Film tearing mechanism, film tearing equipment and film tearing method

A technology of equipment and film disc, applied in the field of film tearing mechanism, can solve the problem of large consumption of tape, and achieve the effect of strong stickiness and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The tearing film structure provided in this embodiment is mainly used in the scene of tearing the battery film, and can perform the film tearing process on sheets with films such as batteries and screens. The tearing film structure in this embodiment has the advantage of high tape utilization. features.

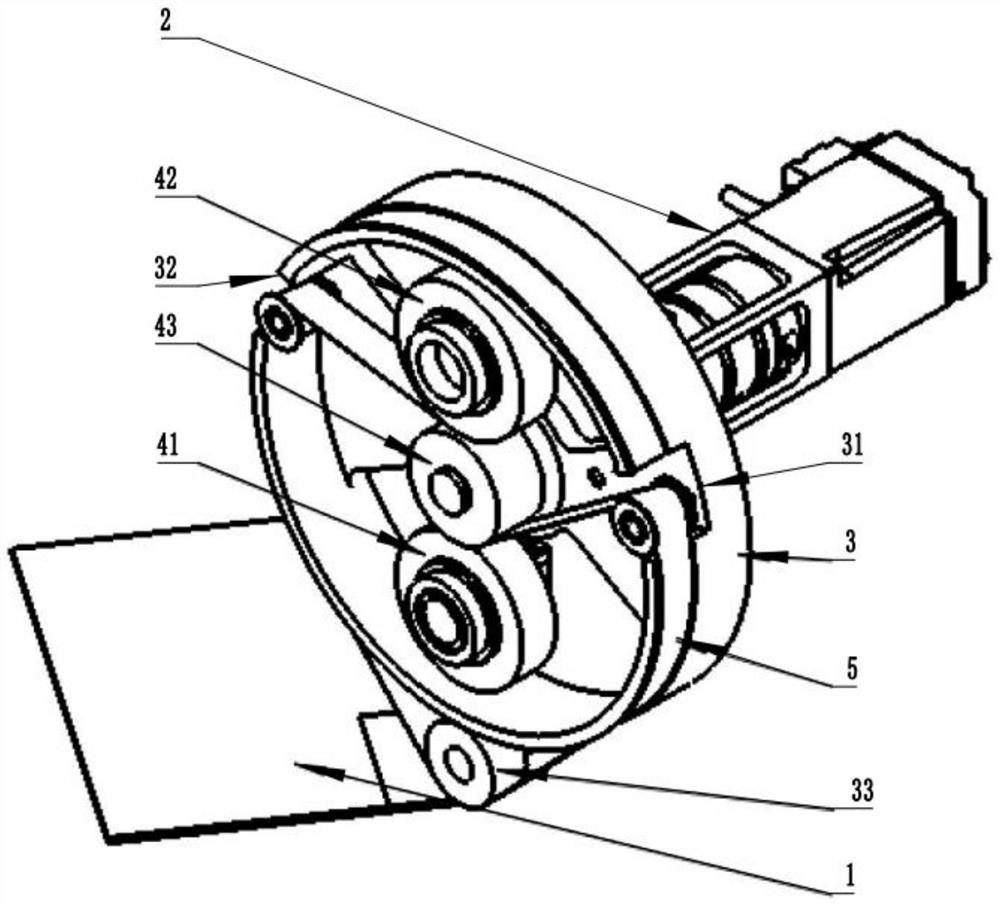

[0050] Such as figure 1 , Figure 4 to Figure 6 As shown, the film tearing mechanism of this embodiment includes a film tearing station 1 for placing sheet materials.

