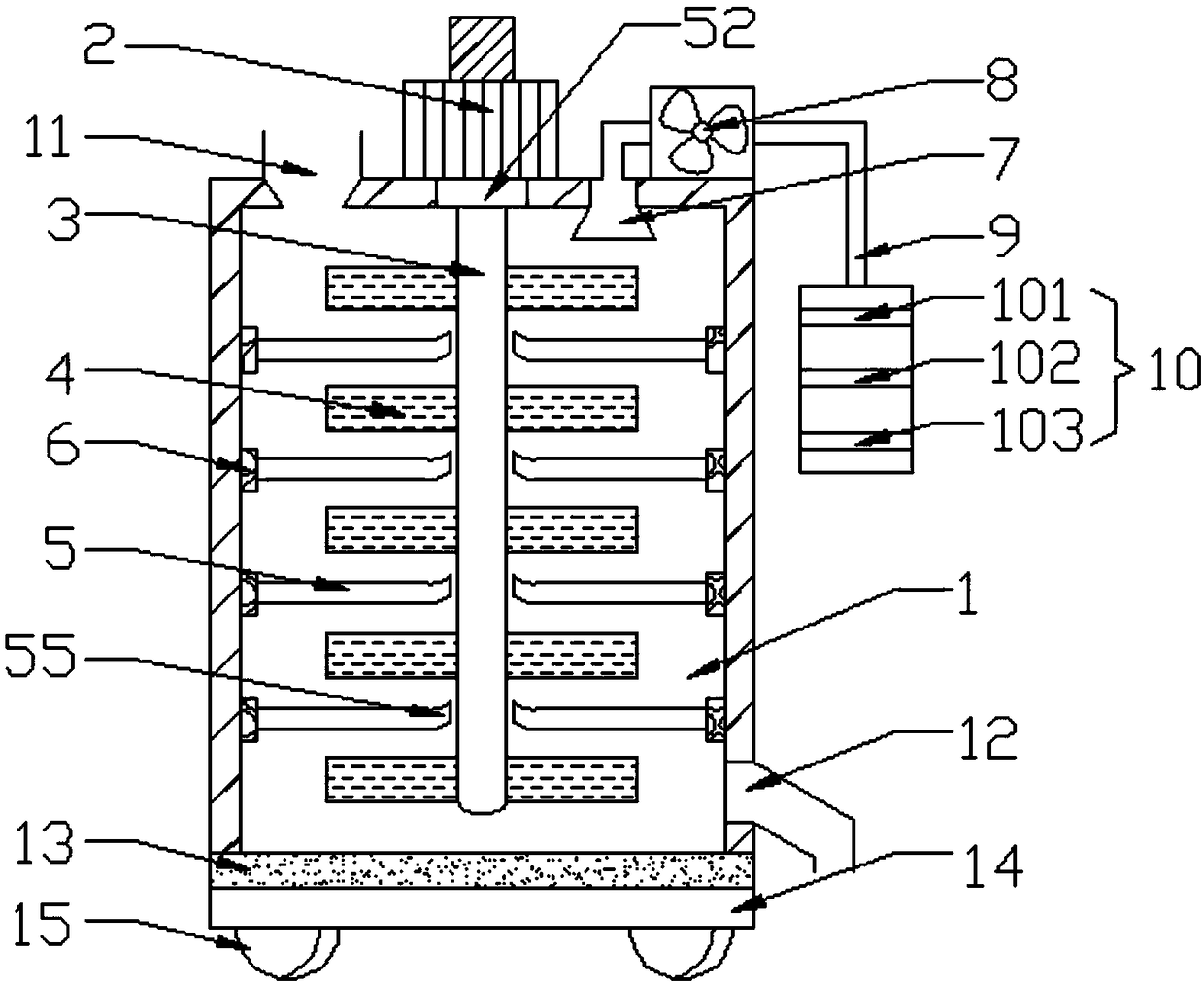

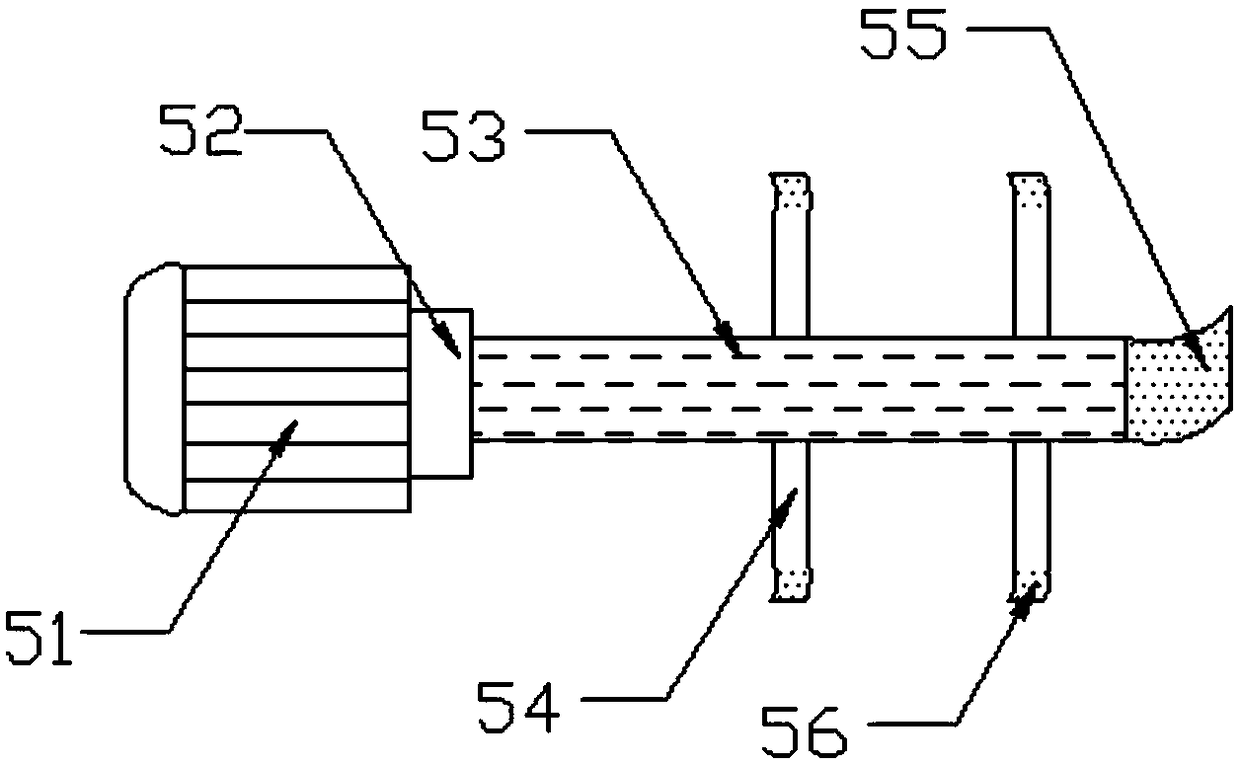

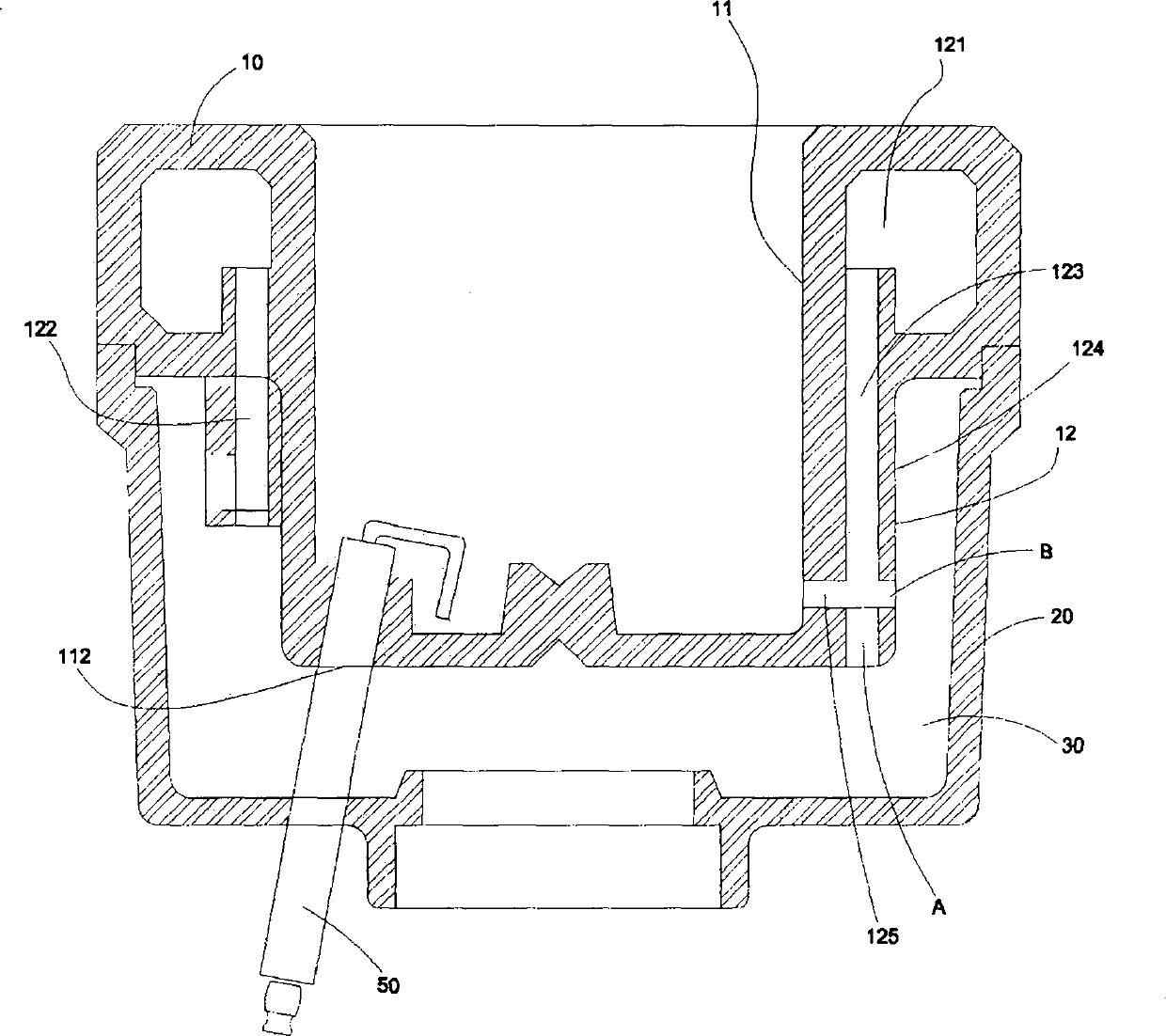

