Environment-friendly high-strength printing packaging paper and production technology thereof

A technology of printing and packaging and production technology, which is applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve the problems of non-moisture proof, low strength, non-wear resistance, etc., and achieve the effect of prolonged service life, high strength and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

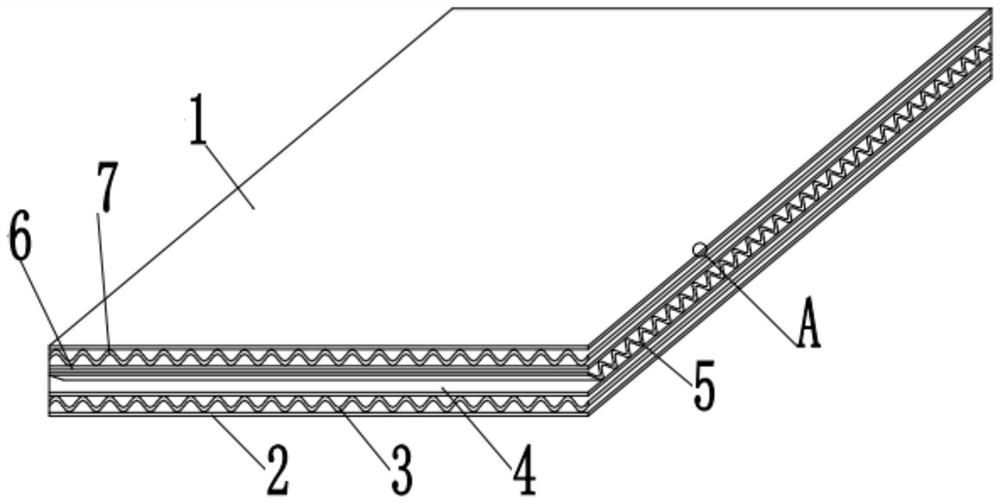

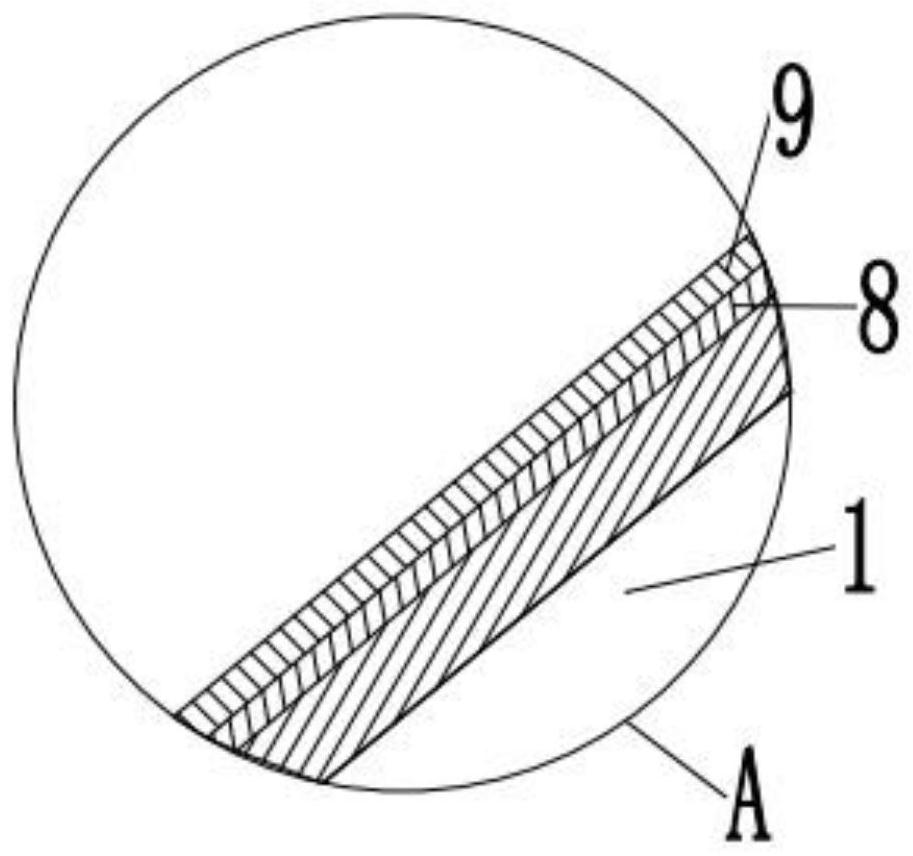

[0041] An environmentally friendly high-strength printing wrapping paper, comprising: a surface layer 1 and a back layer 2, an upper corrugated layer 7 is bonded to the bottom outer wall of the surface layer 1, a lower corrugated layer 3 is bonded to the top outer wall of the back layer 2, and the lower corrugated layer 3 is bonded with a lower interlayer 4, the top outer wall of the lower interlayer 4 is bonded with a middle corrugated layer 5, an upper interlayer 6 is bonded between the middle corrugated layer 5 and the upper corrugated layer 7, and the surface layer 1 and A waterproof layer 8 is bonded to one side of the outer wall of the back layer 2 , and a wear-resistant layer 9 is bonded to one side of the outer wall of the anti-layer.