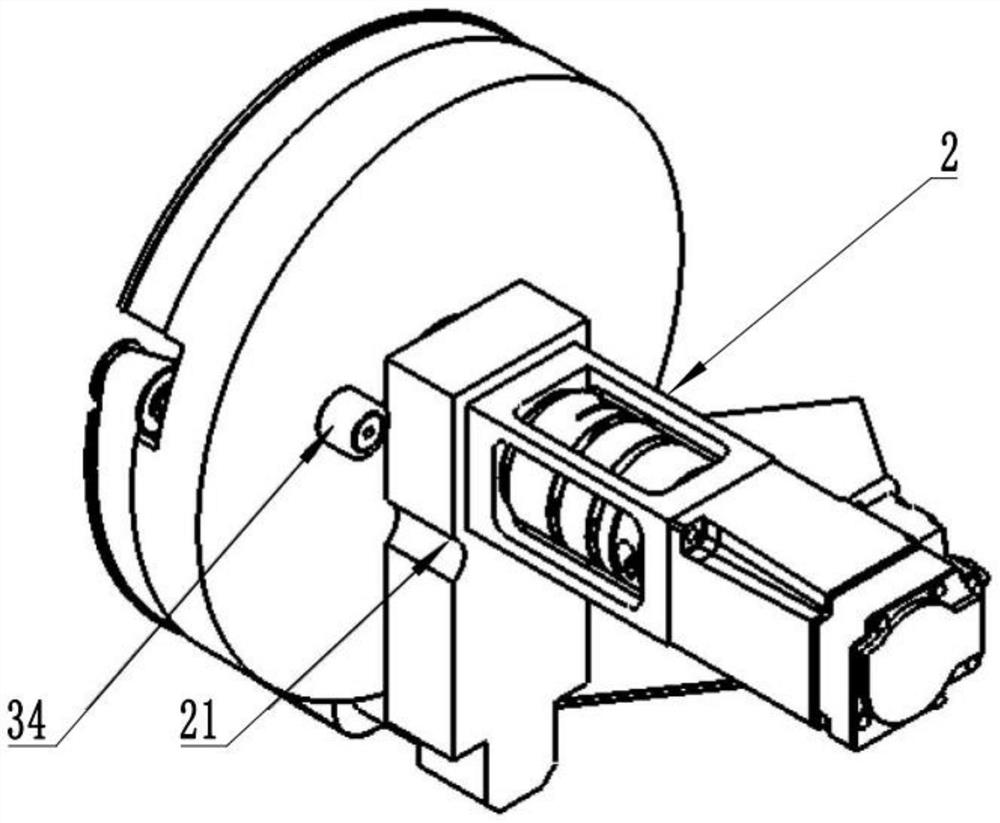

[0051] One side of the film tearing station 1 is provided with a rotating device 2 , and a film tearing disc 3 is installed on the rotating end of the rotating device 2 .

[0052] A mounting groove is formed in the tearing film disc 3 , a first winding device and a second winding device are arranged on the groove bottom of the mounting groove, and an adhesive tape 5 is wound on the first winding device.

[0053] A first glue outlet 31 and a second glue inlet 32 are provided on the outer sidewall of...

Embodiment 2

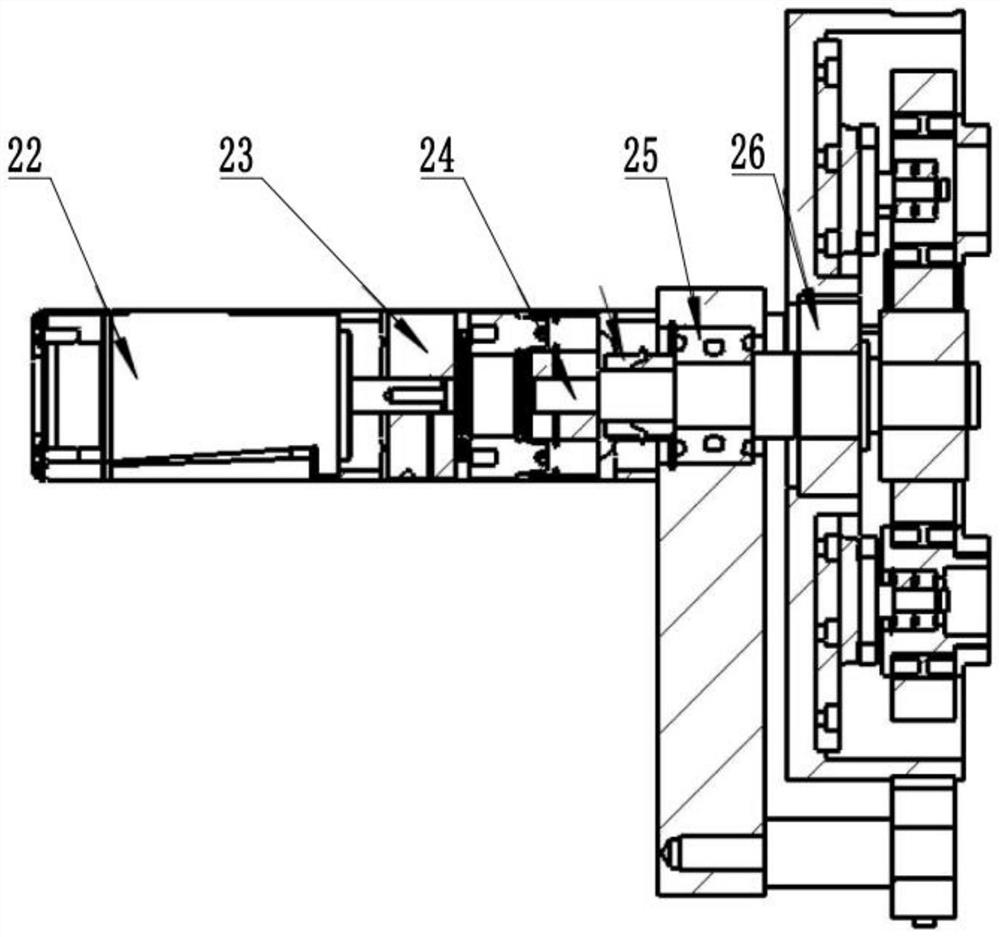

[0074] Such as Figure 7 As shown, the film tearing device includes a conveying mechanism and a film tearing mechanism as in Embodiment 1.

[0075] The conveying mechanism is used to transport the plate to the film tearing station 1 of the film tearing mechanism.

Embodiment 3

[0077] A film tearing method, applied to the film tearing device as in embodiment two; specifically comprising:

[0078] S1, transport the sheet to the film tearing station, so that the film on the sheet is adhered by the new adhesive tape 51;

[0079] S2. Rotate the rotating device 2 along the first direction by a preset first angle; wherein, the first glue outlet 31 is rotated by the first angle along the direction away from the film tearing station 1, and the adhesive tape 5 is along the opposite direction of its extending direction The first length is pulled by the first glue outlet 31 .

[0080] Further, in step S2: rotate the rotating device 2 along the first direction by a preset first angle; wherein, the first glue outlet 31 is rotated by the first angle along the direction away from the film tearing station 1, and the adhesive tape 5 is rotated along its After the first length is pulled by the first glue outlet 31 in the opposite direction of the extension direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com