Production method of composite refined ethanol gasoline and blending ingredient oil used for high purity gasoline

A technology for ethanol gasoline and a production method, which is applied in the petrochemical field, can solve the problems of poor seismic performance, low octane number, complicated production process, etc., and achieves the effects of improving combustion performance, improving gasoline octane number, and strengthening benzene rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

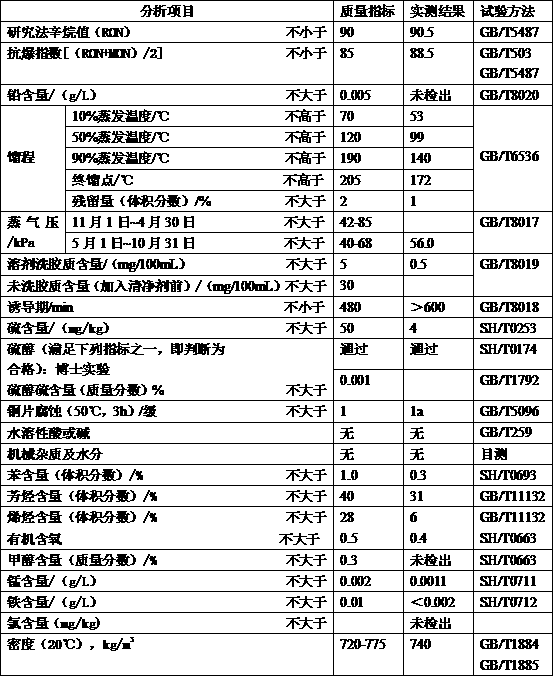

Image

Examples

Embodiment Construction

[0015] Blending component oil for compound refined ethanol gasoline and high-clean gasoline is made of the following components: trimethylbenzene, xylene, toluene, isopentane, naphtha, and alkylation;

[0016] Wherein the percentage of each component accounting for the total weight is: trimethylbenzene accounts for 10%, xylene accounts for 10%, toluene accounts for 10%, isopentane accounts for 22%, naphtha accounts for 24%, and alkylation accounts for 24%; Each component is added into the stirring tank according to the weight ratio, and the pipeline and the circulation pump are used to carry out circulation and airtight stirring, and the components can be mixed evenly.

[0017] Ethanol gasoline can be obtained by adding ethanol to the blending component oil for compound refined ethanol gasoline and high clean gasoline; wherein the weight ratio of compound refined ethanol gasoline and blend component oil for high clean gasoline to ethanol is 9:1.

[0018] Add methyl tert-butyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com