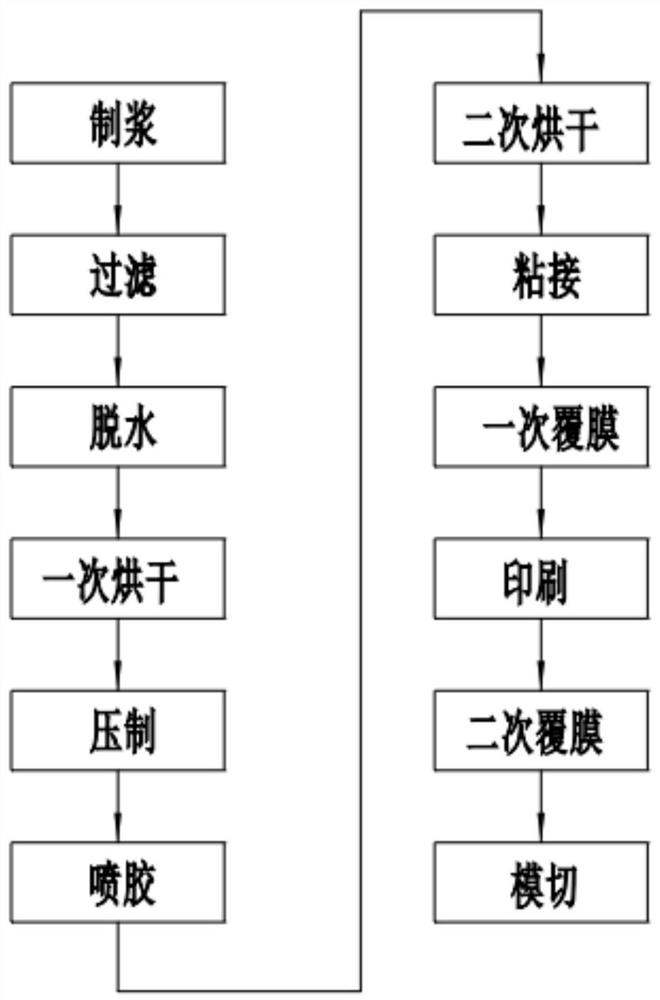

[0042] An environment-friendly and high-strength printing and wrapping paper production process, comprising the following steps:

[0043] S1. Pulping, the recovered waste cartons are pulverized by a pulverizer and then put into a blende...

Embodiment 2

[0064] An environmentally friendly high-strength printing wrapping paper, comprising: a surface layer 1 and a back layer 2, an upper corrugated layer 7 is bonded to the bottom outer wall of the surface layer 1, a lower corrugated layer 3 is bonded to the top outer wall of the back layer 2, and the lower corrugated layer 3 is bonded with a lower interlayer 4, the top outer wall of the lower interlayer 4 is bonded with a middle corrugated layer 5, an upper interlayer 6 is bonded between the middle corrugated layer 5 and the upper corrugated layer 7, and the surface layer 1 and A waterproof layer 8 is bonded to one side of the outer wall of the back layer 2 , and a wear-resistant layer 9 is bonded to one side of the outer wall of the anti-layer.

[0065] An environment-friendly and high-strength printing and wrapping paper production process, comprising the following steps:

[0066] S1. Pulping, the recovered waste cartons are pulverized by a pulverizer and then put into a blende...

Embodiment 3

[0087] An environmentally friendly high-strength printing wrapping paper, comprising: a surface layer 1 and a back layer 2, an upper corrugated layer 7 is bonded to the bottom outer wall of the surface layer 1, a lower corrugated layer 3 is bonded to the top outer wall of the back layer 2, and the lower corrugated layer 3 is bonded with a lower interlayer 4, the top outer wall of the lower interlayer 4 is bonded with a middle corrugated layer 5, an upper interlayer 6 is bonded between the middle corrugated layer 5 and the upper corrugated layer 7, and the surface layer 1 and A waterproof layer 8 is bonded to one side of the outer wall of the back layer 2 , and a wear-resistant layer 9 is bonded to one side of the outer wall of the anti-layer.

[0088] An environment-friendly and high-strength printing and wrapping paper production process, comprising the following steps:

[0089] S1. Pulping, the recovered waste cartons are pulverized by a pulverizer and put into a blender, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com