Light and high-strength metal bridge plate and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the field of building materials, can solve the problems of rusting of steel and steel plates, high transportation costs, joint leaks, etc., to achieve good rust prevention, improve economic benefits, and save steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

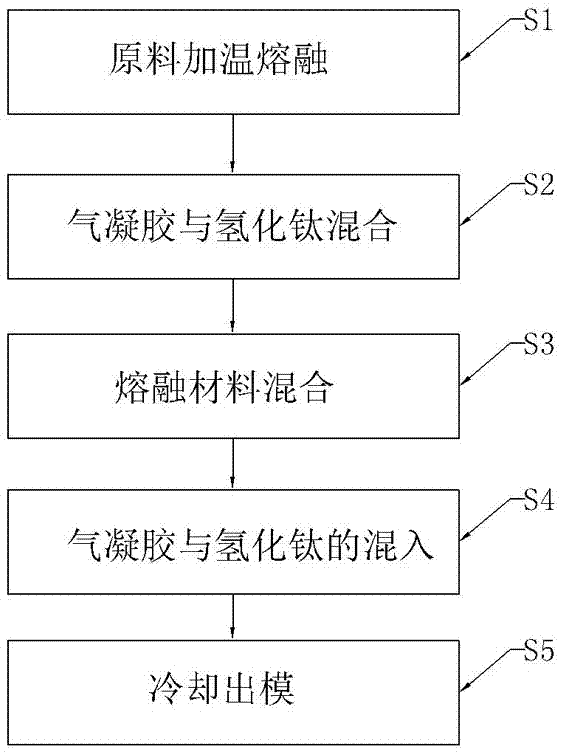

Method used

Image

Examples

no. 1 example

[0050] The light-weight and high-strength metal bridge plate of the present invention, calculated in parts by mass, specifically includes the following components:

[0051] 50 copies of pure aluminum or recycled aluminum scrap;

[0052] 10 copies of pure iron or recycled iron scrap;

[0053] 3 parts of pure magnesium;

[0054] 3 parts of pure nickel;

[0055] 0.1 part of 2000 mesh graphene powder;

[0056] 3 parts of 2000 mesh potassium feldspar powder;

[0057] 2000 mesh fumed silica powder 1 part;

[0058] 0.2 parts of 50nm aerogel powder;

no. 2 example

[0061] The light-weight and high-strength metal bridge plate of the present invention, calculated in parts by mass, specifically includes the following components:

[0062] 70 copies of pure aluminum or recycled aluminum scrap;

[0063] 20 copies of pure iron or recycled iron waste;

[0064] 8 parts of pure magnesium;

[0065] 8 parts of pure nickel;

[0066] 0.3 copies of 2000 mesh graphene powder;

[0067] 8 parts of 2000 mesh potassium feldspar powder;

[0068] 2 parts of 2000 mesh fumed silica powder;

[0069] 0.4 parts of 50nm aerogel powder;

no. 3 example

[0072] The light-weight and high-strength metal bridge plate of the present invention, calculated in parts by mass, specifically includes the following components:

[0073] 60 pieces of pure aluminum or recycled aluminum scrap;

[0074] 15 copies of pure iron or recycled iron waste;

[0075] 5 parts of pure magnesium;

[0076] 5 parts of pure nickel;

[0077] 0.2 parts of 2000 mesh graphene powder;

[0078] 5 parts of 2000 mesh potassium feldspar powder;

[0079] 2000 mesh fumed silica powder 1.5 parts;

[0080] 0.3 parts of 50nm aerogel powder;

[0081] 8 parts of titanium hydride powder.

