Negative ion powder for decoration material and preparation method and application thereof

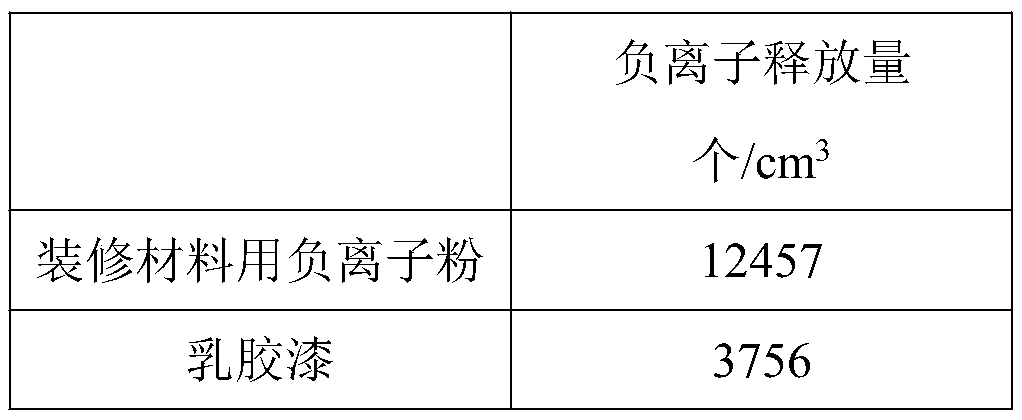

A technology of negative ion powder and tourmaline powder, which is applied in antifouling/underwater coatings, coatings, latex paints, etc., can solve the problems of no antibacterial properties and limited negative ion generating capacity, etc., achieve rich specific surface area, increase release, and improve Effect of anti-aging performance and anti-peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: present embodiment a kind of negative ion powder for decoration material, it is by mass parts by the tourmaline powder of 80 parts~90 parts of porous chitosan film coating and growth nano-silver, 5 parts~10 parts of opal powder and It is made by mixing 5-10 parts of neodymium oxide.

[0026] The beneficial effects of this embodiment are:

[0027] Under the synergistic effect of chitosan and nano-silver in this embodiment, the antibacterial properties of negative ion powder are improved, and by first coating the porous chitosan film, and then carrying out the growth of nano-silver, due to the polarity and complexation of the tourmaline surface Under the combined action of adsorption, it is very easy to adsorb various valence ions. Therefore, platinum chloride enters through the pores of chitosan film, forms growth points on the surface of tourmaline, and then grows nano-silver. The concentration of the solution and the growth time make the tourm...

specific Embodiment approach 2

[0028] Specific embodiment two: present embodiment a kind of preparation method of decoration material negative ion powder, it is finished according to the following steps:

[0029] 1. Chitosan coating of tourmaline powder:

[0030] Prepare a chitosan acid solution with a concentration of 5-15g / L, then immerse the mechanically treated tourmaline powder in the chitosan acid solution with a concentration of 5-15g / L, and stir at a stirring speed of 500r / min-800r Under the condition of 1 / min, stir for 5min to 10min, then stop stirring, let stand at a temperature of 40°C to 60°C, finally centrifuge, wash and dry to obtain tourmaline powder coated with porous chitosan film;

[0031] The thickness of the porous chitosan film in the tourmaline powder coated with the porous chitosan film is 10nm~500nm;

[0032] Second, the growth of nano-silver:

[0033] Use silver nitrate, polyvinylpyrrolidone and ethylene glycol to prepare a silver salt solution, soak the tourmaline powder coated w...

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the mechanically treated tourmaline powder in step 1 is less than 2 μm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com