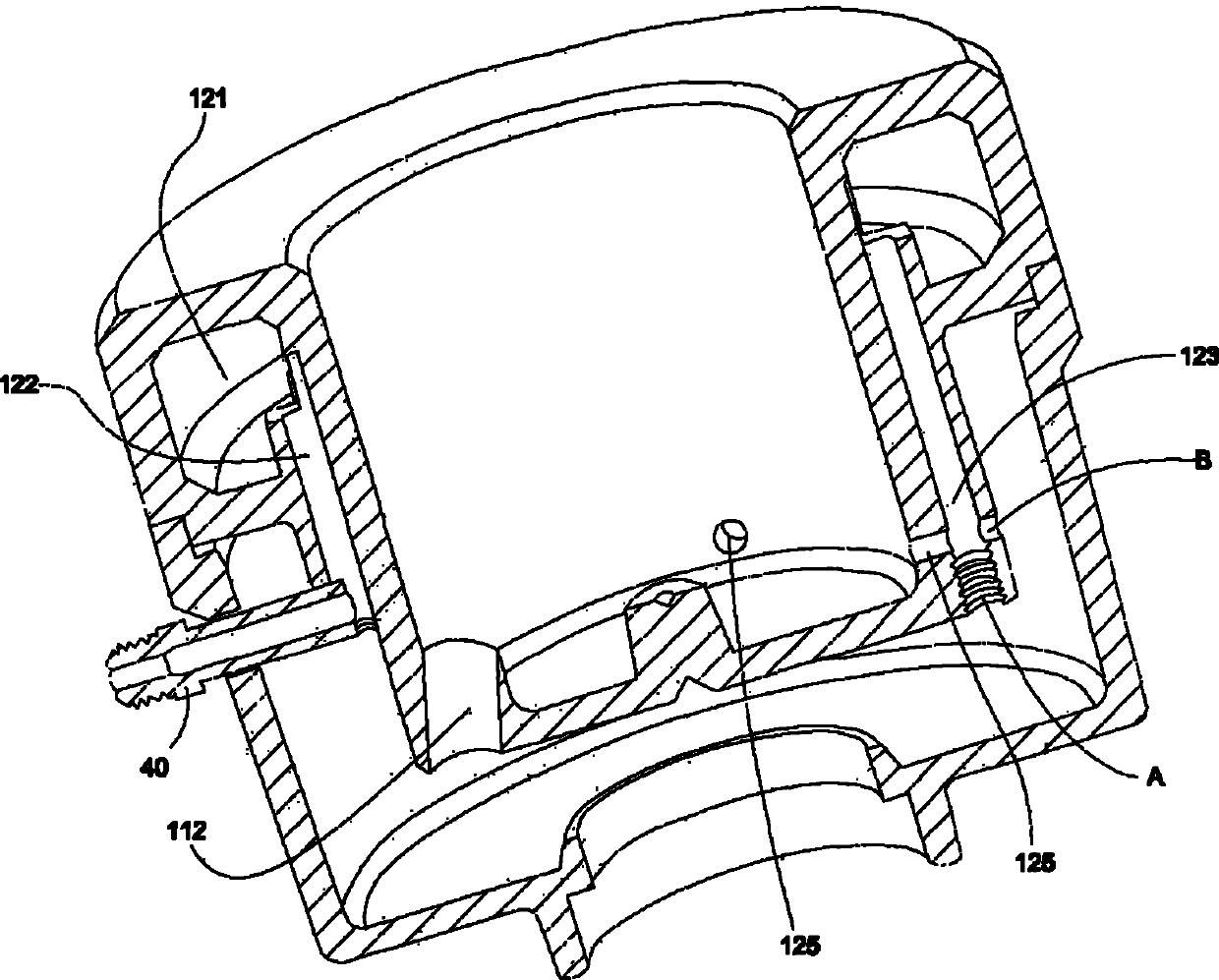

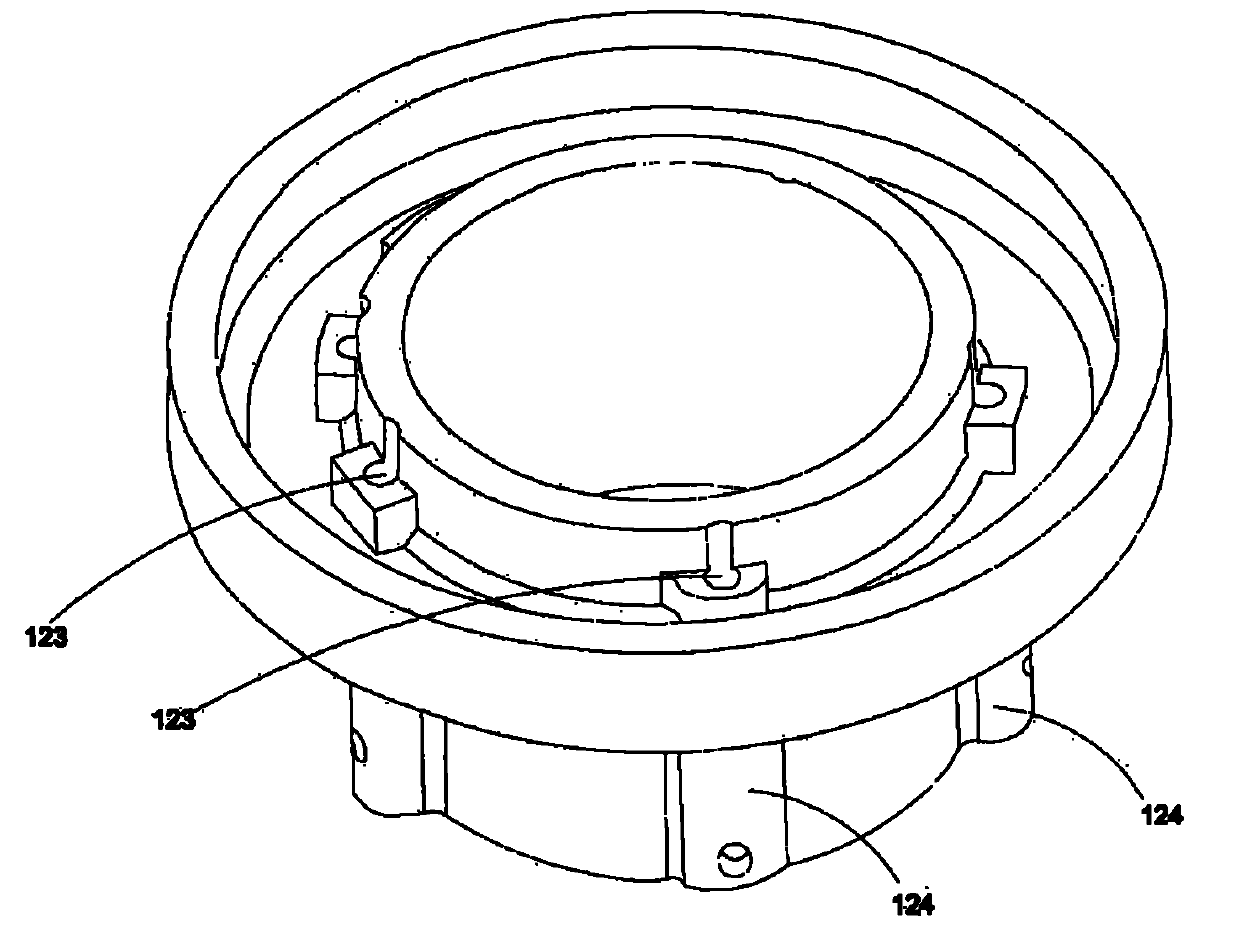

A household environmental protection machine

ActiveCN105903047BSimple structureEasy to useMechanical apparatusLighting and heating apparatusEngineeringSewage

Owner:丽水市正明机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com