Flat-panel display with inverted Y-shaped inclined high-grating single-point cathodic control structure and manufacture process thereof

A flat-panel display, cathode control technology, applied in cold cathode manufacturing, electrode system manufacturing, image/graphic display tubes, etc., can solve the problem that the carbon nanotube cathode manufacturing process does not have a satisfactory solution, hinders field emission The progress of display research and the complexity of the device manufacturing process have achieved the effect of stable and reliable manufacturing process, reduced effective distance, and improved emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the embodiments.

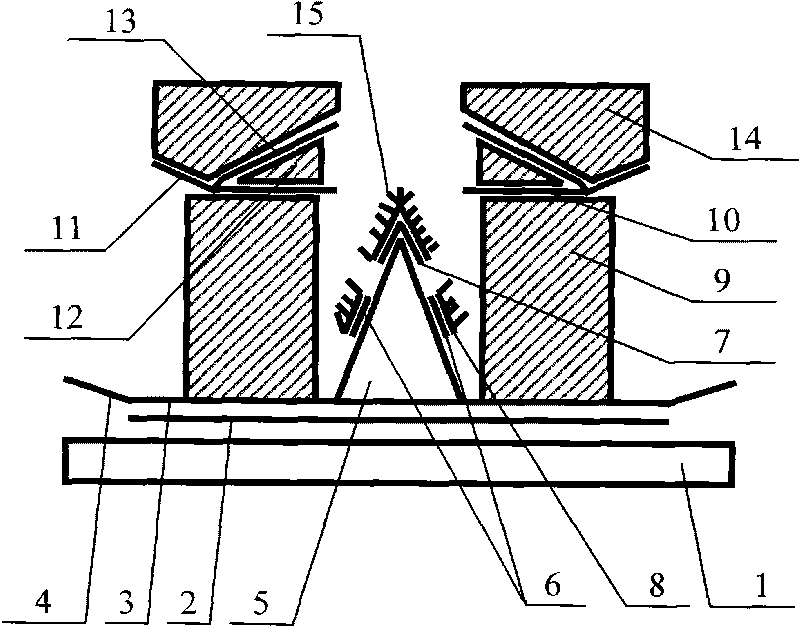

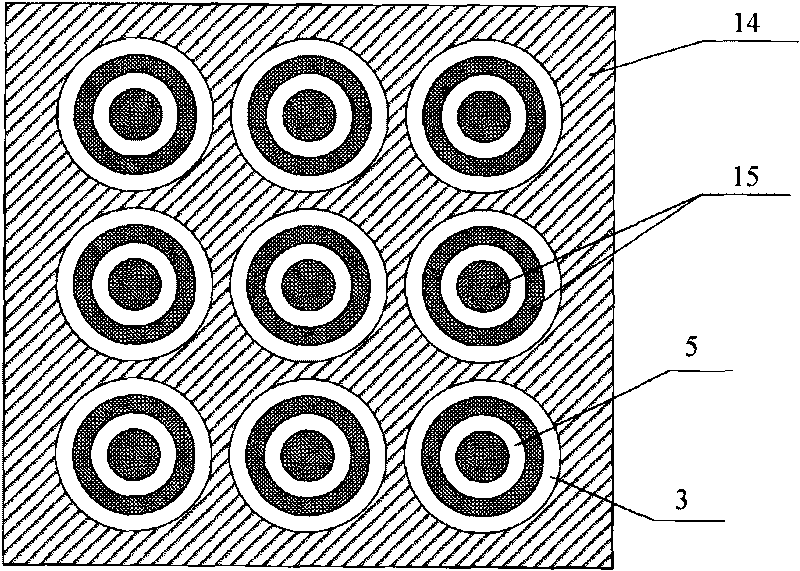

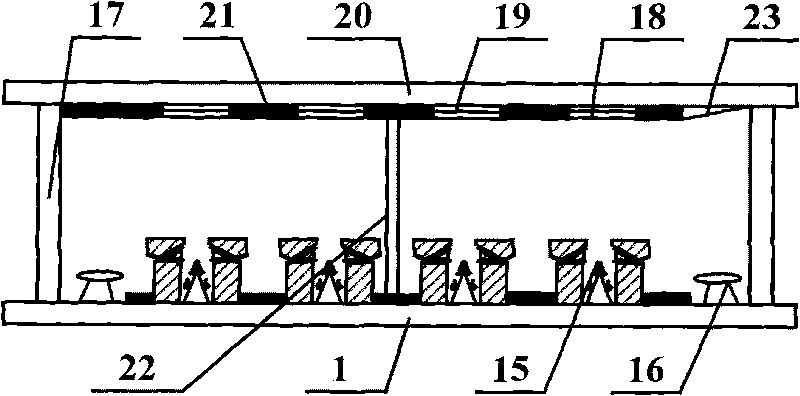

[0042] Such as figure 1 , 2 , Shown in 3, a flat panel display with an inverted Y-shaped inclined high grid single-point cathode control structure, including a sealed vacuum chamber made of an anode glass panel 20, a cathode glass panel 1 and a glass frame 17; it is arranged on the anode glass panel The anode conductive layer 19, the anode wiring layer 23, the anode isolation layer 21 and the phosphor layer 18 above the anode conductive layer are prepared; the isolation supporter 22 and the getter 16 between the anode glass panel and the cathode glass panel; its characteristics in:

[0043] The base material of the inverted Y-shaped slanted high gate single-point cathode control structure is a cathode glass panel; the insulating paste printed and sintered on the cathode glass panel forms a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com