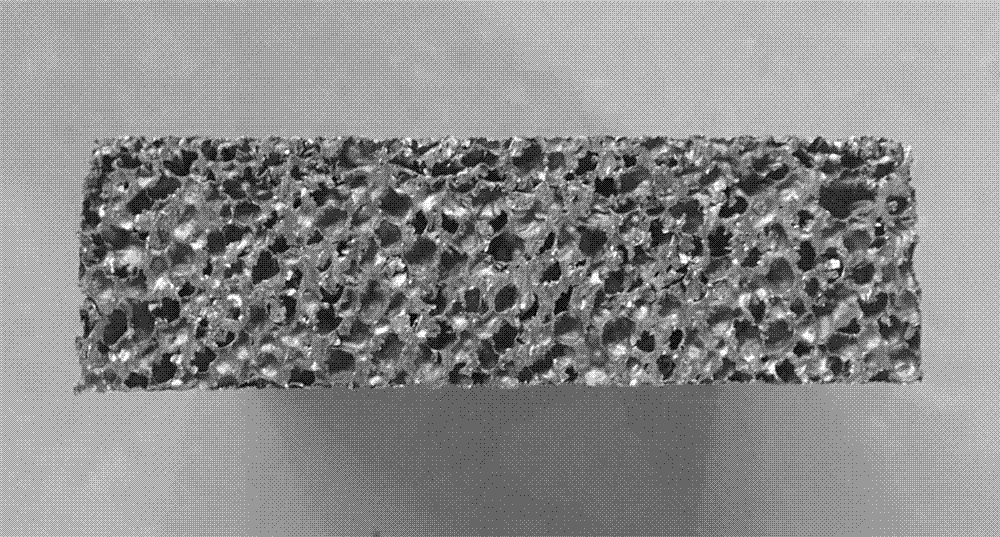

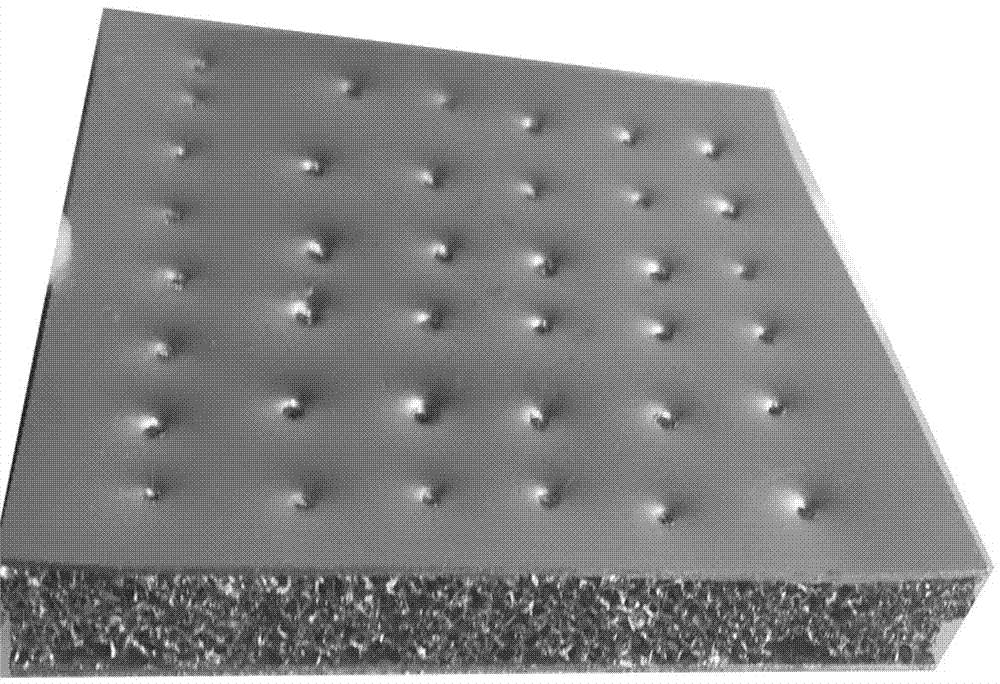

[0082] Compared with the prior art, the present invention adopts modified composite metal bridge plates made of aluminum materials, iron materials, magnesium materials, nickel materials, graphene materials, feldspar powder, fumed silica and aerogels, which are light in weight and strong High, good flexibility, with good compression, tensile, shock and impact resistance. The metal bridge plate of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com