Green ink printing substrate special for medical packing bag

A technology of ink printing and medical packaging, applied in ink, application, household utensils, etc., can solve the problems of pharmaceutical product pollution, secondary pollution, impact, etc., and achieve scientific and reasonable ink formula, convenient processing, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

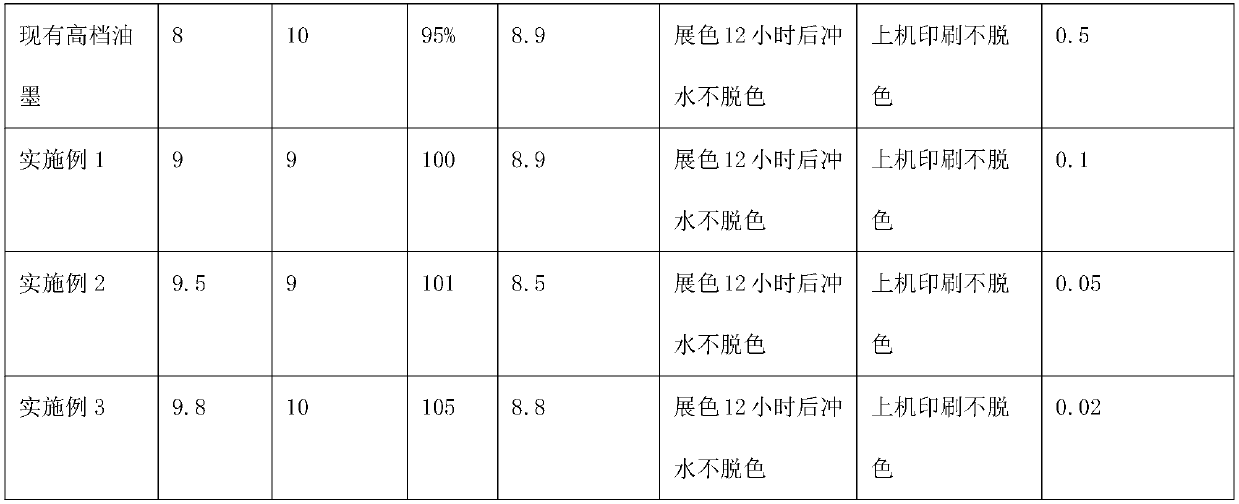

Examples

Embodiment 1

[0020] Weighing: 3kg of titanium dioxide, 5kg of acryl alcohol, 6kg of ethyl acetate, 2kg of polyurethane resin, 1kg of carbon powder, 5kg of curing agent, 3kg of ethyl acetate, 6kg of antistatic agent, 6kg of pigment powder, 6kg of lavender flower, 5kg of orange blossom , soybean oil 5kg, castor oil 3kg, epoxy resin 5kg, sodium methylnaphthalene sulfonate 2kg, deionized water 60kg.

Embodiment 2

[0022] Weighing: 4kg of titanium dioxide, 6kg of acrylic alcohol, 7kg of ethyl acetate, 3kg of polyurethane resin, 2kg of carbon powder, 6kg of curing agent, 4kg of ethyl acetate, 7kg of antistatic agent, 7kg of pigment powder, 7kg of lavender flower, 6kg of orange blossom , soybean oil 6kg, castor oil 4kg, epoxy resin 6kg, sodium methylnaphthalene sulfonate 3kg, deionized water 70kg.

[0023] The method for preparing above-mentioned embodiment 1 or embodiment 2, comprises the following steps:

[0024] ①. Add allyl alcohol, ethyl acetate, polyurethane resin, ethyl acetate, epoxy resin and sodium methylnaphthalenesulfonate in the heating kettle in advance, turn on the heating and stir until the materials are all melted, and set aside;

[0025] ②. Put the deionized water in the raw material into the heating kettle in the above step 1, turn on and stir evenly, and set aside;

[0026] ③. After squeezing the lavender flowers and orange blossoms in the raw materials to extract the ...

Embodiment 3

[0029] Weighing: 5 parts of titanium dioxide, 7 parts of acryl alcohol, 8 parts of ethyl acetate, 4 parts of polyurethane resin, 3 parts of carbon powder, 7 parts of curing agent, 5 parts of ethyl acetate, 8 parts of antistatic agent, 8 parts of pigment powder 8 parts of lavender flower, 7 parts of orange blossom, 7 parts of soybean oil, 5 parts of castor oil, 7 parts of epoxy resin, 4 parts of sodium methylnaphthalenesulfonate, and 80 parts of deionized water.

[0030] The method for preparing above-mentioned embodiment 1, embodiment 2 or embodiment 3 may further comprise the steps:

[0031] ①. Add allyl alcohol, ethyl acetate, polyurethane resin, ethyl acetate, epoxy resin and sodium methylnaphthalenesulfonate in the heating kettle in advance, turn on the heating and stir until the materials are all melted, and set aside;

[0032] ②. Put the deionized water in the raw material into the heating kettle in the above step 1, turn on and stir evenly, and set aside;

[0033] ③. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com